ESAB LAX 380 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

Questo manuale è adatto anche per

LAX 320 valid for serial no. 005--xxx--xxxx

LAX 380 valid for serial no. 645--xxx--xxxx

0455 640 127 011001

LAX 320 - 380WI

LAX 320/320I/

380/380W/380I/380WI

104

Instruction manual Èíñòðóêöèÿ ïî ýêñïëóàòàöèè

-- 2 --

Rights reserved to alter specifications without notice.

Îñòàâëÿåì çà ñîáîé ïðàâî èçìåíÿòü ñïåöèôèêàöèþ áåç ïðåäóïðåæäåíèÿ.

Ðóññêèé 3...............................................

ENGLISH 11..............................................

Ðóññêèé

TOCr

-- 3 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ 4........................................

2 ÂÂÅÄÅÍÈÅ 4.......................................................

2.1 Êîìïëåêò ïîñòàâêè 5.......................................................

3 ÒÅÕÍÈ×ÅÑÊÈÅ ÄÀÍÍÛÅ 5..........................................

4ÓÑÒÀÍÎÂÊÀ 6.......................................................

4.1 Ñáîðêà óñòàíîâêè 7........................................................

4.2 Ïîäêëþ÷åíèå óñòàíîâêè 7..................................................

4.3 Ïîäñîåäèíåíèå ê ýëåêòðè÷åñêîé ñåòè 8.....................................

5 ÒÅÕÍÈ×ÅÑÊÎÅ ÎÏÈÑÀÍÈÅ 8.......................................

6 ÎÁÑËÓÆÈÂÀÍÈÅ 9.................................................

6.1 Ïîïîëíåíèå îõëàæäàþùåé æèäêîñòè 9.....................................

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 10.......................................

ÑÕÅÌÀ 19..............................................................

ÑÏÈÑÎÊ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 23........................................

ÄÎÏÎËÍÈÒÅËÜÍÛÅ ÏÐÈÍÀÄËÅÆÍÎÑÒÈ 38...........................

ba15d1ra

-- 4 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ

Ïåðåä íà÷àëîì ìîíòàæà è ýêñïëóàòàöèè âíèìàòåëüíî èçó÷èòå ñîîòâåòñòâóþùèå èíñòðóêöèè.

ÇÀÙÈÒÈÒÅ ÑÅÁß È ÄÐÓÃÈÕ!

ÎÑ ÒÎÐÎÆÍÎ!

ÄÓÃÎ

Â

Àß Ñ

Â

ÀÐÊÀ È ÐÅÇÊÀ ÎÏÀÑÍÛ ÊÀÊ ÄËß ÈÑÏÎËÍÈÒÅËß ÐÀÁÎÒ, ÒÀÊ È ÄËß

ÏÎÑÒ ÎÐÎÍÍÈÕ ËÈÖ. ÒÐÅÁÓÉÒÅ ÑÎÁËÞÄÅÍÈÅ

Â

ÑÅÕ ÏÐÀ

Â

ÈË ÁÅÇÎÏÀÑÍÎÑÒÈ,

ÄÅÉÑÒ

Â

ÓÞÙÈÕ ÍÀ ÎÁÚÅÊÒÅ, ÊÎÒÎÐÛÅ ÄÎËÆÍÛ Ó×ÈÒÛ

Â

ÀÒÜ Ñ

Â

ÅÄÅÍÈß ÎÁ ÎÏÀÑÍÎÑÒßÕ,

ÏÐÅÄÑÒÀ

Â

ËÅÍÍÛÅ ÈÇÃ ÎÒÎ

Â

ÈÒÅËÅÌ Ñ

Â

ÀÐÎ×ÍÎÃÎ ÎÁÎÐÓÄÎ

Â

ÀÍÈß.

ÎÏÀÑÍÎÑÒÜ ÑÌÅÐÒÅËÜÍÎÃÎ ÏÎÐÀÆÅÍÈß ÝËÅÊÒÐÈ×ÅÑÊÈÌ ÒÎÊÎÌ.

S Ñâàðî÷íûé àãðåãàò óñòàíàâëèâàåòñÿ è çàçåìëÿåòñÿ â ñîîòâåòñòâèè ñ äåéñòâóþùèìè íîðìàìè è

ïðàâèëàìè.

S Íå äîïóñêàéòå êîíòàêòà íàõîäÿùèõñÿ ïîä íàïðÿæ åíèåì äåòàëåé è ýëåêòðîäîâ ñ íåçàùèùåííûìè

÷àñòÿìè òåëà, ìîêðûìè ðóêàâèöàìè è ìîêðî é îäåæäîé.

