ESAB Caddy 250 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

Questo manuale è adatto anche per

cmha2p00

Valid for Serial NO 747 XXX--XXXX0457 552 027 99.01.09

Caddy 250

LHN 250

104

Èíñòðóêöèÿ ïî ýêñïëóàòàöèè

Instruction manual

-- 2 --

Rights reserved to alter specifications without notice.

Îñòàâëÿåì çà ñîáîé ïðàâî èçìåí ÿòü ñïåöèôèêàöèþ áåç ïðåäóïðåæäåí è ÿ.

Ðóññêèé 3...............................................

ENGLISH 9..............................................

Ðóññêèé

TOCr

-- 3 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ 4........................................

2 ÂÂÅÄÅÍÈÅ 4.......................................................

2.1 Òåõíè÷åñê èå äàííûå 5......................................................

2.2 Ñîñòàâ îáîðóäîâàíèÿ 6....................................................

2.3 Îáëàñòü ïðèìåíåíèÿ 6.....................................................

3ÓÑÒÀÍÎÂÊÀ 6......................................................

ÂÍÈÌÀÍÈÅ 6....................................................................

3.1 Ðàáî÷åå ìåñòî 6..........................................................

3.2 Ïîäêëþ÷åíèå 6...........................................................

4 ÐÀÁÎÒÀ ÓÑÒÀÍÎÂÊÈ 7..............................................

4.1 Âê ëþ÷åíèå óñòàíîâêè 7....................................................

4.2 Çàùèòà îò ïåðåãðóçîê 7....................................................

5 Òåõíè÷åñêîå îáñëóæèâàíèå 7.......................................

5.1 ×èñòêà 7...................................................................

6 ÄÈÀÃÍÎÑÒÈÊÀ ÍÅÈÑÏÐÀÂÍÎ ÑÒÅÉ 8...............................

6.1 Âîçìîæíûå íåèñïðàâíîñòè è ìåðû ïî èõ óñòðàíåíèþ 8.....................

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 8......................................

8 Äîïîëíèòå ëüíûå ïðèíàäëåæíîñòè 8................................

ÑÕÅÌÀ 15..............................................................

ÑÏÈÑÎÊ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 16........................................

bh21d02r -- 4 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ

ÏÐÎ×ÒÈÒÅ È ÏÎÉÌÈÒÅ ÈÍÑÒÐÓÊÖÈÞ ÏÎ ÝÊÑÏËÓÀÒÀÖÈÈ ÏÅÐÅÄ ÒÅÌ, ÊÀÊ ÏÎÄÊËÞ×ÈÒÜ

ÎÁÎÐÓÄÎÂÀÍÈÅ È ÍÀ× ÀÒÜ ÐÀÁÎÒÓ

ÇÀÙÈÒÈÒÅ ÑÅÁß È ÎÊÐÓÆÀÞÙÈÕ !

ÏÐÅÄÓÏÐÅÆÄÅÍÈÅ !

ÄÓà ÎÂÀß ÑÂÀÐÊÀ È ÐÅÇÊÀ ÌÎÃÓÒ ÏÐÈ×ÈÍÈÒÜ ÂÐÅÄ ÂÀÌ È ÎÊÐÓÆÀÞÙÈÌ. ÏÐÈÌÈÒÅ

ÍÅÎÁÕÎ ÄÈÌÛÅ ÌÅÐÛ ÁÅÇÎÏÀÑÍÎÑÒÈ ÏÐÈ ÏÐÎÂÅÄÅÍÈÈ ÑÂÀÐÎ×ÍÛÕ ÐÀÁÎÒ.

ÎÇÍÀÊÎÌÜÒÅÑÜ Ñ ÒÅÕÍÈÊÎÉ ÁÅÇÎÏÀÑÍÎÑÒÈ, ÐÀÇÐÀÁÎ ÒÀÍÍÎÉ ÍÀ ÂÀjÅÌ ÏÐÅÄÏÐÈßÒÈÈ.

ÏÎÐÀÆÅÍÈÅ ÝËÅÊÒÐÈ×ÅÑÊÈÌ ÒÎÊÎÌ ÎÏÀÑÍÎ ÄËß ÆÈÇÍÈ !

S Óñòàíîâèòå è çàçåìëèòå ñâàðî÷íûé àïïàðàò â ñîîòâåòñòâèè ñ ïðèìåíÿåìûìè ñòàíäàðòàìè.

