MG MERO 18 P Operating Instructions Manual

- Categoria

- Cucitrici

- Tipo

- Operating Instructions Manual

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 1

Mod.: 804

ET 675, 676

Page 1 of 6 04.05.2018

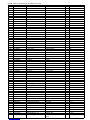

Model

Size of tool

(mm)

Weight

(kg)

Staples

32 mm crown size

for single and light double

corrugated cardboard

for double corrugated

cardboard

MERO 18 P

233 x 230 x

115

2,37

R 1/58 = 15 mm

R 1/34 = 18 mm

Leg length:15 mm, 18 mm, Capacity: 1000 staples

for double corrugated

cardboard

for double and light triple

corrugated cardboard

MERO 22 P

233 x 230 x

115

2,37

R 1/34= 18 mm

R 1/78 = 22 mm

Leg length: 18 mm, 22 mm Capacity: 1000 staples

E:\Bedienungsanleitungen\MERO Bedienungsanl. deutsch-englisch 104\Bedien MERO 22 P englisch 104.doc

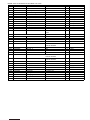

1) Cap

2) Body

3) Collar

4) Adjustment Plate

5) Adjusting Rod

6) Magazine Seat

7) Cover

8) Trigger

1

2

3

4

5

6

7

8

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 2

Mod.: 804

ET 675, 676

Page 2 of 6 04.05.2018

1 Usage

Pneumatic stapling tool for fastening the flaps of filled cartons of single, double or light triple corrugated

cardboard boxes.

2 Important note

It is the customer’s responsibility to have all operators and service personnel read and understand this

manual. This stapling tool may only be used by specially advised persons (s. Annex).

Prior to first use, please lubricate all movable parts, then insert staples (s. Chapter 3.3). The air supply

should be connected with a quick release coupling. It is operated by a motive agent (compressed air). This

stapling device is made solely for normal operation in industrial spheres or similar areas (use as directed).

The tool should be fitted with a maintenance unit with pressure regulator, air cleaner and oil spray units to

ensure smooth trouble free operating and long life.

2.1 Environmental conditions

The tool should be used with indoor conditions (room temperature, etc.). Usage within explosive

atmosphere is only permitted with the manufacturer’s prior approval.

2.2 Emission

The noise level is max. 93 dB(A) (L WA, Is). Heterogeneous gases will not be emitted by the stapling

device.

2.3 Technical Data

Connection: 1/4´´

Operation pressure: 5 - 7 bars; max. 8 bars

Air consumption: 1,1 NL/stapling

2.4 Safety instructions

COUTION: Keep your hands away from base of the machine at all times! Danger of injury!

Never exceed the recommended maximum pressure for the stapling tool.

Do not attempt to use a defective stapling tool.

Never load the stapling tool until you are ready to use it.

Never attempt to fasten into very hard or brittle material such as concrete, steel or tile etc..

Use only clean, dry regulated COMPRESSED AIR. Never use oxygen, carbon dioxide or other

bottled gases.

Always disconnect the tool from the air supply and empty magazine before: work breaks - changing

parts - servicing stapling tool.

3 Operating Instructions

3.1 Functional description

The stapling tool should be fitted with maintenance unit. The maintenance unit should be adjusted to one

drop lubrication, e.g. Unocal RX 22, per 40-50 machine cycles.

The stapler MERO 18 P can be used with the following coiled staples: R 1/58, R 1/34.

The stapler MERO 22 P can be used with the following coiled staples: R 1/34, R 1/78.

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 3

Mod.: 804

ET 675, 676

Page 3 of 6 04.05.2018

3.2 Handling

Insert staples into the magazine (7) (s. Chap. 3.3). Adjust the stapling tool as required (s. Chap. 3.4 - 3.6).

Place the stapler MERO 18 P or MERO 22 P on top of the carton to be sealed in a way that the flap joint

is directly in the centre of the stapling tool (s. arrow in the front of stapler). Then activate trigger (8) to

release stapling. The anvils will extend, clinch the staples and return automatically into the tool. Release

trigger (8). Then move the tool to the next stapling position.

