ESAB SLICE® NEW Exothermic Cutting Equipment Manuale utente

- Tipo

- Manuale utente

SAFETY AND

OPERATING

INSTRUCTIONS

SLICE

®

EXOTHERMIC

CUTTING EQUIPMENT

English

French

Spanish

Italian

SLICE

®

TORCH

SLICE

®

PACKAGE

SLICE

®

STRIKER

Art# A-13635

Revision: AC Issue Date: 24-01-2019 Manual No.: 89250840

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Arcair

®

product. We are proud to have you as our customer and

will strive to provide you with the best service and support in the industry. This product is

backed by our extensive warranty and world-wide service network. To locate your nearest

distributor or service agency visit us on the web at www.esab.com/arcair.

This Manual has been designed to instruct you on the correct installation and use of your Arcair

product. Your satisfaction with this product and its safe operation is our ultimate concern.

Therefore, please take the time to read the entire manual, especially the Safety Precautions.

They will help you to avoid potential hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Arcair is a Global Brand of cutting Products for ESAB. We manufacture and supply to major

welding industry sectors worldwide including; Manufacturing, Construction, Mining, Automotive,

Aerospace, Engineering, Rural and DIY/Hobbyist.

We distinguish ourselves from our competition through market-leading, dependable products

that have stood the test of time. We pride ourselves on technical innovation, competitive prices,

excellent delivery, superior customer service and technical support, together with excellence

in sales and marketing expertise.

Above all, we are committed to develop technologically advanced products to achieve a safer

working environment within the welding industry.

i

!

WARNING

Read and understand this entire Manual and your employer’s safety

practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manu-

facturer's best judgment, the Manufacturer assumes no liability for its

use.

SLICE

®

Exothermic Cutting Equipment

Safety and Operating Instructions

Manual Number: 89250840

Published by:

ESAB Group Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.esab.com/arcair

U.S. Customer Care: (800) 426-1888

International Customer Care: (940) 381-1212

Copyright © 2018 ESAB. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss or damage

caused by any error or omission in this Manual, whether such error results from negligence, accident,

or any other cause.

For Printing Material Specification in the Americas refer to document 47X1920

For Printing Material Specification in Europe refer to document 47X1953

Publication Date: 08-03-2018

Revision Date: 24-01-2019

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

ii

Be sure this information reaches the operator.

You can get extra copies through your supplier.

CAUTION

These INSTRUCTIONS are for experienced operators. If you are not fully familiar

with the principles of operation and safe practices for arc welding and cutting equip-

ment, we urge you to read our booklet, "Precautions and Safe Practices for Arc

Welding, Cutting, and Gouging," Form 52-529. Do NOT permit untrained persons to

install, operate, or maintain this equipment. Do NOT attempt to install or operate this

equipment until you have read and fully understand these instructions. If you do not

fully understand these instructions, contact your supplier for further information. Be

sure to read the Safety Precautions before installing or operating this equipment.

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying labels and/

or inserts when installed, operated, maintained and repaired in accordance with the instructions provided. This equipment must

be checked periodically. Malfunctioning or poorly maintained equipment should not be used. Parts that are broken, missing,

worn, distorted or contaminated should be replaced immediately. Should such repair or replacement become necessary, the

manufacturer recommends that a telephone or written request for service advice be made to the Authorized Distributor from

whom it was purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer. The user of this

equipment shall have the sole responsibility for any malfunction which results from improper use, faulty maintenance, damage,

improper repair or alteration by anyone other than the manufacturer or a service facility designated by the manufacturer.

!

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR

OPERATING.

PROTECT YOURSELF AN D OTHERS!

iii

ASSUREZ-VOUS QUE CE DOCUMENT D’INFORMATION EST DISTRIBUÉ À L’OPÉRATEUR.

DES COPIES SUPPLÉMENTAIRES SONT DISPONIBLES CHEZ VOTRE FOURNISSEUR.

MISE EN GARDE

Les INSTRUCTIONS suivantes sont destinées aux opérateurs qualiés seulement.