S Îáåñïå÷üòå ýëåêòðè÷åñêóþ èçîëÿöèþ îò çåìëè è ñâàðèâàåìûõ äåòàëåé.

S Îáåñïå÷üòå ñîáëþäåíèå áåçîïàñíûõ ðàáî÷èõ ðàññòîÿíèé.

ÄÛÌÛ È ÃÀÇÛ ìîãóò áûòü îïàñíû äëÿ ÷åëîâåêà

S Èñêëþ÷èòå âîçìî æíîñòü âîçäåéñòâèÿ äûìîâ.

S Äëÿ èñêëþ÷åíèÿ âäûõàíèÿ äûìîâ âî âðåìÿ ñâàðêè îðãàíèçóåòñÿ îáùàÿ âåíòèëÿöèÿ ïîìåùåíèÿ, à

òàêæå âûòÿæíàÿ âåíòèëÿöèÿ èç çîíû ñâàðêè.

ÈÇËÓ×ÅÍÈÅ ÄÓÃÈ âûçûâàåò ïîðàæåíèå ãëàç è îæîãè êîæè.

S Çàùèòèòå ãëàçà è êîæó. Äëÿ ýòîãî èñïîëüçóéòå çàùèòíûå ùèòêè, öâåòíûå ëèíçû è çàùèòíóþ

ñïåöîäå æäó.

S Äëÿ çàùèòû ïîñòîðîííèõ ëèö ïðèìåíÿþòñÿ çàùèòíûå ýêðàíû èëè çàíàâåñè.

ÏÎÆÀÐÎÎÏÀÑÍÎÑÒÜ

S Èñêðû (áðûçãè ìåòàëëà) ìîãóò âûçâàòü ïîæàð. Óáåäèòåñü â îòñóòñòâèè ãîðþ÷èõ ìàòåðèàëîâ

ïîáëèçîñòè îò ìåñòà ñâàðêè.

∅ÓÌ - ×ðåçìåðíûé øóì ìîæåò ïðèâåñòè ê ïîâðåæäåíèþ îðãàíîâ ñëóõà

S Ïðèìèòå ìåðû äëÿ çàùèòû ñëóõà. Èñïîëüçóéòå çàòû÷êè äëÿ óøåé èëè äðóãèå ñðåäñòâà çàùèòû

ñëóõà.

S Ïðåäóïðåäèòå ïîñòîðîííèõ ëèö îá îïàñíîñòè.

ÍÅÈÑÏÐÀ

Â

ÍÎÑÒÈ -- Ïðè íåèñïðàâíîñòè îáðàòèòåñü ê ñïåöèàëèñòàì ïî ñâàðî÷íîìó

îáîðóäîâàíèþ

Çàïðåùàåòñÿ èñïîëüçîâàòü èñòî÷íèê ïèòàíèÿ äëÿ îòòàèâàíèÿ òðóá.

ÂÍÈÌÀÍÈÅ!

2 ÂÂÅÄÅÍÈÅ

LAX320/320I ÿâëÿþòñÿ èñòî÷íèêàìè ïèòàíèÿ ñî ñòóïåí÷àòîé ðåãóëèðîâêîé

íàïðÿæåíèÿ, ïðåäíàçíà÷åííûìè ä ëÿ ðàáîòû ñîâìåñòíî ñ ìåõàíèçìîì ïîäà÷è

ïðîâîëîêè MEK 2 äëÿ ñâàðêè ñïëîøíîé ïðîâîëîêîé, íåðæàâåþùåé èëè

à ëþìèíèåâîé ïðîâîëîêîé, à òàêæå ïîðîøêîâîé ïðîâîëîêîé â ñðåäå

çàùèòíûõ ãàçîâ èëè áåç íåå.

LAX 320/380I/380W/380WI ÿâëÿþò ñÿ èñò î÷íèêàìè ïèòàíèÿ ñî ñòóïåí÷àòîé

ðåãóëèðîâêîé íàïðÿæåíèÿ, ïðåäíàçíà÷åííûìè äëÿ ðàáîòû ñîâìåñòíî ñ

ìåõàíèçìàìè ïîäà÷è ïðîâîëîêè MEK 2 èëè ÌÅÊ4 ä ëÿ ñâàðêè ñïëîøíîé

ïðîâîëîêîé, íåðæàâåþùåé èëè àëþìèíèåâîé ïðîâîëîêîé, à òàêæå

ïîðîøêîâîé ïðîâîëîêîé â ñðåäå çàùèòíûõ ãàçîâ èëè áåç íåå.

