Elkron DT600 Guida d'installazione

- Categoria

- Illuminazione di comodità

- Tipo

- Guida d'installazione

DS80IM41-001C

DT600

Rivelatore radio a doppia tecnologia

da esterno a effetto tenda

Dual technology radio detector for

exterior use with curtain effect

Funk-Außendetektor mit doppelter

Technologie und Vorhangeffekt

Détecteur radio à double

technologie pour l'extérieur en

rideau

Manuale d’uso, installazione e programmazione

Installation programming and functions manual

Installations

-, programmier- und gebrauchsanleitun

Notice di installation, programmation et utilization

I EN DE FR

2 DS80IM41-001C

ITALIANO

Il DT600 è un rivelatore a doppia tecnologia da esterno a effetto tenda, con sensore di movimento passivo a infrarossi (PIR) e

micro onda, in grado di rilevare i movimenti in un'area assegnata e trasmetterlo all’unità di controllo per attivare l'allarme

intrusione.

La base del prodotto presenta delle predisposizioni per i fori che consentono l'installazione su una superficie piana, utilizzando,

nel caso fosse necessario, la staffa a 90° o uno snodo (opzionali).

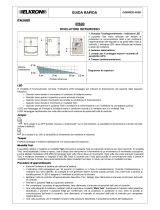

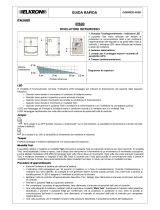

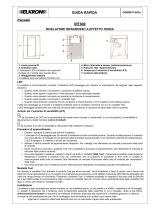

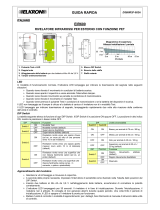

Identificazione dei componenti

1. Filtro LED copri vite

2. Vite di chiusura

3. Vite fissaggio scheda

4. Lente

5. Tamper antiapertura

6. Dip Switch (4 e 5 da non utilizzare:

sempre in OFF)

7. Trimmer portata rivelatore

8. Elemento sensibile PIR

9. LED del rivelatore

10. Vano batteria

11. Pulsante Apprendimento

12. LED interno per le operazioni di apprendimento e

segnalazione batteria

13. Jumper tamper (antiasportazione)

Previsto per collegare la protezione anti asportazione

(opzionale, non fornito a corredo)

14. Per utilizzi futuri (non modificare la posizione)

Fase di inizializzazione

Tale condizione si attiva automaticamente all’inserimento della batteria e ad ogni apertura/chiusura del frontalino. Si manterrà per

60 sec, durante tale tempo il rivelatore non è attivo.

Modalità test (Walk Test)

Aprendo il frontalino del sensore, dopo aver atteso la fase di inizializzazione, si entra nella modalità di test per circa 4 min. In

questa condizione il tempo di interdizione è disabilitato, mentre il LED del rivelatore per la segnalazione degli allarmi viene

automaticamente abilitato.

In questa modalità si possono eseguire le prove di rilevazione verificando gli allarmi tramite l’accensione del LED, così come la

portata della connessione radio (per i dettagli, consultare il manuale della relativa unità di controllo). Trascorsi i 4 minuti, il sensore

si porterà automaticamente nella condizione operativa. Se viene riaperto il frontalino, si riattiverà automaticamente la modalità

test (Walk Test), dopo il tempo di inizializzazione.

Tempo di interdizione e funzionamento a basso consumo

Per evitare elevati consumi della batteria, il rivelatore inibisce automaticamente la segnalazione di allarmi consecutivi per un

tempo definito tempo di interdizione. In questo modo, il movimento continuo di fronte a un rivelatore non scaricherà inutilmente

la batteria. Ne consegue che tra un allarme e quello successivo occorre un periodo di quiete pari al tempo d’interdizione. Questa

caratteristica non è abilitata durante la modalità test ( Walk Test).

Si possono scegliere due tempi di interdizione:

- Dip Switch N° 2 in pos. OFF 4 min (Default)

- Dip Switch N° 2 in pos. ON 8 min

1

2

4

DS80IM41-001C 3

Funzione Supervisione

Quando il rivelatore è in modalità di funzionamento normale, effettua periodicamente un test di autodiagnostica, trasmettendo

un segnale di supervisione randomico ogni 30 - 50 minuti.

Funzione Sensibilità (Aumento di sensibilità)

NORMAL: Dip Switch N°1 in pos. OFF (Default). Indicata per la maggior parte delle installazioni da esterno.

HIGH: Dip Switch N°1 in pos. ON. Indicata qualora sia richiesta una velocità di rilevazione maggiore.

Trimmer (portata sensore)

Regola la portata del sensore (ruotando il trimmer in senso orario si aumenta la portata del rivelatore). Per la regolazione tenere

a riferimento il campo di azione determinato dalla micro onda. Il sensore adeguerà automaticamente il funzionamento

dell'infrarosso a questa regolazione. Di default la posizione del trimmer è ruotata completamente in senso orario.

<NOTA>

Al contrario della microonda, per la quale è possibile stabilire con sufficiente precisione il suo limite di rilevazione, per

l'infrarosso questa condizione non è applicabile. Questo perché la rilevazione dell'infrarosso è condizionata dalla temperatura

ambientale, dall'abbigliamento dell'intruso, dalla assenza/presenza di vento etc. Il trimmer quindi regola automaticamente la

capacità di rilevazione dell'Infrarosso in funzione della portata della microonda selezionata senza necessariamente delimitarne

il suo campo di azione a quello della microonda stessa (l'infrarosso sarà configurato per le condizioni più sfavorevoli a quella

portata).

Indicatore LED rivelatore

Dip Switch N° 3 in pos. OFF

In modalità di funzionamento normale, l'indicatore LED lampeggia per indicare la trasmissione del segnale nelle seguenti

situazioni:

Quando viene alimentato, lampeggia per 60 secondi (fase di inizializzazione).

Quando viene aperto il coperchio e viene azionato l'interruttore tamper, per 4 minuti (modalità test).

Durante la modalità test a ogni movimento rilevato

Se il tamper è aperto, a ogni movimento rilevato

Non lampeggia se viene rilevato un movimento in modalità normale e con tamper chiuso.

Dip Switch N°3 in posizione ON (Default)

Il Led lampeggia anche quando viene rilevato un movimento in modalità funzionamento normale e con tamper chiuso, a scapito

della durata della batteria. Inibito appena inizia il tempo di interdizione.