S Íå êàñàéòåñü îãîëåííûõ ýëåêòðè÷åñêèõ ÷àñòåé èëè ýëåêòðîäîâ ãîëûìè ðóêàìè, ìîêðûìè ïåð÷àòêàìè

èëèìîêðîéîäåæäîé.

S Èçîëèðóéòå ñåáÿ îò çåìëè è çàãîòîâêè.

S Îáåñ ïå÷üòå áåçîïàñíîñòü íà ñâîåì ðàáî÷åì ìåñò å.

ÑÂÀÐÎ×ÍÛÅ ÄÛÌÛ È ÀÝÐÎÇÎËÈ - ìîãóò áûòü îïàñíû äëÿ çäîðîâüÿ.

S Ñòàðàéòåñü, ÷òîáû âàøà ãîëîâà íàõîäèëàñü âíå çîíû äûìà..

S Èñïîëüçóéòå âåíòèëÿöèþ è äûìîîòñîñû äëÿ óäàëåíèÿ äûìîâ è àýðî çîëåé èç çîíû äûõàíèÿ è

îêðóæàþùåãî ïðîñòðàíñòâà

ÈÇËÓ×ÅÍÈÅ ÄÓÃÈ - ìî æåò íàíåñòè âðåä ãëàçàì è êîæå.

S Çàùèùàéòå âàøè ãëàçà è êîæó. Èñïîëüçóéòå ìàñêó ñ ïðàâèëüíî ïîäîáðàííûì çàùèòíûìñòåêëîì è

ñïåöîäåæäó

S Çàùèùàéòå îêðóæàþùèõ ïîñðåäñòâîì ñòåíîê è çàíàâåñîê.

ÏÎÆÀÐÎÎÏÀÑÍÎÑÒÜ

S Èñêðû ïðè ñâàðêå ìîãóò ñòàòü ïðè÷èíîé ïîæàðà. Îáåñïå÷üòå îòñóòñòâèå ïîæàðîîïàñ íûõ ìàòåðèàëîâ

â áëèçëåæàùåé çîíå.

ØÓÌ - Ïîâûøåííûé øóì ìîæåò ïîâðåäèòü ñëóõ

S Çàùèòèòå ñâîè óøè ñ ïîìîùüþ íàóøíèêîâ èëè áåðóøåé.

S Ïðåäóïðåäèòå î ðèñêå îêðóæàþùèõ.

ÑÁÎÉ Â ÐÀÁÎÒÅ - Ïðè ñáîÿõ â ðàáî ò å îáðà òèòåñü çà ïîìîùüþ ê ñïåöèàëèñòó.

2 ÂÂÅÄÅÍÈÅ

Âíèìàíèå !

Èçäåëèå ïðåäíàçíà ÷åíî òîëüêî äëÿ äóãîâîé ñâàðêè.

Âûïðÿìèòåëü LHN 250 - ÿâëÿåòñÿ òðàíçèñòîðíî-óïðàâëÿåìûì èñòî÷íèêîì

ïèòàíèÿ, ïðåäíàçíà÷åííûì äëÿ ðó÷íîé äóãîâîé ñâàðêè (ÌÌÀ), à òàêæå äëÿ

ñâàðêè íåïëàâÿùèìñÿ ýëåêòðîäîì â ñðåäå àðãîíà (TIG) ñ âîçáóæäåíèåì äóãè

ìåòîäîì êàñàíèÿ è î òðûâà.

Ïðèìåíåíèå ñîâðåìåííîé ýëåêòðîíèêè, â òîì ÷èñëå è èíâåðòîðíîé

òåõíîëîãèè, ïîçâîëèëî, íàðÿäó ñ äðóãèìè ïðåèìóùåñòâàìè, îáåñïå÷èòü

áûñòðóþ íàñòðîéêó ïðîöåññà è ï ðîâåäåíèå âûñîêîêà÷åñòâåííîé ñâàðêè, à

òàêæå ïîçâîëèëî óìåíüøèòü âåñ è ãàáàðèòû óñòàíîâêè. Ðåìåíü ñëóæèò äëÿ

óäîáñòâà ïåðåíîñà âûïðÿìèòåëÿ íà ïëå÷å ñâàðùèêà è â êà÷åñòâå ðó÷êè â

çàïðàâëåííîì âèäå.