Si vous n’avez pas une connaissance approfondie des principes de fonctionnement

et des règles de sécurité applicables au soudage à l’arc et à l’équipement de

coupage, nous vous suggérons de lire notre brochure « Précautions et pratiques

de sécurité pour le soudage à l’arc, le coupage et le gougeage », Formulaire 52-

529. Ne permettez PAS aux personnes non qualiées d’installer, d’utiliser ou

d’effectuer des opérations de maintenance sur cet équipement cet équipement. Ne

tentez PAS d’installer ou d’utiliser cet équipement avant d’avoir lu et bien compris

ces instructions. Si vous ne comprenez pas bien les instructions, renseignez-vous

auprès de votre fournisseur. Assurez-vous de lire les Règles de Sécurité avant

d’installer ou d’utiliser cet équipement.

RESPONSABILITÉS DE L’UTILISATEUR

Cet équipement fonctionnera conformément à la description contenue dans ce manuel, les étiquettes d’accompagnement et/

ou les feuillets d’information à condition d’être installé, utilisé, entretenu et réparé selon les instructions fournies. L’équipement

doit être contrôlé de manière périodique. Ne jamais utiliser un équipement qui ne fonctionne correctement bien ou n’est pas

bien entretenu. Les pièces qui sont brisées, usées, déformées ou contaminées doivent être remplacées immédiatement. Dans

le cas où une réparation ou un remplacement est nécessaire, e fabricant recommande de faire une demande de conseil de

service écrite ou par téléphone auprès du distributeur agréé où l’équipement a été acheté.

Cet équipement ou ses pièces ne doivent pas être modiés sans permission préalable écrite du fabricant. L’utilisateur de

l’équipement sera le seul responsable de toute défaillance résultant de toute utilisation, maintenance, réparation incorrectes,

de dommages ou encore de modication apportées par une personne autre que le fabricant ou un centre de service désigné

par ce dernier.

!

ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE LE MANUEL D’UTILISATION AVANT

D’INSTALLER OU D’UTILISER L’UNITÉ.

PROTÉGEZ-VOUS ET LES AUTRES!

iv

DECLARATION OF CONFORMITY

According to

The Low Voltage Directive 2014/35/EU, entering into force 20 April 2016

The EMC Directive 2014/30/EU, entering into force 20 April 2016

The RoHS Directive 2011/65/EU, entering into force 2 January 2013

Type of equipment

EXOTHERMIC CUTTING SYSTEM

Type designation etc.

SLICE Exothermic Torch Cutting System

Brand name or trade mark

Arcair SLICE

Manufacturer or his authorised representative

Name, address, telephone No:

ESAB Group Inc.

2800 Airport Rd

Denton TX 76207

Phone: +01 800 426 1888, FAX +01 603 298 7402

The following harmonised standard in force within the EEA has been used in the

design:

IEC/EN 60974-11:2010 Arc Welding Equipment Part II: Electrode Holders

IEC/EN 60974-10:2014 + AMD 1:2015 Published 2015-06-19 Arc Welding Equipment - Part

10: Electromagnetic compatibility (EMC) requirements

Additional Information: Restrictive use, Class A equipment, intended for use in location

other than residential.

By signing this document, the undersigned declares as manufacturer, or the

manufacturer’s authorised representative, that the equipment in question complies

with the safety requirements stated above.