Batteria

Il rivelatore è alimentato da una batteria al litio CR2 3V, in dotazione all’interno dell’imballo. Il rivelatore è in grado di rilevare lo

stato di batteria scarica, inviando un segnale all’unità di controllo insieme alle normali trasmissioni di segnali affinché la centrale

visualizzi lo stato corrispondente.

<NOTA>

Durante la sostituzione della batteria, dopo aver rimosso la batteria esausta, premere il tamper due volte per

scaricare completamente il dispositivo prima di inserire la batteria nuova.

Per verificare il funzionamento corretto, eseguire un Walk Test di portata e livello di segnale radio premendo il tasto

di apprendimento, tasto 11 (fare riferimento al manuale di istruzioni della unità di controllo).

Apprendimento del rivelatore

Per aprire il sensore, sollevare il filtro LED coprivite e svitare la vite di chiusura

sottostante. Allentare la vite di fissaggio scheda senza svitarla del tutto e

smontare la scheda elettronica, sollevandola dapprima verso l’alto per

sganciarla dalla vite, come illustrato a lato.

Inserire la batteria CR2 nel vano batteria, rispettando la polarità.

L'indicatore LED del rivelatore lampeggerà per 60 secondi (fase di

inizializzazione). Il rivelatore non è ancora attivo.

Abilitare l’unità di controllo all’apprendimento dispositivi. Per i dettagli,

fare riferimento al manuale di istruzione dell’unità di controllo.

Premere il pulsante di apprendimento sul circuito radio e completare il

processo di apprendimento (fare riferimento al manuale di istruzioni

della unità di controllo).

Una volta appreso il rivelatore, porre l’unità di controllo in “Test

dispositivi radio”

Inserire il circuito sul fondo, avvitare la vite e richiudere il frontalino,

posizionando il rivelatore nella posizione in cui lo si vuole installare.

4 DS80IM41-001C

Verificata la copertura radio si potrà riaprire il frontalino, smontare il circuito e fissare il rivelatore direttamente alla parete

o attraverso la staffa e snodo opzionali

Serrare la vite di chiusura.

Applicare il filtro Led copri vite.

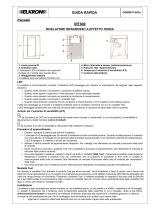

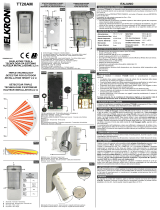

Installazione su superficie piana

Il rivelatore è stato concepito per essere montato su una superficie piana, mediante le viti di fissaggio e i tasselli in

dotazione.

Sulla base sono presenti delle predisposizioni per i fori, dove la plastica è più sottile e può essere forata allo scopo di

effettuare il montaggio.

I. Incidere la sede A e la sede B sul fondo (vedere immagine successiva).

II. Usando la dima dei fori, praticare i fori sulla superficie

III. Fissare il fondo con le apposite viti tramite le sedi A e B.

Montaggio con staffa a 90° (cod. 80SP4D00113)

Fiissare prima la staffa 90° alla parete con le apposite viti e poi fissare il fondo alla staffa tramite le sedi A e B con le viti di

fissaggio. Riavvitare la scheda al fondo.

<

<N

NO

OT

TA

A>

>

La staffa a 90° può essere montata indifferentemente verso destra o sinistra

Montaggio con snodo cod. 80SP5D00113

Lo snodo può essere applicato in orizzontale, o direttamente al muro con le apposite viti e tasselli, o tramite il supporto.

Permette orientamenti di +/- 45° sul piano verticale e +30°, nel verso contrario a quello delle “Frecce di Orientamento”, sul piano

orizzontale.

I. Forare le sedi C e D sul fondo

II. Orientare lo snodo e serrare la vite di bloccaggio snodo.

III. Posizionare il fondo sullo snodo con le viti di fissaggio staffa.

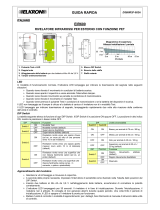

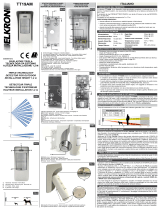

Consigli per l'installazione

L’installazione deve essere effettuata in luoghi protetti da agenti atmosferici.

Il rivelatore è stato concepito per funzionare con una portata di rilevamento di 8 metri, e montato ad un'altezza di 2 metri da terra.

Foro a sfondare per

l’accesso alla vite di

regolazione snodo

DS80IM41-001C 5

Per protezioni di pareti, evitare che una zona sensibile dell'Infrarosso si trovi a contatto con il muro per non annullare il

beneficio del sensore infrarosso a doppio elemento.

Ovviare a questo montando il sensore distaccato dal muro, come illustrato nella tabella sottostante, od orientando il

sensore di qualche grado (< 10°) utilizzando lo snodo opzionale):

Per aumentare l’efficacia della rilevazione si può aumentare anche oltre i 10° l’apertura del rivelatore rispetto al muro,

facendo comunque attenzione a non puntare il rivelatore verso aree con probabili cause di falsi allarmi (passaggi di

mezzi o persone, presenza di oggetti instabili o vegetazione a chioma).

Prediligere installazioni ove ci sia un muro/pavimento a delimitare il campo di rilevazione del sensore. Non puntare quindi

mai il sensore nel vuoto:

Ove non sia possibile una installazione Parete/Parete o Soffitto/Pavimento prediligere l'istallazione a sensore inclinato.

Escludere dalla zona di rilevazione del sensore qualsiasi oggetto in movimento od oscillante.

Linee guida

Per ottimizzare l'impiego del rivelatore, occorre prendere in considerazione le seguenti linee guida.

Si consiglia di installare il rivelatore nelle seguenti posizioni:

Montare il rilevatore ad un'altezza di 1,9-2,0 metri

Montare in un luogo ove gli animali non possano accedere all'area di rilevamento.

Montare in una posizione dove normalmente un intruso attraverserebbe il campo visivo del rivelatore da una parte

all'altra.

Montare dove il campo visivo non sia ostruito, per esempio da tendaggi, ornamenti, ecc.

Limitazioni

Non installare il rivelatore completamente esposto alla luce del sole diretta. Evitare di dirigerlo verso vetrate esposte al

sole.

In installazioni da esterno, evitare che i raggi del SOLE, specialmente nelle ore più calde della giornata, arrivino diretti

all'elemento sensibile dell'Infrarosso.

