INSTRUCTION AND

SERVICE MANUAL

ORIGINAL INSTRUCTION

07536 Repetition Tool for Speed Rivets

Hydro-Pneumatic Power Tool

0753

TYPE

EN

Hydro-Pneumatic Power Tool

FR

Outil électrique hydropneumatique

DE

Hydropneumatisches Setzgerät

IT

Elettroutensile oleopneumatico

PL

Narzędzie pneumatyczno-hydrauliczne

ES

Herramienta hidroneumática

NL

Hydropneumatisch gereedschap

DA

Hydro-pneumatisk el-værktøj

FI

Hydropneumaattinen sähkötyökalu

NO

Hydropneumatisk verktøy

SV

Hydro-pneumatiskt elverktyg

PT

Ferramenta eléctrica hidropneumática

©2021 Stanley Black & Decker inc.

All rights reserved.

The information provided may not be reproduced and/or made public in any way and through any means (electronically or

mechanically) without prior explicit and written permission from STANLEY Engineered Fastening. The information provided

is based on the data known at the moment of the introduction of this product. STANLEY Engineered Fastening pursues a

policy of continuous product improvement and therefore the products may be subject to change. The information provided

is applicable to the product as delivered by STANLEY Engineered Fastening. Therefore, STANLEY Engineered Fastening

cannot be held liable for any damage resulting from deviations from the original specications of the product.

The information available has been composed with the utmost care. However, STANLEY Engineered Fastening will not

accept any liability with respect to any faults in the information nor for the consequences thereof. STANLEY Engineered

Fastening will not accept any liability for damage resulting from activities carried out by third parties. The working names,

trade names, registered trademarks, etc. used by STANLEY Engineered Fastening should not be considered as being free,

pursuant to the legislation with respect to the protection of trade marks.

1. SAFETY DEFINITIONS ................................................................................................................................................... 4

1.1 GENERAL SAFETY RULES .......................................................................................................................................................................... 4

1.2 PROJECTILE HAZARDS .............................................................................................................................................................................. 4

1.3 OPERATING HAZARDS ............................................................................................................................................................................... 5

1.4 REPETITIVE MOTIONS HAZARDS............................................................................................................................................................ 5

1.5 ACCESSORY HAZARDS .............................................................................................................................................................................. 5

1.6 WORKPLACE HAZARDS ............................................................................................................................................................................. 5

1.7 NOISE HAZARDS .......................................................................................................................................................................................... 5

1.8 VIBRATION HAZARDS................................................................................................................................................................................. 5

1.9 ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC & HYDRAULIC POWER TOOLS .................................................... 6

2. SPECIFICATIONS ............................................................................................................................................................ 7

2.1 SPECIFICATION FOR 07536 TOOL .......................................................................................................................................................... 7

2.2 SPECIFICATION FOR 07531 INTENSIFIER ............................................................................................................................................. 7

3. INTENT OF USE .............................................................................................................................................................. 8

3.1 TOOL DIMENSIONS - 07536 MODEL ..................................................................................................................................................... 8

4. PUTTING INTO SERVICE ................................................................................................................................................9

4.1 AIR SUPPLY .................................................................................................................................................................................................... 9

4.2 AIR CURSORS ..............................................................................................................................................................................................10

4.3 LOADING AND RELOADING THE TOOL ..............................................................................................................................................10

4.4 OPERATING PROCEDURE ........................................................................................................................................................................12

5. SERVICING THE TOOL..................................................................................................................................................13

5.1 PNEUMATIC CONTROL BOX ...................................................................................................................................................................13

5.2 DAILY .............................................................................................................................................................................................................13

5.3 WEEKLY .........................................................................................................................................................................................................13

5.4 MOLY LITHIUM GREASE EP 3753 SAFETY DATA..............................................................................................................................13

5.5 SERVICE KIT ..................................................................................................................................................................................................14

5.6 AIR CURSOR TOOL, INTENSIFIER & CONTROL BOX ASSEMBLY 07536-02100 ......................................................................15

6. MAINTENANCE ............................................................................................................................................................16

6.1 DISMANTLING 07536-02200 .................................................................................................................................................................16

6.2 GENERAL ASSEMBLY OF BASE TOOL 07536-02200 .......................................................................................................................18

6.3 PARTS LIST FOR BASE TOOL 07536-02200 .......................................................................................................................................19

6.4 DISMANTLING INSTRUCTIONS ............................................................................................................................................................. 20

6.5 PROTECTING THE ENVIRONMENT .......................................................................................................................................................21

6.6 INTENSIFIER 07531-02200 ......................................................................................................................................................................21

7. PRIMING ......................................................................................................................................................................23

7.1 OIL DETAILS ................................................................................................................................................................................................. 23

7.2 HYSPIN® VG32 AND AWS 32 OIL SAFETY DATA ..............................................................................................................................23

7.3 PRIMING PROCEDURE..............................................................................................................................................................................23

8. FAULT DIAGNOSIS ....................................................................................................................................................... 24

9. EC DECLARATION OF CONFORMITY .......................................................................................................................... 26

10. UK DECLARATION OF CONFORMITY .........................................................................................................................27

11. PROTECT YOUR INVESTMENT! ...................................................................................................................................28

3

ORIGINAL INSTRUCTION ENGLISH

This instruction manual must be read by any person installing or operating this tool with particular attention to the

following safety rules.

