1390306

14 06 2016

TRL255B

ATTENZIONE! Prima di usare la macchina, leggete attentamente le istruzioni per l’uso

CAUTION! Before starting the machine, read the operating instructions carefully

Troncatrice radiale

ISTRUZIONI PER L’USO E ISTRUZIONI DI SICUREZZA

Istruzioni originali

Table saw

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

Translation of the original instructions

- 2 -

- 3 -

- 4 -

- 5 -

- 6 -

i

Questo istruzioni riportano le informazioni e quanto ritenuto neces-

sario per il buon uso, la conoscenza e la normale manutenzione della

macchina. Esse non riportano le informazioni sulle tecniche delle

lavorazioni del legno alle macchine utensili né trattano l’argomento

sulle tipologie e grado di lavorabilità dei vari tipi di legno; l’utilizzatore

troverà maggiori notizie su libri e pubblicazioni specifiche o parteci-

pando a corsi di specializzazione.

Le avvertenze d’uso e le norme di manutenzione si riferiscono a ne-

cessità normali di esercizio. Dalla loro osservanza e dall’adempimento

di quanto prescritto, dipende il regolare funzionamento, la durata e

l’economia di esercizio della macchina.

Queste istruzioni sono parte integrante della macchina e devono ac-

compagnarla in caso di riparazione o di rivendita. Conservate con cura

ed a portata di mano la documentazione fornita in modo da poterla

consultare in caso di necessità.

Per eventuali riparazioni o revisioni che comportino operazioni di

una certa complessità è necessario rivolgersi ai Centri di Assistenza

autorizzati che dispongono di personale specializzato.

La Ditta costruttrice declina qualsiasi responsabilità per danni dovuti a

negligenza, alla mancata osservanza di quanto descritto nel presente

manuale e a danni diretti e/o indiretti causati da un uso improprio

della macchina.

La negligenza a quanto indicato, un cattivo ed inadeguato uso della

macchina e l’esecuzione di modifiche non autorizzate, possono essere

causa di annullamento della garanzia. La prevenzione di qualsiasi

inconveniente è quindi vincolata alla scrupolosa osservanza di quanto

prescritto.

Verificate, all’atto dell’acquisto, che la macchina sia integra e completa.

ATTENZIONE! Prima di usare la macchina, per eseguire cor-

rettamente il trasporto, la messa in servizio, l’avviamento, l’uso,

l’arresto e la manutenzione, leggete ed applicate attentamente le

istruzioni di seguito riportate che fanno riferimento alle figure ed

ai dati tecnici. Prima di iniziare il lavoro prendete familiarità con i

comandi e con il corretto uso della macchina assicurandovi di saper

arrestarla in caso di emergenza. L’uso improprio della macchina

può provocare gravi ferite e danni alle cose. Pensate sempre alla

vostra e altrui sicurezza e comportatevi di conseguenza.

ATTENZIONE! La macchina è destinata esclusivamente per uso

hobbystico ed è idonea ad eseguire tagli perpendicolari, inclinati

ed obliqui di pezzi di legno a forma di parallelepipedo. Non è con-

sentita la lavorazione di metalli, materiali infiammabili e materiali

che generano polveri e nebbie pericolose o nocive alla salute.

Ogni altro impiego, diverso da quello indicato in queste istruzioni,

può recare danno alla macchina e costituire serio pericolo per le

persone e le cose.

DESCRIZIONE MACCHINA (FIG.A)

1 Interruttore acceso/spento

2 Impugnatura

3 Maniglia per trasporto

4 Leva bloccaggio protezione

5 Pulsante bloccaggio lama (solo per sostituzione lama)

6 Motore

7 Lama a disco

8 Protezione lama

9 Basamento

10 Piano girevole

11 Guida di appoggio pezzo

12 Morsa bloccapezzo

13 Supporti pezzo

14 Vite bloccaggio scorrimento testa

15 Vite bloccaggio rotazione piano girevole

16 Aste di guida scorrimento testa

17 Spina e cavo di alimentazione

18 Braccio

19 Leva bloccaggio inclinazione testa

20 Sacchetto raccoglitrucioli

21 Collettore per aspirazione trucioli/polvere

22 Vite bloccaggio morsa

23 Vite bloccaggio supporti pezzo

24 Gancio per fissaggio cavo

25 Inserto in plastica del piano girevole

26 Blocco del piano girevole

27 Viti di battuta del braccio

28 Vite per regolazione profondità del taglio

29 Piedistallo (se presente)

30 Fori per fissaggio al banco/piedistallo

31 Fori per fissaggio piedistallo

32 Sblocco interruttore (se presente)

34 Listello mobile del gruidapezzo

35 Volantino di fissaggio del listello mobile del guidapezzo

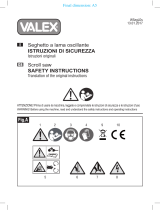

DESCRIZIONE MARCATURE E SIMBOLI (FIG.B)

1 Modello macchina e dati tecnici.

2 Numero di matricola o numero lotto, anno di fabbricazione.

3 ATTENZIONE!

4 Leggete attentamente le istruzioni prima dell’uso.

5 Attenzione! Pericolo taglio e schiacciamento mani. E’ obbliga-

torio indossare guanti di protezione.

6 Attenzione! Pericolo lancio materiale e polveri dannose. E’

obbligatorio indossare occhiali di protezione e una maschera

a protezione delle vie respiratorie.

7 Attenzione! Pericolo rumore elevato. E’ obbligatorio indossare

cuffie di protezione dell’udito.

8 Attenzione! Pericolo di scossa elettrica. Alcune parti della

macchina sono in tensione elettrica, non toccatele e mantenete

una distanza di sicurezza.

9 Attenzione! Pericolo lama in movimento. Mantenete le mani

lontano dalla lama.

10 Attenzione! Prima di ogni controllo, regolazione o manuten-

zione, staccate l’alimentazione elettrica scollegando la spina

della macchina. In caso di cavo di alimentazione danneggiato,

estraete la spina dalla presa della rete di alimentazione prima

di procedere ad un controllo.

11 Attenzione! Pericolo taglio e schiacciamento mani. Mantenete

una distanza di sicurezza dalla lama e dalla zona di taglio.

DATI TECNICI

Tensione di aliment. e frequenza nomin. 230V~50Hz

Potenza nominale motore 1900 W

Velocità di rotazione a vuoto 4860 min-1

Classe isolamento macchina II

Pressione acustica LpA 97dB(A) K=3 *

Potenza acustica LwA 110dB(A) K=3 *

Vibrazioni sull’impugnatura 3,82m/s2 K=1.5 **

Dimensioni totali macchina (b x l x h) 730x880x570 mm

(con piano girevole a 0°)

Peso macchina 11 kg

Lama circolare per legno, corpo in acciaio e denti con placchette di

metallo duro

Diametro est./int. 254/25,4 mm

Spessore denti 2,8 mm

Prestazioni:

Inclinazione testa di taglio per tagli inclinati: 0°-45° senso antiorario

Rotazione testa di taglio per tagli obliqui: 0°-45° a destra / 0°-45° a

sinistra con 9 posizioni di arresto predefinite.

Corsa radiale: 173 mm

Dim. max di taglio (altezza x profondità)

Inclinazione testa 0° Inclinazione testa 45°

senso antiorario

Rotazione testa 0° 70x310 mm 40x310 mm

Rotazione testa 45° a

destra/a sinistra 70x210 mm 40x210 mm

- 7 -

NORME DI SICUREZZA GENERALI

1) I SACCHI DI NYLON NON SONO DEI GIOCATTOLI

ATTENZIONE! Pericolo di soffocamento. I sacchi di nylon

presenti nell’imballaggio possono provocare soffocamento se

infilati sul capo e devono essere tenuti lontani dai bambini; se non

più riutilizzabili devono essere tagliati e smaltiti nei rifiuti.

ATTENZIONE! Quando si usano utensili, rispettare sempre le misure

di sicurezza basilari perridurre il rischio di incendi, scosse elettriche

e danni alle Persone. Leggere tutte le istruzioni prima di utilizzare

il prodotto e conservarle.

2) PERSONE ABILITATE ALL’USO DELLA MACCHINA

L’uso della macchina è vietato ai bambini e ai ragazzi, alle persone

inesperte non perfettamente a conoscenza delle istruzioni d’uso

contenute nel presente manuale ed agli estranei. Leggi e regolamenti

locali possono prevedere una età minima per l’uso della macchina.

L’operatore deve essere adeguatamente addestrato all’utilizzo, alla

regolazione e al funzionamento in sicurezza della macchina.

3) RESPONSABILITA’ DELL’OPERATORE

L’operatore è responsabile verso terzi di eventuali incidenti o danni

a persone e cose causati dall’uso della macchina.

4) MANTENETE UNA POSIZIONE DI LAVORO STABILE E SICURA

Quando lavorate mantenete una posizione di lavoro stabile e sicura.

5) FATE ATTENZIONE ALLA ZONA DI LAVORO

Fate attenzione alle mani, al pezzo in lavorazione, all’utensile di

taglio, ai trucioli prodotti dalla lavorazione e in generale a tutte le

parti in movimento.

6) OPERATE CON ATTENZIONE

Non distraetevi e controllate sempre quello che state facendo:

usate il buon senso. Non usate mai la macchina in condizioni di

stanchezza, malessere, sotto l’effetto di alcool, droghe o farmaci

che riducono la vigilanza.