Date Signature Position

15 September, 2016

Flavio Santos General Manager

Accessories and Adjacencies

2018

v

Table of Contents

SECTION 1: INTRODUCTION ........................................................................................1

1.01 How to Use this Manual ............................................................1

1.02 Receipt of Equipment ................................................................1

1.03 Description ...............................................................................1

SECTION 2: SAFETY PRECAUTIONS ...........................................................................2

SECTION 3: PROCESS FUNDAMENTALS .....................................................................5

SECTION 4: EQUIPMENT .............................................................................................6

4.01 SLICE Torch ..............................................................................6

4.02 SLICE Striker ............................................................................6

4.03 SLICE Packs .............................................................................6

4.04 Cutting Rods ............................................................................. 7

4.05 SLICE Components ...................................................................8

4.06 Charging the Ignition Source .....................................................9

SECTION 5: CUTTING DATA ......................................................................................10

5.01 Material Cutting Rates ............................................................10

5.02 Cutting Electrode Types ..........................................................11

5.03 SLICE Cutting Torches .............................................................11

SECTION 6: OPERATION ............................................................................................12

6.01 Cutting without Power ............................................................12

6.02 Cutting with Power .................................................................13

6.03 Hole Piercing ..........................................................................14

6.04 Copper and Copper Alloys ....................................................... 15

SECTION 7: IMPORTANT PROCESS VARIABLES .......................................................16

7.01 Oxygen Pressure.....................................................................16

7.02 Amperage ...............................................................................17

7.03 Travel Speed ...........................................................................17

7.04 Electrode-To-Work Angle ........................................................17

SECTION 8: APPLICATIONS ......................................................................................18

SECTION 9: TROUBLESHOOTING ..............................................................................19

9.01 General troubleshooting ..........................................................19

9.02 Ignition source led display guide ............................................. 20

SECTION 10: PARTS LISTING ....................................................................................22

SECTION 11: STATEMENT OF WARRANTY ................................................................25

vi

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

This Page Intentionally Blank

SLICE EXOTHERMIC CUTTING EQUIPMENT

1

89250840

SECTION 1: INTRODUCTION

1.01 How to Use this Manual

To ensure safe operation, read the entire manual, including the chapter on safety instructions and

warnings.

Throughout this manual, the words WARNING, CAUTION, and NOTE may appear. Pay particular

attention to the information provided under these headings. These special annotations are easily

recognized as follows:

NOTE!

An operation, procedure, or background information which requires

additional emphasis or is helpful in efcient operation of the system.

!

CAUTION

A procedure which, if not properly followed, may cause damage to the

equipment.

!

WARNING

A procedure which, if not properly followed, may cause injury to the

operator or others in the operating area.

WARNING

Gives information regarding possible electrical shock injury. Warnings

will be enclosed in a box such as this.

1.02 Receipt of Equipment

When you receive the equipment, check it against the invoice to make sure it is complete and

inspect the equipment for possible damage due to shipping. If there is any damage, notify the carrier

immediately to file a claim. Furnish complete information concerning damage claims or shipping

errors to the location in your area, listed on the back cover of this manual. Include a full description

of the parts in error.

If you want additional or replacement copies of this manual, please contact Arcair at the address

and phone number in your area listed on the inside back cover of this manual. Include the Manual

number (Page i).

1.03 Description

Arcair

®

SLICE

®

systems can cut, burn or pierce almost any metallic, non-metallic or composite

material. The SLICE exothermic torch cuts right through hard-to-cut materials such as mild, stainless

and alloy steels, cast iron, aluminum, magnesium and other non-ferrous metals, slag and refractory

materials, and concrete or brick.

2

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

SECTION 2: SAFETY PRECAUTIONS

!

WARNING

SERIOUS INJURY OR DEATH may result if welding and cutting equipment

is not properly installed, used, and maintained. Misuse of this equipment

and other unsafe practices can be hazardous. The operator, supervisor, and

helper must read and understand the following safety warnings and instruc-

tions before installing or using any welding or cutting equipment, and be

aware of the dangers of the welding or cutting process. Training and proper

supervision are important for a safe work place. Keep these instructions for

future use. Additional recommended safety and operating information is refer-

enced in each section.

!

WARNING

This product contains chemicals, including lead, or otherwise produces

chemicals known to the State of California to cause cancer, birth defects

and other reproductive harm. Wash hands after handling.

ELECTRIC SHOCK CAN CAUSE INJURY OR DEATH

The purchaser is responsible for the safe installation, operation, and use of all products

purchased, including compliance with all applicable ISO standards and local codes in

the country of use. Do not service or repair equipment with power on. Do not operate

equipment with protective insulators or covers removed. Service or repair to equipment

must be done by qualified and/or trained personnel only.

Do not contact electrically live parts. Always wear dry welding gloves that are in good condition.

Aluminized, protective clothing can become part of the electrical path. Keep oxygen cylinders, chains,

wires, ropes, cranes, and hoists away from any part of the electrical path. All ground connections must

be checked periodically to determine if they are mechanically strong, and electrically adequate for the

required current. When engaged in AC welding/cutting under wet conditions or where perspiration

is a factor, the use of automatic controls for reducing the no load voltage is recommended to reduce

shock hazards. Accidental contact must be prevented when using open circuit voltage exceeding 80

volts AC, or 100 volts DC by adequate insulation or other means. When welding is to be suspended for

any length of time, such as during lunch or overnight, all electrode holders and electrodes should be

removed from the electrode holder and the power supply should be turned off to prevent accidental

contact. Keep MIG Guns, electrode holders, TIG torches, Plasma torches, and electrodes away from

moisture and water. See safety and operating references 1, 2, and 8.