Always wear impact-resistant eye protection during operation of the tool. The grade of protection required should

be assessed for each use.

Use hearing protection in accordance with employer’sinstructions and as required by occupational health and

safety regulations.

Use of the tool can expose the operator’shands to hazards, including crushing, impacts, cuts and abrasions and

heat. Wear suitable gloves to protect hands.

1. SAFETY DEFINITIONS

The denitions below describe the level of severity for each signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates apotentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates apotentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates apotentially hazardous situation which, if not avoided, may

result in property damage.

Improper operation or maintenance of this product could result in serious injury and property damage. Read and

understand all warnings and operating instructions before using this equipment. When using power tools, basic safety

precautions must always be followed to reduce the risk of personal injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

1.1 GENERAL SAFETY RULES

• For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining,

changing accessories on, or working near the tool. Failure to do so can result in serious bodily injury.

• Only qualied and trained operators must install, adjust or use the tool.

• DO NOT use outside the design intent of placing STANLEY Engineered Fastening Blind Rivets.

• Use only parts, fasteners, and accessories recommended by the manufacturer.

• DO NOT modify the tool. Modications can reduce the eectiveness of safety measures and increase the risks to the

operator. Any modication to the tool undertaken by the customer will be the customer’sentire responsibility and void

any applicable warranties.

• Do not discard the safety instructions; give them to the operator.

• Do not use the tool if it has been damaged.

• Prior to use, check for misalignment or binding of moving parts, breakage of parts, and any other condition that aects

the tool’soperation. If damaged, have the tool serviced before using. Remove any adjusting key or wrench before use.

• Tools shall be inspected periodically to verify that the ratings and markings required by this part of ISO 11148 are

legibly marked on the tool. The employer/user shall contact the manufacturer to obtain replacement marking labels

when necessary.

• The tool must be maintained in asafe working condition at all times and examined at regular intervals for damage

and function by trained personnel. Any dismantling procedure will be undertaken only by trained personnel. Do not

dismantle this tool without prior reference to the maintenance instructions.

1.2 PROJECTILE HAZARDS

• Disconnect the tool from the air supply before performing any maintenance, attempting to adjust, t or remove anose

assembly or accessories.

• Be aware that failure of the workpiece or accessories, or even of the inserted tool itself can generate high-velocity

projectiles.

• Always wear impact-resistant eye protection during operation of the tool. The grade of protection required should be

assessed for each use.

• The risks to others should also be assessed at this time.

• Ensure that the workpiece is securely xed.

• Check that the means of protection from ejection of fastener and/or mandrel is in place and is operative.

• Warn against the possible forcible ejection of mandrels from the front of the tool.

• DO NOT operate atool that is directed towards any person(s).

4

ENGLISH ORIGINAL INSTRUCTION

1.3 OPERATING HAZARDS

• Use of the tool can expose the operator’shands to hazards, including crushing, impacts, cuts and abrasions and heat.

Wear suitable gloves to protect hands.

• Operators and maintenance personnel shall be physically able to handle the bulk, weight and power of the tool.

• Hold the tool correctly; be ready to counteract normal or sudden movements and have both hands available.

• Keep tool handles dry, clean, and free from oil and grease.

• Maintain abalanced body position and secure footing when operating the tool.

• Release the start-and-stop device in the case of an interruption of the hydraulic supply.

• Use only lubricants recommended by the manufacturer.

• Contact with hydraulic uid should be avoided. To minimise the possibility of rashes, care should be taken to wash

thoroughly if contact occurs.

• Material Safety Data Sheets for all hydraulic oils and lubricants is available on request from your tool supplier.

• Avoid unsuitable postures as it is likely for these positions not to allow counteracting of normal or unexpected

movement of the tool.

• If the tool is xed to asuspension device, make sure that the xation is secure.

• Beware of the risk of crushing or pinching if nose equipment is not tted.

• DO NOT operate tool with the nose casing removed.

• Adequate clearance is required for the tool operator’shands before proceeding.

• When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent activation.

• DO NOT abuse the tool by dropping or using it as ahammer.

• Care should be taken to ensure that spent mandrels do not create ahazard.

1.4 REPETITIVE MOTIONS HAZARDS

• When using the tool, the operator can experience discomfort in the hands, arms, shoulders, neck or other parts of the

body.

