Model SO328

OPERATORS MANUAL

Manual No. 513591 Rev.3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or pro-

vide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: [email protected]

© 2014 PW Stoelting, LLC

stoeltingfoodservice.com

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious per-

sonal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your at-

tention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equip-

ment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

SECTION DESCRIPTION PAGE

1. INTRODUCTION

1.1 Remote Possibilities.......................................................................................... 1

1.2 Features ............................................................................................................ 1

1.3 Freezer Specifications ....................................................................................... 2

2. INSTALLATION INSTRUCTIONS

2.1 Safety Precautions............................................................................................. 3

2.2 Shipment and Transit ......................................................................................... 3

2.3 Freezer Installation ............................................................................................. 3

2.4 Installing Permanent Wiring ................................................................................ 4

3. INITIAL SET-UP AND OPERATION

3.1 Operator's Safety Precautions............................................................................ 5

3.2 Operating Controls and Indicators ...................................................................... 5

3.3 Disassembly of Freezer Parts ............................................................................ 5

3.4 Cleaning the Freezer Parts ................................................................................ 6

3.5 Sanitize Freezer and Freezer Parts.................................................................... 6

3.6 Assembly of Freezer .......................................................................................... 6

3.7 Sanitizing........................................................................................................... 7

3.8 Cleaning & Sanitizing of SO328 with Fill-o-matic II and Fill-o-matic III .................. 8

3.9 Initial Freeze Down and Operation ..................................................................... 8

3.10 Removing Product ............................................................................................. 8

3.11 SO328 Operation............................................................................................... 8

4. PREVENTATIVE MAINTENANCE

4.1 Routine Cleaning ............................................................................................... 11

4.2 Preventative Maintenance .................................................................................. 11

4.3 Extended Storage .............................................................................................. 11

4.4 Consistency Adjustment ..................................................................................... 11

5. REPLACEMENT PARTS INFORMATION

5.1 Ordering Parts ................................................................................................... 13

5.2 Reference Drawing ............................................................................................ 13

6. ACCESSORIES

6.1 Fill-o-matic II ....................................................................................................... 15

6.2 Fill-o-matic III ...................................................................................................... 17

6.3 Fill-o-matic Connections .................................................................................... 19

TABLE OF CONTENTS

FIGURE TITLE PAGE

1 Model SO328 ................................................................................... 1

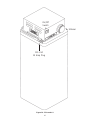

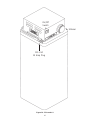

2 Freezer Specifications...................................................................... 2

3 Leveling Unit ..................................................................................... 3

4 Electrical Box.................................................................................... 4

5 Controls ............................................................................................ 5

6 Disassembling Freezer..................................................................... 6

7 Front Door and Auger Assembly ....................................................... 6

8 Rear Seal Assembly ......................................................................... 6

9 Consistency Adjustment....................................................................11

10 Fill-o-matic II .....................................................................................16

11 Fill-o-matic III.....................................................................................18

LIST OF ILLUSTRATIONS

1

1.1 REMOTE POSSIBILITIES

The Stoelting Optima delivers frozen drink profits by the pitcher. The Model SO328 is a high-volume producer of

ready-to-serve frozen cocktails or frozen neutral base for those special drink recipes. From an extra-small space,

the Optima’s compact design and high capacity output will give you extra-large profits.

SECTION 1

INTRODUCTION

Figure 1. Model SO328

1.2 FEATURES

High Capacity

- 15-18 gallons per hour per

cylinder output

- Thick, stackable slush for

post-mixing

- Or, ready-to-serve pre-mixed

products

High Efficiency Evaporator/Auger

- Stainless steel construction

- Long life auger blades

- Quiet, smooth operation

- 8 qt. freezing cylinder capacity

Consistency Control

- Adjustable for thick or thin

products

- Sensitive to product demand

- 24 volt control circuits

Dispensing Head Door

- ”No-Freeze” design prevents

blockages

- Fast dispense for quick fill of

pitchers

- Controlled dispense for drinks

by the glass

- Convenient pull-type handle

- Attractive, clear, see-thru

design

- Visible, moving product for

merchandising appeal

2

Electrical Refrigeration Crated Dimensions Dimensions

208/230/60/1 HFC-404A environmentally- Width: 22" (55.9cm) Width: 17.6"(44.7cm)

20 amp circuit & plug friendly refrigerant Depth: 30" (76.2cm) Depth: 26.1"(66cm)

per side 2 HP (14,800 BTUH) high- Height: 66" (167.7cm) Height: 61.2"(155cm) w/casters

12 running amps efficiency compressor Weight: 400lbs.(182kg) Weight: 350lbs.(159kg)

1/2 HP Drive Motor Air or water cooled.