7) MANTENETE UNA DISTANZA DI SICUREZZA

Mantenete le persone e gli animali lontano dalla vostra zona di

lavoro e dalla macchina. Non toccate le parti che sono in tensione

elettrica.

8) PROTEGGETE IL VOSTRO CORPO

L’uso della macchina genera rumore, calore, polveri, fumi, vi-

brazioni, il lancio di trucioli e schegge. Operate sempre con dei

dispositivi di protezione individuale a norma per evitare lesioni al

corpo, alle mani, agli occhi, all’udito, alle vie respiratorie. Indossate

abbigliamento robusto con maniche e polsini stretti, occhiali di pro-

tezione, guanti da lavoro, cuffie antirumore, maschera antipolvere

e calzature antinfortunistiche. Non indossate abbigliamento largo,

sciarpe, nastri di tessuto e gioielli perché potrebbero impigliarsi

nelle parti in movimento della macchina. Indossare copricapi di

protezione per raccogliere i capelli lunghi. Gli occhiali da vista non

sono adatti a proteggere gli occhi.

9) EFFICIENZA DELLA MACCHINA

Controllate sempre l’efficienza e l’integrità della macchina; se

in cattivo stato può provocare gravi incidenti. Non utilizzate la

macchina se l’interruttore non consente di accendere o spegnere

la macchina.

10) INTEGRITA’ DELLA MACCHINA

Non togliete alcun componente dalla macchina se non espressa-

mente indicato nelle presenti istruzioni e non modificate in alcun

modo la configurazione originale.

11) NON SMONTATE LA MACCHINA

Non smontate per alcun motivo la macchina. Non utilizzate la

macchina senza le protezioni.

12) NON MANOMETTETE ALCUN COMPONENTE DELLA MACCHINA

Non manomettete, non modificate, non togliete alcun componente

della macchina.

13) VERIFICATE LA SOLIDITA’ DELLA MACCHINA

Verificate periodicamente il serraggio della viteria della macchina

e il fissaggio della lama.

14) UTILIZZATE LA MACCHINA IN UN LUOGO BEN AERATO E VENTI-

LATO

La macchina deve essere utilizzata in un luogo ben aerato e

ventilato in modo assicurare un sufficiente raffreddamento e un

ricambio d’aria del locale.

15) NON UTILIZZATE LA MACCHINA IN AMBIENTI PERICOLOSI

Non utilizzate la macchina in un ambiente con pericolo di esplo-

sione e/o incendio, in locali poco ventilati, in presenza di liquidi,

umidità, gas, vapori, acidi ed elementi infiammabili e/o esplosivi.

16) TRASPORTO DELLA MACCHINA

Le operazioni di trasporto della macchina devono essere eseguite

con attenzione. Afferrate la macchina solo sulla maniglia apposita.

Non trasportate la macchina tirandola per il cavo di alimentazione

o altre sue parti.

17) POSIZIONAMENTO DELLA MACCHINA

Posizionate e fissate la macchina mediante bulloneria sopra un

banco da lavoro o piedistallo con superficie piana, solida e inin-

fiammabile che dovrà supportare il peso totale e le sollecitazioni

derivate dall’uso. Fissate il piedistallo al pavimento. E’ vietato usare

la macchina senza fissarla solidamente e su superfici infiammabili

come legno, plastica ecc. Periodicamente verificate il fissaggio.

18) LAVORATE CON LUMINOSITA’ ADEGUATA

Lavorate solo durante le ore di buona luminosità o con una illumi-

nazione artificiale corrispondente.

19) NON ESPONETE LA MACCHINA AGLI AGENTI ATMOSFERICI

Non lasciate la macchina esposta agli agenti atmosferici quali

pioggia, nebbia, sole, alte o basse temperature.

20) NON TOCCATE LA MACCHINA SE SIETE BAGNATI

Non usare la macchina a piedi nudi o bagnati. Non toccare la

macchina con le mani bagnate.

21) CONTROLLO PRIMA DI AVVIARE LA MACCHINA

Prima di inserire la spina alla rete elettrica verificare che l’interrut-

tore sia su OFF “O” (spento), che il pezzo in lavorazione sia ben

posizionato e supportato, che la testa di taglio sia regolata e che

le chiavi di servizio siano state tolte. Non utilizzate la macchina

se gli inserti del piano girevole sono usurati e la protezione lama

è rotta o non funziona.

22) VERIFICHE CORRETTO MONTAGGIO

Non utilizzate la macchina se il sacco raccoglitrucioli o il tubo

dell’aspiratrucioli/polvere (non in dotazione) non sono collegati

al collettore di scarico.

23) VERIFICHE FUNZIONALI

Controllate che la protezione mobile della lama non sia danneggiata

e che il suo movimento segua la salita/discesa della testa di taglio.

Non utilizzate la macchina se la protezione non copre la lama nella

posizione di riposo.

24) POSIZIONATE BENE IL PEZZO IN LAVORAZIONE

E’ molto importante per la vostra sicurezza che il pezzo in la-

vorazione sia ben posizionato contro la guida poggiapezzo, che

sia serrato dalla morsa e che sia supportato alle due estremità

mediante piedistalli (non in dotazione). Non tagliate pezzi a sezione

circolare ma solo pezzi che hanno lati piani e perpendicolari come

tavole, listelli ecc.; non tagliate rami o tronchi d’albero. Non tagliate

pezzi che contengono chiodi o viti oppure avvolti da nastro, corde

o altro. Non tagliate pezzi in costa ma appoggiate il lato lungo

sulla base della macchina.

25) MATERIALI NON CONSENTITI

Non è consentita la lavorazione di metalli, materiali infiammabili

ed esplodenti, materiali che generano polveri e nebbie pericolose

o nocive alla salute.

26) PREVENITE POSSIBILI INCIDENTI

Effettuate sempre una prova di funzionamento a vuoto prima di

iniziare il lavoro; durante questo periodo fate in modo che nessuno

si avvicini alla macchina e mantenete una distanza di sicurezza.

Utilizzate sempre occhiali, guanti, maschera e cuffie di protezione.

A macchina in funzione non toccate la lama, pericolo di lesioni

gravi! Dopo aver sostituito dei componenti effettuate sempre un

controllo generale prima di accingervi alla lavorazione.

27) UTILIZZATE SOLO LAME ADATTE A QUESTA MACCHINA

Questa macchina è stata progettata per utilizzare lame specifiche

per il taglio del legno; è vietato utilizzare lame adatte ad altri materiali

e dischi abrasivi. Non utilizzate lame realizzate in acciaio super

rapido HSS. La velocità max stampigliata sulla lama deve essere

sempre maggiore a quella indicata nei dati tecnici della macchina.

Utilizzate lame conformi alle normative in vigore nel paese in cui

vi trovate.

28) MANEGGIATE LA LAMA CON ATTENZIONE

La lama ha parti molto taglienti: maneggiatela con attenzione e

indossate sempre guanti protettivi, pericolo di lesioni gravi!

29) UTILIZZATE SOLO LAME IN PERFETTE CONDIZIONI

Non utilizzate lame danneggiate e deformate; se usurata sostituitela

con una nuova.

30) NON SOLLECITATE LA LAMA

Non sottoponete la lama a sollecitazioni quali: urti, flessioni, pres-

- 8 -

sioni eccessive, tensioni termiche, variazioni irregolari di velocità,

vibrazioni. In queste condizioni l’utensile ha una durata limitata e

può rompersi senza preavviso con pericoloso lancio di frammenti.

31) Sostituite l’inserto di plastica del piano (Fig.A pos.25) girevole

quando usurato.

32) A MACCHINA IN FUNZIONE NON TOCCATE LE PARTI IN MO-

VIMENTO

ATTENZIONE! Pericolo di ferite gravi! Durante il funzionamen-

to non toccate la lama e tutte le parti in movimento. Fate attenzione

al movimento delle braccia e delle mani. Togliete il pezzo solo dopo

aver spento la macchina e scollegato il cavo di alimentazione dalla

presa elettrica.

33) MACCHINA NON OPERATIVA

Posizionare l’interruttore su OFF “O” (spento), staccate l’alimenta-

zione elettrica scollegando la spina della macchina quando: non la

usate, la lasciate incustodita, la trasportate, il cavo di alimentazione

è danneggiato, fissate e smontate il pezzo in lavorazione, effettuate

le regolazioni, la manutenzione e la pulizia.

34) ATTENDETE L’ARRESTO COMPLETO DELLA MACCHINA

Il motore, le parti meccaniche rotanti e la lama girano ancora per

diversi secondi dopo aver spento la macchina. Durante la fase di

arresto queste parti non devono essere toccate, pericolo di lesioni

gravi!

35) NON ABBANDONATE LA MACCHINA FINCHE’ E IN FUNZIONE

Non abbandonate la macchina finché è in funzione e nella fermata

rimanete accanto fino al completo arresto delle parti in movimento.

36) MANTENETE PULITO E IN ORDINE IL POSTO DI LAVORO

Il disordine e la mancanza di pulizia sono fonti di pericolo. Fate in

modo che attorno alla macchina non ci siano attrezzi od oggetti

che potrebbero essere danneggiati. Non posizionate attrezzi od

oggetti sulla macchina che potrebbero cadere accidentalmente.

Eliminate frequentemente i residui di taglio dalla macchina e dal

pavimento; effettuate l’operazione solo a macchina ferma e con

testa di taglio nella posizione di riposo.

37) POLVERI DANNOSE ALLA SALUTE

Le polveri di alcuni tipi di legno sono molto dannose alla salute.

Indossate le protezioni alle vie respiratorie, evacuate i trucioli

prodotti e dotate il locale di un estrattore per il ricambio dell’a-

ria.