bh21d02r -- 5 --

2.1 Òåõíè÷åñêèå äàííûå

ïðè ÏÂ 35%

ïðè ÏÂ 60%

ïðè ÏÂ 100%

250 A/30 V

180A/27V

140A/26V

Äèàïàçîí ðåãóëèðîâàíèÿ ñâàðî÷íîãî

òîêà (ïëàâíî ðåãóëèðóåòñÿ)

4-250 A

Íàïðÿæåíèå õîëîñòîãî õ îäà 50-80 V

Ïàðàìåòðû ñåòè

íàïðÿæåíèå

÷àñòîòà

ïðåäîõðàíèòåëü

ñå÷åíèå ñåòåâîãî êàáåëÿ

400 Â ïåðåì. òîê

50/60 Hz

16 A*

3x1,5 ìì

2

**

Êëàññ çàùèòû IP 23

Êëàññ ïðèìåíåíèÿ

Ãàáàðèòû L x W x H 472x142x256

Âåñ 11 ê ã

Ïðè ñâàðêå íà òîêàõ äî 100 A äîñòàòî÷íî ïðåäîõðàíèòåëÿ 10 A..

** Ñå÷åíèå ñåòåâîãî êàáåëÿ ñîãëàñíî øâåäñêèõ ñòàíäàðòîâ.

Ïðîäîëæèòåëüíîñòü Âêëþ÷åíèÿ (ÏÂ)

Ï îçíà÷àåò: âîçìîæíóþ ïðîäîëæèòåëüíîñòü ðàáîòû óñòàíîâêè áåç

ïåðåãðóçêè, âû÷èñëåííóþ â % îò 10-òè ìèíó òíîãî öèê ëà.

Êëàññ çàùèòû

Êîä IP õàðàêòåðèçóåò êëàññ èçîëÿöèè óñòàíîâêè îò ïîïà äàíèÿ ïûëè è âëàãè.

Îáîðóäîâàíèå ñ ìàðêèðîâêîé IP 23 ïðåäíàçíà÷åíî ä ëÿ íàðóæíûõ è

âíóòðåííèõ ðàáîò

Êëàññ ïðèìåíåíèÿ

Ñèìâîë îçíà÷àåò, ÷òî óñòàíîâêà ïðèãîäíà ê ïðèìåíåíèþ â óñëîâèÿõ ñ

ïîâûøåííîé ýëåêòðîîïàñíîñòüþ.

bh21d02r -- 6 --

2.2 Ñîñòàâ îáîðóäîâàíèÿ

Âûïðÿìèòåëü LHN 250 èìååò ðàçú¸ì äëÿ ïóëüòà äèñòàíöèîííîãî óïðàâëåíèÿ,

ðàáîòà êîòîðîãî àêòèâèðóåòñÿ àâòîìàòè÷åñêè ïðè åãî ïîäêëþ÷åíèè.

Âíèìàíèå! Äëÿ àâòîçàïóñêà äèñòàíöèîííîãî óïðàâëåíèÿ êîíòàêòû L è M áëîêà

ÄÓ äîëæíû áûòü ñîåäèíåíû.

êîìïëåêò ïîñòàâêè LHN 250 âõîäèò: 3 ì ñåòåâîãî êàáåëÿ, ïî 5ì ñâàðî÷íîãî è

âîçâðàòíîãî êàáåëÿ ñ ðàçú¸ìàìè òèïà ÎÊÑ äëÿ áûñòðîé ñìåíû ïîëÿðíîñòè.

Çàâîäñêîé íîìåð èçã îòîâèòåëÿ óêàçàí íà ôèðìåííîé òàáëè÷êå.

2.3 Îáëàñòü ïðèìåíåíèÿ

LHN 250 ïðåäíàçíà÷åí äëÿ ñâàðêè íà ïîñòîÿííîì òîêå áîëüøèíñòâà

ìàëîóãëåðîäèñòûõ, ëåãèðîâàííûõ, íåðæàâåþùèõ ñòàëåé è ÷óãóíà.

LHN 250 ïîçâîëÿåò èñïîëüçîâàòü øòó÷íûå ýëåêòðîäû îò j1.6 äî j 5 ìì.