1.3 FREEZER SPECIFICATIONS

Figure 2. Freezer Specifications

3

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The

labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be

checked periodically to be sure they can be recognized

as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, INC.

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Leveling Unit

A. Uncrate the freezer.

B. The freezer must be placed in a solid level position. To

level adjust casters. Figure 3.

C. The freezer is equipped with an air cooled condenser

and requires correct ventilation; the front is the intake

and the back is the discharge. Both front and back

require 3" clearance for proper operation.

D. Place all switches in the OFF position.

E. Connect the two power cords. The plug is designed for

208/230 volt/20 amp duty. The unit must be connected

to a properly grounded receptacle. The electrical cord

furnished as part of the freezer has a three prong

grounding type plug. The use of an extension cord is

not recommended. If one must be used, use one with

a size 12 gauge or heavier with a ground wire. Do not

use an adaptor to get around grounding requirements.

CAUTION

DO NOT ALTER OR DEFORM PLUG IN ANY WAY!

F. Install the drip tray, cover and other miscellaneous

parts on the freezer.

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and in-

spected at the factory. Upon arrival at the final destina-

tion, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RE-

SPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED. Do not pay the

freight bill until the freezer has been checked for dam-

age. Have the carrier note any visible damage on the

freight bill. If concealed damage and/or shortage is found

later, advise the carrier within 10 days and request

inspection. The customer must place claim for damages

and/or shortages in shipment with the carrier. Stoelting,

Inc. cannot make any claims against the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

4

2.4 INSTALLING PERMANENT WIRING

If permanent wiring is required by local codes, the following

procedure must be performed.

WARNING

DISCONNECT FREEZER FROM THE SOURCE

OF ELECTRICAL SUPPLY BEFORE SERVICING.

A. Remove the right side and left panels and electrical box

covers to gain access to the power cord.

B. Remove the strain relief connector from the bottom of

the freezer base cut and remove the power cord.

C. Install permanent wiring according to local code.

D. Connect black wire to black wire. Connect the white

wire to white wire. Connect the green or yellow and

green striped ground wire to the grounding screw.

E. Replace all covers and panels.

Figure 4. Electrical Box

5

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer. Read and understand the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating condi-

tions. Never operate the freezer if unusual or exces-

sive noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the

operator know the function of each operating control.

Refer to Figure 4 for the location of the operating

controls on the freezer.

A. Pump OFF/ON Switch

The pump OFF/ON Switch is a two position switch.

In the OFF position the pump will not run. In the ON

position the pump will run until the proper liquid level

is reached, then stop. If the hopper does not fill

completely, place the switch in the OFF position,

then back to ON to continue filling.

WARNING

THE CLEAN/OFF/SERVE SWITCH MUST BE PLACED

IN THE OFF POSITION WHEN DISASSEMBLING FOR

CLEANING OR SERVICING. THE FREEZER MUST BE

DISCONNECTED FROM ELECTRICAL SUPPLY BE-

FORE REMOVING ANY ACCESS PANEL.

B. CLEAN/OFF/SERVE Switch

The CLEAN/OFF/SERVE switch is a three position

toggle and refrigeration switch used to control the

operation of the agitator. When the switch is placed

in the CLEAN position, the agitator will rotate.

When the switch is placed in the OFF position, nothing

will operate. When the switch in placed in the SERVE

position, the agitator and refrigeration system will run

until proper consistency is reached then stop.

C. Mix Low Light

The Mix Low light will illuminate when you are low on

mix.