SMOKE, FUMES, AND GASES CAN BE DANGEROUS TO YOUR HEALTH

Ventilation must be adequate to remove smoke, fumes, and gases during operation to

protect operators and others in the area. Vapors of chlorinated solvents can form the

toxic gas "Phosgene" when exposed to ultraviolet radiation from an electric arc. All

solvents, degreasers, and potential sources of these vapors must be removed from the

operating area. Use air-supplied respirators if ventilation is not adequate to remove all

fumes and gases. Oxygen supports, and vigorously accelerates fire and should never be used for

ventilation. See safety and operating references 1, 2, 3, and 4.

SLICE EXOTHERMIC CUTTING EQUIPMENT

3

89250840

ARC RAYS, HOT SLAG, AND SPARKS CAN INJURE EYES AND BURN SKIN

Welding and cutting processes produce extreme localized heat and strong ultraviolet

rays. Never attempt to weld/cut without a federally compliant welding helmet with the

proper lens. A number 12 to 14 shade filter lens provides the best protection against arc

radiation. When in a confined area, prevent the reflected arc rays from entering around

the helmet. Approved shielding curtains and appropriate goggles should be used to

provide protection to others in the surrounding area. Skin should be protected from arc rays, heat, and

molten metal. Always wear protective gloves and clothing. All pockets should be closed and cuffs sewn

shut. Leather aprons, sleeves, leggings, etc. should be worn for out-of-position welding and cutting, or

for heavy operations using large electrodes. Hightop work shoes provide adequate protection from foot

burns. For added protection, use leather spats. Flammable hair preparations should not be used when

welding/cutting. Wear ear plugs to protect ears from sparks. Where work permits, the operator should

be enclosed in an individual booth painted with a low reflective material such as zinc oxide. See safety

and operating references 1, 2, and 3.

WELDING SPARKS CAN CAUSE FIRES AND EXPLOSIONS

Combustibles reached by the arc, flame, flying sparks, hot slag, and heated materials can

cause fire and explosions. Remove combustibles from the work area and/or provide a fire

watch. Avoid oily or greasy clothing as a spark may ignite them. Have a fire extinguisher

nearby, and know how to use it. If welding/cutting is to be done on a metal wall, partition,

ceiling, or roof, precautions must be taken to prevent ignition of nearby combustibles on the other side.

Do not weld/cut containers that have held combustibles. All hollow spaces, cavities, and containers

should be vented prior to welding/cutting to permit the escape of air or gases. Purging with inert gas is

recommended. Never use oxygen in a welding torch. Use only inert gases or inert gas mixes as required

by the process. Use of combustible compressed gases can cause explosions resulting in personal injury

or death. Arcing against any compressed gas cylinder can cause cylinder damage or explosion. See

safety and operating references 1, 2, 5, 7, and 8.

4

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

SAFETY AND OPERATING REFERENCES

1. Code of Federal Regulations (OSHA) Section 29, Part 1910.95, 132, 133, 134, 139, 251, 252,

253, 254 and 1000. U.S. Government Printing Office, Washington, DC 20402.

2. ANSI Z49.1-2012 "Safety in Welding, Cutting, and Allied Processes".

3. ANSI Z87.1-2015 "American National Standard for Occupational and Educational Personal

Eye and Face Protection Devices".

4. ANSI/ASSE Z88.2-2015 "American National Standard Practices for Respiratory Protection".

American National Standards Institute Inc., 1430 Broadway, New York, NY 10018.