• While using the tool, the operator should adopt acomfortable posture whilst maintaining asecure footing and

avoiding awkward or o-balance postures. The operator should change posture during extended tasks; this can help

avoid discomfort and fatigue.

• If the operator experiences symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling,

numbness, burning sensations or stiness, these warning signs should not be ignored. The operator should tell the

employer and consult aqualied health professional.

1.5 ACCESSORY HAZARDS

• Disconnect the tool from the air supply before tting or removing the nose assembly or accessory.

• Use only sizes and types of accessories and consumables that are recommended by the manufacturer of the tool; do

not use other types or sizes of accessories or consumables.

1.6 WORKPLACE HAZARDS

• Slips, trips and falls are major causes of workplace injury. Be aware of slippery surfaces caused by use of the tool and

also of trip hazards caused by the air line or hydraulic hose.

• Proceed with care in unfamiliar surroundings. There can be hidden hazards, such as electricity or other utility lines.

• The tool is not intended for use in potentially explosive atmospheres and is not insulated against contact with electric

power.

• Ensure that there are no electrical cables, gas pipes, etc., which can cause ahazard if damaged by use of the tool.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

• Care should be taken to ensure that spent mandrels do not create ahazard.

1.7 NOISE HAZARDS

• Exposure to high noise levels can cause permanent, disabling hearing loss and other problems, such as tinnitus (ringing,

buzzing, whistling or humming in the ears). Therefore, risk assessment and the implementation of appropriate controls

for these hazards are essential.

• Appropriate controls to reduce the risk may include actions such as damping materials to prevent workpieces from

“ringing”.

• Use hearing protection in accordance with employer’sinstructions and as required by occupational health and safety

regulations.

• Operate and maintain the tool as recommended in the instruction manual, to prevent an unnecessary increase in the

noise level.

1.8 VIBRATION HAZARDS

• Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms.

• Wear warm clothing when working in cold conditions and keep your hands warm and dry.

5

ORIGINAL INSTRUCTION ENGLISH

• If you experience numbness, tingling, pain or whitening of the skin in your ngers or hands, stop using the tool, tell

your employer and consult aphysician.

• Where possible Support the weight of the tool in astand, tensioner or balancer, because alighter grip can then be used

to support the tool.

1.9 ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC & HYDRAULIC POWER TOOLS

• The operating supply air must not exceed 7 bar (100 PSI).

• Air under pressure can cause severe injury.

• Never leave operating tool unattended. Disconnect air hose when tool is not in use, before changing accessories or

when making repairs.

• DO NOT let air exhaust opening on the mandrel collector face in the direction of the operator or other persons. Never

direct air at yourself or anyone else.

• Whipping hoses can cause severe injury. Always check for damaged or loose hoses and ttings.

• Prior to use, inspect airlines for damage, all connections must be secure. Do not drop heavy objects on hoses. A sharp

impact may cause internal damage and lead to premature hose failure.]

• Cold air shall be directed away from hands.

• Whenever universal twist couplings (claw couplings) are used, lock pins shall be installed and whipcheck safety cables

shall be used to safeguard against possible hose-to-tool or hose-to-hose connection failure.

• DO NOT lift the placing tool by the hose. Always use the placing tool handle.

• Vent holes must not become blocked or covered.

• Keep dirt and foreign matter out of the hydraulic system of the tool as this will cause the tool to malfunction.

• Oil under pressure can cause severe injury.

• Prior to use, inspect hydraulic hoses for damage. All hydraulic connections must be clean, fully engaged and tight

before operation. Do not drop heavy objects on hoses. A sharp impact may cause internal damage and lead to

premature hose failure.

• DO NOT pull or move the intensier unit using the hoses. Always use the unit handle.

• Use only clean oil and lling equipment.

• Only recommended hydraulic uids may be used.

• Maximum temperature of the hydraulic uid at the inlet is 100°C (212°F).

WARNING: While a small amount of wear and marking will naturally occur through normal and correct use of mandrels,

they must be regularly examined for excessive wear and marking, with particular attention to the head diameter, the

tail jaw gripping area of the shank or heavy pitting of the shank and any mandrel distortion. Mandrels which fail during

use could forcibly exit the tool. It is the customer’s responsibility to ensure that mandrels are replaced before any

excessive levels of wear and always before the maximum recommended number of placings. Contact your STANLEY

Engineered Fastening representative who will let you know what that gure is by measuring the broach load of your

application with our calibrated measuring tool.

STANLEY Engineered Fastening policy is one of continuous product development and improvement and we reserve

the right to change the specication of any product without prior notice.