38) LE RIPARAZIONI DEVONO ESSERE EFFETTUATE DA PERSONALE

AUTORIZZATO

Non tentate di riparare la macchina o di accedere a organi interni,

rivolgetevi sempre presso i centri assistenza autorizzati. Interventi

effettuati da personale non autorizzato fa decadere immediatamen-

te la garanzia e potrebbe generare pericolo. Conservate la prova

di acquisto per eventuali interventi in garanzia.

39) RICHIEDETE E FATE INSTALLARE SOLO RICAMBI ORIGINALI

Richiedete e fate installare solo ricambi originali, rivolgetevi al

vostro rivenditore di fiducia. L’utilizzo di ricambi non originali fa

decadere la garanzia e potrebbe generare un serio pericolo.

40) RIPONETE LA MACCHINA IN UN LUOGO SICURO

Quando non la usate, riponete la macchina in un luogo asciutto e

lontano dalla portata dei bambini.

41) RISCHI RESIDUI

ATTENZIONE! La scrupolosa osservanza di queste istruzioni

con l’utilizzo dei mezzi di protezione individuale minimizzano i rischi

di incidente ma non li eliminano completamente.

42) ATTENETEVI SEMPRE A QUESTE ISTRUZIONI

Utilizzate la macchina solo nei modi descritti in queste istruzioni.

Non utilizzatela per scopi a cui non è destinata.

NORME DI SICUREZZA ELETTRICHE

1) NON TOCCATE LE PARTI IN TENSIONE ELETTRICA

ATTENZIONE! Pericolo di scossa elettrica. Alcune parti della

macchina sono in tensione elettrica.

2) MANTENETE I BAMBINI E GLI ANIMALI LONTANI DAGLI APPA-

RECCHI ELETTRICI

I bambini e gli animali devono essere tenuti lontani dagli apparecchi

collegati alla rete elettrica.

3) VERIFICATE LA TENSIONE DI ALIMENTAZIONE

La tensione di alimentazione deve corrispondere a quella dichiarata

sulla targhetta dati tecnici. Non utilizzate altro tipo di alimentazione.

4) UTILIZZATE UN APPARECCHIO SALVAVITA

È consigliato l’uso di un apparecchio salvavita sulla linea di alimen-

tazione elettrica per un campo di intervento secondo le normative

vigenti nel Paese di utilizzo; consultate il vostro elettricista di

fiducia.

5) COLLEGAMENTO ALLA RETE ELETTRICA

Prima di collegare o scollegare la macchina dalla rete di alimen-

tazione, assicuratevi che l’interruttore si trovi nella posizione OFF

“O” (spento).

6) NON MANOMETTETE IL CAVO DI ALIMENTAZIONE

Non manomettete il cavo di alimentazione. Non sostituite la spina

del cavo di alimentazione; utilizzate solo una presa adattata alla

spina della macchina. Utilizzate il cavo di alimentazione esclusi-

vamente per gli scopi a cui è destinato.

7) CONTROLLATE IL CAVO DI ALIMENTAZIONE

Il cavo di alimentazione e il cavo di prolunga (se presente) devono

essere controllati periodicamente e prima di ogni uso per vedere

se presentano segni di danneggiamento o di invecchiamento. Se

non risultassero in buone condizioni scollegate immediatamente il

cavo e non usate la macchina ma fatela riparare presso un centro

di assistenza autorizzato.

8) MANTENETE IL CAVO DI ALIMENTAZIONE IN POSIZIONE SICURA

Tenete il cavo di alimentazione e il cavo di prolunga (se presente)

lontani dalla zona di lavoro e dall’utensile di taglio, da superfici

umide, bagnate, oliate, da bordi taglienti, da fonti di calore, da

combustibili e da zone di transito veicolare e pedonale.

9) NON CALPESTATE O SCHIACCIATE IL CAVO DI ALIMENTAZIONE

Non passate mai sopra il cavo di alimentazione. Siate coscienti

della sua posizione in ogni momento.

10) NON USATE LA MACCHINA IN PRESENZA DI LIQUIDI

Non bagnate la macchina con liquidi e non esponetela ad ambienti

umidi. Non lasciatela all’aperto.

11) UTILIZZATE UN CAVO DI PROLUNGA IDONEO ALLA MACCHINA

Utilizzate solamente cavo per prolunga omologato idoneo alla

potenza della macchina che utilizzate e dimensionato in base alla

sua lunghezza; consultate il vostro elettricista di fiducia.

12) SCOLLEGATE LA MACCHINA IMPUGNANDO SOLO LA SPINA

Per estrarre la spina dalla presa impugnate solo la spina ; non

tirare il cavo di alimentazione!

13) EVITATE IL CONTATTO DEL CORPO CON SUPERFICI MESSE A

MASSA O A TERRA

Evitate il contatto del corpo con superfici messe a massa o a

terra, come frigoriferi, termosifoni, tubi e serramenti metallici

ecc. E’ consigliato l’utilizzo di una pedana che isoli elettricamente

l’utilizzatore dal pavimento.

RISCHI RESIDUI

Queste illustrazioni mostrano i rischi principali nell’uso della macchina.

Leggete attentamente il libretto istruzioni della macchina.

Lancio di materiale e polvere verso gli

occhi ed il corpo dell’operatore. Indos-

sate occhiali di protezione e maschera

antipolvere.

Rumore elevato generato dalla mac-

china. Indossate cuffie a protezione

dell’udito.

- 9 -

Lama e schegge di legno che provo-

cano ferite alle mani. Indossate guan-

ti protettivi e mantenete una distanza

di sicurezza dalla zona di taglio.

Rischio di scossa elettrica con pe-

ricolo di morte. Non toccate le parti

in tensione elettrica e mantenete una

distanza di sicurezza. Prima di ogni

manutenzione scollegate la spina

dalla presa di alimentazione.

TERMINOLOGIA ADOTTATA

MACCHINA

Assieme di tutti i componenti elettrici e meccanici.

TRONCATRICE RADIALE

Macchina destinata al taglio di pezzi di legno come tavole, listelli ecc.

con lati piani e perpendicolari; il pezzo rimane fermo mentre la testa

di taglio effettua tutti i movimenti.

TESTA DI TAGLIO

Parte composta dal motore, lama di taglio, impugnatura, interruttore

e protezioni mobili/fisse che trasla rispetto al pezzo.

INTERRUTTORE

Parte il cui azionamento ha funzione di avviare e spegnere la macchina.

UTENSILE O LAMA

Attrezzo circolare destinato ad asportare materiale dal pezzo.

CONTRACCOLPO

Movimento improvviso verso l’alto della testa di taglio durante la fase

di troncatura, dovuto al contatto della lama con elementi duri come

chiodi, viti, nodi del legno ecc.

OPERATORE - UTILIZZATORE

E’ la persona incaricata di installare, far funzionare, regolare, manuten-

zionare, pulire la macchina. E’ la persona responsabile della macchina.

TRASPORTO E SOLLEVAMENTO (FIG. A-C)

ATTENZIONE! La Ditta Costruttrice declina ogni responsabilità

per gli eventuali danni diretti e/o indiretti causati da errati trasporti

o sollevamenti.

ATTENZIONE! Prima effettuare le seguenti operazioni assicura-

tevi che la spina della macchina sia scollegata dalla rete elettrica.

Le operazioni di trasporto e sollevamento della macchina devono

essere eseguite con attenzione per evitare incidenti e danni.

1)Tirate completamente la testa di taglio verso di voi in modo che le

barre di scorrimento (pos.16) siano rientrate sopra il basamento

(pos.9); fissate la vite che impedisce lo scorrimento (pos.14), la

vite pos.15 e la leva pos.19.

2)Per sollevare la macchina utilizzate la maniglia (pos.3) posta

sulla parte superiore. Sollevare la macchina con estrema cautela

e trasferitela lentamente, senza scosse o movimenti bruschi. Non

trasportatela tirandola per il cavo di alimentazione o altre sue parti.

MESSA IN SERVIZIO (FIG. A)

ATTENZIONE! La Ditta Costruttrice declina ogni responsabilità

per gli eventuali danni diretti e/o indiretti causati da errate instal-

lazioni e allacciamenti.

ATTENZIONE! Prima effettuare le seguenti operazioni assicura-

tevi che la spina della macchina sia scollegata dalla rete elettrica.

La macchina è fornita con alcuni componenti smontati e prima di

usarla deve essere pulita ed installata.

Nella scelta della posizione della macchina è opportuno considerare:

- che la posizione prevista non sia umida e sia al riparo dagli agenti

atmosferici.

- che la zona di appoggio risulti perfettamente in piano, su di un

pavimento antisdrucciolo e con una capacità di carico adeguata al

peso della macchina.

- che attorno alla macchina sia prevista un’ampia zona operativa libera

da impedimenti.

- che il locale sia custodito e chiuso per impedire il libero accesso.

- che vi sia una buona illuminazione.

- che sia posizionata in vicinanza dell’interruttore generale con diffe-

renziale.

- che l’impianto di alimentazione sia dotato di messa a terra conforme

alle norme.

- che la temperatura ambiente sia compresa tra 10° e 35° C.

- che l’ambiente di lavoro non sia in atmosfera esplosiva.

Togliete la parte superiore dell’imballo e verificate visivamente la

perfetta integrità della macchina e dei componenti; a questo punto

eliminate l’imballo e procedete ad una accurata pulizia per togliere gli

eventuali oli protettivi utilizzati per il trasporto.