Ñâàðêà íåïëàâÿùèìñÿ ýëåêòðîäîì â ñðåäå àðãîíà (TIG)

TIG ñâàðêà îñîáåííî ýôôåêòèâíà ïðè âûñîêèõ òðåáîâàíèÿõ ê êà÷åñòâó

ñâàðíîãî øâà, à òàêæå ïðè ñâàðêå òîíêîëèñòîâûõ êîíñòðóêöèé. Äëÿ ñâàðêè

ìåòîäîì TIG óñòàíîâêó Caddy íåîáõîäèìî äîîñíàñòèòü: ãîðåëêîé TIG ñ

ãàçîâûì êëàïàíîì, áàëëîíîì Ar, ðåãóëÿòîðîì Ar, âîëüôðàìîâûì

íåïëàâÿùèìñÿ ýëåêòðîäîì è ïðè íåîáõîäèìîñòè ïðèñà äî÷íûìè ïðóòêàìè.

Äóãà âîçáóæäàåòñÿ çà ñ÷¸ò êàñàíèÿ è îòðûâà ýëåêòðîäà îò èçäåëèÿ.

3ÓÑÒÀÍÎÂÊÀ

ÏÐÅÄÓÏÐÅÆÄÅÍÈÅ !

Ýòî îáîðóäîâàíèå ïðåäíàçíà÷åíî äëÿ ïðîìûøëåííîãî èñïîëüçîâàíèÿ.

Ïðè ïðèìåíåíèè â äîìàøíèõ óñëîâèÿõ îíî ìîæåò âûçâàòü ðàäèîïîìåõè.

Îòâåòñòâåííîñòü íåñåò ïîëüçîâàòåëü îáîðóäîâàíèÿ.

3.1 Ðàáî÷åå ìåñòî

Óñòàíîâêà äîëæíà ðàñïîëàãàòüñÿ â óäîáíîì äëÿ ðàáîòû ìåñòå, íå

ïåðåêðûâàÿ äîñòóïà âîçäóõà â âåíòèëÿöèîííûå ñå÷åíèÿ.

3.2 Ïîäêëþ÷åíèå

Äëÿ ðàáîòû ñ ìàêñèìà ëüíîé íàãðóçêîé íåîáõîäèìî óñòàíîâèòü ïëàâêèå

ïðåäîõðàíèòåëè 16A.

LHN 250 ñíàáæåí óñòðîéñòâîì êîìïåíñàöèè êîëåáàíèé ïèòàþùåé ñåòè, ò.å.

ïðè êîëåáàíèÿõ íàïðÿæåíèÿ ñåòè +/_10 % êîëåáàíèå â ñâàðî÷íîé ñåòè íå

ïðåâûñÿò +/_0 ,2 %.

Ïàðàìåòðû ñåòè äëÿ LHN 250: 400V, 3 ôàçû, 50 Hz èëè 60 Hz.

bh21d02r -- 7 --

4 ÐÀÁÎÒÀ ÓÑÒÀÍÎÂÊÈ

4.1 Âêëþ÷åíèå óñòàíîâêè

Âêëþ÷åíèå óñòàíîâêè ïðîèçâîäèòñÿ âûêëþ÷à òåëåì íà çàäíåé ñòåíêå LHN 250.

Ïðè ýòîì çàãîðàåòñÿ áåëàÿ êîíòðîëüíàÿ ëàìïà íà ïåðåäíåé ïàíåëè.

1. Ƹëòàÿ ëàìïà ï åðåãðóçêè

2. Ðó÷êà ïëàâíîé ðåãó ëèðîâêè ñâàðî÷íîãî òîêà â ïðåäåëàõ 4-250 A

3. Áåëàÿ êîíòðîëüíàÿ ëàìïà

4. Ðàçú¸ì ïóëüòà äèñòàíöèîííîãî óïðàâëåíèÿ

Âíèìàíèå!

Íåîáõîäèìî èñïîëüçîâàòü òîëüêî ðåêîìåíäóåìûå ñå÷åíèÿ ñâàðî÷íîãî è

âîçâðà òíîãî êàáåëÿ (íå ìåíåå 35 ìì

2

)

(Ñì. Ñïèñîê çàïàñíûõ ÷àñòåé).