For an optimal fastening result apply staples approx. 1cm to the rim of the carton.

Caution: The stapler should only be moved with the anvils completely returned into the tool

to avoid damage to the retractable anvils!

3.3 To load staples

Before inserting staples disconnect air supply!

The cover (7) has to be squeezed slightly and folded backward. Insert the coil as shown into the magazine

seat and push the staples into the stapling tool until stop. Then fold the cover (7) forward until the cover is

locked.

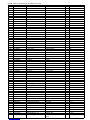

3.4 Adjusting leg length of staples

Before adjusting disconnect air supply!

Loosen screw with hexagonal recessed hole (I) with 3 mm hexagon spanner, turn the adjusting rod (5)

180° with a screw driver to the required position. For long leg length turn adjusting rod (5), so that L is in

upright position, for short leg length turn adjusting rod (5), so that S is in upright position. Fasten the

screw again with hexagonal recessed hole (I).

8

5

7

Staple coil

7

MERO 18 P

Leg length

15 mm

R 1/58

18 mm

R 1/34

MERO 22 P

Leg length

18 mm

R 1/34

22 mm

R 1/78

adjusting

rod -

position

S

L

S

L

I

5

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 4

Mod.: 804

ET 675, 676

Page 4 of 6 04.05.2018

Loosen screws (S) in magazine seat (6) and move right (R)

and left (L) stapling plate outward for long leg length (18)

and inward for short leg length (15). Fasten screws (S)

again.

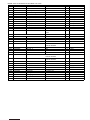

3.5 Staple clinch control (closed or open clinch)

Should adjustment of the staple clinch be necessary, it

should be carried out as follows: turn collar (3) with a matching tool (W), e.g. 2,5 mm rod, turn the collar

(3) counter clockwise for a looser clinch, turn the collar (3) clockwise for a tight clinch. For thick carton

quality a looser clinch may be recommendable as the staple can penetrate deeper into the carton.

3.6 Adjustment of penetration

For adjusting the penetration of the anvils loosen front screw (F) by means of a 6 mm hexagon spanner

(I). Move body up or down into the required position. Fasten front screw (F) again. If the body (2) is in

the upper position, the stapling penetration (A) is maximal. If the body (2) is in the lower position,

penetration (B) is minimal.

F

2

Tight clinch

Looser clinch

Middle position for optimal clinch

B

A

A = penetration adjustment

B = anvil

C = staple

Tight clinch

offene Heftung

R

S

L

W

3

open clinch

open clinch

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 5

Mod.: 804

ET 675, 676

Page 5 of 6 04.05.2018

3.7 Malfunction check list

For regulations, disassembly or repairs, always disconnect tool from air installation.

Malfunction

Cause

How to clear

Air leakage of trigger/Cylinder/

exhaust port

O-ring/s is/are defect

Remove O-rings

Send stapler to manufacturer

Slow and short travel cycling

Trigger defect or loose

Fasten screws, exchange trigger

Jammed staples

Trigger defect or loose

Fasten screws, exchange trigger

Send stapler to manufacturer

Screws at anvils loose

Fasten screws

Wrong staple size adjusted

Adjust correct staple size

Insufficient lubrication

Lubricate moving parts

Uneven clinch

Wrong staple size adjusted

Adjust stapling accord. to chapter 3.4

– 3.6.

Unclinched staple

Anvils defective or loose

Fasten screws at anvils or exchange

anvils.

Send stapler to manufacturer.

Trigger defective or loose

Fasten screws at trigger or exchange

trigger.

Send stapler to manufacturer.

3.8 De-jamming

Should a staple jam inside the tool, do not trigger any more. This can damage the anvils. Disconnect air

supply. Turn lever (H) as shown. Remove the jammed staples with an according tool, e.g. a spanner.