RU

ba15d1ra

-- 5 --

Ïîäðîáíûå ñâåäåíèÿ î ïðèíàäëåæíîñòÿõ ESAB äëÿ äàííîãî èñ òî÷íèêà

ïèòàíèÿ ïðèâåäåíû íà ñòð. 38.

2.1 Êîìïëåêò ïîñòàâêè

LAX 320/320I

Èñòî÷íèê ïèòàíèÿ.

Îáðàòíûé êàáåëü äëèíîé 4,5ì ñ çàæèìîì.

Ñåòåâîéêàáåëüäëèíîé5ìèãàçîâûéøëàíã.

Âêëþ÷àÿ: Ðóêîÿòêó (êðåïèòñÿ äâóìÿ áîëòàìè), ïîäñòàâêó äëÿ ãàçîâîãî áàëëîíà

(êðåïèòñÿ äâóìÿ áîëòàìè).

Øòûðü êðåïëåíèÿ ïðîâîëîêîïîäàþùåãî ìåõàíèçìà.

LAX 380/380I/380W/380WI

Èñòî÷íèê ïèòàíèÿ ìîæåò ïîñòàâëÿòüñÿ ñ áëîêîì âîäÿíîãî îõëàæäåíèÿ èëè áåç

íåãî.

Îáðàòíûé êàáåëü ä ëèíîé 5ì ñ çàæèìîì.

Ñåòåâîéêàáåëüäëèíîé5ìèãàçîâûéøëàíã.

Âêëþ÷àÿ: Ïîäñòàâêó äëÿ ãàçîâîãî áàëëîíà (êðåïèòñÿ äâóìÿ áîëòàìè). Øòûðü

êðåïëåíè ÿ ï ðîâîëîêîïîäàþùåãî ìåõàíèçìà.

3 ÒÅÕÍÈ×ÅÑÊÈÅ ÄÀÍÍÛÅ

LAX 320/320I

Íàïðÿæåíèå 400--415V, 3∼

∼∼

∼50/60 Hz 230/400--415/500V 3∼

∼∼

∼50 Hz

230/440--460 3∼

∼∼

∼60Hz

Äîïóñòèìàÿ íàãðóçêà ïðè

ÏÂ

195 A/24 V 195 A/24 V

ïðè ÏÂ 60% 250 A/27 V 250 A/27 V

ïðè ÏÂ 30% 320 A/30 V 320 A/30 V

Ïðåäåëû ðåãóëèðîâàíèÿ

òîêà

40A/16V--320A/30V 40A/16V--320A/30V

Íàïðÿæåíèå õîëîñòîãî

õîäà

16--40 V 16--40 V

Ìîùíîñòü õîë. õîäà 50 W 50 W

ÊÏÄ 0,71 0,71

Ôàêòîð ìîùíîñòè 0,97 0,97

Óïðàâëÿþùåå íàïðÿæåíèå 42 V, 50/60 Hz 42 V, 50/60 Hz

Ãàáàðèòû ÄõØõÂ 770 x 560 x 640 770 x 560 x 640

Ìàññà 110 kg 110 kg

Ê ëàññ çàùèòû IP 23 IP 23

Êëàññ ïðèìåíåíèÿ

LAX 380/380I/380W/380WI

Íàïðÿæåíèå 400--415V, 3∼

∼∼

∼50 Hz 230/400--415/500V 3∼

∼∼

∼50 Hz

230/440--460 3∼

∼∼

∼60Hz

Äîïóñòèìàÿ íàãðóçêà ïðè

ÏÂ

280 A/28 V 280 A/28 V

ïðè ÏÂ 60% 350 A/32 V 350 A/32 V

ïðè ÏÂ 50% 380 A/33 V 380 A/33 V

Ïðåäåëû ðåãóëèðîâàíèÿ

òîêà

50A/17V--380A/33V 50A/17V--380A/33V

RU

ba15d1ra

-- 6 --

LAX 380/380I/380W/380WI

Íàïðÿæåíèå õîëîñòîãî

õîäà

17--45 V 17--45 V

Ìîùíîñòü õîë. õîäà 130 W

340 W (LAX380W/WI)

130 W

340 W (LAX380W/WI)

ÊÏÄ 0,75 0,75

Ôàêòîð ìîùíîñòè 0,96 0,96

Óïðàâëÿþùåå íàïðÿæåíèå 42 V, 50/60 Hz 42 V, 50/60 Hz

Ãàáàðèòû ÄõØõÂ 800 x 640 x 835 800 x 640 x 835

Ìàññà 143 kg

157 kg (LAX380W/WI)