4.2 Çàùèòà îò ïåðåãðóçîê

Äëÿ çàùèòû îò ïåðåãðåâà âûïðÿìèòåëè LHN 250 èìååò âñòðîåííîå

òåðìîðåëå, ñðàáàòûâàþùåå ïðè ïðåâûøåíèè òåìïåðàòóðû âûøå äîïóñòèìîé

âåëè÷èíû. Ïðè ýòîì îáåñòî÷èâàþòñÿ ñâàðî÷íûå êàáåëè è çàãîðàåòñÿ

îðàíæåâàÿ êîíòðîëüíàÿ ëàìïà. Ïðè ïîíèæåíèè ò åìïåðàòóðû òåðìîðåëå

àâòîìàòè÷åñêè âêëþ÷àåò âûïðÿìèòåëü.

5 Òåõíè÷åñêîå îáñëóæèâàíèå

5.1 ×èñòêà

LHN 250 íå òðåáóåò ñïåöèàëüíîãî îáñëóæèâàíèÿ. Îáû÷íî äîñòàòî÷íî

ïðîäóâàòü óñòàíîâêó ÷èñòûì ñæàòûì âîçäóõîì è î÷èùàòü âîçäóøíûé ôèëüòð.

Åñëè óñòàíîâêà ýêñïëóàòèðóåòñÿ â î÷åíü çàãðÿçíåííûõ óñëîâèÿõ ôèëüòð íà äî

î÷èùàòü êàê ìîæíî ÷àùå.

bh11d001

bh21d02r -- 8 --

6 ÄÈÀÃÍÎÑÒÈÊÀ ÍÅÈÑÏÐÀÂÍÎÑÒÅÉ

6.1 Âîçìîæíûå íåèñïðàâíîñòè è ìåðû ïî èõ óñòðàíåíèþ

Âèä íåèñïðàâíîñòè Ìåðû ïî èõ óñòðàíå íèþ

Íå âîçáóæäàå òñÿ äóãà îò ñâàðî÷íîã î

èñòî÷íèêà ïèòàíèÿ

S Óáåäèòåñü, ÷òî ñåòåâîé âûêëþ÷àòåëü

âê ëþ÷åí.

S Ïðîâåðüòå ïðàâèëüíîñòü ñîåäèíåíèÿ

ñâàðî÷íûõ êàáåëåé.

S Óáåäèòåñü, ÷òî âåëè÷èíà ñâàðî÷íîãî

òîêà óñòàíîâëåíà ïðàâèëüíî.

ïðîöåññå ñâàðêè ïðîèçîøëî îòêëþ÷åíèå

èñòî÷íèêà ïèòàíèÿ.

S Ïðîâåðüòåíåðàáîòàëîëèòåðìîðåëå

(çàãîðåëàñü îðàíæåâàÿ ëàìïà íà

ïåðåäíåé ïàíåëè).

S Ïðîâåðüòå ïðåäîõðàíèòåëü.

Òåðìîðåëå ñðàáàòûâàåò î÷åíü ÷àñòî. S Ïðîâåðüòåíåçàáèòëèâîçäóøíûé

ôèëüòð.

S Óáåäèòåñü, ÷òî ñâàðê à íå âåëàñü íà

çàâûøåííûõ ðåæèìàõ. (ïåðåãðóçêà

èñòî÷íèê à ïèòàíèÿ).

Íèçêîå êà÷åñòâî ñâàðêè. S Ïðîâåðüòå ïðàâèëüíîñòü ïîäêëþ÷åíèÿ

ñâàðî÷íûõ êàáåëåé.

S Óáåäèòåñü, ÷òî âåëè÷èíà ñâàðî÷íîãî

òîêà óñòàíîâëåíà ïðàâèëüíî.

S Ïðîâåðüòå ñîñòîÿíèå øòó÷íûõ

ýëåêòðîäîâ.

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ

Ïðè çàêàçå çàïàñíûõ ÷àñòåé, ïîæàëóéñòà, óêàæèòå òèï óñòàíîâêè, ñåðèéíûé

íîìåð, íàçâàíèå è àðòèêóëüíûé íîìåð çàïàñíîé äåòà ëè. Ýòî ïîìîæåò

óïðîñòèòü çàêàç è óñêîðèòü îòãðóçêó.

8 Äîïîëíèòåëüíûå ïðèíàäëåæíîñòè

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHA1 25 ì 0367 657 880

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHA1 10 ì 0367 657 881

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHA2 Hotstart 0367 601 880

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHB1 0367 317 880

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHB2 0367 318 880

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHC2 0367 620 880

Ïóëüò äèñòàíöèîííîãî óïðàâëåíèÿ PHA5 0367 970 880

ÊàáåëüäëÿïóëüòàÄÓ 5 ì 036 7 144 881

ÊàáåëüäëÿïóëüòàÄÓ 10 ì 0367 144 882

ÊàáåëüäëÿïóëüòàÄÓ 1,5 ì 0367 144 883

ENGLISH

TOCe

-- 9 --

1SAFETY 10...........................................................