Tabella della distanza A

in funzione della portata

Portata

Distanza A

8 mt 70 cm

4 mt 35 cm

2 mt 18 cm

6 DS80IM41-001C

Non installare il rivelatore in aree ove sono presenti dispositivi che possono provocare cambiamenti repentini di

temperatura nell'area di rilevamento, ovvero condizionatori d'aria, termosifoni, ecc.

Evitare gli ostacoli di grandi dimensioni nell'area di rilevamento.

Non puntare direttamente verso sorgenti di calore, come fuochi o caldaie, e non installare sopra radiatori.

Evitare che vi siano oggetti in movimento nell'area di rilevamento, ovvero tende, tappezzerie, ecc.

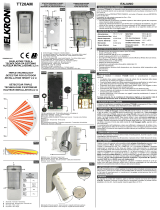

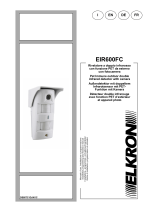

Diagrammi di rilevazione

Specifiche tecniche

Alimentazione: 1 batteria CR2 3V

Autonomia: 2 anni (valore tipico, può variare in base all’uso)

Banda di frequenza Microonda: 24,12 – 24,13 Ghz

Banda di frequenza bidirezionale: 868,6 – 868,7 MHz

Assorbimento di corrente in stand by (operativa): 15uA (solo rivelatore) + modulo TX

Assorbimento di corrente in allarme con LED accesso: 3,5 mA + modulo TX

Portata microonda: minima 2m / massima 8m con regolazione da trimmer

Potenza radio Microonda massima trasmessa: 18,68 dBm

Potenza radio bidirezionale massima trasmessa: 1,81 dBm

Livello di protezione: IP54

Temperatura lavoro: - 10°C/+55°C

Umidita Ambientale: 95%

Peso: 300g

Dimensioni senza accessori 110 x 42 x 62 mm

DICHIARAZIONE DI CONFORMITÀ UE SEMPLIFICATA

Il fabbricante, URMET S.p.A., dichiara che il tipo di apparecchiatura radio: RIVELATORE DOPPIA TECNOLOGIA DA ESTERNO

EFFETTO TENDA DT600 è conforme alla direttiva 2014/53/UE. Il testo completo della dichiarazione di conformità UE è disponibile

al seguente indirizzo Internet: www.elkron.com

FR / UK / RUS

Diagramma di rilevazione standard Diagramma di rilevazione alla massima altezza

DS80IM41-001C 7

ENGLISH

The DT600 is a dual technology detector for exterior use with a curtain effect and passive infra-red (PIR) and microwave motion

sensor capable of detecting movements in an assigned area and indicate them to the control panel to activate the intrusion alarm.

The base of the product has holes to allow installation on a flat surface, using - if necessary - the 90° bracket and an articulation

(optional).

Identification of the components

1. LED filter screw covers

2. Closure screws

3. Card-fastening screws

4. Lens

5. Anti-opening tamper

6. Dip Switch (never use 4 and 5: always

OFF)

7. Detector capacity trimmer

8. PIR sensitive element

9. Detector LED

10. Battery compartment

11. Learning Button

12. Internal LED for the learning operations and battery

signals

13. Jumper tamper (removal protection)

Intended to connect the removal protection (optional, not

included)

14. For future uses (do not modify the position)

Initialisation phase

This condition is activated automatically when the battery is enabled and at each opening/closure of the front panel. It will remain

in this mode for 60 seconds, during which the detector is not active.

Test mode (Walk Test)

By opening the front panel of the sensor, after having waited for the initialisation phase to finish, the Test Mode is launched and

lasts about 4 minutes. In this condition the cut-off time is disabled, while the LED of the detector of the alarm signal is automatically

enabled.

When in this mode, the detection tests can be conducted to verify the alarms by turning on the LED and the radio connection

capacity can be tested (for details, consult the manual for the control unit). After 4 minutes, the sensor will automatically revert to

operating condition. If the front panel is reopened, the test mode (Walk Test) will be automatically reactivated, after the initialisation

time.

Cut-off time and low-consumption operation

To avoid high consumption of the battery, the detector automatically inhibits consecutive alarm signals for a set cut-off time. In

this way, the continuous movement in front o fa detector will not deplete the battery uselessly. Then between one alarm and the

next one there will be a period of silence equal to the cut-off time. This feature is not enabled during the test mode (Walk Test).

There is a choice of two cut-off times:

- Dip Switch N° 2 in OFF position 4 min (Default)

- Dip Switch N° 2 in ON position 8 min

Supervision Function

When the detector is in normal functioning mode, it periodically conducts a self-diagnostic test, transmitting a random

supervision signal every 30-50 minutes.

1

2

4

8 DS80IM41-001C

Sensitivity Function (Increase of Sensitivity)

NORMAL: Dip Switch N°1 in OFF position (Default). Recommended for most exterior installations.

HIGH: Dip Switch N°1 in ON position. Recommended when a higher detection speed is required.

Trimmer (sensor capacity)

This regulates the sensor capacity (turning the trimmer clockwise increases the detector capacity). To adjust it, keep in mind the

operating area determined by the microwave. The sensor will automatically adapt the functioning of the infra-red with this

regulation. The trimmer default position is completely clockwise turned.

<NOTE>

Unlike the microwave, for which it is possible to establish its detector limit with sufficient precision, this condition is not

applicable for the infra-red. The reason is because the detection of the infra-red is conditioned by the ambient temperature,

by the intruder’s clothing, by the absence/presence of wind, etc. The trimmer therefore automatically regulates the infra-red

detection capacity in function of the capacity of the microwave selected without necessarily defining its operating area as that

of the microwave itself (the infra-red will be configured for the most unfavourable conditions at that capacity).

Detector LED indicator

Dip Switch N° 3 in OFF position

In the normal operating mode, the LED indicator blinks to indicate the transmission of the signal in the following situations:

When it is powered, it blinks for 60 seconds (initialisation phase).

When the cover is open and the tamper switch is activated, for 4 minutes (test mode).

During the test mode for every movement detected

If the tamper is open, for every movement detected.

It does not blink if a movement is detected in normal mode and with the tamper closed.

Dip Switch N°3 in ON position (Default)

The LED also blinks when a movement is detected in normal operating mode and with the tamper closed, at the cost of depleting

the battery. It is inhibited as soon as the cut-off time starts.

Battery

The detector is powered by a CR2 3V lithium battery provided in the package. The detector is capable of detecting the flat

battery status, sending a signal to the control unit together with the normal transmission of signals so that the control unit

displays the corresponding status.

<NOTE>

During the replacement of the battery, after having removed the dead battery, press the tamper twice to completely

discharge the device before inserting the new battery.