143 kg

157 kg (LAX380W/WI)

Ê ëàññ çàùèòû IP 23 IP 23

Êëàññ ïðèìåíåíèÿ

Ðàáî÷èé öèêë

Ðàáî÷èé ö èêë ïðåäñòàâëÿåò ñîáîé äîëþ (â %%) äåñÿòèìèíóòíîãî èíòåðâàëà, â òå÷åíèå

êîòîðîé ìîæíî ïðîèçâîäèò ü ñâàðê ó ïðè îïðåäåëåííîé íàãðóçêå á åç ïåðåãðóçêè

èñòî÷íèêà ïèòàíèÿ ñâàðî÷íîãî àãðåãàòà.

Êëàññ êîæóõà

Íîðìû IP óêàçûâàþò êëàññ êîæóõà, ò.å., ñòåïåíü çàùèòû îò ïðîíèêíîâåíèÿ òâåðäûõ

îáúåêòîâ è âîäû. Îáîðóäîâàíèå ñ ìàðêèðîâêîé IP 23 ïðåäíàçíà÷åíî äëÿ íàðóæíîé è

âíóòðåííåé óñòàíîâêè.

Ê ëàññ çîíû óñòàíîâêè

Ýòîò ñèìâîë îçíà÷àåò, ÷òî èñòî÷íèê ïèòàíèÿ ïðåäíàçíà÷åí äëÿ èñïîëüçîâàíèÿ â çîíàõ

ñ ïîâûøåííîé îïàñíîñòüþ ïîðàæåíèÿ ýëåêòðîòîêîì.

4ÓÑÒÀÍÎÂÊÀ

Ââîä â ýêñïëóàòàöèþ äîëæåí ïðîèçâîäèòüñÿ êâàëèôèöèðîâàííûì

ñïåöèàëèñòîì.

ÂÍÈÌÀÍÈÅ!

Íàñòîÿùåå èçäåëèå ïðåäíàçíà÷åíî äëÿ ïðîìûøëåííîãî èñïîëüçîâàíèÿ. Ïðè

èñïîëüçîâàíèè â áûòîâûõ óñëîâèÿõ îíî ìîæåò ñîçäàâàòü ðà äèî÷àñòîòíûå ïîìåõè.

Ïîëüçîâàòåëü îòâå÷àåò çà ïðèíÿòèå ñîîòâåòñòâóþùèõ ìåð ïðåäîñòîðîæíîñòè.

Ïðè ïîäúåìå èñòî÷íèê ïèòàíèå êðåïèòñÿ ñ

ïîìîùüþ ñïåöèàëüíîé ïîäúåìíîé ñêîáû. Ðó÷êà

ïðåäíàçíà÷åíà òîëüêî ä ëÿ ïåðåìåùåíèÿ ïî

ïîâåðõíîñòè.

Èíñòðóêöèÿ ïî âûïîëíåíèþ

ïîäúåìíî-òðàíñïîðòíûõ ðàáîò

Ïîäñîåäèíèòå ñåòåâîé êàáåëü àïïàðàòà, èñïîëüçóÿ ïðåäîõðàíèòåëè,

ñîîòâåòñòâóþùèå ìåñòíûì íîðìàì.

Ñå÷åíèå ñåòåâîãî êàáåëÿ ñîîòâåòñòâóåò øâåäñêèì íîðìàì. Óáåäèòåñü, ÷òî

ñâàðî÷íûé âûïðÿìèòåëü íå íàêðûò èëè óñòàíîâëåí â òàêîì ìåñòå, â êîòîðîì

íåò ïðåïÿòñòâèé íîðìàëüíîìó îõëàæäåíèþ.