ATTENZIONE! Prima di tagliare la fascetta in plastica che tiene

abbassata la testa di taglio, mantenete premuta verso il basso

l’impugnatura (pos.2) in modo che la testa di taglio non scatti

improvvisamente verso l’alto.

1) Procuratevi un banco (non in dotazione) su cui appoggerete la

macchina e una serie di bulloneria (non in dotazione) per fissarla

ad esso. Se all’interno dell’imballo è presente un piedistallo (fig. L

pos.29) procedete al suo montaggio come illustrato in figura; fissate

il piedistallo al pavimento.

2) Posizionate la macchina e fissatela in maniera ben salda utilizzando

i fori presenti sulla base (Fig.L pos.30).

3) Procedete al montaggio dei componenti come illustrato in figura; in

caso di dubbio rivolgetevi al vostro rivenditore. Alcuni componenti

devono essere montati solo se necessari alla lavorazione che vi

accingete ad effettuare.

4) Avvitate il pomello (pos.15) che permette il bloccaggio del piano

girevole.

5) Montate i 2 supporti laterali (pos.13) e fissateli con i volantini

(pos.23). Montate la morsa bloccapezzo (pos.12) e il sacchetto

raccoglitrucioli (pos.20).

6) Verificate che lama (pos.7) sia ben fissata e che possa ruotare

liberamente (per fissaggio vedere capitoli seguenti).

7) Verificate il corretto funzionamento della protezione lama (pos.8);

abbassando e sollevando la testa di taglio la protezione in automatico

scopre o racchiude la lama. In caso di guasto al meccanismo della

protezione non avviare la macchina ma rivolgetevi ad un centro

assistenza autorizzato.

8) Predisponete la morsa bloccapezzo (pos.12) nel suo alloggiamento e

fissatela con il volantino (pos.22). nb. la morsa può essere montata

a seconda della necessità nella parte sinistra oppure destra del piano

di lavoro.

Assicuratevi di avere montato correttamente tutte le parti, verificate la

solidità dell’assemblaggio e la stabilità della macchina.

REGOLAZIONI (FIG. A)

ATTENZIONE! Prima di ogni controllo o regolazione posizionate

l’interruttore su OFF”O” (spento) e staccate l’alimentazione elet-

trica scollegando la spina della macchina.

La macchina viene fornita già regolata e non necessita di particolari

regolazioni; se necessario effettuate le seg. operazioni.

- 10 -

REGOLAZIONE PERPENDICOLARITA’ LAMA E INCLINAZIONE DEL

BRACCIO POS.18

Per effettuare la regolazione della perpendicolarità della lama rispetto

al piano girevole (pos.10) e l’inclinazione del braccio (pos.18), inter-

venite sulle 2 viti (pos.27); è utile utilizzare una squadretta a 90° (non

in dotazione) posta tra lama e piano.

REGOLAZIONE PROFONDITA’ DI TAGLIO (CORSA CIRCOLARE DELLA

TESTA DI TAGLIO)

Per effettuare la regolazione della profondità di taglio intervenite sulla

posizione della vite (pos.28).

AVVIAMENTO E ARRESTO

ATTENZIONE! Prima di avviare la macchina è obbligatorio in-

dossare occhiali, guanti, cuffie e maschera di protezione (non in

dotazione alla macchina).

ATTENZIONE! Durante l’avviamento e l’arresto della macchina

fate in modo che nessuno si avvicini alla macchina. Mantenete

una distanza di sicurezza da tutte le parti in movimento e dalla

zona di taglio.

ATTENZIONE! Il motore, le parti meccaniche rotanti e la lama

girano ancora per diversi secondi dopo aver spento la macchina.

Durante la fase di arresto queste parti non devono essere toccate,

pericolo di lesioni gravi!

Prima di mettere in funzione la macchina, verificate l’integrità dei

componenti e controllate che le viteria sia serrata.

AVVIAMENTO

1) Verificate che il pezzo sia ben posizionato e supportato.

2) Verificate che le chiavi di servizio siano state riposte.

3) Inserite la spina del cavo di alimentazione alla presa.

4) Posizionatevi di fronte alla macchina ed assicuratevi che persone

ed animali siano lontani.

5) Con la mano destra afferrate saldamente l’impugnatura (pos.2)

6) Con il pollice premete lo sblocco interuttore (pos.32, se presente)

7) Per avviare premete l’interruttore (pos.1).

L’interruttore è del tipo ad “azione mantenuta”; pertanto la macchina

rimarrà accesa per il tempo che voi mantenete premuto l’interruttore.

Se osservate delle anomalie di funzionamento spegnete la macchina

e consultate il capitolo “Ricerca guasti ed interventi ammessi”.

ARRESTO

Per arrestare la macchina rilasciate l’interruttore (pos.1).

Quando non lavorate spegnete la macchina e staccate la spina dalla

presa.

AVVERTENZE E CONSIGLI D’USO

ATTENZIONE! Prima di ogni controllo o regolazione posizionate

l’interruttore su OFF”O” (spento) e staccate l’alimentazione elet-

trica scollegando la spina della macchina.

Dopo aver letto attentamente i capitoli precedenti, seguite scrupolosa-

mente queste avvertenze e consigli che vi permetteranno di ottenere

il massimo delle prestazioni dalla vostra macchina. Procedete con

calma, solo dopo aver acquisito una buona esperienza riuscirete a

sfruttarne a fondo le potenzialità. Per prendere familiarità con tutti i

comandi, fate delle prove di utilizzo a vuoto senza montare pezzi in

lavorazione.

OPERATORE

La posizione normale dell’operatore è quella davanti la macchina, con

mano destra sull’impugnatura; solo in questa posizione è possibile

eseguire il taglio.

Attenzione! Mantenete le mani e il viso lontano dalla lama e dalla

zona di taglio, pericolo di lesioni gravi!

PEZZO IN LAVORAZIONE

Il pezzo che tagliarete dovrà avere forma, dimensioni e peso compatibili

con la macchina.

Sul pezzo segnate con una riga la linea di taglio; posizionatelo sopra

la base della macchina (pos.9-10) facendo attenzione a non toccare

la lama ed appoggiatelo contro la guida di appoggio (pos.11). Il lato

più lungo del pezzo deve essere appoggiato alla base; non tagliate

pezzi con lato maggiore messo in verticale.

Attenzione! Per la vostra sicurezza è importante che la macchina

sia fissata al banco o piedistallo.

Su questa macchina si possono montare pezzi di dimensioni definite

(spessore H e profondità P, vedasi cap. Dati Tecnici) a seconda del

tipo di taglio; per supportare i pezzi lunghi è necessario dotarsi di una

coppia di piedistalli da sistemare a destra e a sinistra della macchina,

che impediscono ai 2 spezzoni di ribaltarsi con pericolo per l’operatore.

Allineate la linea precedentemente tracciata con il piano teorico che

la lama effettuerà nel movimento verso il basso.

La morsa (pos.12) è indispensabile per bloccare il pezzo: avvitate la

vite sul pezzo.

Attenzione! Per la vostra sicurezza è importante che il pezzo sia

correttamente bloccato. Non tagliate pezzi a sez. circolare, legni

vecchi o fragili, legni irregolari, legni con crepe, legni con chiodi o

viti, rami o tronchi. Non tagliate pezzi corti. Effettuate sempre uno

scrupoloso controllo visivo del pezzo.

Attenzione! Rammentate sempre che un contraccolpo provoca il

sollevamento improvviso della testa di taglio ed è possibile che

l’impugnatura vi sfugga dalla mano.

UTENSILE LAMA

Verificate prima di ogni utilizzo la sua perfetta integrità, l’assenza di rot-

ture e deformazioni. Periodicamente controllate l’affilatura della lama.

Quando è necessario sostituirla seguite le indicazioni dei capitoli

seguenti.

Attenzione! L’efficienza e la perfetta integrità della lama producono

un miglior risultato e minimizzano il rischio di incidenti.

ASPIRAZIONE TRUCIOLI E POLVERE

La macchina è dotata di un collettore (pos.21) per lo scarico e aspira-

zione dei trucioli/polvere. E’ comunque da tener presente che durante

il taglio parte del materiale asportato verrà scagliato anche attorno

alla macchina e sul pezzo.

Per un taglio singolo è sufficiente montare il sacchetto raccoglitrucioli

(pos.20) in dotazione, che deve essere infilato a fondo sul collettore

come illustrato in fig.A: a fine taglio svuotate il sacchetto .

Per un numero di tagli maggiore e soprattutto per una aspirazione

ottimale, collegare il collettore (pos.21) ad un aspiratore di trucioli/

polvere di legno, mediante un tubo flessibile in materiale plastico,

entrambi non forniti con la macchina; il vostro rivenditore di fiducia

potrà consigliarvi nella scelta più idonea.

Attenzione! Non avviate la macchina se non è montato il tubo di

aspirazione. Non infilate all’interno del collettore le dita o attrezzi

per tentare di estrarre il materiale, pericolo di lesioni gravi!

LAVORAZIONE, TAGLI E MOVIMENTI

Il pezzo in lavorazione è fermo sulla macchina, mentre l’utensile si

muove manualmente rispetto al pezzo per asportare il materiale.

Il motore fornisce l’energia per il movimento rotatorio dell’utensile,

mediante un gruppo ingranaggi.