In case of severe jamming the driver guidance unit 27 can also be removed to gain more space for

clearing the jamming (may be removed quite easely as it is only fixed on 2 bolts. Then turn lever (H) in

the original position. Connect air supply. The machine is now ready for stapling again.

3.9 Unauthorized application and operation

Use stapler only for the defined materials and operations. Use only original staples.

If the stapling tool is not used as directed, the manufacturer is not liable for any damage

H

Plunger

Guide

unit 27

OPERATING INSTRUCTIONS

Pneumatic Carton Stapler for coiled staples

MERO 18 P + MERO 22 P

Page: 6

Mod.: 804

ET 675, 676

Page 6 of 6 04.05.2018

resulting from this undue use. Any risk of damage is borne solely by the user.

Use as directed also means observing the operating, servicing and maintenance conditions laid down by

the manufacturer of the tool.

The stapler may only be used, maintained and repaired by persons who are familiar with it and have been

advised of the dangers.

The relevant accident prevention regulations as well as other generally recognized industrial safety and

medical regulations must be observed.

Unauthorized modifications to this stapler or the use of spare parts or staples which are not original parts

from the manufacturer exclude any liability of the manufacturer for any resultant damage.

3.10 General Instructions

When not in use disconnect air supply and remove all staples.

Important - General Instructions

It is the customer’s responsibility to have all operators and service

personnel read and understand this manual.

MG tools are ruggedly built for long, dependable operation.

Details about safety as well as all necessary information for the tool’s

proper care and general maintenance are contained in this book.

Safety rules

NEVER exceed the recommended maximum pressure for the tool

(normally 6 bars).

DO NOT attempt to use a defective stapler.

NEVER load the stapler until you are ready to use it

DO NOT reload when you release a stapling operation

Only operate the tool when in contact with the carton surface.

At all times keep hands clear of base of machine whilst activating trigger.

Do not attempt to staple on to hard surface.

NEVER USE oxygen, combustible gases or high pressure compressed gas

tanks as air supply for the tool

Always disconnect air supply and empty magazine before: work breaks,

changing parts, servicing tools or clearing a jammed staple, storing tool at

the end of the day

ALWAYS utilise couplers on the compressor side of the air supply

system (couplers when disconnected automatically shut off the flow of

air)

4 Maintenance and Personal Safety Instructions (training, education)

Operation and usage of the stapler is only allowed to specially advised and trained persons.

For maintenance: Always disconnect the tool from the air supply.

For repair use only original spare parts from the manufacturer (s. spare parts list).

The following actions/inspections have to be regularly accomplished by specially advised and trained

persons:

Clean stapler regularly

Oil all movable parts weekly (no oil containing graphite!).

Check the pneumatic operating unit. Refill oil and remove water if necessary.

The pneumatic operating unit should be adjusted to one oil drop per 40-50 machine cycles.

Remark: Advised and trained persons are those who have the education and the experience to use

stapling tools. They have also knowledge of governmental safety and accident prevention instructions

and technical guidelines as DIN, etc. They can also judge function and operating reliability of staplers.

5 Shut down instructions

If the stapler will not be used disconnect air supply and remove all staples.

Seite 1 von 1 P:\Technik\MERO\Stücklisten\2017\Juli\Deckblatt PL MERO 18_22 P.docx

MEZGER Heftsysteme GmbH

Saganer Straße 24 Postfach (P.O.B.) 551170

D-90475 Nürnberg D-90218 Nürnberg

Tel.: +49 911 98494 0 Fax: +49 911 984 94 30

Mail: [email protected] Internet: www.mezger.eu

Stückliste

Spare Parts List

MERO 18/22 P

pneumatisch/pneumatic

MODEL: RAIA-19-GR & RAIA-22-GR / MERO 18P & 22P

Item

Parts No.

Beschreibung

Description

Q'ty

Spec.