To check that it is functioning correctly, conduct the Walk Test for the radio signal level capacity by pressing the

learning button, button 11 (see the control unit instruction manual).

Detector learning

To open the sensor, lift the LED filter screw covers and loosen the closure

screws beneath it. Loosen the screws that hold the card in place without

unscrewing them completely and disassemble the electronic card, lifting it

upward first to release it from the screw, as illustrated here.

Insert the CR2 battery into the battery compartment, taking care to

observe the polarity.

When the detector LED indicator is powered, it blinks for 60 seconds

(initialisation phase). The detector is not yet activated.

Enable the control unit for the learning device. For details, see the

control unit instruction manual.

Press the learning button on the radio circuit and complete the learning

process (see the control unit instruction manual).

Put the control unit in “Radio Device Test” mode after the detector

learning procedure.

Insert the circuit on the bottom, tighten the screws and close the front

panel, positioning the detector in the where it is to be installed.

Once the radio cover is checked, it is possible to reopen the front panel, disassemble the circuit and attach the detector

directly onto the wall or using the bracket and optional articulation.

Tighten the closure screws.

Apply the LED filter screw covers.

Installation on flat surfaces

The detector was designed to be assembled on a flat surface, using the fastening screws and the anchor bolts provided.

The base is marked where the plastic is thinner for boring holes suitable for installation.

I. Cut seat A and seat B on the bottom (see the image below).

II. Using the holes template, make holes on the surface.

Card screw

DS80IM41-001C 9

III. Fix the bottom using the special screws in seats A and B.

Installation with the 90° bracket (ref. 80SP4D00113)

First fix the 90° bracket to the wall with the special screws and then fix the base to the bracket using seats A and B with the

fastening screws. Re-screw the card to the base.

<

<N

NO

OT

TE

E>

>

The 90° bracket can be assembled either to the right or left as desired.

Installation with articulation (ref. 80SP5D00113)

The articulation can be applied horizontally, or directly to the wall with the special screws and anchor bolts, or using the support.

It is possible to orient the base at +/- 45° on a vertical plane and +30°, on the side opposite the “Orientation Arrow”, on the

horizontal plane.

I. Puncture seats C and D on the base.

II. Orient the articulation and tighten the articulation blocking screws.

III. Position the base on the articulation with the bracket fastening screws.

Installation precautions

The detector was designed to work within a detection field of 8 metres and is installed at a height of 2 metres above the ground.

To protect walls, ensure that a zone sensitive to the infra-red is not in contact with the wall so that the benefit of the two-

element infra-red sensor is not compromised.

Seat A

Seat B

Card fastening screw

90° bracket

Wall fastening

screws

Seat C

Seat D

Orientation arrows

Articulation

Support

Centering

elements

Puncture to the very bottom to

access the articulation adjustment

screws.

10 DS80IM41-001C

Avoid this problem by installing the sensor detached from the wall, as illustrated in the table below, or orienting the sensor

a few degrees (< 10°) using the optional articulation):

In order to increase the effectiveness of the detection the opening of the detector in relation to the wall can be increased

even more than 10°, taking care not to orient the detector towards areas likely to cause false alarms (passage of vehicles

or people, presence of moving objects or trees).

It is preferable to install the device where there is a wall/floor that defines the sensor detection area. So never orient the

sensor toward an empty space:

Where a Wall/Wall or Ceiling/Floor installation is not possible, an inclined sensor installation system is recommended.

Exclude all moving or oscillating objects from the sensor detection zone.

Guidelines

To optimise the use of the detector, the following guidelines must be taken into consideration.

It is recommended that the detector be installed in the following positions:

Install the detector at a height of 1.9-2.0 metres.

Install the detector in a place where animals cannot enter the detection area.

Install the detector in a position where an intruder would normally cross the detector's field of vision from one side to the

other.

Install the detector where the field of vision is not obstructed, for example by curtains, ornaments, etc.

Restrictions

Do not install the detector completely exposed to direct sunlight. Avoid orienting it towards glass windows exposed to the

sun.

Distance A table in function of the capacity

Range

Distance A

8 m 70 cm

4 m 35 cm

2 m 18 cm

YES

YES

Wall/Wall Ceiling/Floor

Inclined sensor

DS80IM41-001C 11

In exterior installations, do not allow the infra-red sensor to be exposed to direct SUNLIGHT, especially during the hottest

hours of the day.

Do not install the detector in an area where there are devices that can cause sudden changes of temperature in the

detection area, like air conditioners, radiators, etc.

Do not allow large obstacles in the detection area.

Never orient the device directly towards sources of heat like fires or boilers, and do not install over radiators.

Never allow moving objects into the detection area, like curtains, tapestries, etc.

Detection diagrams

Technical specifications

Power supply: 1 battery CR2 3V

Autonomy: 2 years (typical value, can vary according to use)

Microwave radio frequency band: 24,12 – 24,13 GHz

Two-way radio frequency band: 868,6 – 868,7 MHz

Absorption of current in stand-by: 15uA (detector only) + TX module

Absorption of current during alarm with LED on: 3,5 mA + TX module

Microwave capacity: minimum 2 m / maximum 8 m with trimmer regulation

Microwave maximum radio power transmitted: 18,68 dBm

Two-way maximum radio power: 1,81 dBm

Level of protection: IP54

Working temperature: - 10°C/+55°C

Ambient humidity: 95%

Weight: 300g

Dimensions without accessories WxHxD 110 x 42 x 62 mm

SIMPLIFIED CE DECLARATION OF CONFORMITY

The manufacturer, URMET S.p.A., hereby declares that the type of radio device: DUAL TECHNOLOGY DETECTOR FOR

EXTERIOR USE WITH CURTAIN EFFECT DT600 is in conformity with Directive 2014/53/EU. The complete text of the EU

declaration of conformity is available at the following link: www.elkron.com.

FR / UK / RUS

Standard detection diagram Detection at the maximum height diagram

YES

Side view

Side view

Top view

12 DS80IM41-001C

DEUTSCH

Der DT600 ist ein Außendetektor mit doppelter Technologie und Vorhangeffekt. Er ist mit passivem Infrarot-Bewegungssensor

(PIR) kombiniert mit Mikrowellentechnologie ausgestattet und in der Lage, die Bewegung in einem zugeordneten Bereich zu

erfassen und an ein Steuergerät zu übertragen, um den Einbruchalarm auszulösen.