CAUTION

DO NOT OPERATE FREEZER WHEN THE LOW

MIX LIGHT IS ILLUMINATED OR DAMAGE TO

THE FREEZER COULD RESULT.

3.3 DISASSEMBLY OF FREEZER PARTS

CAUTION

PLACE THE CLEAN/OFF/SERVE SWITCH IN THE

OFF POSITION BEFORE DISASSEMBLING FOR

CLEANING OR SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced

to ensure safety to both the operator and the customer

and to maintain good freezer performance and a quality

product. Frequency of cleaning must comply with the

local health regulations.

To disassemble the freezer, refer to the following steps:

A. Remove hopper cover.

B. Remove the front door by turning off the knobs, and

then pull the front door off the studs.

Figure 5. Controls

Clean Off Serve Switch

Pump Off On Switch

Mix Low

6

Figure 6. Disassembling Freezer

C. Remove the spigot body from the front door bypulling

the retaining pin out of the spigot handle. Push the

spigot body thru the bottom of the front door.

D. Remove the agitator assembly from the freezer. Pull

the agitator assembly out of the freezer barrel.

E. Keep the rear of the agitator assembly tipped up

once it is clear of the freezer barrel to avoid dropping

rear seal.

F. Remove the front agitator support bearing and the

two agitator blades.

G. Remove the rear seal assembly.

H. Wipe socket lubricant from the drive end (rear) of the

agitator with a cloth or paper towel.

I. Remove all “O” Rings.

WARNING

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE THE “O” RINGS.

Figure 7. Front Door and Auger Assembly

Figure 8. Rear Seal Assembly

3.4 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to

the wash sink for cleaning. To clean freezer parts refer

to the following steps:

A. Place all parts in warm (120°F) mild detergent (Joy

or equivalent) water and clean with brushes provided.

Rinse all parts with clean hot (135°F) water.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

B. Wash the freezer barrel with warm (120°F) detergent

(Joy or equivalent) water and brushes provided.

C. The exterior should be kept clean at all times to

perserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth or

sponge to apply the cleaner.

D. Remove the drip tray insert and drain tray. Clean with

a detergent solution (Joy or equivalent). Rinse with

clean hot water.

3.5 SANITIZE FREEZER AND FREEZER PARTS

A. Use a sanitizer mixed according to manufacturer’s

instructions to provide a 100 parts per million

strength solution. Mix sanitizer in quantities of no

less than 4 gallons (15 liters) of 120°F water. Allow

the sanitizer to contact the surfaces to be sanitized

for 5 minutes. Any sanitizer must be used only in

accordance with the manufacturer’s instructions.

B. Place all parts in the sanitizing solution, then remove

and let air dry.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following

steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be used

when lubrication of parts is specified.

SOFT RUBBER

SURFACE

HARD CARBON

SURFACE

7

WARNING

THE UNITED STATES DEPARTMENT OF AGRI-

CULTURE AND FOOD AND DRUG ADMINISTRA-

TION REQUIRE THAT ALL CLEANING AND SANI-

TIZING SOLUTIONS USED WITH FOOD PRO-

CESSING EQUIPMENT BE CERTIFIED FOR THIS

USE. USE “STERA-SHEEN” OR EQUIVALENT.

When sanitizing the freezer, refer to local sanitary

regulations for applicable codes and recommended

sanitizing products and procedures. The frequency of

sanitizing must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions

to provide a 100 parts per million strength solution. Mix

sanitizer in quantities of no less than 4 gallons (15

liters) of 120°F water. Allow sanitizer to contact the

surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the

manufacturer’s instructions.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

soft serve freezer. We therefore include a sample

with each new freezer. For further information read

the directions on the packet. Other products may

be as effective.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MAY CAUSE CORROSION OF STAIN-

LESS STEEL PARTS.

In general, sanitizing may be conducted as follows:

A. Prepare 4 gallons (15 liters) of sanitizing solution

following manufacturers instructions, then pour into

hopper, brush hopper walls, and inside of hopper

cover.

If using an auto fill. Pour sanitizing solution into the

mix container, brush mix container, draw tube and

pick up hose. Pump sanitizer from mix containers

into the freezer hopper. Brush hopper walls, hopper

cover, hose adapter and retaining clip.