6

ENGLISH ORIGINAL INSTRUCTION

2. SPECIFICATIONS

2.1 SPECIFICATION FOR 07536 TOOL

Air Pressure Minimum - Maximum 5-7 bar (70-100 lbf/in2)

Free Air Volume Required @ 5.1 bar /75 lbf/in22.6 litres (0.09 ft3)

Stroke Minimum 25 mm (1 in)

Pull Force @ 5.5 bar /80 lbf/in23.89 kN (875 lbf)

Cycle time Approximately 1 second

Weight Pistol 1.2 kg (2.64 lb)

2.2 SPECIFICATION FOR 07531 INTENSIFIER

Air Pressure Minimum - Maximum 5-7 bar (70-100 lbf/in)

Intensication Ratio 32:1

Noise values determined according to noise test code ISO 15744 and ISO 3744. 07536

A-weighted sound power level dB(A), LWA Uncertainty noise: kWA = 2.3 dB(A) 79.5 dB(A)

A-weighted emission sound pressure level at the work station

dB(A), LpA

Uncertainty noise: kpA = 2.3 dB(A) 68.5 dB(A)

C-weighted peak emission sound pressure level dB(C), LpC, peak Uncertainty noise: kpC = 2.5 dB(C) 96.9 dB(C)

Vibration values determined according to vibration test code ISO 20643 and ISO 5349. 07536

Vibration emission level, ahd:Uncertainty vibration: k = 0.25 m/s 0.97 m/s

Declared vibration emission values in accordance with EN 12096

7

ORIGINAL INSTRUCTION ENGLISH

3. INTENT OF USE

The pneumatic 07536 tool is a hand held light weight tool designed to place 1/16” Avlug® making it ideal for batch or ow-

line assembly in a wide variety of applications throughout all industries.

The Hand Tool and Intensier have been tested as separate items and combined. They must only be used together and for

no other purposes. Refer to "Putting into Service" on page 9-12 for connection details.

Part numbers are shown to order a complete tool but no nose equipment.

The tool number for the 07536 model is 07536-02200.

See the general assemblies on pages 15-22.

DO NOT use under wet conditions or in the presence of ammable liquids or gases.

3.1 TOOL DIMENSIONS - 07536 MODEL

Part Number 07536-02100

0753

60

2.36

28

1.10

98

3.85

130

5.12

475

18.70 338

13.30

51

2

163

6.41

140

5.51

54

2.12

201

7.91

420

16.54

333

01.31

502

19.76

Dimensions in mm.

8

ENGLISH ORIGINAL INSTRUCTION

4. PUTTING INTO SERVICE

4.1 AIR SUPPLY

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators

and automatic oiling/ltering systems on the main air supply. To ensure maximum tool life and minimum tool maintenance

they should be tted within 3 metres of the tool (see diagram below).

Air supply hoses should have a minimum working eective pressure rating of 150% of the maximum pressure produced

in the system or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and

should be armoured where operating conditions may result in hoses being damaged. All air supply hoses MUST have a

minimum bore diameter of 6.4 millimetres or / inch.

8

6

4

2

0

10

12

41

16

TAKE OFF POINT

FROM MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

3

M

E

T

R

E

S

M

A

X

I

M

U

M

AIR LUBRICATION

PERMISSABLE

0753

TYPE

Follow the steps below when connecting the tool to the intensier and main air supply:

• Push the end of the large hydraulic hose from the tool into the quick release connector on the end of the intensier.

• On the front face of the intensier (Refer to page 15):

• Push the blue pneumatic (4mm OD) line into the reducer tting which is located in the left hand bulkhead

connector.

• Push the black pneumatic (4mm OD) line into the plastic collet of the right hand bulkhead connector.

• On the front face of the control box (Refer to page 15):

• Push the silver pneumatic (3mm OD) line into the reducer labelled ‘Cursor’ on the front face of the control box - LH

side.

• Push the green pneumatic (4mm OD) line into the reducer labelled ‘Tail Jaws’ on the front face of the control box -

middle.

• Push the white pneumatic (4mm OD) line into the reducer labelled ‘Signal’ on the front face of the control box - RH

side.

• Fit a pneumatic hose between the male connector at the rear of the intensier and main air supply.

9

ORIGINAL INSTRUCTION ENGLISH

4.2 AIR CURSORS

0753

TYPE

TOOL

BARREL

CURSOR

NOSE

JAWS

Air Cursor Selection

See separate data sheet 07900-00863 for nose assembly components.

CURSOR

IMPORTANT

If tted incorrectly, the cursor will not allow the loading of the tool and feeding of the fasteners.

While the cursor will be tted the correct way round when the tool is supplied, we recommend that you check its orientation

before tting the nose equipment. The slightly concave end of the cursor should point towards the front of the tool as

shown in the illustration.

To reverse the orientation of the cursor, follow these steps:

Extreme caution must be exercised whe undertaking the following procedure. Care must be taken to avoid the barrel and

protruding mandrel.