001

A01200110

Deckel

CAP

1

002

A02800201

Kolben

PISTON

1

003

A02800301

Kolbenstange

PISTON ROD

1

004

A00100401

Zwischenstück

BLOCK

1

005

A00100501

Feder

SPRING

1

006

A00100601

Manschette

COLLAR

1

007

ADCS-P31

Zylindergehäuse

BODY UNIT

1

1/4"-18NPT

008

A00100803

Nippel

AIR PLUG

1

009

A00100902

Zwischenstück

BLOCK

1

010

A00101001

Feder

SPRING

1

011

A00101101

Auslösehebel

TRIGGER

1

012

A00101201

Feder

SPRING

1

013

A00101301

Verbindungsbolzen

ROD

1

014

A00101402

Kontrollhebel

TRIGGER'S CONTROL

1

015

A00101501

Feder

SPRING

1

016

A00101601

Ventil

VALVE

1

017

A00101702

Ventilrohr

TUBE

1

018

A00101801

Einstellbolzen

ADJUSTING ROD

1

019

A00101901

Einstellplättchen

ADJUSTING PLATE

1

020

A01102501

Vorderplatte

FRONT PLATE

1

18P

020

A01102503

Vorderplatte

FRONT PLATE

1

22P

021

A00102102

Greifer rechts

RIGHT TEETH

1

18P

022

A00102202

Greifer links

LEFT TEETH

1

18P

021

A01200501

Greifer rechts

RIGHT TEETH

1

22P

022

A01200601

Greifer links

LEFT TEETH

1

22P

023

A00102301

Greiferhalter

TEETH SEAT

2

024

A00102401

Greifergelenk

PLATE

2

025

A03700902

Treiberblock

DRIVER

1

027

A03600102

Treiberführung

DRIVER GUIDE

1

029

A02300404

Formblock

ANVIL

1

030

A03600202

Vorschub

PUSHER

1

031

A02201101

Feder

SPRING

2

032

A02200501

Vorschubblock

ANVIL CAP

1

033

A02201201

Feder

SPRING

1

034

A02200901

Platte

PLATE

1

035

A02202901

Federhalter

TOP GUIDE

1

036

A02201803

Blattfeder

LEAF SPRING

1

037

A02300605

rechte Klammernführung

RIGHT COIL GUIDE

1

18P

037

A03700601

rechte Klammernführung

RIGHT COIL GUIDE

1

22P

038

A02300705

linke Klammernführung

LEFT COIL GUIDE

1

18P

038

A03700701

linke Klammernführung

LEFT COIL GUIDE

1

22P

039

A03600505

Magazin

MAGAZINE SEAT

1

040

A02201301

Befestigungsschaft

SHAFT

1

041

A02201905

Unterlegscheibe

WASHER

1

T =

1.35㎜

042

A02200801

Bolzen

SHAFT

1

043

A02201001

Arretierhebel

LEVER

1

044

A02201402

Abdeckung

COVER

1

045

A02300801

Platte

PLATE

2

47

A02202402

Scheibe

WASHER

2

48

BAI1401

Schalldämpfer

SILENCER

1

501

BAC0604142

Sechskantschr. M4 x 0,7-14

HEX.SOC.HD.BOLT

4

M4 x 0.7-14

503

BAB017537

O-Ring 1,78 x 53,7

O-RING

1

φ1.78 x φ53.7

504

BAD02061

Sechskantmutter M6 x 1

HEX.NUT

1

M6 x 1

505

BAE06094

Scheibe 1/4" x 5/8"x 1T

WASHER

1

1/4" x 5/8" x 1T

506

BAB017076

O-Ring DM 1,78 x DM 7,65

O-RING

1

φ1.78 x φ7.65

507

BAB057476

O-Ring 5,7 x 47,6

O-RING

1

φ5.7 x φ47.6

508

A00104101

Unterlegscheibe 8 x 23 x 1,6

WASHER

1

φ8 x φ23 x 1.6T

510

BAC0604102

Sechskantschraube

HEX.SOC.HD.BOLT

1

M4 x 0.7-10

511

BAA025014

Federstift DM 2,5 - 14

SPRING PIN

1

φ2.5-14

512

BAC0312122

Sechskantschr. M12 x1,75-12

HEX.SOC.HDLESS.