Die Basis des Produkts ist bereits für die Öffnungen ausgelegt, die die Installation auf einer ebenen Oberfläche gestatten. Sollte

dies notwendig sein, können dazu die 90°-Halterung oder ein Gelenk verwendet werden (Optionen).

Identifizierung der Bauteile

1. LED-Filter zur Schraubenabdeckung

2. Verschlussschraube

3. Befestigungsschraube Platine

4. Linse

5. Öffnungsschutz-Tamper

6. Dip-Switch (4 und 5 nicht zu verwenden:

immer auf OFF)

7. Trimmer Detektorreichweite

8. PIR-Fühlglied

9. LED des Detektors

10. Batterieraum

11. Einlern-Taste

12. Innere LED für Einlernvorgänge und Batterieanzeige

13. Jumper-Tamper (Demontageschutz)

Zum Anschluss des Demontageschutzes vorgesehen

(Option, nicht im Lieferumfang enthalten)

14. Für spätere Verwendungen (Position nicht ändern)

Initialisierungsphase

Diese Phase wird beim Einlegen der Batterie und bei jedem Öffnen/Schließen des Frontteils automatisch aktiviert. Sie dauert 60

s und während dieser Zeit ist der Detektor nicht aktiv.

Test-Modus (Walk Test)

Durch Öffnen des Frontteils des Sensors nach dem Ende der Initialisierungsphase beginnt der Test-Modus, der ca. 4 min dauert.

Unter diesen Bedingungen ist die Sperrzeit deaktiviert, während die LED des Detektors für die Alarmmeldung automatisch aktiviert

wird.

In diesem Modus können die Erfassungstests durchgeführt werden, indem die Alarme anhand des Aufleuchtens der LED sowie

die Reichweite der Funkverbindung überprüft werden (wegen Einzelheiten siehe Handbuch des jeweiligen Steuergeräts). Nach

Ablauf der 4 Minuten ist der Sensor automatisch betriebsbereit. Wird das Frontteil erneut geöffnet, wird nach der

Initialisierungszeit automatisch wieder der Test-Modus aktiviert (Walk Test).

Sperrzeit und Energiesparmodus

Um einen hohen Energieverbrauch der Batterie zu vermeiden, sperrt der Detektor die Meldung von aufeinanderfolgenden

Alarmen für einen als Sperrzeit bezeichneten Zeitraum. Auf diese Art und Weise entlädt die kontinuierliche Bewegung vor einem

Detektor die Batterie nicht unnötigerweise. Daraus folgt, dass zwischen einem Alarm und dem nachfolgenden eine Ruhepause

erforderlich ist, die der Sperrzeit entspricht. Diese Eigenschaft ist während des Test-Modus (Walk Test) nicht aktiviert.

Es können zwei Sperrzeiten gewählt werden.

- Dip-Switch Nr. 2 in Pos. OFF 4 min (Standard)

- Dip-Switch Nr. 2 in Pos. ON 8 min

Überwachungsfunktion

Befindet sich der Detektor in der normalen Betriebsart, führt er regelmäßig einen Eigendiagnose-Test durch und überträgt alle

30 - 50 Minuten ein zufälliges Überwachungssignal.

1

2

4

DS80IM41-001C 13

Empfindlichkeitsfunktion (Empfindlichkeitssteigerung)

NORMAL: Dip-Switch Nr. 1 in Pos. OFF (Standard) Für den Großteil der Außeninstallationen angezeigt.

HIGH: Dip-Switch Nr. 1 in Pos. ON. Angezeigt, wenn eine höhere Erfassungsgeschwindigkeit verlangt wird.

Trimmer (Detektorreichweite)

Regelt die Reichweite des Sensors (durch Drehen des Trimmers im Uhrzeigersinn wird die Detektorreichweite erhöht). Zum

Einstellen auf den von der Mikrowelle bestimmten Wirkungsbereich Bezug nehmen. Der Sensor passt die Infrarotfunktion

automatisch dieser Einstellung an. Die Standardposition des Trimmers wird vollständig im Uhrzeigersinn gedreht.

<HINWEIS>

Im Gegensatz zur Mikrowellenfunktion, deren Erfassungsgrenze ausreichend genau festgestellt werden kann, gilt dies für die

Infrarotfunktion nicht. Dies ist dadurch bedingt, dass die Infraroterfassung von der Umgebungstemperatur, der Kleidung des

Eindringlings, den Windverhältnissen, usw. abhängig ist. Der Trimmer regelt daher die Infrarot-Erfassungsleistung abhängig

von der ausgewählten Mikrowellenreichweite, ohne diese dabei notwendigerweise auf den Wirkungsbereich der Mikrowelle

zu beschränken (die Infrarotleistung wird für die ungünstigsten Bedingungen bei dieser Reichweite konfiguriert).

LED-Anzeige Detektor

Dip-Switch Nr. 3 in Pos. OFF

In der normalen Betriebsart blinkt die LED-Anzeige, um die Signalübertragung in den folgenden Situationen anzuzeigen:

Bei Stromversorgung blinkt sie 60 Sekunden (Initialisierungsphase).

Wenn die Abdeckung geöffnet und der Tamper-Schalter betätigt wird 4 Minuten lang (Test-Modus).

Während des Test-Modus bei jeder erfassten Bewegung

Bei geöffnetem Tamper bei jeder erfassten Bewegung

Sie blinkt nicht, wenn im Normalbetrieb eine Bewegung erfasst wird und der Tamper geschlossen ist.

Dip-Switch Nr. in Position ON (Standard)

Die Led blinkt auch, wenn eine Bewegung im Normalbetrieb und bei geschlossenem Tamper erfasst wird, was zu Lasten der

Batteriedauer erfolgt. Unterdrückt, sobald die Sperrzeit beginnt.

Batterie

Der Detektor wird von einer in der Verpackung enthaltenen Lithiumbatterie CR2 3V versorgt. Der Detektor ist in der Lage, die

entladene Batterie zu erkennen und zusammen mit den normalen Signalübertragungen ein Signal an das Steuergerät zu

senden, damit die Zentrale den entsprechenden Status anzeigt.

<HINWEIS>

Während des Ersetzens der Batterie und nach dem Entfernen der entladenen Batterie den Tamper zweimal

betätigen, um die Vorrichtung vollkommen zu entladen, bevor die neue Batterie eingelegt wird.

Um die korrekte Funktionsweise zu überprüfen, einen Walk Test hinsichtlich der Reichweite und des

Funksignalempfangs ausführen, indem die Einlern-Taste betätigt wird, Taste 11 (siehe hierzu Bedienungsanleitung

des Steuergeräts).