• Remove the Nose Assembly if there is one.

• Insert an empty mandrel fully into the tool.

• Close the Tail Jaws 32, by switching on the tail jaw switch

(items 18 and 19).

• The cursor will pop out of the barrel after a short delay.

• Open the Tail Jaws 32, by switching o the tail jaw switch

(items 18 and 19), this will release the mandrel.

• Remove the cursor from the mandrel and insert the cursor

into the barrel.

4.3 LOADING AND RELOADING THE TOOL

IMPORTANT

The procedure for loading the tool and for tting the nose equipment to the tool is integral.

When ordering a complete tool or system you will normally be supplied with all the nose equipment required for the

fastener to be placed.

If you have been supplied with a nose jaw, mandrels and mandrel follower springs proceed with loading the tool and tting

the nose equipment as shown below.

TOOL

BARREL

CURSOR

CONCAVE END

NOSE

JAWS

Item numbers in bold refer to the general assembly and parts list for the 07536-02200 Tool on pages 18-19.

10

ENGLISH ORIGINAL INSTRUCTION

Loading the Tool

• Connect the air supply to the tool.

• Open Tail Jaws 32 which grip the mandrel, by switching o the tail jaw switch (items 18 and 19).

• Screw selected nose jaws onto Barrel 44 of the tool.

•* Insert a mandrel into the tail end of the fasteners through the paper pod.

• Slide the mandrel follower spring onto the mandrel ensuring correct orientation.

• Gripping the tail end of the mandrel, tear o the paper pod from around the fasteners.

• Open the nose jaws either by rotating the outer ring on Cam operated jaws or by pushing outwards on the jaw ends, as

illustrated below left.

• Insert the previously assembled mandrel, mandrel follower spring and fasteners into the nose jaws until the rst

fastener to be placed is protruding from the nose jaw.

• Close the nose jaws and adjust so that the rst fastener protrudes by 1.5mm - 3mm (/” to /”), as shown in the

illustration below right.

• Close the Tail Jaws 32 to ensure the mandrel is gripped, by switching on the tail jaw switch (items 18 and 19).

1.5mm - 3mm

(1/16 " - 1/8 ")

Re-loading the Tool

• Open Tail Jaws 32 of tool, by switching o the tail jaws (items 18 and 19).

• Open the nose jaws and pull the empty mandrel and mandrel follower spring out of the tool.

• Reload the tool by following the above instructions, starting at stage •*.

Setting the Tool - Adjustable Nose Assemblies Only

Insert the previously assembled mandrel (see Loading the Tool •*) or the disposable mandrel against the stop within the Tail

Jaw Piston Assembly 60.

While holding the mandrel, close the Tail Jaws 32, which grip the mandrel, by switching on the tail jaw switch (18 and 19).

Screw the lock nut onto the Barrel 44 of the tool.

Rotate the nose assembly onto the Barrel 44.

Adjust the nose assembly so that the rst fastener protrudes by 1,5mm-3mm (/”-/”), as shown in the illustration on page 11.

Tighten the lock nut against the nose assembly to prevent the nose jaw assembly from moving.

Item numbers in bold refer to the general assembly and parts list for the 07536-02200 Tool on pages 18-19.

11

ORIGINAL INSTRUCTION ENGLISH

Re-loading the Tool

Open the tail jaws of the tool, by switching o the tail jaw switch (18-19).

Open the jaws and pull the empty mandrel and follower spring out of the tool.

Insert the new mandrel against the stop within the too, and close the Tail Jaws 32 which grip the mandrel, by switching on

the tail jaw switch (18 and 19).

Close the Tail Jaws 32.

4.4 OPERATING PROCEDURE

IMPORTANT

You must check that the cursor orientation and the nose equipment are correct before attempting to operate the tool.

• Push the fastener, protruding from the nose jaws, fully into the application holes ensuring that the tool is held square.

• Operate the trigger without releasing - the mandrel head is pulled through the fastener, forming the fastener into the

application.

• Remove the tool.

• Release the trigger. The next fastener will be automatically presented through the nose jaws, ready for placing.

Item numbers in bold refer to the general assembly and parts list for the 07536-02200 Tool on pages 18-19.

12

ENGLISH ORIGINAL INSTRUCTION

5. SERVICING THE TOOL

Regular servicing should be carried out and a comprehensive inspection performed annually or every 500,000 cycles,

whichever is sooner.

IMPORTANT

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

5.1 PNEUMATIC CONTROL BOX

IMPORTANT

Under no circumstances must the pneumatic box be opened. The box is a closed item.

The internal adjustments are preset and must not be altered or tampered with.

Only Authorised STANLEY Engineered Fastening personnel may dismantle this control box.

CAUTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals

may weaken the materials used in these parts.