RU

ba15d1ra

-- 7 --

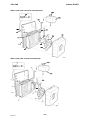

4.1 Ñáîðêà óñòàíîâêè

ba15s00

3

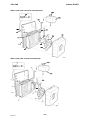

4.2 Ïîäê ëþ÷åíèå óñòàíîâêè

ba15

s005

ba14

s006

ba14

s007

XT1

TC1

RU

ba15d1ra

-- 8 --

4.3 Ïîäñîåäèíåíèå ê ýëåêòðè÷åñêîé ñåòè

LAX 320/320I 3∼ 50 Hz 3∼ 50/60 Hz 3∼ 50 Hz 3∼ 60 Hz 3∼ 60 Hz

Íàïðÿæåíèå Â 230 400/415 500 230 440/460

Òîê, A , ïðè 100% ÏÂ 16 9 7 16 8

ïðè 60% ÏÂ 23 14 10 23 12

ïðè 30% ÏÂ 35 20 16 34 18

Ñå÷åíèå êàá åëÿ, ìì2 4x4 4x2,5 4x2,5 4x4 4x2,5

Ïðåäîõðàíèòåëü, A 20 16 16 20 16

LAX 380/380I/380W/380WI 3∼ 50 Hz 3∼ 50/60 Hz 3∼ 50 Hz 3∼ 60 Hz 3∼ 60 Hz

Íàïðÿæåíèå Â 230 400/415 500 230 440/460

Òîê, A , ïðè 100% ÏÂ 28 16 13 28 14

ïðè 60% ÏÂ 41 23 18 40 20

ïðè 50% ÏÂ 45 27 20 45 22

Ñå÷åíèå êàá åëÿ, ìì2 4x6 4x2,5 4x2,5 4x6 4x2,5

Ïðåäîõðàíèòåëü, A 35 20 20 35 20

5 ÒÅÕÍÈ×ÅÑÊÎÅ ÎÏÈÑÀÍÈÅ

A Âûêëþ÷àòåëü ñåòè G Êëåììà èíäóêòèâíîñòè

B Ïåðåêëþ÷àòåëü íàïðÿæåíèÿ, 4 ñòóïåíè H Ñâàðî÷íûé ðàçúåì, ê ëåììà «+»

C Ïåðåêëþ÷àòåëü íàïðÿæåíèÿ, 10

ñòóïåíåé

J Ðàçúåì êàáåëÿ óïðàâëåíèÿ ïîäàþùèì

ìåõàíèçìîì

D Èíäèêàòîðíàÿ ëàìïà ïåðåãðóçêè.

Âêëþ÷àåòñÿ ïðè ïåðåãðåâå

K Àâòîìàòè÷åñêèé ïðåäîõðàíèòåëü 42Â, @

E Èíäèêàòîðíàÿ ëàìïà ïèòàíèÿ L Ðàçúåì øëàíãà âîäÿíîãî , LAX 380

F Ìåñòî äëÿ èçìåðèòåëüíûõ ïðèáîðîâ

(ïîñòàâëÿþòñÿ îò äåëüíî)

RU

ba15d1ra

-- 9 --

Òåðìîâûêëþ÷àòåëü ïðåäîòâðàùàåò ïåðåãðåâ. Ïîñëå îõëàæäåíèÿ èñòî÷íèêà îí

àâòîìàòè÷åñêè âêëþ÷àåòñÿ.

Èñòî÷íèêè ïèòàíèÿ ìîãó ò áûòü îáîðóäîâàíû öèôðîâûìè ïðèáîðàìè äëÿ

èçìåðåíèÿ ñâàðî÷íîãî òîêà è íàïðÿæåíèÿ (ïîñòàâëÿþòñÿ

äîïîëíèòåëüíî).Ïîñëå ïðåêðàùåíèÿ ñâàðêè ïðèáîðû ïðîäîëæàþò ïîêàçûâàòü

ïîñëåäíèå çíà÷åíèÿ.

6 ÎÁÑËÓÆ ÈÂÀÍÈÅ

Ïðèìå÷àíèå:

Âñå ãàðàíòèéíûå îáÿçàòåëüñòâà ïîñòàâùèêà ò åðÿþò ñèëó â ñëó÷àå ïîïûòêè

ïîêóïàòåëÿ ñàìîñòîÿòåëüíî óñòðàíèòü êàêóþ-ëèáî íåèñïðàâíîñòü ìàøèíû â

òå÷åíèå ãàðàíòèéíîãî ïåðèîäà.

Ïîäêëþ÷åíèå, îáñëóæèâàíèå è ðåìîíò ñâàðî÷íîãî îáîðóäîâàíèå, ñâÿçàííûå

ñî ñíÿòèåì çàùèòíûõ ùèòêîâ, âûïîëíÿþòñÿ ëèöàìè, ïðîøåäøèìè

ñîîòâåòñòâóþùóþ ýëåêòðîòåõíè÷åñêóþ ïîäãîòîâêó è àòòåñòîâàííûìè íà ïðàâî

âûïîëíåíèÿ ò à êèõ ðàáîò.

Î÷èñòêà

Ðåãóëÿðíî ïðîâåðÿéòå ÷èñòîòó èñòî÷íèêà ïèòàíèÿ.