2 INTRODUCTION 10...................................................

2.1 Technical data 11............................................................

2.2 Equipment 12................................................................

2.3 Field of application 12.........................................................

3 INSTALLATION 12....................................................

3.1 Placing 12...................................................................

3.2 Connection 12...............................................................

4 OPERATION 13.......................................................

4.1 Start--up 13..................................................................

4.2 Overload protection 13........................................................

5 MAINTENANCE 13....................................................

5.1 Cleaning 13.................................................................

6 FAULT TRACING 14...................................................

6.1 Possible faults and measures to take 14.........................................

7 ORDERING OF SPARE PARTS 14......................................

8 EXTRA ACCESSORIES 14.............................................

DIAGRAM 15............................................................

SPARE PARTS LIST 16...................................................

-- 1 0 --

bh21d02e

1SAFETY

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU-

TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

2 INTRODUCTION

Note!

This product is solely intended for arc welding.

The LHN 250 are one transistor controlled welding power source designed for

welding with coated electrodes and for TIG welding ( touch start).

The advanced electronics provide rapid control response, low power demand and

excellent welding characteristics. Inverter technology contributes to low weight and

compact dimensions of the units.

The rounded slimline shape of the unit makes it comfortable to carry. The strap can

be folded to serve as a carrying handle, or fully extended to serve as a shoulder

strap.

-- 1 1 --bh21d02e

2.1 Technical data

Performance:

at 35% duty cycle

at 60% duty cycle

at 100% duty cycle

250 A/30 V

180 A/27 V

140 A/26 V

Setting range continuously variable 4--250 A

Open circuit voltage 50--80 V

Mains supply:

voltage

frequency

fuse

mains cable, area

400 V AC

50/60 Hz

16 A*

3x1,5 mm

2

**

Enclosure class IP 23

Application class

Dimensions L x W x H 472x142x256

Weight 11 kg

*When welding below 100 A a 10 A slow fuse is adequate..

**Power cable ratings complies with Swedish regulations..

Duty cycle

The duty cycle refers to the tim e in per cent of a ten--minute period that you can weld

at a certain load without overloading the welding power source.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against

penetration by solid objects or water. Equipment marked IP 23 is designed for indoor

and outdoor use.

Application class

The sym bol indicates that the power source is designed for use in areas where

there is an increased electrical hazard.

-- 1 2 --

bh21d02e

2.2 Equipment

LHN 250 is equipped with a remote control socket which activates automatically

when a remote control device is connected. NOTE! T he contact pins L and M must

be strapped in the remote device’s connection cable for automatic activation to

function.Theinverterissuppliedwitha3meterlongmainscable.

LHN 250 is delivered with 5 m eter long welding and return cables. These are

attached to cable connectors allowing quick change of polarity.

The manufacturer’s serial number is stamped on the rating plate.

2.3 Field of application

LHN 250 supply direct current, which allows you to weld most alloyed and

non--alloyed steels, stainless steels and cast iron.

With the LHN 250 you can use coated electrodes from 1.6 to 5 mm.

Tig--welding

TIG welding is particularly useful when high quality standards are r equired and when

welding thin sheet.

Before using the LHN 250 for T IG welding it m ust be equipped with a T IG torch and

gas valve, a cylinder of argon, an argon regulator, tungsten electrodes and, if

necessary, suitable filler metal.

The best method to use is the touch start, where you gently stroke the tungsten

electrode against the workpiece to establish the arc.

3 I NSTALLATION

WARNING

This product is intended for repair and maintenance welding

In domestic or office environment this product may cause r adio interference.

It is the responsibility of the user to take adequate precautions.

3.1 Placing

Place the machine so that there is nothing to prevent the cooling air from passing

through it.

3.2 Connection

To get maximum performance from the LHN 250 it must be fitted with a 16A slow

fuse.

The LHN 250 have mains voltage compensation, which means that ¦10%

fluctuation in the supply voltage produces only ¦0.2% variation in the welding

voltage.

