bh11d001

bh11d1ra -- 8 --

5ÝÊÑÏËÓÀÒÀÖÈß

Îáùèå ïðàâèëà òåõíèêè áåçîïàñíîñòè ïðè ðàáîòå ñ îáîðóäîâàíèåì

ïðèâîäÿòñÿ íà ñòð. 4. Ïðî÷òèòå èõ äî èñïîëüçîâàíèÿ îáîðóäîâàíèÿ!

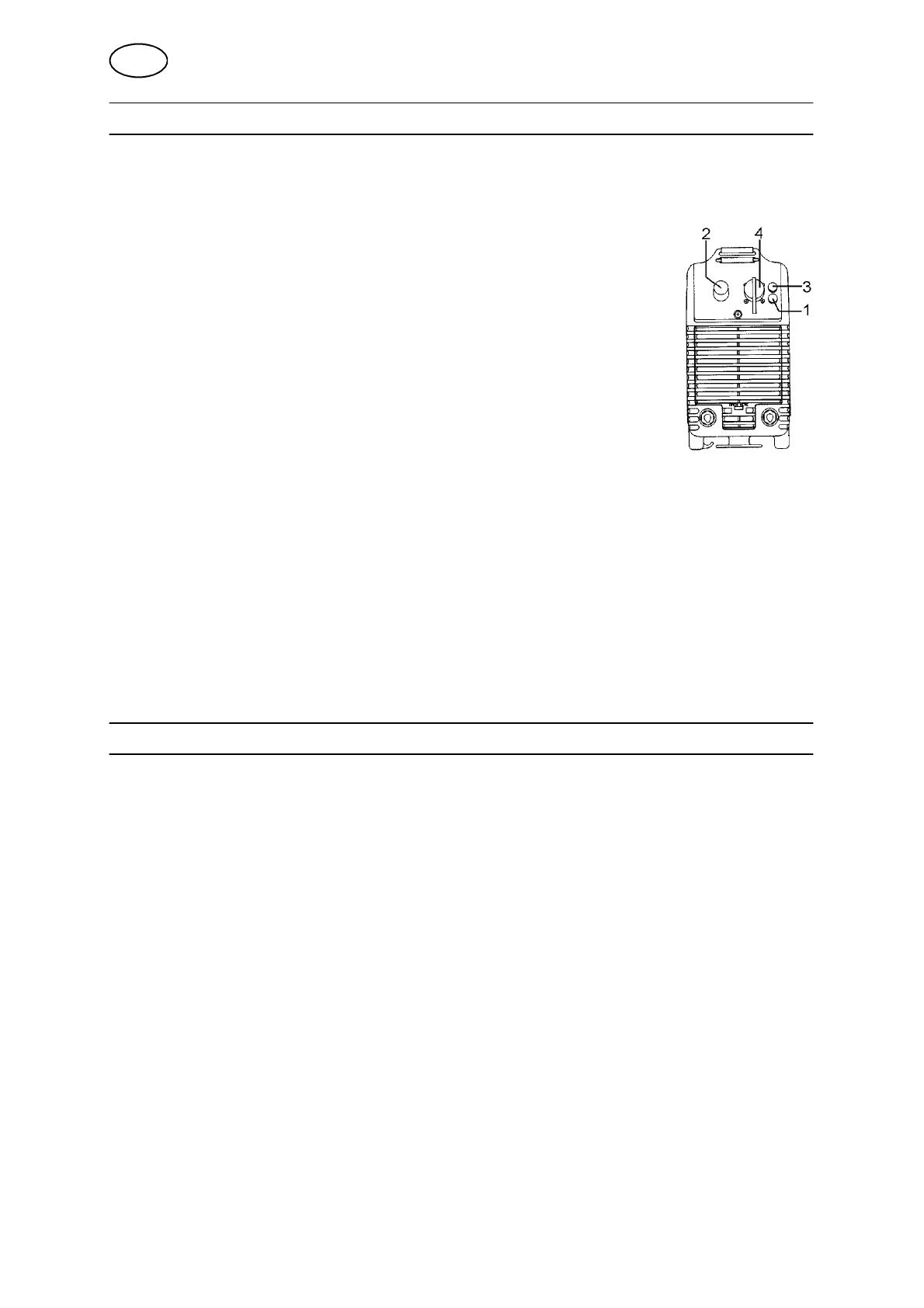

Ñåòåâîé âûêëþ÷àòåëü ðàñïîëîæåí íà çàäíåé ïàíåëè Professional

200. Ïðè âêëþ÷åííîì ïèòàíèè íà ïåðåäíåé ïàíåëè çàãîðàåòñÿ

áåëàÿ èíäèêàòîðíàÿ ëàìïî÷êà.