Seguite le seguenti avvertenze che sono valide per tutti i tipi di

taglio:

- verificate che leve e viti siano avvitate in modo da fissare salda-

mente le parti mobili

- il pezzo in lavorazione deve essere ben serrato

- il pezzo deve appoggiarsi contro la guida (pos.11)

- mantenete ben salda l’impugnatura (pos.2)

- mantenete una distanza di sicurezza dalla zona di taglio

- avvicinate con gradualità ed attenzione la lama verso il pezzo

- il taglio deve avvenire in un’unica passata

- non caricate troppo il gruppo di taglio sul pezzo per non sollecitare

la lama e il motore

- sollecitazioni eccessive provocano la rottura della lama e del pezzo

- non sollecitate lateralmente la lama

- la lama ferma non deve toccare il pezzo

- 11 -

- non avviare la macchina se la lama è a contatto del pezzo

- non avviare la macchina se la lama e scoperta dalla protezione

(pos.8)

- a macchina in funzione non azionate il pulsante di bloccaggio

lama (pos.5)

- per pulire la zona di taglio utilizzate un pennello con impugnatura

lunga

La macchina permette di eseguire vari tipi di tagli:

- taglio perpendicolare al pezzo

- taglio inclinato

- taglio obliquo

- taglio combinato inclinato/obliquo

Con qualsiasi tipo di taglio sopra descritto è possibile muovere la testa

di taglio in senso radiale per eseguire tagli di ampia larghezza; essa

è dotata di 2 aste di guida (pos.16) che scorrono su dei cuscinetti a

sfera per la massima scorrevolezza e precisione. E’ possibile bloccare

lo scorrimento avvitando la vite (pos.14).

TAGLIO PERPENDICOLARE (fig.D)

Posizione iniziale:

- testa di taglio in posizione di riposo

- piano girevole (pos.10) bloccato dalla vite (pos.15) su 0°

- braccio (pos.18) bloccato dal volantino (pos.19) su 0°

- testa di taglio spinta verso dietro e vite (pos.14) non serrata per

pezzi larghi

Esecuzione taglio:

- spigere il pezzo contro la guida di appoggio (pos.11) e serrarlo con

la morsa (pos.12) in maniera salda

ATTENZIONE! Mantenere le mani lontane dalla zona di taglio.

- con la mano destra afferrare l’impugnatura (pos.2), premere l’inter-

ruttore (pos.1) per avviare la macchina

- sbloccare il fermo della protezione azionando la leva (pos.4)

- abbassare lentamente e completamente la testa di taglio fino a

tagliare il pezzo

- alzare lentamente la testa di taglio e non appena la lama è fuori dal

pezzo rilasciare l’interruttore per spegnere la macchina

- accompagnare la testa di taglio fino alla posizione di riposo

- spingere verso dietro la testa di taglio.

TAGLIO SCORREVOLE (fig.D)

- Tirare la testa di taglio verso di sè

- Avviare la macchina e abbassare completamente la testa di taglio

- Spingere verso dietro la testa di taglio fino al completamento del

taglio

- Alzare la testa di taglio e spegnere la macchina.

ATTENZIONE! La lama tenderà a sollevare il pezzo verso l’alto, è

perciò obbligatorio fissarlo con la morsa bloccapezzo (pos.12).

TAGLIO INCLINATO (fig.E)

Attenzione! L’esecuzione di questo taglio espone maggiormente la

lama e il pericolo di gravi ferite è maggiore: prestate attenzione

alle vostre mani e mantenete una distanza di sicurezza.

Posizione iniziale:

- testa di taglio in posizione di riposo

- piano girevole (pos.10) bloccato dalla vite (pos.15) su 0°

- braccio (pos.18) bloccato dal volantino (pos.19) su un angolo

compreso tra 0° e 45°

- testa di taglio spinta verso dietro e vite (pos.14) non serrata per

pezzi larghi

ATTENZIONE: Per evitare il contatto tra la lama e la guida di appoggio

(Fig.A pos.11) è fondamentale posizionare la parte superiore scor-

revole della guida in corrispondenza dell’angolo di taglio impostato.

Vedi esempi in Fig.L.

Esecuzione taglio:

- spingere il pezzo contro la guida di appoggio (pos.11) e serrarlo con

la morsa (pos.12) in maniera salda

ATTENZIONE! Mantenere le mani lontane dalla zona di taglio.

- con la mano destra afferrare l’impugnatura (pos.2), premere l’inter-

ruttore (pos.1) per avviare la macchina

- sbloccare il fermo della protezione azionando la leva (pos.4)

- abbassare lentamente e completamente la testa di taglio fino a

tagliare il pezzo

- alzare lentamente la testa di taglio e non appena la lama è fuori dal

pezzo rilasciare l’interruttore per spegnere la macchina

- accompagnare la testa di taglio fino alla posizione di riposo

- spingere verso dietro la testa di taglio.

TAGLIO OBLIQUO (fig.F)

Posizione iniziale:

- testa di taglio in posizione di riposo

- Premere e mantenere premuta la leva di sblocco (Fig.A pos.26) e

ruotare il piano girevole bloccandolo su un angolo compreso nella

scala graduata (per facilitare la scelta il piano ha dei fermi su gli angoli

caratteristici, è comunque possibile impostare un qualsiasi angolo)

- avvitare completamente il pomello (FigA pos.15)

- braccio (pos.18) bloccato dal volantino (pos.19) su 0°

- testa di taglio spinta verso dietro e vite (pos.14) non serrata per

pezzi larghi

Esecuzione taglio:

- spingere il pezzo contro la guida di appoggio (pos.11) e serrarlo con

la morsa (pos.12) in maniera salda

ATTENZIONE! Mantenere le mani lontane dalla zona di taglio.

- con la mano destra afferrare l’impugnatura (pos.2), premere l’inter-

ruttore (pos.1) per avviare la macchina

- sbloccare il fermo della protezione azionando la leva (pos.4)

- abbassare lentamente e completamente la testa di taglio fino a

tagliare il pezzo

- alzare lentamente la testa di taglio e non appena la lama è fuori dal

pezzo rilasciare l’interruttore per spegnere la macchina

- accompagnare la testa di taglio fino alla posizione di riposo

- spingere verso dietro la testa di taglio.

TAGLIO COMBINATO INCLINATO E OBLIQUO (fig.G)

Attenzione! L’esecuzione di questo taglio espone maggiormente la

lama e il pericolo di gravi ferite è maggiore: prestate attenzione

alle vostre mani e mantenete una distanza di sicurezza.

Posizione iniziale:

- testa di taglio in posizione di riposo

- piano girevole (pos.10) bloccato dalla vite (pos.15) su un angolo

compreso nella scala graduata (per facilitare la scelta il piano ha dei

fermi su gli angoli caratteristici, è comunque possibile impostare un

qualsiasi angolo)

- braccio (pos.18) bloccato dal volantino (pos.19) su un angolo

compreso tra 0° e 45°

- testa di taglio spinta verso dietro e vite (pos.14) non serrata per

pezzi larghi

Esecuzione taglio:

- spingere il pezzo contro la guida di appoggio (pos.11) e serrarlo con

la morsa (pos.12) in maniera salda

ATTENZIONE! Mantenere le mani lontane dalla zona di taglio.

- con la mano destra impugnare l’impugnatura (pos.2), premere

l’interruttore (pos.1) per avviare la macchina

- sbloccare il fermo della protezione azionando la leva (pos.4)

- abbassare lentamente e completamente la testa di taglio fino a

tagliare il pezzo

- alzare lentamente la testa di taglio e non appena la lama è fuori dal

pezzo rilasciare l’interruttore per spegnere la macchina

- accompagnare la testa di taglio fino alla posizione di riposo

- spingere verso dietro la testa di taglio.

LAMA

ATTENZIONE! La parte tagliente può provocare gravi ferite,

utilizzate guanti di protezione!

- Utilizzate lame di qualità con caratteristiche idonee alla macchina

che utilizzate in base ai dati tecnici della stessa; il vostro rivenditore

di fiducia potrà aiutarvi nella scelta più idonea. Osservate anche le

eventuali istruzioni fornite a corredo.

- Non utilizzate lame di dubbia provenienza e prive dei dati tecnici.

Esse devono riportare le dimensioni nominali, il numero di denti, il

numero di giri massimo, la freccia che indica il senso di rotazione.

- Il numero di giri e le dimensioni sono elementi basilari per la scelta.

Il suo numero di giri deve essere sempre maggiore o uguale a quello

riportato sulla macchina. Le dimensioni devono essere uguali a

quelle riportate sui dati della macchina.

- 12 -

- Utilizzate lame conformi alle normative in vigore nel paese in cui vi

trovate.

- Non utilizzate lame in acciaio super rapido HSS (high speed steel)

o dischi abrasivi da troncatura.

- Eseguire sempre un controllo visivo: non deve presentare deforma-

zioni, rotture o danni.

La nostra azienda fornisce una serie completa di lame adatte alla

vostra macchina, che possono essere acquistate presso il vostro

rivenditore di fiducia.

SOSTITUZIONE DELLA LAMA (FIG. H)

ATTENZIONE! Prima di ogni sostituzione posizionate l’interruttore

su OFF”O” (spento) e staccate l’alimentazione elettrica scollegando

la spina della macchina.

ATTENZIONE! A fine taglio la lama raggiunge temperature ele-

vate: attendete il suo raffreddamento prima di sostituirla.

ATTENZIONE! Anche se la lama è ferma è comunque molto

tagliente: per evitare ferite gravi utilizzate i guanti.

ATTENZIONE! Il montaggio della lama deve essere eseguito a

perfetta regola d’arte. Un montaggio errato genera pericoli molto

gravi.