LHN 250 is intended for 400V, 3 phase supplies. It can be used with 50 Hz or

60 Hz supplies.

-- 1 3 --bh21d02e

4OPERATION

4.1 Start--up

The power switch is at the r ear of the LHN 250. The white lamp on the fr ont will glow

when the power is on.

1. Yellow lamp

2. Welding current control 4--250 A

3. White lamp

4. Remote control socket

The current is adjusted using the knob on the front.

Important!

Only use the accompanying welding cab le and return cable, with a

cross--section al area of 35 mm@.

(See list of spare parts for order number).

4.2 Overload protection

To save you worrying about overloading the LHN 250 it has a thermal cut--out that

will trip before the tempera ture becomes too high. You can tell when the rectifier has

been overloaded because the yellow light comes on and it will no longer be possible

to weld.

5 MAINTENANCE

5.1 Cleaning

Normally it is sufficient to blow the welding power source clean regularly using dry

compressed air (reduced pressure), and to clean the filter in the front regularly.

In dusty and dirty environment the welding power source should be cleaned at

shorter intervals.

bh11d001

-- 1 4 --

bh21d02e

6 FAULT TRACING

6.1 Possible faults and measures to take

Type of fault Measure

No arc is generated by the welding power

source.

S Make sure the mains switch is on.

S Check that the welding and return cables

are properly connected.

S Make sure the welding current set is correct.

The welding current is interrupted in the course

of welding.

S Check if the thermal cut--out has tripped (the

orange indicating lamp on the front panel is

on).

S Check the mains fuse.

The thermal cut--out trips frequently. S Check that the filter is not packed with dust.

S Check that the ratings of the welding power

source have not been exceeded (overload

of the power source).

Poor welding result. S Check that the welding and return cables

are properly connected.

S Make sure the welding current set is correct.

S Check that there is nothing wrong with the

electrodes.

7 ORDERING OF SPARE PARTS

When ordering a spare part, please state the type and serial number of the m achine

as well as number of the spare part, according to the spare parts list.

This will simplify dispatch and ensure you get the right part.