5.2 DAILY

• Daily, before use or when rst putting the tool into service. Pour a few drops of clean lubricating oil into the air inlet of

the intensier if no lubricator is tted on air supply. If the tool is in continuous use, the air hose should be disconnected

from the main air supply and the tool lubricated every two to three hours.

• Check for air and oil leaks. If damaged, hoses and couplings should be replaced.

• If there is no lter on the pressure regulator, bleed the airline to clear it of accumulated dirt or water before connecting

the air hose to the intensier. If there is a lter, drain it.

• Check that the nose equipment is correct.

• Check mandrels regularly for signs of wear or damage monitoring the number of placings (read the safety instructions

on page 4-6).

5.3 WEEKLY

• Conduct the full “Daily” procedures as described above.

• Remove, inspect, clean and grease the Tail Jaws (refer to “Tail Jaw Cylinder” in the "Maintenance Section" page 16).

• Check oil level in the intensier Unit reservoir is approximately 12mm (1/2”) below the transparent cover plate.

5.4 MOLY LITHIUM GREASE EP 3753 SAFETY DATA

Grease can be ordered as a single item, the part number is shown in the Service Kit page 14.

First Aid

SKIN:

As the grease is completely water resistant it is best removed with an approved emulsifying skin cleaner.

INGESTION:

Ensure the individual drinks 30ml Milk of Magnesia, preferably in a cup of milk.

EYES:

Irritant but not harmful. Irrigate with water and seek medical attention.

Fire

FLASH POINT: Above 220°C.

Not classied as ammable.

Suitable extinguishing media: CO2, Halon or water spray if applied by an experienced operator.

Environment

Scrape up for burning or disposal on approved site.

13

ORIGINAL INSTRUCTION ENGLISH

Handling

Use barrier cream or oil resistant gloves.

Storage

Away from heat and oxidising agent.

5.5 SERVICE KIT

For all servicing we recommend the use of the Service Kit (part number 07900-05300).

SERVICE KIT

ITEM PART Nº DESCRIPTION Nº OFF ITEM PART Nº DESCRIPTION Nº OFF

07900-00157 CIRCLIP PLIERS 1 07900-00352 SEAL REMOVAL HOOK 1

07900-00006 SPATULA 1 07900-00710 BARREL PLUG REMOVAL SPAN-NER 1

07900-00446 EXTRACTOR 1 07900-00725 BULLET 1

07900-00603 BARREL VICE JAWS 1 07900-00243 SCREWDRIVER 1

07900-00520 /" ROD 1 07900-00717 INTENSIFIER SPANNER 1

07900-00521 /" ROD 1 07900-00013 /" ALLEN KEY 1

07900-00602 'O' RING ASSEMBLY BULLET 1 07900-00617 LOCTITE® MULTI-GASKET 574 50ml PACK 1

07900-00595 18mm SPANNER 1 07900-00469 2.5mm ALLEN KEY 1

07900-00434 32mm SPANNER 1 07900-00351 3mm ALLEN KEY 1

07900-00237 /" × /" B.S.W. SPANNER 1 07900-00224 4mm ALLEN KEY 1

07900-00012 /" × /" SPANNER 1 07900-00225 5mm ALLEN KEY 1

07900-00008 /" × 1/2" SPANNER 1 07992-00020 80g TIN MOLY LITHIUM GREASE EP 3753 1

Note: Spanner sizes are measured 'across ats' unless otherwise specied.

14

ENGLISH ORIGINAL INSTRUCTION

5.6 AIR CURSOR TOOL, INTENSIFIER & CONTROL BOX ASSEMBLY 07536-02100

4 5

9

2

6

3

7 8

1

BLUE PIPE

BLACK PIPE

PART SECTION 'A-A'

(PROTECTION PLATE REMOVED)

AA

CURSOR

TAIL JAWS

SIGNAL

SILVER

PIPE

GREEN

PIPE

WHITE

PIPE

ITEM PART No DESCRIPTION No OFF

1 07536-02200 AIR CURSOR HAND TOOL 1

2 07531-02200 INTENSIFIER TOOL 1

3 07007-02024 AIR CURSOR CONTROL BOX 1

4 07005-10071 T CONNECTOR 1

5 07005-10072 8 MM TUBING (2.50 m) 1

6 74405-12080 MODIFIED M8 NUTSERT 8

7 07001-00469 M8 × 15 SOCKET CAP HEAD SCREW 2

8 07002-00105 M8 WASHER 4

9 07005-01573 MALE CONNECTOR 8MM TUBE 1

10 07005-01977 MALE/FEMALE REDUCER 6MM /4MM 1

15

ORIGINAL INSTRUCTION ENGLISH

6. MAINTENANCE

Every 500,000 cycles the tool should be completely dismantled and new components should be used where worn, damaged

or when recommended. All ‘O’ rings and seals should be renewed and lubricated with Moly Lithium grease EP 3753 before

assembling.