5. AWS F4.1:2017. "Safe Practices for the Preparation of Containers and Piping for Welding,

Cutting, and Allied Processes"

6. AWS C5.3:2000 (R2011) "Recommended Practices For Air Carbon Arc Gouging And Cutting".

American Welding Society, 8669 NW 36 Street, PO Box 130, Miami, Florida 33166-6672

7. NFPA 51B:2014 "Standard for Fire Prevention During Welding, Cutting, and Other Hot Work"

National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, Massachusetts,

USA 02169-7471

8. NFPA-70:2017 "National Electrical Code". National Fire Protection Association (NFPA), 1

Batterymarch Park, Quincy, Massachusetts, USA 02169-7471

9. CAN/CSA-W117.2-12 (R2017) "Safety in Welding, Cutting and Allied Processes". Canadian

Standards Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W 1R3.

SLICE EXOTHERMIC CUTTING EQUIPMENT

5

89250840

SECTION 3: PROCESS FUNDAMENTALS

The SLICE Exothermic Cutting process uses an exothermic chemical reaction that burns, melts or

vaporizes most materials. The reaction begins with an electrical arc or alternate energy source that

causes a steel cutting rod to burn. Oxygen flows through the center of the rod.

Because of the rod’s design, the burning makes excess heat ("exo - thermic") which cuts the

workpiece. Once started, the burn will continue as long as oxygen flows through the rod. The heat

created melts the material being cut. The velocity of oxygen through the rod blows the molten material

away, creating the kerf or cut line.

This arc ignition process led to invention of the oxy-arc torch and design of equipment for underwater

construction and salvage.

The electrical arc that starts the burn can be from a welding power source that delivers at least 100

amps, a 12-volt lead acid or similar low-impedance battery. The cutting process can run without

power, using the heat of the reaction only, or with power, cutting with an electrical arc from a welding

power source providing more heat.

HISTORY

The exothermic cutting rod is a small oxygen lance. A prime example of the combustion triangle is one

side being fuel (the steel lance); the oxygen source (pure oxygen being forced through the lance); the

heat of combustion (some external source of heat). However, when the lance pierces a slag puddle,

the puddle becomes the source of heat until the lance is withdrawn, at which time burning stops.

In 1888, a published paper described passing oxygen through a steel tube and heating the tube to

a bright red. Heat resulted. In 1901, Ernst Henner filed a German patent on an early oxygen lance

made of two concentric tubes. In 1902, documentation shows that the oxygen lance replaced oil

and gas torches for opening furnace taps in steel blast furnaces. The oxygen lance has since been

used to cut rocks and concrete structures. An example is cutting up reinforced concrete structures

such as bunker emplacements and tank traps built in Europe during World War II.

An ideal way to start the lance, workers found, was to use a welding power source on conductive

material to strike an arc and start the burn. This process worked well in construction, even in mud

and water.

Around 1940, the burning bar or exothermic lance was first marketed as a cutting tool. A flexible

version made of an insulated cable was introduced around 1960. Not until the early 1980’s were

smaller burning bars designed for hand torch use, above and below water. A one-piece unit now

allows for adequate rod surface exposure to an oxygen supply for exothermic cutting. Arcair, an ESAB

brand, is a world leader in metal removal and cutting and sells this exothermic cutting equipment

under the trade name Arcair SLICE.

6

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

SECTION 4: EQUIPMENT

4.01 SLICE Torch

The SLICE Torch, a gun-shaped tool, provides a means of gripping the rod and supplying the oxygen

and power to the cutting rod. The basic torch includes 10 ft. (3.05 m) of power cable and oxygen

hose. The power cable can carry 200 amps in a power cutting operation. The oxygen hose includes

a standard size oxygen fitting and is ready to be connected to the user’s oxygen regulator. This

standard torch has a flexible hand shield which is easily replaceable if damaged, plus the torch is

molded from a super tough Thermo plastic.

An optional 6" (152 mm) collet extension and 6" (152 mm) diameter extension shield is available

to help reduce torch wear or damage when piercing. Also available is a 3/8" (9.5 mm) adapter kit

consisting of a collet chuck, Collet Nut, washer, and flashback arrestor needed to adapt the torch for

using the 3/8" (9.5 mm) diameter cutting rods.

4.02 SLICE Striker

A SLICE Striker is available for cutting without power. The striker is an insulated piece of copper

plate with a serrated surface. By scratching the rod against the copper plate an arc is initiated and

the cutting process begins. Striker wear can be extended by using the smallest exposed portion of

the copper plate and gradually increasing.