B. Place the CLEAN/OFF/SERVE switch in the CLEAN

position. Check for leaks around the front door seal.

C. After five minutes, open spigot to drain sanitizing

solution. When solution has drained, place the

CLEAN/OFF/SERVE switch in the OFF position.

Allow the freezer barrel to drain completely.

NOTE

The United Sates Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for

this use. Use lubricants only in accordance with

the manufacturer’s instructions.

A. Assemble spigot “O” Rings onto parts dry, without

lubrication. Then apply a thin film of sanitary

lubrication to exposed surfaces of the “O” Rings.

B. Assemble the rear seal assembly onto the agitator.

Be sure the “O” Ring is in place before installing

the rear seal. Do not lubricate.

C. Lubricate the agitator drive (rear) with a small

amount of white socket lubricant. A small container

of socket lubricant is shipped with the freezer.

D. Install the two plastic agitator blades onto the

agitator. Install front agitator bearing to the door.

E. Push the auger into the freezer barrel and rotate

slowly until the agitator engages the drive socket.

F. Install the spigot body with “O” Rings into the front

door from the bottom. Push straight up until the

spigot is in place. Place the spigot handle into the

spigot and insert the retainer pin.

G. Install door “O” Ring after lubricating.

H. Install the front door on the freezer.

I. Install the knobs on the freezer studs.

CAUTION

FINGER TIGHTEN THE KNOBS EVENLY. DO NOT

OVER-TIGHTEN KNOBS.

Look for the proper seal between the freezer barrel door,

“O” Ring, and front door.

J. Install hopper cover.

3.7 SANITIZING

Sanitizing must be done after the freezer is clean and

just before filling with mix. Sanitizing the night before

is not effective. However, you should always clean the

freezer and parts after using it.

8

ÊÊ

ÊÊ

Ê

3.8 CLEANING & SANITIZING OF S0328 WITH

FILL-O-MATIC II AND FILL-O-MATIC III

A. Empty freezer & mix container of product.

B. Mix 4 gallons of warm (120°F) detergent (Joy or

equivalent) water and pour into mix container, brush

mix container, pick up hose and draw tube. Pump

detergent water into freezer hopper.

C. Mix sanitizer according to manufacturers instructions

in quantities no less than 4 gallons. Pour sanitizer

into mix container. Brush mix container, hose and

draw tube to sanitize. Pump sanitizer into freezer

hopper, empty remaining sanitizer from mix container

and let air dry.

D. Drain detergent & sanitizer solution from the freezer.

E. Disassemble freezer according to Section 3, 3.3.

F. Clean freezer and parts according to Section 3, 3.4.

G. Sanitize freezer & parts according to Section 3, 3.5.

H. Assemble per Section 3, 3.6.

I. Sanitize per Section 3, 3.7.

3.9 INITIAL FREEZE DOWN AND OPERATION

This section covers the recommended operating

procedures to be followed for the safe operation of the

freezer.

A. Sanitize just prior to use.

B. Place the CLEAN/OFF/SERVE switch in the OFF

position.

C. With the spigot open, pour one cup of mix into the

hopper. Allow approximately 8 oz. of sanitizing

solution and mix to drain out. Close the spigot and

fill the hopper with mix.

D. Place the CLEAN/OFF/SERVE switch in the

SERVE position. The product will be ready to serve

in about 15 minutes.

3.10 REMOVING PRODUCT

Before disassembly, all product must be removed.

A. Open spigot and completely drain freezer.

B. Prepare not less than 3 gallons of warm detergent

water and pour into hopper. (When using auto fill

pump thru auto fill).

C. Use a brush to clean the hopper then completely

drain freezer.

3.11 SO328 OPERATION INFORMATION FOR

SERVICE PERSONNEL

The SO328 is a cocktail/slush freezer. It is available in

208-230 volt, either air-cooled or water-cooled. The air-

cooled version has front-to-back airflow requiring three

inches of air space in the front and back for proper

refrigeration. This unit is not supplied with a pump,

however, Stoelting does offer the Fill-O-Matic II (electric)

and Fill-O-Matic III (gas) pumps. This freezer is intended

for use with non-dairy products only and will produce

15-18 GPH.