Ïåðèîäè÷íîñòü è îáúåì ðàáîò ïî î÷èñòêå çàâèñÿò îò èñïîëüçóåìîãî

ñâàðî÷íîãî ïðîöåññà, âðåìåíè ãîðåíèÿ äóãè, ðàçìåùåíèÿ èñòî÷íèêà è

óñëîâèé îêðóæàþùåé ñðåäû. Îáû÷íî äîñòàòî÷íî î÷èñòèòü èñòî÷íèê ïèòàíèÿ

ïó òåì îáäóâêè ñæàòûì âîçäóõîì (ïîíèæåííîãî äàâëåíèÿ) îäèí ðàç â ãîä.

Ïðè ñèëüíîì çàãðÿçíåíèè ðåêîìåíäóåòñÿ î÷èñòèòü èñòî÷íèê ïèòàíèÿ ùåòêîé

è ïûëåñîñîì.

S Îòêëþ÷èòå èñòî÷íèê ïèòàíèÿ ñâàðî÷íîãî àãðåãàòà îò ñåòè.

S

Âûíüòå âèëêó èç ðàçúåìà. Çàêðîéòå è çàïðèòå ðàçúåì äëÿ èñêëþ÷åíèÿ

âîçìîæíîñòè íåñàíêöèîíèðîâàííîãî ïîäêëþ÷åíèÿ.

Íà ñòàöèîíàðíûõ óñòàíîâêàõ îòêëþ÷èòå çàùèòíûé âûêëþ÷àòåëü.

Çàáëîêèðóéòå åãî â îòêëþ÷åííîì ïîëîæåíèè.

S Äëÿ îáëåã÷åíèÿ äîñòóïà ñíèìèòå çàùèòíûå ùèòêè èñòî÷íèêà ïèòàíèÿ.

Ïîñëå î÷èñòêè ïåðåä ïîäêëþ÷åíèåì èñòî÷íèêà ïèòàíèÿ ê ñåòè óñòàíîâèòå íà

ìåñòî ñíÿòûå çàùèòíûå ùèòêè.

6.1 Ïîïîëíåíèå îõëàæäàþùåé æèäêîñòè

Ðåêîìåíäóåòñÿ èñïîëüçîâà òü ñìåñü èç 50% âîäû è 50%

ýòèëåíãëèêîëÿ.

ba11

kyla

RU

ba15d1ra

-- 1 0 --

Ïðè èñïîëüçîâàíèè àãðåãàòà ïîäà÷è ïðîâîëîêè ñ ïðîòèâîâåñîì âîçíèêàåò îïàñíîñòü

îïðîê èäûâàíèÿ.

Çàêðåïèòå îáîðóäîâàíèå, îñîáåííî ïðè óñòàíîâêå íà íåðîâíîé èëè íàê ëîííîé

ïîâåðõíîñòè.

Ñ ïîìîùüþ ïðèëàãàåìûõ ëåíò îãðàíè÷üòå óãîë ïîâîðîòà àãðåãàòà ïîäà÷è ïðîâîëîêè.

Çàïðåù àåòñÿ ïåðåìåùàòü îáîðóäîâàíèå, äåðæà åãî çà ãîðåëêó.

ÎÑÒÎÐÎÆÍÎ!

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ

Çàïàñíûå ÷àñòè çàêàçûâàþòñÿ ÷åðåç áëèæàéøåå ïðåäñò àâèòåëüñòâî ESAB,

à äðåñ êîòîðîãî ìîæíî íàéòè íà ïîñëåäíåé ñòðàíèöå îáëîæêè.

Ïðè çàêàçå çàïàñíûõ ÷àñòåé óêàæèòå òèï ìàøèíû è åå íîìåð, à òàêæå

íàèìåíîâàíèå äåòà ëè è åå íîìåð èç ïåðå÷íÿ çàïàñíûõ ÷àñòåé. Ýòî óïðîñòèò

äîñòàâêó è îáåñïå÷èò ïîëó÷åíèå òðåáóåìûõ çàïàñíûõ ÷àñòåé.

RU

ENGLISH

-- 1 1 --

TOCe

1 DIRECTIVE 12........................................................

2SAFETY 12...........................................................

3 INTRODUCTION 13...................................................

3.1 Standard delivery 13..........................................................

4 TECHNICAL DATA 13.................................................

5 INSTALLATION 14....................................................

5.1 Assembly of components 15...................................................

5.2 Electrical installation 15.......................................................

5.3 Mains supply 16..............................................................

6 OPERATION 16.......................................................

7 MAINTENANCE 17....................................................

7.1 Topping up coolant 17.........................................................

8 ORDERING OF SPARE PARTS 18......................................

DIAGRAM 19............................................................