1. Æåëòàÿ èíäèêàòîðíàÿ ëàìïî÷êà

2. Óñòàíîâêà âåëè÷èíû ñâàðî÷íîãî òîêà â ïðåäåëàõ 3-140A.

3. Áåëàÿ èíäèêàòîðíàÿ ëàìïî÷êà.

4. Ðàçúåì äèñòàíöèîííîãî óïðàâëåíèÿ.

Âåëè÷èíà ñâàðî÷íîãî íàïðÿæåíèÿ óñòàíàâëèâàåòñÿ ðóêîÿòêîé,

ðàñïîëîæåííîé íà ïåðåäíåé ïàíåëè.

Âíèìàíèå!

Íåîáõîäèìî èñïîëüçîâàòü òîëüêî ðåê îìåíäóåìûå ñå÷åíèÿ ñâàðî÷íîãî è

âîçâðà òíîãî êàáåëÿ (íå ìåíåå 25 ìì

2

)

(Ñì. Ñïèñîê çàïàñíûõ ÷àñòåé).

5.1 Ç àùèòà îò ïåðåãð óçîê

Äëÿ çàùèòû îò ïåðåãðåâà âûïðÿìèòåëè Professional 200 èìååò âñòðîåííîå

òåðìîðåëå, ñðàáàòûâàþùåå ïðè ïðåâûøåíèè òå ìïåðà òóðû âûøå äîïóñòèìîé

âåëè÷èíû. Ïðè ýòîì îáåñòî÷èâàþòñÿ ñâàðî÷íûå êàáåëè è çàãîðàåòñÿ

îðàíæåâàÿ êîíòðîëüíàÿ ëàìïà. Ïðè ïîíèæåíèè òåìïåðàòóðû òåðìîðåëå

àâòîìàòè÷åñêè âêëþ÷àåò âûïðÿìèòåëü.

6 Òåõíè÷åñêîå îáñëóæèâàíèå

Ðåãóëÿðíîå òåõíè÷åñêîå îáñëóæèâàíèå èìååò âàæíîå çíà÷åíèå äëÿ

îáåñïå÷åíèÿ áåçîïàñíîñòè è íàäåæíîñòè.

Ïðèìå÷àíèå:

à àðàíòìèéíûå îáÿçàòåëüñòâà ïîñòàâùèêà òåðÿþò ñèëó, åñëè ïîêóïàòå ëú

ñàìîñòîÿòåëúíî ïûòàåòñÿ ïð îèçâåñòè êàêèå-ëèáî ðàáîòû ïî óñòðàíåíèþ

íåèñïðàâíîñòåé èçäåëèÿ â òå÷åíèå ãàðàíòèéíîãî ñðîêà.

Òåõíè÷åñêîå îáñëóæèâàíèå äîëæíî âûïîëíÿòüñÿ ïðîôåññèîíàëüíî

ïîäãîòîâëåííûì ïåðñîíàëîì.

Òîëüêî ëèöà, èìåþùèå êâàëèôèêàöèþ ýëåêòðèêà (àòòåñòîâàííûé ïåðñîíàë),

èìåþò ïðàâî ñíèìàòü ïàíåëè, îáåñïå÷èâàþùèå áåçîïàñíîñòü ðàáîòû.

6.1 ×èñòêà

Professional 200 òðåáóåò ìèíèìàëüíîãî îáñëóæèâàíèÿ. Îáû÷íî îíî ñâîäèòñÿ ê

ðåãóëÿðíîé ÷èñòêå ôèëüòðà, ðàñïîëîæåííîãî íà ïåðåäíåé ïàíåëè î÷èñòè

âûïðÿìèòåëÿ ðàç â ãîä ïðîäóâêîé ñæàòûì âîçäóõîì.

Ïðè ðàáîòå âûïðÿìèòåëÿ â çàãðÿçíåííûõ èëè ïûëüíûõ óñëîâèÿõ ÷èñòêó

ïðîâîäÿò ÷àùå. Ðåøåòêà ôèëüòðà ñíèìàåò ïóòåì åå î òæ àòèÿ (âñò àâèâ â ùåëü

ðåøåòêè îòâåðòêó, íàïðèìåð) è ïåðåìåùåíèÿ åå îñòîðîæíî ââåðõ.

RU