Einlernen des Detektors

Zum Öffnen des Sensors den LED-Filter über der Schraube anheben und die

Verschlussschraube darunter lösen. Die Befestigungsschraube der Platine

lösen, ohne sie vollständig abzuschrauben und die Platine entnehmen, indem

diese zuerst nach oben angehoben wird, um sie von der Schraube zu lösen, wie

in der seitlichen Abbildung dargestellt.

Die Batterie CR2 in das Batteriefach einsetzen und dabei auf die

Polarität achten.

Die LED-Anzeige des Detektor blinkt 60 Sekunden lang

(Initialisierungsphase). Der Detektor ist noch nicht aktiv.

Das Steuergerät für das Einlernen von Geräten aktivieren. Wegen

Einzelheiten auf die Bedienungsanleitung des Steuergeräts Bezug

nehmen.

Die Einlern-Taste auf dem Funkkreis betätigen und das

Einlernverfahren abschließen (siehe hierzu Bedienungsanleitung des

Steuergeräts).

Sobald der Detektor eingelernt wurde, das Steuergerät auf "Funkgeräte-Test" stellen.

Den Schaltkreis unten einsetzen, die Schraube anziehen und das Frontteil wieder anbringen. Dann den Detektor in die

Position bringen, in der er installiert werden soll.

Nach Überprüfung des Funkempfangs kann das Frontteil wieder geöffnet, der Schaltkreis ausgebaut und der Detektor

direkt an der Wand oder mit Hilfe der Halterung oder des Gelenks (Optionen) befestigt werden.

Die Verschlussschraube anziehen.

Den Led-Filter über der Schraube anbringen.

Platinenschraube

14 DS80IM41-001C

Installation auf ebener Oberfläche

Der Detektor wurde auf die Montage auf einer ebenen Oberfläche mit den im Lieferumfang enthaltenen

Befestigungsschrauben und Dübeln ausgelegt.

Die Basis ist dort, wo der Kunststoff dünner ist, für die Bohrungen ausgelegt, um die Montage zu gestatten.

I. Den Sitz A und den Sitz B auf dem Boden einschneiden (siehe Bilder im Anschluss).

II. Unter Verwendung der Bohrschablone die Bohrungen an der Oberfläche anbringen.

III. Den Boden mit den dafür vorgesehenen Schrauben über die Sitze A und B befestigen.

Montage mit 90°-Halterung (Cod. 80SP4D00113)

Zuerst die 90°-Halterung mit den dafür vorgesehenen Schrauben an der Wand und dann den Boden über die Sitze A und B mit

den Befestigungsschrauben an der Halterung anbringen. Die Platine wieder am Boden verschrauben.

<

<H

HI

IN

NW

WE

EI

IS

S>

>

Die 90°-Halterung kann sowohl nach rechts als auch nach links montiert werden.

Montage mit Gelenk Cod. 80SP5D00113

Das Gelenk kann waagerecht entweder mit den dafür vorgesehenen Schrauben und Dübeln direkt an der Wand oder mit dem

Halter angebracht werden.

Es gestattet Ausrichtungen von +/- 45° in der senkrechten Ebene und +30° in Gegenrichtung zu den "Ausrichtungspfeilen" in der

waagerechten Ebene.

I. Die Sitze C und D auf dem Boden durchbohren.

II. Das Gelenk ausrichten und die Feststellschraube des Gelenks anziehen.

III. Den Boden mit den Befestigungsschrauben der Halterung auf dem Gelenk positionieren.

Empfehlungen für die Installation

Der Detektor wurde für den Betrieb bei einer Erfassungsreichweite von 8 Metern und auf einer Montagehöhe von 2 Metern

ausgelegt.

Sitze A

Sitze B

Platinenbefestigungsschraub Wandbefestigungsschraube

90°-Halterung

Sitze C

Sitze D

Ausrichtungspfeile

Halter

Gelenk Zentrierer

Öffnung für den Zugang zur

Gelenkeinstellschraube

DS80IM41-001C 15

Zum Schutz von Wänden vermeiden, dass ein empfindlicher Bereich des Infrarotsensors die Wand berührt, um nicht den

Vorteil des Infrarotsensors mit doppeltem Element aufzuheben.

Dem abhelfen, indem der Sensor in einem Abstand zur Wand montiert wird, wie in der unten stehenden Tabelle

angegeben, oder indem der Sensor um einige Grade gedreht wird (< 10°) unter Verwendung der Gelenkoption):

Um die Wirksamkeit der Erfassung zu steigern, kann die Öffnung des Detektors im Verhältnis zur Wand auch über 10°

erhöht werden, wobei in jedem Fall darauf zu achten ist, den Detektor nicht auf Bereiche mit möglichen Ursachen für

falsche Alarme zu richten (Durchgang von Fahrzeugen oder Personen, instabile Gegenstände oder Baumkronen).

Installationen, bei denen eine Mauer/ein Boden den Erfassungsbereich des Sensors begrenzt, sind zu bevorzugen. Den

Sensor nie ins Leere richten:

Wo eine Wand/Wand- oder Decke/Wand-Installation nicht möglich ist, die Installation mit geneigtem Sensor bevorzugen.

Aus dem Erfassungsbereich des Sensors jegliche sich bewegenden oder schwingenden Gegenstände ausschließen.

Leitlinien

Um den Einsatz des Detektors zu optimieren, es wird empfohlen, den Detektor in den folgenden Positionen zu installieren:

Den Detektor auf einer Höhe von 1,9-2,0 Metern montieren.

An einer Stelle montieren, in dem Tiere nicht in den Erfassungsbereich gelangen können.

Tabelle des Abstands A abhängig von der

Reichweite

Reichweite Abstand A

8 m 70 cm

4 m 35 cm

2 m 18 cm

NEIN

JA

JA

Wand/Wand

Mauer/Boden

Geneigter Sensor

16 DS80IM41-001C

In einer Position montieren, in der ein Eindringling normalerweise den Sichtbereich des Detektors von einer Seite zur

anderen überqueren würde.

Dort montieren, wo der Sichtbereich nicht versperrt ist, zum Beispiel durch Vorhänge, Wandschmuck, usw.

Einschränkungen

Den Detektor nicht vollständig direktem Sonnenlicht ausgesetzt installieren. Vermeiden, den Detektor auf der Sonne

ausgesetzte Glasflächen zu richten.