SPARE PARTS LIST 23...................................................

ACCESSORIES 38.......................................................

-- 1 2 --

ba15d1ea

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guaran-

tee that welding power source LAX 320/320I/380/380W/380I/380WI from serial

number 521/550 complies with standard EN 60974 --1, in accordance with the re-

quirements of directive (73/23/EEC) and addendum (93/68/EEC) and with standard

EN 50199 in accordance with the requirements of directive (89/336/EEC) and add-

endum (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Paul Karlsson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 12336

Laxå 95--12--10

2SAFETY

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU -

TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

Do not use the power source for thawing frozen pipes.

WARNING!

GB

-- 1 3 --

ba15d1ea

3 INTRODUCTION

LAX 320/320I is a step switched power source, intended for use together with the

wire feed unit MEK 2 for welding with solid steel, stainless steel or aluminium wire as

well as tubular wire with or without shielding gas.

LAX 320/380I/380W/380WI is step switched power sources, intended for use to-

gether with the wire feed units MEK 2 and MEK 4 for welding with solid steel, stain -

less steel or aluminium wire as well as tubular wire with or without shielding gas.

See p ag e 38 for details of ESAB’s accessories for the power source.

3.1 Standard delivery

LAX 320/320I

Power source.

Return cable 4.5 m with r eturn clamp.

Mains cable 5 m and gas hose.

Includes: Handle, (fitted with 2 screws), gas cylinder shelf (fitted with 2 screws).

Post for wire feed unit.

LAX 380/380I/380W/380WI

Power source, can be supplied with or without water cooling unit..

Return cable 5 m with return clamp.

Mains cable 5 m and gas hose.

Includes: Gas cylinder shelf, (fitted with 2 screws). Post for wire feed unit.

4 TECHNICAL DATA

LAX 320/320I

Voltage 400--415V, 3∼

∼∼

∼50/60 Hz 230/400--415/500V 3∼

∼∼

∼50 Hz

230/440--460 3∼

∼∼

∼60Hz

Permissible load at

100 % duty cycle

195 A/24 V 195 A/24 V

at 60 % duty cycle 250 A/27 V 250 A/27 V

at 30 % duty cycle 320 A/30 V 320 A/30 V

Setting range (DC) 40A/16V--320A/30V 40A/16V--320A/30V

Open circuit voltage 16--40 V 16--40 V

Open circuit power 50 W 50 W

Efficiency 0,71 0,71

Power factor 0,97 0,97

Control voltage 42 V, 50/60 Hz 42 V, 50/60 Hz

Dimensions lxwxh 770 x 560 x 640 770 x 560 x 640

Weight 110 kg 110 kg

Enclosure class IP 23 IP 23

Application classification

GB

-- 1 4 --

ba15d1ea

LAX 380/380I/380W/380WI

Voltage 400--415V, 3∼

∼∼

∼50/60 Hz 230/400--415/500V 3∼

∼∼

∼50 Hz

230/440--460 3∼

∼∼

∼60Hz

Permissible load at

100 % duty cycle

280 A/28 V 280 A/28 V

at 60 % duty cycle 350 A/32 V 350 A/32 V

at 50 % duty cycle 380 A/33 V 380 A/33 V

Setting range (DC) 50A/17V--380A/33V 50A/17V--380A/33V

Open circuit voltage 17--45 V 17--45 V

Open circuit power 130 W

340 W (LAX380W/WI)

130 W

340 W (LAX380W/WI)

Efficiency 0,75 0,75

Power factor 0,96 0,96

Control voltage 42 V, 50/60 Hz 42 V, 50/60 Hz

Dimensions lxwxh 800x640x835 800x640x835

Weight 143 kg

157 kg (LAX380W/WI)

143 kg

157 kg (LAX380W/WI)

Enclosure class IP 23 IP 23

Application classification

Duty cycle

The duty cycle refers to the time as a percentage of a ten--minute period that you can weld at a cer-

tain load without overloading the welding power source.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP 23 is designed for indoor and outdoor use.

Application class

The symbol indicates that the power source is designed for use in areas with increased

electrical hazard.

5 I NSTALLATION

The installation must be executed by a professional.

WARNING!

This product is intended for industrial use. In a domestic environment this product may cause radio

interference. It is the user’s responsibility to take adequate precautions.

The power supply should be lifted by means of its lifting

eye. The handle is only intended for pulling it along the

ground.

Lifting instructions

Connect the power supply lead using the appropriate fuse in conformance with local

regulations.

Cable areas acc. to Swedish regulations. Make sure the welding rectifier is not cov-

ered or positioned so that cooling is obstructed.