Per eseguire la sostituzione procedete come di seguito indicato. L’o-

perazione deve essere fatta da una persona esperta; in caso di dubbio

rivolgetevi ad un centro assistenza autorizzato.

1) Staccate la spina dalla presa elettrica

2) Per eseguire correttamente il successivo rimontaggio, osservate

attentamente i vari componenti prima di procedere

3) Togliete la vite dal carter centrale (Fig.H1)

4) Azionate la leva di sblocco (Fig.H2)

5) Fate scorrere verso l’alto la protezione trasparente (Fig.H3)

6) Sollevate il carter centrale (Fig.H4 pos.1) fino a scoprire la vite

che fissa la lama (Fig.H4 pos.2)

7) Premete il pulsante di blocco lama (Fig.H5) e con la chiave in

dotazione svitate completamente la vite che fissa la lama girandola

in senso orario (la lama ha filetto sinistro) (Fig.H6)

8) Togliete la flangia esterna e sfilate la lama (Fig.H7)

9) Pulite i componenti e la lama nuova

10) Montate la nuova lama prestando attenzione a rispettare il senso

di rotazione: la freccia della lama deve corrispondere con quella

stampigliata sulla macchina

11) Rimontate la flangia esterna prestando attenzione al foro sagomato

della stessa, che dovrà essere infilato sull’albero sagomato del

motore

12) Premete il pulsante di bloccaggio lama (Fig.H5)

13) Avvitate la vite in senso antiorario (Fig.H6) e fissatela bene senza

colpirla con martello o altro

14) Riportate in posizione il carter centrale e fissatelo con la vite. Il

carter deve andare completamente in appoggio sulla vite (Fig.H8)

15) Assicuratevi che la protezione trasparente che copre la lama

funzioni correttamente:

- in posizione di riposo la protezione deve coprire completamente la

lama e la leva di sbloccaggio deve impedire una apertura accidentale

della protezione

- quando la testa di taglio viene spinta verso il basso e dopo aver

azionato la leva di sbloccaggio, la protezione deve ruotare automa-

ticamente e scoprire la lama

- quando la testa di taglio viene spinta verso l’alto, la protezione deve

ruotare automaticamente e coprire la lama

16) Verificate che la lama giri liberamente senza irregolarità

17) Effettuate una prova di funzionamento a vuoto per almeno 1

minuto.

MANUTENZIONE

ATTENZIONE! Prima di ogni controllo o manutenzione posizio-

nate l’interruttore su OFF”O” (spento) e staccate l’alimentazione

elettrica scollegando la spina della macchina.

ATTENZIONE! Non manomettete o tentate di riparare parti del

motore o parti elettriche.

La durata e il costo d’esercizio della macchina dipendono anche

da una costante e scrupolosa manutenzione, osservate sempre le

seguenti istruzioni.

PULIZIA DOPO OGNI UTILIZZO

- Pulite regolarmente ed abbiate cura della vostra macchina, vi garan-

tirete una perfetta efficienza ed una lunga durata della stessa.

- Rimuovete i trucioli/polvere prodotti utilizzando una spazzola morbida

e un aspiratore; consegnate il materiale ad un punto di raccolta per

il riciclaggio.

- Rimuovete le tracce di resina che si attaccano sulla macchina

- Non spruzzate o bagnate d’acqua la macchina.

- Non usate infiammabili, detergenti o solventi vari, potreste rovinare

irrimediabilmente la macchina. Le parti in plastica sono aggredibili

da agenti chimici.

- Non utilizzate un getto d’aria compressa per la pulizia: pericolo lancio

trucioli e schegge!

- Prestate particolare attenzione alla pulizia dell’interruttore, dell’im-

pugnatura, alle feritoie di ventilazione del motore, alla lama, alle

leve di comando, al piano girevole, alla base, alla feritoia centrale

del piano girevole.

Per la vostra sicurezza verificate periodicamente lo stato dei seg.

componenti, se danneggiati o usurati fateli sostituire:

- lama

- protezione lama

- guida di appoggio pezzo

- collettore di scarico

- inserti in plastica del piano girevole

- spina e cavo di alimentazione

LUBRIFICAZIONE

Dopo la pulizia:

- proteggete con un sottile strato di olio le 2 aste di guida (pos.16)

- lubrificate con olio le superfici di scorrimento su cui ruota la testa

di taglio fissata al braccio (pos.18); senza smontare alcuna parte

versare delle gocce di olio sulle zone di scorrimento e muovere la

testa di taglio alcune volte in modo che l’olio penetri all’interno.

Le parti metalliche non verniciate del piano e della base non neces-

sitano di olio protettivo.

SPAZZOLE DEL MOTORE

Il motore di questa macchina è equipaggiato con una coppia di

spazzole in grafite; la verifica e la sostituzione deve essere eseguita

da un centro assistenza autorizzato. L’usura completa delle spazzole

comporta l’impossibilità all’avviamento della macchina.

- 13 -

RICERCA GUASTI E INTERVENTI AMMESSI

LA MACCHINA NON SI AVVIA

OPPURE SI ARRESTA E NON

RIPARTE

Mancanza di energia elettrica Controllate che il cavo elettrico

e la prolunga (se presente)

non siano danneggiati.

Controllate l’interruttore gene-

rale dell’impianto di alimen-

tazione.

Spazzole in grafite usurate Rivolgetevi ad un centro assi-

stenza autorizzato.

Guasto elettrico Rivolgetevi ad un centro assi-

stenza autorizzato.

LA TESTA DI TAGLIO NON SI

ABBASSA

Leva di bloccaggio protezione

lama inserita

Azionare la leva e contem-

poraneamente abbassare la

testa di taglio.

LA MACCHINA VIBRA ECCES-

SIVAMENTE

Lama senza tagliente o dan-

neggiata

Sostituite la lama.

Lama montata in modo errato Smontate la lama e rimonta-

tela correttamente seguendo

le istruzioni.

Fissaggio insufficiente della

macchina al banco/piedistallo

Migliorate il fissaggio della

macchina.

LA MACCHINA FA FATICA A

TAGLIARE

Lama senza tagliente o dan-

neggiata

Sostituite la lama.

IL PIANO GIREVOLE NON

RUOTA O SI SPOSTA CON

DIFFICOLTÀ

Residui di taglio sotto il piano

girevole

Pulire.

Vite di fissaggio avvitata Svitare di alcuni giri la vite di

fissaggio.

ATTENZIONE! Se dopo aver eseguito gli interventi sopra descritti

la macchina non funziona correttamente o in caso di anomalie

diverse da quelle indicate, spegnetela e portatela presso un centro

di assistenza autorizzato o fate intervenire un tecnico autorizzato

richiedendo ricambi originali. Fate sempre riferimento al modello

macchina e numero di matricola riportati sull’etichetta dati tecnici.

RIMESSAGGIO

- Scollegate la macchina dalla rete elettrica.

- Effettuate una accurata pulizia di tutta la macchina e sue parti ac-

cessorie (vedi paragrafo Manutenzione).

- Proteggete le parti non verniciate con un olio protettivo.

- Riponete la macchina lontano dalla portata dei bambini, in posizione

stabile e sicura e in luogo asciutto, temperato e libero da polveri.

Al locale di rimessaggio non devono avere accesso i bambini e gli

estranei.

- Proteggete la macchina dalla luce diretta, tenetela possibilmente al

buio o in penombra.

- Non chiudete la macchina in sacchi di nylon, potrebbe formarsi

dell’umidità e danneggiare la macchina.

- Utilizzate l’imballo originale per proteggere la macchina.

DEMOLIZIONE

I rifiuti elettrici ed elettronici possono contenere sostanze peri-

colose per l’ambiente e la salute umana; non devono pertanto essere

smaltiti con quelli domestici ma mediante una raccolta separata

negli appositi centri di raccolta o riconsegnati al venditore nel caso

di acquisto di una apparecchiatura nuova analoga. Lo smaltimento

abusivo dei rifiuti comporta l’applicazione di sanzioni amministrative.

GARANZIA

Il prodotto è tutelato a norma di legge contro non conformità rispetto

alle caratteristiche dichiarate purché sia stato utilizzato esclusivamente

nel modo descritto dalle istruzioni, non sia stato manomesso in alcun

modo, sia stato conservato correttamente, sia stato riparato da tecnici

autorizzati e, ove previsto, siano stati utilizzati solo ricambi originali.

In caso di utilizzo industriale o professionale oppure in caso di impiego

simile la garanzia ha validità di 12 mesi.

Sono esclusi dalla garanzia i componenti soggetti ad usura o deterio-

ramento dovuto all’uso normale.

Per emettere una richiesta di intervento in garanzia è necessario

presentare la prova di acquisto al rivenditore o ad centro assistenza

autorizzato.

DICHIARAZIONE DI CONFORMITA’

La ditta indicata in etichetta dichiara sotto la propria responsabilità

che il prodotto ivi citato è conforme ai requisiti essenziali di sicurezza

e salute contenuti nelle seguenti direttive europee:

2006/42/CE, 2014/30/CE, 2011/65/CE

___________________________________________________

Persona autorizzata a costituire il fascicolo tecnico presso/ The person

authorized to compile the technical file is in

Valex SpA - Via Lago Maggiore 24 - 36015 Schio (VI) - Italy

Schio, 06 2016

Un procuratore

ARRIGO ZANELLA

- 14 -

g

This manual contains information deemed necessary for proper use,

knowledge and standard machine maintenance. It does not include

information on machine tool woodworking techniques nor does it

discuss the types and processing capabilities of the various types

of wood; the user will find further information in specific books and

publications or by attending special training courses.