8 EXTRA ACCESSORIES

Remote control device PHA1 25 m 0367 657 880

Remote control device PHA1 10 m 0367 657 881

Remote control device PHA2 Hotstart 0367 601 880

Remote control device PHB1 0367 317 880

Remote control device PHB2 0367 318 880

Remote control device PHC2 0367 620 880

Remote control device PHA5 0367 970 880

Connecting cable 5 m 0367 144 881

Connecting cable 10 m 0367 144 882

Connecting cable 1.5 m 0367 144 883

Diagram Ñõåìà

-- 1 5 --bh21e02a

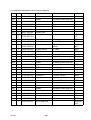

Spare parts list Ñïèñîê çàïàñíûõ ÷àñòå é

-- 1 6 --bh21s02a

Edition

98.02.01

cmha2

p

00

Ordering numbers LHN 250

0457 516 880 LHN 250 , Caddy 250

c=component designation in the circuit diagram

Item Qty Ordering no. Denomation Notes C

101 1 0366 296 003 Knob

102 1 0366 295 002 Switch 3--way QF1

103 1 0193 307 104 Cable clamp

104 1 0456 193 881 Mains cable

105

106 1 0468 208 001 Strap

107 1 0468 497 001 Clamp

108 1 0321 475 881 Knob

109 1 0366 285 001 Cover

110 2 0467 796 001 Grating

111 1 0468 462 001 Filter

112 1 0468 214 001 Cover

113 1 0369 857 886 W elding cable Complete

114 1 0369 857 887 Return cable Complete

101

102

103

104

106

107

108

109

110

111

112

113

114

-- 1 7 --bh21s02a

-- 1 8 --bh21s02a

c=component designation in the circuit diagram

Item Qty Ordering no. Denomation Notes C

201 1 0468 461 001 Gable

202 1 Busbar Included in sets item 500

203 4 0366 588 001 Nut

204 1 0457 392 001 Front

205 2 0366 306 881 Connector OKC XS12

206 1 0457 558 001 Current bar

207 1 0457 559 001 Current bar

208 5

5

0193 260 001

0193 260 180

Connector XS02,04

,07

209 1 0193 260 062 Connector XS09

210 1 0191 870 616 Potentiometer 10 kW 2W RP01

211 1

1

0193 759 001

0193 759 002

Indicator lamp 28V, white

Yellow

HL01

V05

212 1 0368 544 003 Burndy socket 12--way XS11

220 1 0468 029 001 Control transformer TC01

225 2 0192 903 506 Capacitor 1000 mF C02,03

227 1 Busbar Included in sets item 500

228 1 Busbar Included in sets item 500

229 1 0193 260 154 Connector 6--way 0.75mm@ XS01

1 0193 260 184 Cap 6--way

230 1 0193 260 150 Connector 2--way 0.75mm@ XS02

1 0193 260 180 Cap 2--way

231 1 0193 260 153 Connector 5--way 0.75mm@ XS10

1 0193 260 183 Cap 5--way

232 1 0193 260 006 Connector 7--way 0.35mm@ XS03

1 0193 260 185 Cap 7--way

234 1 Busbar Included in sets item 500

235 1 Busbar Included in sets item 500

236 1 0467 802 001 Guide

237 1 0481 870 884 Circuit board AP01

240 1 0455 661 029 Rivet

241 1 0486 328 880 Circuit board AP05

7 0194 034 001 Ferrite ring core L08,L09,

L10

-- 1 9 --bh21s02a

240

241

220

234

227

220

201

202

229

208

230

231

232

235

225

237

236

228

209

210

211

212

205

207

206

203

204

-- 2 0 --bh21s02a

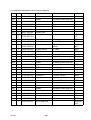

c=component designation in the circuit diagram

Item

Qty

Ordering no. Denomation Notes c

301 1 0467 801 001 Fan 24 VDC EV01

302 1 Circuit board Included in sets item 504 AP02

303

304

1

2

0192 883 150

0193 316 208

Capacitor

Rectifier bridge

0.1 ⊃F 1000 VDC C01

V01,02

305 1 0467 800 001 Insulation

308 2 0467 797 001 Guide

309 2 0467 793 180 Heat sink

310 1 Circuit board Included in sets item 504 AP03

311 21 Spring Included in sets item 504

312 1 0468 016 881 Inductor Secondary L01

313

314

315

1

2

1

0192 716 004

0193 529 017

0468 496 001

Diode

Capacitor

Holder

4.7 ⊃F

V06

C05

316

317

318

319

320

1

1

1

2

2

0468 215 880 Inductor

Winding

Bobbin

Core

Clip

Complete

Included in item 316

Included in item 316

Included in item 316

Included in item 316

L02

321 1 0457 304 880 Shunt 120 mV at 140 A RS01

322

323

1

1

0320 805 886

0394 516 035

Capacitor

Spacer

0.1⊃F 400 VDC C04

324 1 Busbar Included in sets item 505

325 1 0320 655 009 Thermal cutout Opens at 130˚C,

Included in item 312

ST01

326 1 0457 308 880 Transformer coil TC02

327

328

1

4

0467 799 001

0193 312 101

Clip

Ferrite core

329 1 0193 669 002 Connector 2--way XS08

329a 0193 590 302 Sleeve 2 per connector

330 1 0455 646 883 Rectifier unit Complete

331 1 0457 557 880 Resistor Complete 8,2 k″ 5W R02

332 3 0193 948 001 Diode module V03,04

333 1 0455 650 005 Busbar Included in sets item 505

334 1 0455 650 004 Busbar Included in sets item 505

335 2 0467 648 884 Capacitor Complete C06

336 1 0455 650 006 Busbar Included in sets item 505

337 2 0191 745 011 Spacer sleeve

338 2 0455 569 002 Ferrite ring core L06,07

339 1 0455 569 003 Ferrite ring core L05

340 1 0468 538 002 Current bar Included in sets item 505

341 2 0457 695 001 Washer

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

ESAB Caddy 250 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

- Questo manuale è adatto anche per

in altre lingue

- English: ESAB Caddy 250 User manual

Documenti correlati

-

ESAB LHO 110 Manuale utente

-

ESAB LHN 250 Manuale utente

-

ESAB LHN 250 Manuale utente

-

ESAB LAF 1000 / LAF 1000M DC Manuale utente

-

ESAB LTN 160, LTN 200 Manuale utente

-

ESAB LTR 200 Manuale utente

-

ESAB LTN 255 Manuale utente

-

ESAB LHN 140 Manuale utente

-

ESAB LTS 250 Manuale utente

-

ESAB LHL 315 Manuale utente