IMPORTANT

Safety Instructions appear on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The airline must be disconnected before any servicing or dismantling is attempted, unless specically instructed otherwise.

It is recommended that any dismantling operation be carried out in clean conditions.

Prior to dismantling the tool, you will need to remove the nose equipment.

For total tool servicing we advise that you proceed with the dismantling of sub-assemblies in the order shown below

after having disconnected the hydraulic hose from the intensier unit, air lines from the intensier and control box, thus

separating the pistol unit from the intensier unit.

The potentially dangerous substances that could have deposited on the machine as a result of work processes must be

removed before maintenance.

6.1 DISMANTLING 07536-02200

TAIL JAW CYLINDER

• Manually ip the retaining Clip 53 up and remove the End Cap 59.

• Using an Allen Key*, remove one Cap Head Screw 6 ensuring that any trapped air in the tail jaw cylinder is exhausted.

Remove the second Cap Head Screw 6.

• Pull out Rear Plug 50. Note: To aid extraction there is a 5mm thread on the rear face of the plug.

• Extract air tail jaw components, comprising Tail Jaw Piston Assembly 60, Stop 52, ‘O’ Ring 12 and Jaws 32.

• Extract the remaining components, comprising of Spring 36 and Jaw Housing 42.

• Free length of spring 36 should be 38.1mm (1.5”). Replace if necessary.

• Remove piston assembly seal ‘O’ Ring 11.

• Disconnect Air Cursor Concertina Tube (Green) 49 from Elbow Connector 22.

• Disconnect Air Cursor Concertina Tube (Silver) 38 from Barb Elbow 30.

• Using an Allen Key*, remove all ve handle moulding securing Screws 3, 4 and all four Nuts 8 from the tool handle.

• Grip Barrel 44 in a vice using soft jaws* to avoid damage.

• Using a box spanner*, unscrew Barrel Plug 46, preventing Barrel 44 turning by using an open ended spanner*.

• Pull the Tail Jaw Cylinder 47 from the tool.

• Remove ‘O’ Ring 14, Rubbing Strip 41 and Barrel Return Spring 37.

• Coat the face of Tail Jaws 32 with Moly Lithium grease, in contact with Jaw Housing 42, before assembling.

• Assemble in reverse order of dismantling.

HYDRAULIC PISTON

• Remove Tail Jaw Cylinder 47 as described earlier.

• Grip Body 45 in vice using soft jaws* to avoid damage, undo Stroke Limiter 40.

• Using an Allen Key*, loosen Screw 5 that is clamping the Switch Block 54 to the barrel 44.

* Refers to items included in the 0753 Mkll Service Kit. For complete list see page 14.

Item numbers in bold refer to the general assemblies and parts lists on pages 18-19.

16

ENGLISH ORIGINAL INSTRUCTION

• Hold the tool rmly and pull the Barrel 44 from the Body 45 (a small quantity of hydraulic oil may be ejected from inside

the head assembly).

• Remove Piston 39 carefully so as not to damage head bore.

• Remove Seal 16.

• Seal 17 is dicult to remove without damaging, but can remain in place during cleaning (provided it is not aected by

cleaning process). If however, Seal 17 requires renewing proceed as follows:

• Using spatula*, prise out Seal 17 from Body 45, taking care not to damage body cavity and bores. The removed Seal 17

MUST be discarded.

• To replace Seal 17, unscrew Bleed Plug Assembly 43 until inside face is level with internal bore of the Body 45. This will

provide a smooth passage for insertion of a new Seal 17 through rear of Body 45.

• Ensure the Seal 17 is well greased and the correct way round with the open end of the seal facing the rear tail jaws.

• Complete assembly in reverse order of dismantling.

TRIGGER ASSEMBLY

• To dismantle/service assembly, remove covers from the tool as described earlier.

• Disconnect all air hoses from assembly, taking care not to damage them. Remove assembly.

• Using a spanner*, unscrew the Retainer 34 and remove. Take care to keep the Spring 31.

• Prise o the ‘O’ Ring 10 taking care not to damage the Spindle 35 and Retainer 34 seatings.

• Clean and re-assemble using a new ‘O’ Ring 10.

• Check length of Spring 31 which must be 12.7mm (0.5”) free length – replace if necessary.

• Assembly in reverse order of dismantling.

TAIL JAW ON/OFF VALVE

• The unit is designed so that minimum of servicing is required during the life of the tool.

• If it is necessary to dismantle the valve, proceed as follows:

• Remove Trigger Housing 56 as described in section “Hydraulic Piston”.

• Using a screwdriver*, carefully remove the Chrome Star-lock Washer 18 from Air Tail Jaw Spool 55 and discard washer.

• Extract Air Tail Jaw Spool 55 from Switch Block 54.