GB

-- 1 5 --

ba15d1ea

5.1 Assembly of components

ba15s00

3

5.2 Electrical installation

ba15

s005

ba14

s006

ba14

s007

XT1

TC1

GB

-- 1 6 --

ba15d1ea

5.3 Mains supply

LAX 320/320I 3∼ 50 Hz 3∼ 5060 Hz 3∼ 50 Hz 3∼ 60 Hz 3∼ 60 Hz

Voltage V 230 400/415 500 230 440/460

Current A at100% duty cycle 16 9 7 16 8

at 60% duty cycle 23 14 10 23 12

at 30% duty cycle 35 20 16 34 18

Cable area mm

2

22

2

4x4 4x2,5 4x2,5 4x4 4x2,5

Fuse, slow A 20 16 16 20 16

LAX 380/380I/380W/380WI 3∼ 50 Hz 3∼ 50/60 Hz 3∼ 50 Hz 3∼ 60 Hz 3∼ 60 Hz

Voltage V 230 400/415 500 230 440/460

Current A at100% duty cycle 28 16 13 28 14

at 60% duty cycle 41 23 18 40 20

at 50% duty cycle 45 27 20 45 22

Cable area mm

2

22

2

4x6 4x2,5 4x2,5 4x6 4x2,5

Fuse, slow A 35 20 20 35 20

6 OPERATION

A Main switch on/off G Inductance connection

B Voltage selector 4--step H Welding socket + pol.

C Voltage selector 10--step J Sleeve socket 23--pol. wire feed unit

D Indicator lamp thermal overload, lights up in

case of overheating

K Automatic fuse 42 V AC-- circuit

E Mains indicator lamp L Quick coupling water, LAX 380

F Space for digital meters (optional)

GB

-- 1 7 --

ba15d1ea

A thermal cut--out prevents overheating. Resetting takes place automatically when

the power source has cooled.

The power sources can be equipped with instruments to display the current and vol-

tage. The instruments have a hold function and can be calibrated.

7 MAINTENANCE

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

Only those persons who have appropriate electrical knowledge (authorised

personnel) may remove the safety plates to connect or carry out service,

maintenance or repair work on welding equipment.

Cleaning

Check r egularly that the power source is free from dirt.

How often, and to what extent, cleaning should be carried out depends on the

welding process, arc time, disposition and the surrounding environment. It will

normally suffice to blow the power source clean using compressed air (reduced

pressure) once a year.

If the power source is very dirty, brushing and vacuuming are recommended.

S Disconnect the welding power source from the mains current supply.

S Remove the adapter from the socket. Lock the socket to prevent unauthorised

connection.

At fixed installations, the safety switch should be set to the off position. Lock

the switch.

S Remove the power source’s safety plates for best access.

After cleaning, all safety plates must be mounted before you connect the power

source to the mains supply.

7.1 Topping up coolant

We recommend a 50/50 % mixture of water and ethylene glycol.

ba11kyl

a

GB

-- 1 8 --

ba15d1ea

There is a risk of tipping if the wire feed cabinet is fitted with a counterbalance arm. Secure the

equipment, especially if used on an uneven or sloping surface.

Limit the angle of rotation of the wire feed cabinet using the straps supplied.

When moving the equipment, do NOT pull on the torch.

WARNING!

8 ORDERING OF SPARE PARTS

LAX 320/320I/380/380W/380I/380WI is designed and tested in accordance

with the EN 60974--1 (IEC 60974--1) international standard.

It is the obligation of the service unit which has carried out the service or re-

pair work to make sure that the product still conforms to the said standard.

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as desig-

nation and spare part number as shown in the spare parts list.

This will simplify dispatch and ensure you get the right part.

GB

Diagram Ñõåìà

-- 1 9 --

ba15e12a

LAX 320/320I

230--500V

-- 2 0 --

ba15e12a

LAX 320

400--415 V

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

ESAB LAX 380 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

- Questo manuale è adatto anche per

Documenti correlati

-

ESAB MEK 2 Manuale utente

-

ESAB LAX 320, LAX 380 Manuale utente

-

ESAB LAX 320, LAX 380 Manuale utente

-

ESAB LAX 320, LAX 380 Manuale utente

-

ESAB MEK 4 Manuale utente

-

ESAB MEK 4C Manuale utente

-

ESAB MEK 20 Manuale utente

-

ESAB MEK 44C Manuale utente

-

ESAB LAW 400, LAW 500 Manuale utente

-

ESAB LUD 450 Manuale utente