1. Filling

To fill the freezer, pour mix into hopper until full. To fill

freezers with the optional Fill-O-Matic pump, connect

the pump and turn the pump switch on, electric model

or turn the gas on, gas model. Then turn the pump

switch on, located on the freezer, this will open the

solenoid valve and the freezer will begin to fill. The

liquid level control circuit is designed with a fill timer.

This timer is designed to shut the compressor off if

the top level probe is not satisfied before the timer

expires. If the top level probe is not satisfied before the

timer times out, it locks the compressor out and

freezing will not occur, if this happens, turn the fill

switch off and then back on, this will reset the timer.

2. Operation

Once the freezer is full of mix, turn the clean-off-serve

switch to the “serve” position. The drive motor will start

immediately. The compressor utilizes a 10 second

delay-on-make / delay-on-break timer therefore, the

compressor will start 10 seconds later. The compressor

will continue to run until the drive motor torque switch is

satisfied, then after a 10 second delay stop. The drive

motor runs continuously in the “serve” or “clean” switch

positions. There is no night mode or standby mode. If

product is left in the freezer overnight we recommend to

simply turn the freezer off. Do not run the freezer in

"clean” overnight. Freeze down time will typically be 6-

10 minutes depending on the type of product used and

the starting product temperature.

3. Pump Operation

When the mix level in the hopper drops below the

bottom level probe, the solenoid valve opens and the

pump begins to fill until the top level probe is satisfied.

When satisfied, the solenoid valve closes, and pump

will continue to run until shut off pressure is reached.

The electric pump will run until the pressure reaches the

cut-out pressure of the pump. A gas pump will continue

to run until the pressure in the mix line equals the gas

pressure of the pump. If you wish to use the product in

the hopper prior to cleaning, turn the mix pump off and

turn the freezer pump switch off. This will disable the fill

timer and allow the compressor to continue to run. Be

cautioned that once the hopper is empty, the barrel

could freeze up. Only run the freezer until the hopper is

empty or damage may occur.

9

4. Fill Timer Operation

The timer has ten dip switches, all switches placed in

the “on” position are added together to make up the

total time delay. This freezer leaves the factory with 64,

128 and 256 in the “on” position, this is a total of 448

seconds. The preset time should be enough to fill the

hopper up to the top level probe. Fill time may be depen-

dent on what style pump is employed. The purpose of

the timer is to disable the compressor if the mix supply

runs out. When the timer expires, the mix low light will

illuminate. If the mix low light is illuminated, the com-

pressor is locked out of the electrical circuit and will not

run. It may be necessary to change the timer settings

to more closely match the pumping capacity of your

pump.

10

11

4.1 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm

soapy water and wipe dry. Do not use highly abrasive

materials as they will mar the finish.

4.2PREVENTATIVE MAINTENANCE

It is recommended that a maintenance schedule be

followed to keep the freezer clean and operating prop-

erly.

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCON-

NECTED.

A. Daily

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth or

sponge to apply the cleaner.

2. Remove the drip tray and insert. Clean the drip

tray and insert and front of the freezer with a soap

solution.

B. Weekly

1. Check “O” Rings and rear seal for excessive wear

and replace if necessary.

2. Clean filter. To remove lift up and pull bottom out and

down, then wash, dry and reinstall.

C. Monthly

CAUTION

THE FREEZER HAS AN AIR COOLED CON-

DENSER AND MUST HAVE PROPER AIR CIRCU-

LATION. FAILURE TO CLEAN THE CONDENSER

ON A REGULAR BASIS MAY RESULT IN SERI-

OUS FREEZER DAMAGE AND COULD VOID

FREEZER WARRANTY.

1. Visually inspect the condenser for dirt by shining a

light through the coil from the fan side of the con-

denser.

2. If the condenser is dirty, using compressed air or

CO2 tank, blow out the dirt from the fan side of the

condenser.

3. An alternative method of cleaning the condenser is to

use a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of refrigera-

tion efficiency will result, causing extended run time

or soft product consistency.