SLICE Striker

1” open

SLICE Striker

2” open

SLICE Striker

Full open

The SLICE striker comes standard with a 10 ft. (3.05 m) cable.

4.03 SLICE Packs

SLICE

®

Utility Pack

Includes a rugged carrying case. Power connections (12 volt battery only), tong style

battery clamps makes power connection quick and easy. Industrial oxygen hose

connected to the torch; industry standard Oxygen hose supplies the torch with oxygen

and standard fittings used to connect to oxygen regulators.

SLICE

®

Battery Pack

Includes a rugged carrying case. Power connections twist-lock style connection;

easy to connect to battery ignition source for both torch and striker and color coded

connectors. Industrial oxygen hose connected to the torch; industry standard Oxygen

hose supplies the torch with oxygen, standard fittings used to connect to oxygen

regulators, and color coded connections.

SLICE EXOTHERMIC CUTTING EQUIPMENT

7

89250840

SLICE

®

Industrial Pack

Versatility for industrial type applications. Industrial cart capable of carrying a 9"

diameter oxygen cylinder. Packed with the basic items needed to do a cutting job; SLICE

Torch Assembly - 10 ft leads, striker assembly, oxygen regulator, battery charger, and

cutting rod holder. Industrial oxygen hose connected to the torch; industry standard

Oxygen hose supplies the torch with oxygen and standard fittings used to connect to

oxygen regulators.

SLICE

®

Complete Pack

Rugged aluminum carrying case; packed with the basic items needed to do a

cutting job. Self-contained cutting system lends itself well to the emergency

type cutting situations where seconds count. Complete unit weights 70

lbs (31.75 kg). Storage compartment with hinged door for parts storage

during transportation. Power connections twist-lock style connection; easy

to connect to battery ignition source assembly for both torch and striker

and color coded connectors. Industrial oxygen hose connected to the torch;

industry standard Oxygen hose supplies the torch with oxygen. Standard

fittings used to connect to oxygen regulators.

4.04 Cutting Rods

SLICE Cutting Rods are made of carbon steel, by rolling a steel strip into a rod, and are coated or

uncoated. The coating is made of arc stabilizers and a binder. Several advantages to using the

coated rods with power include:

• More efficient cutting rates (more cut per inch of rod burnt and more cut per minute of burn time)

• Easier rod operation

• Protection from burning out on the side of the rod, especially when piercing

Rod Size Uses

1/4" x 22"

6.4 mm x 558.8 mm

Standard size cutting rods used in a variety of jobs. Recommended for

all straight-line cutting and most general-cutting applications. Coated

or uncoated.

1/4" x 44"

6.4 mm x 1117.6 mm

Used when greater length is needed to reach the cutting area or when

piercing holes in materials thicker than 18" (457,2 mm). Uncoated.

3/8" x 18"

9.5 mm x 457.2 mm

Used for heavy piercing with a large bore. Coated or uncoated.

3/8" x 36"

9.5 mm X 914.4 mm

Used when added length is needed to complete cutting. Uncoated.

NOTE!

All SLICE cutting torches come ready to use the 1/4" (6.4 mm) diameter

rods. Use of the 3/8" (9.5 mm) diameter rods requires the 3/8" (9.5 mm)

conversion kit, Part Number 94-463-032.

8

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

4.05 SLICE Components

Art# A-13635

Figure 1: SLICE Torch

SLICE Torch

Oxygen Valve Lever

Oxygen Hose

Connection

Torch Cable

Power Assisted Torch End

Collet Nut

Black Male Connector

Striker Cable

SLICE Striker

Art# A-13637

Red Male Connector

Figure 2: SLICE Torch and Striker

SLICE EXOTHERMIC CUTTING EQUIPMENT

9

89250840

Art # A-13638

FAULT CHARGING CHARGED

STRIKER

TEST

TORCH

DC

IN

22-30V

Cam Lock Female

Terminal F/ Torch

Cam Lock Female

Terminal F/ Striker

Test Button

DC Input

Fault / Charge Status Gauge

CAUTION

THIS UNIT CONTAINS A LEAD ACID BATTERY WHICH RELEASES EXPLOSIVE

HYDROGEN GAS WHEN BEING CHARGED. CHARGE THIS BATTERY ONLY IN A

VENTILATED LOCATION DESIGNATED AS A LEAD-ACID BATTERY CHARGING

AREA. DO NOT CHARGE THIS BATTERY WHILE OPERATING THIS TORCH.