Warnings on use and maintenance regulations refer to normal operating

needs. Normal machine operations, working life and economy depend

on their observance.

These instructions are an integral part of the machine and must

accompany it in the case of repair or resale. Carefully keep the docu-

mentation supplied with the machine close at hand for consultation

in case of need.

For any repairs or revisions that require complex operations, please

contact authorised service centres which have specialised personnel.

The manufacturer is not liable for damages due to negligence, failure

to observe the instructions in this manual and direct and/or indirect

damages caused by improper use of the machine.

Failure to observe the indications, poor and inadequate machine use

and unauthorised tampering may void the warranty. Accident preven-

tion therefore depends on the strict observance of what is established

in this manual.

Upon purchase, make sure the machine is integral and complete.

IMPORTANT! Before using the machine, in order to ensure that

handling, initial start-up, starting, use, stopping, and maintenance

are carried out properly, read the instructions below that refer to

the drawings and technical data and apply them carefully. Before

starting work you should familiarise yourself with the controls and

the correct use of this machine. Make sure you know how to stop

it in case of emergency. Incorrect use of this machine may result

in serious injury and damage to property. Always consider your

safety and the safety of others and act accordingly.

IMPORTANT! The machine is exclusively intended for DIY use

and it is suitable for making perpendicular, tilted and slanted cuts

on parallelepiped shaped pieces of wood. Cutting metal, flammable

materials and materials that generate harmful or toxic dust and

vapours is prohibited. Any use other than that indicated in these

instructions may damage the machine and constitute a serious risk

to both persons and property.

MACHINE DESCRIPTION (FIG.A)

1 On/off switch.

2 Hand grip

3 Handle for transporting

4 Guard lock lever

5 Blade lock button (only to replace the blade)

6 Engine

7 Disc blade

8 Blade guard

9 Base

10 Rotary table

11 Supporting guide for the piece

12 Piece-locking vice

13 Piece supports

14 Sliding head lock screw

15 Rotary table rotation lock screw

16 Sliding head guide rods

17 Power supply plug and cable

18 Arm

19 Head angle lock lever

20 Dust/chip bag

21 Sawdust collector

22 Vice lock screw

23 Piece supports lock screw

24 Cable mounting hook

25 Rotary table plastic insert

26 Rotary table lock

27 Arm’s stop screws

28 Cutting depth regulation screw

29 Pedestal (where fitted)

30 Counter/stand fastening holes

31 Stand fastening holes

32 Release button (where fitted)

34 Guide piece’s mobile panel

35 Handwheel of the guide piece’s mobile panel

DESCRIPTION OF SYMBOLS AND SIGNS (FIG. B)

1 Machine model and technical specifications.

2 Serial number or batch number, year of manufacture.

3 IMPORTANT!

4 Read the instructions carefully before use.

5 Warning! Risk of cutting and crushing hands. It is compulsory

to wear protection gloves.

6 Warning! Risk of material ejection and dangerous dust emission.

It is compulsory to wear eye protection and a mask to protect

your respiratory tracts.

7 Warning! Risk of loud noise. It is compulsory to use ear protection.

8 Warning! Risk of electric shocks. Some parts of the machine are

electrically-powered. Do not touch them and keep a safe distance.

9 Warning! Risk of moving blade. Keep your hands away from the

blade.

10 Warning! Before any control, adjustment or maintenance, always

disconnect the machine from the power supply by unplugging it.

Should the power supply cable be damaged, remove the plug

from the power supply socket before inspecting it.

11 Warning! Risk of cutting and crushing hands. Keep a safe

distance from the blade and the cutting area.

TECHNICAL DATA

Power voltage and nominal frequency 230 V~50 Hz

Nominal engine power 1900 W

Idle rotation speed 4,860 min-1

Machine insulation class II

Acoustic pressure LpA 97dB(A) K=3 *

Acoustic power level LwA 110dB(A) K=3 *

Hand grip vibrations 3.82m/s2 K=1.5 **

Total machine dimensions (b x l x h) 730x880x570 mm

(with the rotary table at 0°)

Machine weight 11 kg

Circular blade for wood, steel body and teeth with carbide tips

Ext./int. diameter 254/25.4 mm

Teeth thickness 2.8 mm

Performance:

Cutting head angle for cuts on a slope: 0°-45° anti-clockwise direction

Cutting head rotation for angle cuts or cuts on a slope: 0°-45° to the

right / 0°-45° to the left with 9 pre-set stop positions.

Radial stroke: 173 mm

Max. cutting dimensions (height x depth)

Head angle 0° Head angle 45° anti-

clockwise direction

Head rotation 0° 70x310 mm 40x310 mm

Head rotation 45° to the

right/to the left 70x210 mm 40x210 mm

GENERAL SAFETY REGULATIONS

1) NYLON BAGS ARE NOT TOYS

IMPORTANT! Suffocation hazard. Nylon packaging bags can

cause suffocation if placed on the head and must be kept out of

the reach of children. If they cannot be reused they must be cut up

and thrown in the garbage.

IMPORTANT! When using tools, always respect essential safety

measures to reduce risk of fire, electrical shocks and injury to

people. Read all instructions before using the product and keep

them for future reference.

- 15 -

2) PEOPLE AUTHORIZED TO USE THE MACHINE

This machine must not be used by children, teens or any persons

not fully aware of the instructions for use contained in this manual.

Local laws and regulations may establish a minimum age for use

of the machine. The operator must be adequately trained to use,

adjust and safely operate the machine.

3) OPERATOR RESPONSIBILITY

The operator is responsible for other people as far as accidents or

damage to people or property caused by the use of the machine

is concerned.

4) MAINTAIN A STABLE AND SAFE WORKING POSITION

When working maintain a stable, safe position.

5) PAY ATTENTION IN THE WORK AREA

Be careful of hands, the piece to be processed, the cutting tool,

chips produced during work and, in general, all parts in motion.

6) USE CAUTION WHILE WORKING

Do not allow yourself to be distracted and always pay attention

to what you are doing. Use your common sense. Never use the

machine when tired, ill or under the influence of alcohol, drugs or

medicines that reduce alertness.

7) KEEP A SAFE DISTANCE FROM THE MACHINE

Keep people and animals away from the machine and your work

area. Do not touch electrically-powered parts.

8) PROTECT YOUR BODY

The use of the machine generates noise, heat, dust, smoke, vibra-

tions, flying chips and splinters. Always use personal protective

equipment in accordance with the law to prevent injury to the body,

hands, eyes, hearing and respiratory tracts. Wear strong clothing,

with tight sleeves and cuffs, eye protection, working gloves, safety

earmuffs, dust masks and safety shoes. Do not wear loose clothing,

scarves, ribbons and jewellery that could be caught in moving parts

of the machine. Wear protective hairnet to gather long hair. Normal

glasses are not suitable for protecting your eyes.

9) EFFICIENCY OF THE MACHINE

Always make sure the machine is in good working order and

integral; it could cause serious accidents if in poor conditions. Do

not use the machine if the switch does not allow you to switch the

machine on or off.

10) INTEGRITY OF THE MACHINE

Do not remove any components from the machine unless expressly

indicated in these instructions and do not modify the original

configuration in any way.

11) DO NOT DISASSEMBLE THE MACHINE

Do not disassemble the machine for any reason. Do not use the

machine without the guards installed.

12) DO NOT TAMPER WITH ANY OF THE MACHINE’S COMPONENTS

Do not tamper, modify or remove any component from the machine.

13) VERIFY THE SOLIDITY OF THE MACHINE

Periodically check screw and blade tightness.

14) USE THE MACHINE IN A WELL-VENTILATED AREA

The machine must be used in a well-ventilated area in order to

ensure sufficient cooling and air circulation.

15) DO NOT USE THE MACHINE IN DANGEROUS ENVIRONMENTS

Do not use the machine in areas with a risk of explosion and/or

fire, in poorly ventilated spaces or in the presence of inflammable

and/or explosive materials, dampness, gases, vapours, and acids.

16) MOVING THE MACHINE

The machine should be moved with caution. Hold the machine by

the handle provided only. Do not attempt to move the machine by

pulling on the power cable or other machine parts.

17) POSITIONING OF THE MACHINE

Use the nuts and bolts to position and secure the machine on the

work bench or stand with a flat, solid and non-flammable surface

that must support the total machine weight and vibrations caused

by use. Secure the stand to the floor. Using the machine without

securing it and on flammable surfaces such as wood, plastic, etc.

is prohibited. Periodically check fastenings.

18) WORK WITH ADEQUATE LIGHTING

Only work when there is sufficient daylight or suitable artificial lighting.

19) DO NOT EXPOSE THE MACHINE TO ATMOSPHERIC AGENTS

Do not expose the machine to the elements such as rain, fog, sun,

high, and low temperatures.

20) DO NOT TOUCH THE MACHINE IF YOU ARE WET

Never use this machine with bare or wet feet. Do not touch the

machine with wet hands.

21) CHECK BEFORE STARTING UP THE MACHINE

Before plugging the machine in, make sure the switch is OFF “O”,

that the piece in process is well positioned and supported, the

cutting head is adjusted, and the service keys are removed. Do

not use the machine if the rotary table inserts are worn and the

blade guard is broken or does not function.

22) CHECK CORRECT ASSEMBLY

Do not use the machine if the dust/chip bag or the chip/dust vacu-

um tube (not supplied) are not connected to the exhaust manifold.