1

M12 x 1.75-12

BOLT

MODEL: RAIA-19-GR & RAIA-22-GR / MERO 18P & 22P

Item

Parts No.

Beschreibung

Description

Q'ty

Spec.

513

A00104401

Auslösehebelschr M4 x0,7- 7

TRIGGER SCREW

2

M4 x 0.7-7

514

BAE01042

Federscheibe M4

SPRING WASHER

2

M4

515

BAA030020

Federstift pin DM 3-20

SPRING PIN

1

φ3-20

516

BAE02042

äuß GreiferbeilagscheibeM4

OUTSIDE TEETH WASHER

1

M4

517

BAC0404102

Sechskantschr. M4 x 0,7-10

HEX.SOC.HD.BOLT

1

M4 x 0.7-10

518

BAA030010

Federstift DM 3-10

SPRING PIN

1

φ3-10

519

BAB017124

O-ring 1,78 - 12,42

O-RING

1

φ1.78 x φ12.42

520

BAB017076

O-Ring DM 1,78 x DM 7,65

O-RING

2

φ1.78 x φ7.65

521

BAB016145

O-Ring 1, 6 - 14,5

O-RING

1

φ1.6 x φ14.5

522

BAB016150

O-Ring 1, 6 - 15

O-RING

1

φ1.6 x φ15

523

BAB016155

O-Ring 1 ,6 - 15,5

O-RING

1

φ1.6 x φ15.5

524

BAB016160

O-Ring 1 ,6 - 16

O-RING

1

φ1.6 x φ16

525

A00104702

Stange 4,9 - 17,5

ROD

2

φ4.9-23

526

BAC0306142

Sechskantschr. M 6 x 1-14

HEX.SOC.HDLESS.

1

M6 x 1-14

BOLT

527

BAC0608162

Sechskantschraube

HEX.SOC.HD.BOLT

1

M8 x 1.25-16

528

BAA050014

Federstift DM 5-14

SPRING PIN

2

φ5-14

529

BAA030010

Federstift DM 3-10

SPRING PIN

4

φ3-10

530

BAC0605142

6.schr. M5 x 0,8-14

HEX.SOC.HD.BOLT

6

M5 x 0.8-14

531

BAD01051

Mutter

LOCK NUT

1

M5 x 0.8

532

A00106201

6.-Senkschraube M5 x 0,8-12

HEX.SOC.FLAT COUNTER

2

M5 x 0.8-12

SNK HD.SCREW

533

A00104501

Stift 3,98 - 13

PIN

4

φ3.98-13

534

A00104602

Stift 6,05 - 8

PIN

2

φ6.05-8

537

BAA060016-R

Federstift

SPRING PIN

2

φ6-16

538

BAA040022

Federstift 4 - 22

SPRING PIN

3

φ4-22

540

BAC0205202

6-Senkschraube M 5x0,8-20

HEX.SOC.FLAT COUNTER

1

M5 x 0.8-20

SNK HD.SCREW

541

BAC0205082

6-Senkschraube M 5x0,8-8

HEX.SOC.FLAT COUNTER

4

M5 x 0.8-8

SNK HD.SCREW

542

BAC0703063

Senkschraube

ROUND HD.SCREW

4

M3 x 0.5-6

543

BAF10252

E-Ring 2,5

E-RING

2

φ2.5

544

BAA040020

Federstift 4 - 20

SPRING PIN

1

φ4-20

545

BAF22002

C-Ring

C-RING

1

φ20

孔用

546

BAF10252

E-Ring 2,5

E-RING

1

φ2.5

548

A00104901

Plastik-Stift

PLASTIC PIN

1

549

A02203102

Unterlegscheibe 8

WAVE WASHER

1

φ10.5

550

C0011201A

Aufhängung

COUNTER BALANCE HANGER

1

551

BAF22002

C-Ring

C-RING

1

φ20

552

BAI1305

LUFTSTECKER ADAPTER

AIR PLUG ADAPTOR

1

1/4"-18NPT→1/4"-19PT

626

628

621

622

659

131 637

612

112

118

614

115

615

616

617

113

618

114

619

625

624

T

129

M

661

623

159

662

126

657

629

62:

631

127

636

627

123

11:

121

124

122

134

128

645

125

632

634

635

633

116

117

638

63:

12: 5

3

2

4

641

656

SBJB.2:.SS!)2/:ϩØ1/:ϩ*

SBJB.33.HS!)3/4ϩØ1/:ϩ*

SBJB.2:.HS!)3/4ϩØ1/:ϩ*

653

119

644

643

133 135

SBUB.2:

SBTB.2:

148

143

156

13:

649

138

141

132

142

145

144

652

149

654

14:

151

648

136

158

147

146

639

642

651

SBTB.23

155!

3125023022

154

153

655

152

65:

663

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE

Seite: /

Ändrg.: 0313

ET

06.03.13 hg C:\Daten Gumbinger\Verwaltung\Konformitaet\Konformitaet 0313.doc

Der Hersteller bzw. Importeur dieses pneumatischen Heftgerätes, die Firma

erklärt in alleiniger Verantwortung, daß das Produkt (s. Bedienungsanleitung), auf das sich diese Erklärung

bezieht, mit der folgenden Norm übereinstimmt:

DIN EN ISO 12100: „Sicherheit von Maschinen“

gemäß den Bestimmungen der EG-Maschinenrichtlinie (2006/42 EG).

The manufacturer resp. importer of this pneumatic stapling tool, the company

declares under sole responsibility that the product (see attached instruction manual), to which the declaration

relates, is in confirmity with the following standard:

DIN EN ISO 12100: „Safety of Machinery“

following the provisions of the Directive Regarding Machinery (2006/42 EC).

Nous, le manufacteur resp. importeur de cet appareil pneumatique, la maison

déclarons sous notre seule responsabilité que le produit (selon mode d'emploi) auquel se réfère cette déclaration

est conforme a la norme

DIN EN ISO 12100: „Sécurité des Machines“

Conformément aux dispositions de Directive des Machines (2006/42 CE).

Noi

dichiariamo che chesto prodotto è conforme alle norme o ad altri documenti normativi

DIN EN ISO 12100: « sicurezza macchina »

In conformita alle dispoizioni delle Directiva Macchine (2006/42 CE).

MEZGER Heftsysteme GmbH

Saganer Straße 24

D-90475 Nürnberg

MEZGER Heftsysteme GmbH

Saganer Straße 24

D-90475 Nürnberg (Germany)

MEZGER Heftsysteme GmbH

Saganer Straße 24

D-90475 Nürnberg (Allemagne)

Nürnberg, 07.03.13

................................................................................................

ppa/p.p. Gumbinger

Prokurist und Unit Manager

Authorised representative and Unit Manager

Fondé de pouvoir et Unit Manager

MEZGER Heftsysteme GmbH

Saganer Straße 24

D-90475 Nürnberg (Allemagne)

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

MG MERO 18 P Operating Instructions Manual

- Categoria

- Cucitrici

- Tipo

- Operating Instructions Manual

in altre lingue

- English: MG MERO 18 P

Altri documenti

-

Hitachi N 5024A2 Manuale utente

-

Hitachi N 5008AC Manuale utente

-

Parkside PET 25 A1 Operation and Safety Notes

-

Parkside PET 25 B1 Operation and Safety Notes

-

Parkside PDT 40 A1 Operation And Safety Notes Original Operating Instructions

-

Parkside PET 25 A1 Original Operation Manual

-

Duplo DBM-120 Manuale utente

-

Stanley TRE550 Manuale del proprietario

-

Parkside 331116_1907 Translation Of The Original Instructions

-

Parkside 286098 Translation Of The Original Instructions