Bei Außeninstallationen vermeiden, dass die SONNENSTRAHLEN, insbesondere während der wärmsten Stunden des

Tages, direkt auf das empfindliche Element des Infrarotsensors treffen.

Den Detektor nicht in Bereichen installieren, in denen Vorrichtungen vorhanden sind, die wiederholte

Temperaturschwankungen im Erfassungsbereich verursachen können bzw. Klimaanlagen, Heizkörper, usw.

Große Hindernisse im Erfassungsbereich vermeiden.

Nicht direkt auf Wärmequellen wie Herde oder Heizkessel richten und nicht über Heizkörpern installieren.

Vermeiden, dass sich bewegliche Gegenstände im Erfassungsbereich befinden wie Vorhänge, Wandbehänge, usw.

Erfassungsdiagramme

Technische Daten

Versorgungsspannung: 1 3 V-Batterie CR2

Autonomie: 2 Jahre (normaler Wert, kann je nach Verwendung schwanken)

Mikrowellen maximale ubertragene funkleistung:: 24,12 – 24,13 Ghz

Bidirektionale maximale ubertragene funkleistung: 868,6 – 868,7 MHz

Stromaufnahme im Standby: 15 uA (nur Detektor) + TX-Modul

Stromaufnahme im Alarmzustand bei eingeschalteter LED: 3,5 mA + TX-Modul

Mikrowellenempfindlichkeit: min. 2 m / max. 8 m bei Einstellung über Trimmer

Mikrowellen fundfrequenz band: 18,68 dBm

Bidirektionale fundfrequenz band: 1,81 dBm

Schutzgrad: IP54

Betriebstemperatur: - 10°C/+55°C

Umgebungsfeuchtigkeit: 95 %

Gewicht: 300g

Abmessungen ohne Zubehör 110 x 42 x 62 mm

Standarderfassungsdiagramm Erfassungsdiagramm auf maximaler Höhe

JA

NEIN

Ansicht von oben

Seitenansicht

Seitenansicht

DS80IM41-001C 17

VEREINFACHTE EU-KONFORMITÄTSERKLÄRUNG

Der Hersteller, URMET S.p.A., erklärt, dass der Funkgerätetyp: AUSSENDETEKTOR MIT DOPPELTER TECHNOLOGIE UND

VORHANGEFFEKT DT600 der Richtlinie 2014/53/UE entspricht. Der ungekürzte Text der EU-Konformitätserklärung steht unter

der folgenden Internetadresse zur Verfügung: www.elkron.com.

FR / UK / RUS

18 DS80IM41-001C

FRANÇAIS

Le détecteur DT600 est équipé de la double technologie pour l'extérieur en rideau avec capteur de mouvement passif aussi bien

à infrarouge (PIR) qu'à micro-ondes, en mesure pour détecter les mouvements dans une zone donnée et les signaler à l'unité de

contrôle pour l’activation de l'alarme d’intrusion.

La base du produit présente des trous prédécoupés pour l'installation sur une surface plate, le cas échéant, à l'aide de l'étrier à

90° ou d'une articulation (en option).

Identification des pièces

1. Filtre LED couvre-vis

2. Vis de fermeture

3. Vis de fixation de la carte

4. Lentille

5. Tamper anti-ouverture

6. Dip Switch (4 et 5 à ne pas utiliser :

toujours sur OFF)

7. Régulateur potentiomètre (Trimmer)

portée détecteur

8. Élément sensible PIR

9. LED du détecteur

10. Logement des batteries

11. Touche Apprentissage

12. LED interne pour les opérations d'apprentissage et

de signalisation de la batterie

13. Interrupteur tamper (anti-sabotage)

Prévu pour relier la protection anti-sabotage (option, non

fournie de série)

14. Pour les utilisations futures (ne pas modifier la

position)

Procédure d'initialisation

Cette condition s'active automatiquement lors de l'introduction de la batterie et à chaque ouverture/fermeture de la façade. Elle

dure 60 secondes au cours desquelles le détecteur reste inactif.

Mode test (Walk Test)

Lors de l'ouverture de la façade du capteur et après la procédure d'initialisation, le dispositif accède en mode de test pendant 4

minutes environ. Dans cette condition, le temps d'interdiction est désactivé, alors que la LED du détecteur pour la signalisation

des alarmes est activée automatiquement.

Dans ce mode, il est possible d'effectuer des tests de détection en vérifiant les alarmes par l'allumage de la LED, ainsi que la

portée de la connexion radio (pour les détails, consulter le manuel concernant l'unité de contrôle). Après ces 4 minutes, le capteur

devient automatiquement opérationnel. Si la façade est ouverte à nouveau, le mode Test (Walk Test) s'active automatiquement,

après la période d'initialisation.

Temps d'interdiction et fonctionnement à faible consommation

Afin d'éviter toute consommation élevée de la batterie, le détecteur exclut automatiquement la signalisation des alarmes

consécutives pendant une période de temps définie temps d'interdiction. Ainsi, le mouvement continu en face d'un détecteur ne

déchargera inutilement

la batterie. Par conséquent, entre une alarme et l'autre, la période de repos nécessaire est égale au

temps d'interdiction. Cette caractéristique n'est pas activée pendant le mode Test (Walk Test).

Il existe deux temps d'interdiction

:

- Dip Switch N. 2 en pos. OFF 4 min (par défaut)

- Dip Switch N. 2 en pos. ON 8 min

1

2

4

DS80IM41-001C 19

Fonction Supervision

Quand le détecteur est en mode fonctionnement normal, il effectue périodiquement un test d'auto-diagnostique, en transmettant

un signal de supervision aléatoire toutes les 30 - 50 minutes.

Fonction Sensibilité (Augmentation de la sensibilité)

NORMAL : Dip Switch N.1 en pos. OFF (par défaut). Appropriée pour la plupart des installations pour l'extérieur.

HIGH : Dip Switch N.1 en pos. ON. Appropriée en cas de demande de vitesse de détection plus élevée.

Régulateur potentiomètre (Trimmer) (portée détecteur)

Il module la portée du capteur (en tournant le trimmer dans le sens des aiguilles d'une montre, la portée du détecteur est

augmentée). Pour son réglage, se reporter au champ d’action déterminé par la micro-onde. Le détecteur adaptera

automatiquement le fonctionnement de l’infrarouge à ce réglage. La position du trimmer est complètement tournée dans le sens

des aiguilles d'une montre.