23) FUNCTIONAL TESTS

Check that the mobile blade guard is not damaged and that its

motion follows the ascending/descending of the cutting head. Do

not use the machine if the guard does not cover the blade in its

rest position.

24) MAKE SURE THAT THE PIECE TO BE PROCESSED IS WELL

POSITIONED

It is very important for your safety that the piece to be processed

is well positioned against the appropriate supporting guide, that

it is locked against the vice and that its two extremities rest on

specific stands (not supplied). Do not cut pieces with circular

sections but only pieces with flat and perpendicular sides, like

tables, panels etc.; do not cut tree branches or trunks. Do not cut

pieces that contain nails or screws or are wrapped in tape, cord

or other materials. Do not cut pieces on a slant. Rest them on the

base of the machine.

25) PROHIBITED MATERIALS

Cutting metal, flammable materials, and materials that generate

harmful or toxic dust and vapours is prohibited.

26) PREVENT POSSIBLE ACCIDENTS

Always test operations without a work piece before beginning

work; at this stage, make sure no one gets close to the machine

and keep safety distances. Always use protective goggles, gloves,

masks and ear protection. When the machine is running, do not

touch the blade. Serious injury hazard! After replacing components,

always run a general check before starting work.

27) ONLY USE BLADES SUITED FOR THIS MACHINE

This machine was designed to use specific blades to cut wood;

using blades suited for other materials and for abrasive disks is

prohibited. Do not use HSS, high speed steel blades. The maximum

speed stamped on the blade must always be higher than that

indicated on the machine’s technical specifications. Use blades

which conform to the regulations in force in the country of use.

28) HANDLE THE BLADE WITH CAUTION

The blade has very sharp edges: handle it with caution and always

wear protective gloves. Serious injury hazard!

29) ONLY USE BLADES IN PERFECT WORKING CONDITION

Do not use damaged or deformed blades; if worn, replace them

with new blades.

30) DO NOT FORCE THE BLADE

Do not subject the blade to: collision, bending, excessive pressure,

heat, irregular speed changes, vibrations. In these conditions, the

tool has a limited working life and may break without warning with

the risk of flying fragments.

31) Replace the plastic insert in the rotary (Fig. A pos.25) table when

it is worn.

32) DO NOT TOUCH MOVING PARTS WHILE THE MACHINE IS

RUNNING

IMPORTANT! Serious injury hazard! Do not touch the blade or

any part in motion while the machine is running. Pay attention to

arm and hand movements. Only remove the work piece after turning

off and unplugging the machine.

33) MACHINE NOT WORKING

Turn the switch to OFF “O” (switched off), disconnect the power

supply to the machine by removing the plug from the socket when:

Not in use, left unattended, moved, the power cable is damaged,

when fixing or removing the work piece, during adjustments,

maintenance and cleaning.

34) WAIT FOR THE MACHINE TO STOP COMPLETELY

The motor, the moving parts and the blade continue to run for a

short while after the machine is switched off. During this time,

these parts must not be touched. Serious injury hazard!

35) DO NOT LEAVE THE MACHINE UNATTENDED WHILE RUNNING

Do not leave the machine unattended while running and wait until

all moving parts fully stop before leaving the machine after turning

it off.

- 16 -

36) KEEP THE WORKPLACE CLEAN AND TIDY

Mess and dirt are sources of danger. Make sure there are no tools

or objects around the machine that could be damaged. Do not

place tools or objects on the machine that could accidentally fall.

Remove cutting waste from the machine and floor often; carry

out operations only when the machine is stopped and the cutting

head is in its rest position.

37) HARMFUL DUST

The dust produced by some types of wood is very harmful to your

health. Wear appropriate masks, extract the saw dust produced

and equip the room with an extractor for air exchange.

38) REPAIRS MUST BE CARRIED OUT BY AUTHORISED PERSONNEL

Do not attempt to repair this machine or to gain access to its in-

ternal parts. Always contact an authorised service centre. Service

by unauthorised personnel will cause the warranty to be annulled

and could create a dangerous situation. Keep proof of purchase

for warranty purposes.

39) REQUEST AND HAVE ORIGINAL SPARE PARTS ONLY INSTALLED

Request and use only original spare parts. Please contact your

dealer. The use of non-original spare parts will cause the warranty

to be annulled and could create serious danger.

40) STORE THE MACHINE IN A SAFE PLACE

When not in use, keep the machine in a dry place out of the reach

of children.

41) REMAINING RISKS

IMPORTANT! Strict observance of the instructions with the use

of individual means of protection minimalists risks of accidents but

does not completely rule them out.

42) ALWAYS FOLLOW THESE INSTRUCTIONS

Only use this machine as described in these instructions. Do not

use it for purposes for which it was not intended.

ELECTRICAL SAFETY REGULATIONS

1) DO NOT TOUCH LIVE PARTS

IMPORTANT! Risk of electric shocks. Some parts of the machine

are electrically powered.

2) KEEP CHILDREN AND ANIMALS AWAY FROM ELECTRICAL DEVICES

Keep children and animals away from the devices connected to the power

supply.

3) CHECK THE POWER SUPPLY VOLTAGE

The power supply voltage must correspond to that indicated on the

technical data plate. Do not use any other type of power supply.

4) USE A CUTOUT BOX

It is advisable to fit a cutout box on the power supply line that trips at the

levels laid down in standards currently in force in the Country in which

the machine is used. Contact your local electrician.

5) CONNECTION TO THE POWER SUPPLY

Before connecting or disconnecting the machine to or from the power

supply, make sure that the switch is in the OFF “O” position (switched

off).

6) DO NOT TAMPER WITH THE POWER CORD

Do not tamper with the power cord. Do not replace the power cable plug;

only use a socket suited for the machine plug. Only use the power cable

as intended.

7) CHECK THE POWER CORD

The power cord and extension cord (where fitted) must be checked re-

gularly and before each use for signs of damage or wear and tear. If they

are not found to be in good condition disconnect them immediately and

do not use the machine until an authorised service centre has repaired it.

8) KEEP THE POWER CORD IN A SAFE POSITION

Keep the power cable and extension cable (where applicable) away from

the working area, damp, wet or oily surfaces, or surfaces with sharp

edges, heat sources, fuel and transit areas for vehicles or pedestrians.

9) DO NOT STEP ON OR CRUSH THE POWER CORD

Never step on the power cord. Be aware of its position at all times.

10) DO NOT USE THE MACHINE IN THE PRESENCE OF LIQUIDS

Do not wet it with liquids and do not expose it to damp environments. Do

not leave it outdoors.

11) USE AN EXTENSION CORD SUITABLE FOR THE MACHINE

Only use an extension cable that is suitable for the power of the machine

you are using and sised according to its length; consult your local elec-

trician.

12) DISCONNECT THE MACHINE ONLY BY PULLING THE PLUG

To remove the plug from the socket, pull on the plug only and not

on the power cable!

13) AVOID TOUCHING SURFACES THAT ARE EARTHED

Avoid body contact with earthed surfaces such as refrigerators,

radiators, pipes and metallic fixtures, etc. Using a platform to

electrically insulate the user from the floor is recommended.

RESIDUAL RISKS

These illustrations show the main risks involved with using the ma-

chine. Read the machine instruction manual carefully.

Material and dust flying towards the

operator’s eyes and body. Use eye

protection and an anti-dust mask.

Loud noise generated by the machi-

ne. Use ear protection.

Blade and sharp burrs which could

cut hands. Wear protective gloves

and keep a safe distance from the

cutting area.

Risk of electric shock and danger of

death. Do not touch the electrically

live parts and keep a safe distance.

Before any maintenance operations,

unplug the machine from the power

supply.

TERMINOLOGY USED

MACHINE

Assembly of all electrical and mechanical units.

TABLE SAW

Machine designed for cutting wooden pieces such as tables, panels

etc. featuring flat and perpendicular sides. The piece stays still while

the cutting head carries out all the movements.

CUTTING HEAD

Unit consisting of the engine, cutting blade, hand grip, switch and fixed

/ mobile guards, which moves in relation to the piece.

- 17 -

SWITCH

If activated, this part switches the machine on and off.

BLADE OR TOOL

Circular tool designed to remove material from the piece.

KICKBACK

Sudden upward movement of the cutting head during the truncation

stage, caused by the blade’s contact with hard parts such as nails,

screws, wood knots, etc.

OPERATOR - USER

The person responsible for installing, operating, adjusting, maintaining

and cleaning the machine. It is the person in charge of the machine.

TRANSPORT AND LIFTING (FIG. A-C)

Important! the manufacturer is not liable for any direct and/or

indirect damage caused by incorrect transport or lifting.

Important! before carrying out the following operations, make

sure that the machine’s plug is disconnected from the mains.

The machine must be transported and lifted with caution to avoid

accidents and damage.

1) Pull the cutting head completely towards you so that the sliding bars

(pos. 16) are recessed under the base (pos.9); secure the screw that

prevents sliding (pos.14), the screw pos.15 and the lever pos.19.

2) To lift the machine use the handle (pos.3) on the upper part. Lift

the machine with extreme care and move it slowly, without jerks or

sudden movements. Do not attempt to move the machine by pulling

on the power cord or other machine parts.

STARTING UP (FIG. A)

Important! the manufacturer is not liable for any direct and/or

indirect damage caused by incorrect installation or connections.

Important! before carrying out the following operations, make

sure that the machine’s plug is disconnected from the mains.

The machine is supplied with some disassembled components and

before using it, it must be cleaned and installed.

When choosing where to put the machine, the following should be

considered:

- that the planned position is not damp and is protected from atmo-

spheric agents.