4.3 EXTENDED STORAGE

Refer to the following steps for storage of the freezer

over any long period of shutdown time:

A. Turn CLEAN/OFF/SERVE switch to the OFF

position.

B. Disconnect (unplug) from the electrical supply

source.

C. Clean thoroughly with a warm detergent all parts that

come in contact with the mix. Rinse in clear water

and dry all parts. Do not sanitize.

NOTE

Do not let the cleaning or sanitizing solution stand

in the hopper or in the freezer barrel during the shut-

down period.

D. Remove, disassemble, and clean the front door, and

agitator parts. Place the agitator blades and the front

agitator support bearing in a plastic bag with a moist

paper towel to prevent them from becoming brittle.

4.4 CONSISTENCY ADJUSTMENT

The consistency adjustment knob is located behind the

back panel. Remove the lower back panel to access.

Turn clockwise for a thicker product and counterclock-

wise for a thinner product. Figure 9. Allow 15-30

minutes for the product to change consistency.

WARNING

DO NOT OPERATE FREEZER WITH BACK PANEL

REMOVED.

SECTION 4

PREVENTIVE MAINTENANCE

Figure 9. Consistency Adjustment

12

13

SECTION 5

REPLACEMENT PARTS INFORMATION

5.1 ORDERING PARTS

To assure receipt of the proper replacement parts, supply

your dealer or distributor with the following information:

A. MODEL NUMBER of equipment.

B. SERIAL NUMBER of model (stamped on nameplate).

C. PART NUMBER, PART NAME, AND QUANTITY

NEEDED. Many part names and numbers are listed

on drawings included in this manual.

NOTE

Minimum billing is $50.00.

D. WIRING DIAGRAMS reflect changes in effect with the

Serial Number which are also indicated by a suffix.

5.2 REFERENCE DRAWINGS

The following pages contain reference drawings and parts

lists that will aid the user when operating the freezer.

DECALS AND TAGS

PART NUMBER DESCRIPTION

324105 DECAL - CAUTION: ELECT. SHOCK

324107 DECAL - CAUTION MOVING PARTS

324141 DECAL - CAUTION: ROTATING BLADES

324798 DECAL - CLEAN-OFF-SERVE SWITCH

324208 DECAL - REFRIG. LEAK CHECK

324393 DECAL - STOELTING SWIRL LOGO

324509 DECAL - CLEANING

324566 DECAL - WIRED ACCORDING TO . . .

324686 DECAL - DANGER STARTS AUTOMATICALLY

324689 DECAL - REAR SEAL ASSEMBLY

324799 DECAL - PUMP ON/OFF

324801 DECAL - MIX LOW

14

Item Stoelting P/N Qty. Description

1 1170882 1 Auger Bushing

2 4177009 1 Auger Weldment

3 667892 1 Seal, Shaft

4 3172965 1 Rear Seal Adapter

5 624857 1 Ring, O, 2-1/4 ID x 2-5/8 OD x 3/16 CS

6 162157 2 Blade, Scraper

7 508048 As Reqd Lubricant

8 2177118 1 Washer, Acetron 1.25 OD x .94 ID x .060"

9 336525-SV 1 Door, Front

10 625310 1 Ring, Quad 5.75 ID

11 1171908 1 Pin, Door

12 570196 1 Pin, 1/4 x 2-1/2 Cotterless

13 3177001 1 Spigot

14 624655 2 Ring, O, 1 x 1-1/4 x 1/8 70 Duro

15 2170877 1 Handle, Spigot

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

in altre lingue

- English: Stoelting SO328 User manual

Documenti correlati

Altri documenti

-

DeWalt DPC10QTC Manuale utente

-

Senco PC1010N Operating Instructions Manual

-

COMAC SANEX Use and Maintenance Manual

-

Crathco Manual – Pump version Manuale utente

-

Crathco Manual – Gravity version Manuale utente

-

Crathco Manual Manuale utente

-

Crathco Manual Manuale utente

-

Taylor C117 Manuale utente

-

Crathco Manual Manuale utente

-

Follett Horizon Elite HC*2110N series Operation And Service Manual