Figure 3: SLICE Battery Ignition Source

4.06 Charging the Ignition Source

There are 3 LEDs on the Ignition Source panel (FAULT, CHARGING, and CHARGED). Fully charged

status will display all LEDs green. For explanation of LED readouts refer to Section 9.2 Ignition Source

LED Display Guide. The AC/DC Power Adapter (p/n 96-076-043) is required to complete these steps.

NOTE!

It is recommended that the unit be recharged after every use or when-

ever the Charge Status LEDs shows 50% or less.

Charging the Ignition Source:

1. Press the TEST button on the Ignition Source panel to check status. If the LEDs do not present

all green LEDs then proceed with the steps below.

2. Insert the AC/DC Power Adapter Output connector into the DC Input socket on the Ignition Source

panel and plug the Power Adapter input cord into a 120 V, 60Hz or 240 V 50Hz wall outlet.

3. Keep the unit plugged in until fully charged. Charging time can be between 2-5 hours. On the

Ignition Source panel amber LEDs will display when fully charged.

4. Disconnect the AC/DC Power Adapter connector from the Ignition Source and push the Test

button to confirm full charge status. All the LEDs will display green.

10

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

SECTION 5: CUTTING DATA

The following chart helps determine the best settings for a specific use as a result of extensive

laboratory testing of the SLICE Equipment to determine the best cutting rates. Actual cutting results

obtained in the field vary due to conditions and experience of the user. Various usages of SLICE

Equipment return various results. Adjust the settings for any use. Use the following chart as a guide.

Oxygen pressure of 80 psi (551.6 kPa) achieves the best cutting. Some operations may require higher

or lower oxygen pressures - minimum 40 psi (275.8 kPa); maximum 100 psi (689.5 kPa). Amperage

over 200 amps does not improve cutting speed.

Find the right metal and thickness. For composites or unlisted metals, locate the listed type that most

resembles the material to be cut.

NOTE!

All these cutting values are based on 1/4" (6.4 mm) diameter ux-

coated rods. Cutting rates with 1/4" (6.4 mm) bare rods are slightly

less than the values listed in the chart.

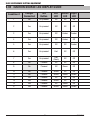

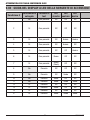

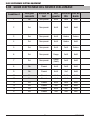

5.01 Material Cutting Rates

Material Type Material Thickness

Length of Cut per

Inch Rod Used

Cutting Speed

in(mm) in(cm) in/min cm/min

Carbon Steel

1/8 (3.2) 2.25 (5.7) 72 183

1/4 (6.4) 1.5 (3.8) 52 132

3/8 (9.5) 1.38 (3.5) 42 106

1/2 (12.7) 1.25 (3.2) 35 89

3/4 (19.1) .75 (1.9) 22 56

Stainless

1/8 (3.2) 2.0 (5.1) 65 165

1/4 (6.4) 1.13 (2.9) 36 91

Aluminum

1/4 (6.4) 1.75 (4.4) 58 147

3/8 (9.5) 1.25 (3.2) 38 97

3/4 (19.1) .75 (1.9) 23 58

SAMPLE SELECTIONS:

The approximate cut/inch rod x amount of cut per rod = cut per rod used

Data: Cutting 3/8" (9.5 mm) aluminum with 1/4" (6.4 mm) fluxed rod

1.25" (3.2 cm) x 19" (48.3 cm) = 23.8" (60.5 cm). Approximate cut/min arc time = 38" (97 cm)

Data: Cutting 1/4" (6.4 mm) carbon steel with 1/4" fluxed rod

1.5" (3.8 cm) x 19" (48.3 cm) = 28.5" (72.4 cm). Approximate cut/min arc time = 52" (132 cm)

SLICE EXOTHERMIC CUTTING EQUIPMENT

11

89250840

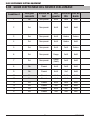

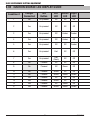

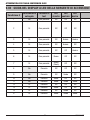

5.02 Cutting Electrode Types

Cutting rates in this chart were obtained using 80 PSI (551.6 kPa) oxygen pressure and 1/4" x 22"

(6.4 mm x 559 mm) cutting rods. These rates are averaged values based on multiple cutting tests.