<REMARQUE>

Si la limite de détection de la micro-onde peut être établie avec suffisamment de précision, la même condition ne s’applique

pas à l’infrarouge. En effet, la détection de l’infrarouge dépend de la température ambiante, des vêtements portés par l’intrus,

de l’absence/présence de vent, etc. Le trimmer règle donc automatiquement la capacité de détection de l’infrarouge en

fonction de la portée de la micro-onde sélectionnée, sans forcément en délimiter le champ d’action sur celui de la micro-onde

même (l'infrarouge sera configuré pour les conditions les plus défavorables à la portée en question).

Témoin LED du détecteur

Dip Switch N. 3 en pos. OFF

En mode de fonctionnement normal, le témoin LED clignote à indiquer la transmission du signal dans les situations suivantes :

Quand il est détecté, la LED clignote pendant 60 secondes (procédure d'initialisation).

Quand le couvercle est ouvert et l'interrupteur tamper est activé, la LED clignote pendant 4 minutes (mode Test).

Pendant le mode test à chaque mouvement détecté

Si le tamper est ouvert, à chaque mouvement détecté

La LED ne clignote pas si un mouvement est détecté en mode normal et avec le tamper fermé.

Dip Switch N. 3 en position ON (par défaut)

La LED clignote également quand un mouvement est détecté en mode de fonctionnement normal et avec le tamper fermé, au

détriment de la durée de la batterie. Il est exclu dès le démarrage du temps d'interdiction.

Batterie

Le détecteur est alimenté par une batterie au lithium CR2 3V, fournie avec le produit. Le détecteur est en mesure de détecter

quand la batterie est épuisée, en envoyant un signal à l’unité de contrôle avec les normales transmissions des signaux afin que

la centrale affiche l'état correspondant.

<REMARQUE>

Lors du remplacement de la batterie, après avoir déposé la batterie épuisée, appuyer sur le tamper deux fois afin

de décharger complètement le dispositif avant d'installer la nouvelle batterie.

Pour vérifier le bon fonctionnement, effectuer un Walk Test de la portée et le niveau du signal radio en appuyant sur

la touche d'apprentissage, touche 11 (se reporter au manuel des instructions de l'unité de contrôle).

Apprentissage du détecteur

Pour ouvrir le capteur, soulever le filtre LED cache-vis et dévisser la vis de

fermeture en dessous. Desserrer la vis de fixation de la carte sans la dévisser

complètement , puis démonter la carte électronique en la soulevant vers le haut

pour la décrocher de la vis, tel que montré dans l'image ci-contre.

Introduire la batterie CR2 dans le logement de la batterie, en

respectant la polarité.

Le témoin LED du détecteur clignote pendant 60 secondes (procédure

d'initialisation). Le détecteur n'est pas encore actif.

Activer l’unité de contrôle lors de l'apprentissage des dispositifs. Pour

les détails, se reporter au manuel d'instructions de l’unité

d’alimentation.

Appuyer sur la touche d'apprentissage sur le circuit radio et compléter

la procédure d'apprentissage (se reporter au manuel d'instructions de

l'unité de contrôle).

Après avoir effectué l'apprentissage du détecteur, mettre l’unité de

contrôle en mode "Test dispositifs radio".

Vis de la carte

20 DS80IM41-001C

Insérer le circuit sur la base, visser la vis et refermer la façade en plaçant le détecteur dans la position où l'on veut

l'installer.

Après avoir vérifié la couverture radio, il est possible de ré-ouvrir la façade, de démonter le circuit et de fixer le détecteur

directement au mur ou à l'aide de l'étrier et de la rotule fournis en option.

Serrer la vis de fermeture.

Appliquer le filtre LED cache-vis.

Montage sur une surface plane

Le détecteur est conçu pour être monté sur une surface plane, à l'aide des vis de fixation et des chevilles fournies avec

le dispositif.

La base présente des trous prédécoupés en plastique plus mince qui peut être percée pour le montage.

I. Inciser le siège A et le siège B de la base (voir l'image suivante).

II. Utiliser un gabarit pour percer les trous sur la surface.

III. Visser la base avec les vis dans les sièges A et B.

Montage avec étrier à 90° (code 80SP4D00113)

Accrocher l'étrier à 90° au mur à l'aide des vis prévues à cet effet, puis fixer la base à l'étrier dans les sièges A et B avec les vis

de fixation. Visser la carte à la base.

<

<R

RE

EM

MA

AR

RQ

QU

UE

E>

>

L'étrier à 90° peut être indifféremment installé à droite ou à gauche.

Montage avec rotule (code 80SP5D00113)

La rotule doit être installée horizontalement ou directement au mur à l’aide des vis et des chevilles prévues à cet effet ou à l'aide

du support.

Elle permettra des orientations de +/- 45° sur le plan vertical et de +30° dans le sens contraire à celui des "Flèches d’Orientation",

sur le plan horizontal.

I. Percer les sièges C et D sur la base

II. Orienter la rotule et serrer sa vis de blocage.

III. Positionner la base sur la rotule à l’aide des vis de fixation de l’étrier.

Sièges A

Sièges B

Vis de fixation de

la carte

Étrier à 90°

Vis de fixation murale

Flèches

d’orientation

Siège C

Siège D

Rotule

Support

Éléments de

centrage

Orifice à enfoncer pour

l'accès à la vis de

réglage de la rotule

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Elkron DT600 Guida d'installazione

- Categoria

- Illuminazione di comodità

- Tipo

- Guida d'installazione

in altre lingue

- English: Elkron DT600 Installation guide

- français: Elkron DT600 Guide d'installation

- Deutsch: Elkron DT600 Installationsanleitung

Documenti correlati

-

Elkron EIR600 Guida d'installazione

Elkron EIR600 Guida d'installazione

-

Elkron IM600 Guida d'installazione

Elkron IM600 Guida d'installazione

-

Elkron IRT600 Guida d'installazione

Elkron IRT600 Guida d'installazione

-

Elkron IR600FC Guida d'installazione

Elkron IR600FC Guida d'installazione

-

Elkron IR600 Guida Rapida

Elkron IR600 Guida Rapida

-

Elkron IRT600 Guida Rapida

Elkron IRT600 Guida Rapida

-

Elkron EIR600 Guida Rapida

Elkron EIR600 Guida Rapida

-

Elkron TT20AM Guida d'installazione

Elkron TT20AM Guida d'installazione

-

Elkron TT19AM Guida d'installazione

Elkron TT19AM Guida d'installazione

-

Elkron EIR600FC Guida d'installazione

Elkron EIR600FC Guida d'installazione