Actual cutting rates may vary due to parameters used and operator expertise.

Part No.

Diameter

in(mm)

Length

in(mm)

Coated or

Uncoated.

Package

Quantity

Oxygen

Flow Rate

CFM(CMM)

Burn

Time

(sec)

42-049-002 1/4 (6.4) 22 (559) Coated 25 7.5 (.21) 40-45

42-049-003 1/4 (6.4) 22 (559) Coated 100 7.5 (.21) 40-45

43-049-002 1/4 (6.4) 22 (559) Uncoated 25 7.5 (.21) 40-45

43-049-003 1/4 (6.4) 22 (559) Uncoated 100 7.5 (.21) 40-45

43-049-005 1/4 (6.4) 44 (1117) Uncoated 25 7.5 (.21) 80-90

42-049-005 3/8 (9.5) 18 (457) Coated 50 12 (.34) 30-35

43-049-007 3/8 (9.5) 18 (457) Uncoated 50 12 (.34) 30-35

43-049-009 3/8 (9.5) 36 (914) Uncoated 25 12 (.34) 60-70

5.03 SLICE Cutting Torches

Part No.

Cable

Size

Power Cable

Length ft(m)

Oxygen

Hose Length

ft(m)

Cutting with

Power

Cutting without

Power

03-003-010 #1

10 (3.05) 10 (3.05)

Recommended Can Be Used

03-003-011 #6 Limited Use Only Recommended

03-003-012 #10 Not Recommended Recommended

12

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

SECTION 6: OPERATION

SLICE Exothermic Cutting uses heat from a chemical reaction between a consumable steel rod and

oxygen flowing through the rod. Test data show that little or no oxygen remains. The oxygen not

used in the reaction blows the molten material out of the cut area. This action creates the kerf that

allows cut progression.

6.01 Cutting without Power

Cutting without power uses the heat reaction from the rod and the oxygen to cut. To initiate this type

of cutting, ignite the rod from a spark supplied by a 12-volt battery or by a welding power source

capable of delivering a 100-amp surge. Once this spark has ignited the rod, the electrical path is

broken and the heat of the reaction melts the material and cuts it.

Battery

+ -

SLICE Torch

Striker

Oxygen Supply

Art# A-13639

Figure 4: Cutting without Power

Cutting without power can be done in remote areas. Support equipment and bulky power sources

are not needed.

1. Connect the torch to either terminal of a 12-volt battery or constant-current welding power

source, then connect the striker or a strike plate to the other terminal. If using a welding

power source, set output level for 100 amps.

2. Turn ON the oxygen supply and adjust the regulator to the proper working pressure. Insert

the cutting rod into the collet and tighten the Collet Nut.

3. Tap the cutting rod on a hard, ungrounded surface to seat the rod in the torch.

4. Depress the torch oxygen valve lever and check for oxygen leaks around the Collet Nut.

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

ESAB SLICE® NEW Exothermic Cutting Equipment Manuale utente

- Tipo

- Manuale utente

in altre lingue

Documenti correlati

-

ESAB SLICE® Exothermic Cutting Equipment Manuale utente

-

ESAB SLICE® NEW Exothermic Cutting Equipment Manuale utente

-

ESAB SLICE® NEW Exothermic Cutting Equipment Manuale utente

-

ESAB Mig U5000i Manuale utente

-

ESAB Mig 5000i Manuale utente

-

ESAB Mig U5000i Manuale utente

-

ESAB Mig 5000i Manuale utente

-

ESAB Mig U5000i Manuale utente

-

ESAB Mig 5000i Manuale utente

-

ESAB N7500 Gouging System Manuale utente

Altri documenti

-

Miller LA245667 Manuale del proprietario

-

Miller KB076607 Manuale del proprietario

-

Garmin STRIKER Vivid5cv Istruzioni per l'uso

-

Miller KF959177 Manuale del proprietario

-

Miller BIG 30A DIESEL Manuale del proprietario

-

Miller KB127936 Manuale del proprietario

-

Cannondale Slice Multisport Manuale del proprietario