• Taking care not to damage the Air Tail Jaw Spool 55, remove the ‘O’ Rings 12.

• Clean spool and ret new ‘O’ Rings 12 using assembly bullet* and insert into Switch Block 54, noting its orientation.

• Fit New Chrome Star-lock Washer 18 by clamping in a soft jaw vice to prevent damage. DO NOT USE UNDUE FORCE.

• Complete assembly in reverse order of dismantling.

HANDLE & END CAP

• Clean and inspect mouldings for cracks or other damage.

CURSOR

• Clean and oil cursor assembly occasionally with a little light oil.

IMPORTANT

Check the tool against daily and weekly servicing.

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating.

* Refers to items included in the 0753 Mkll Service Kit. For complete list see page 14.

Item numbers in bold refer to the general assemblies and parts lists on pages 18-19.

17

ORIGINAL INSTRUCTION ENGLISH

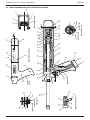

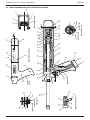

6.2 GENERAL ASSEMBLY OF BASE TOOL 07536-02200

8

4

8

4

4

8

8

3

8

3

48

HANDLE COVER DETAILS

WW

14

44

25

17 6445 37 3242

1211

11

V

V

15

16 45 47 60

39 41 33 49

36

2

(GREEN PIPE) (SILVER PIPE)

52

38

40

29

20

24

PART SECTION 'W'-'W'

PART SECTION 'V'-'V'

6

9

69

53

X

X

TRIGGER VALVE DETAIL

35

26

21

34 31

56

10

50

13

28 27

59

57 RH

58 LH

43

11

5

51

18

SECTION 'X'-'X'

55

19

12

22 (BLUE PIPE)

22 (WHITE PIPE)

(BLACK PIPE)

WW

61

30, 38

22, 49

2

2

18

ENGLISH ORIGINAL INSTRUCTION

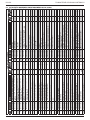

6.3 PARTS LIST FOR BASE TOOL 07536-02200

07536-02200 PARTS LISTS

ITEM PART N° DESCRIPTION QTY SPARES ITEM PART N° DESCRIPTION QTY SPARES

1 07007-00392 CABLE TIE (NOT SHOWN) 1 - 34 07220-00803 RETAINER 1 -

2 07001-00499 M3×5 LONG SOCKET SET

SCREW 3 - 35 07241-00208 SPINDLE 1 -

3 07001-00262 M4×22 LONG SOCKET

HEAD CAP SCREW 1 - 36 07154-00404 SPRING 1 -

4 07001-00401 M4×10 LONG SOCKET

HEAD CAP SCREW 4 - 37 07490-03002 BARREL RETURN SPRING 1 -

5 07001-00404 M5×6 LONG SOCKET

HEAD SET SCREW 1 - 38 07536-02211 3MM AIR CURSOR CON-

CERTINA TUBE - SILVER 1 -

6 07001-00504 M4×6 LONG SOCKET

HEAD CAP SCREW 2 2 39 07536-00203 PISTON 1 -

7 40 07530-00204 STROKE LIMITER 1 -

8 07002-00134 M4 HEX NUT 4 - 41 07530-00206 RUBBING STRIP 1 1

9 07002-00153 M4 WASHER [PLASTIC] 2 - 42 07536-00208 JAW HOUSING 1 -

10 07003-00022 'O' RING 1 - 43 07530-00500 BLEED PLUG ASSEMBLY

[ITEMS 62 TO 65] 1 -

11 07003-00113 'O' RING 3 3 44 07536-02201 BARREL 1 -

12 07003-00121 'O' RING 3 3 45 07530-02202 BODY 1 -

13 07003-00142 1/8" BSP BONDED SEAL 1 1 46 07530-02205 BARREL PLUG 1 -

14 07003-00167 'O' RING 1 1 47 07536-02207 TAIL JAW CYLINDER 1 -

15 07003-00386 'O' RING 2 - 48 07530-02210 LABEL 2 -

16 07003-00236 SEAL [DYNAMIC] 1 1 49 07536-02212 4MM AIR CURSOR CON-

CERTINA TUBE - GREEN 1 -

17 07003-00237 SEAL [STATIC] 1 - 50 07536-02213 REAR PLUG 1 -

18 07004-00058 1/8" STARLOCK WASHER

CHROME 1 - 51 07530-00310 BLANKING PLUG 2 -

19 07004-00059 1/8" STARLOCK WASHER

BLACK 1 - 52 07536-02214 STOP 1 -

20 07005-10073 3MM CONNECTOR 1 - 53 07530-02220 CLIP 1 -

21 07005-01357 COLLET TYPE CON-

NECTOR 1 - 54 07530-02301 SWITCH BLOCK 1 -

22 07005-01571 ELBOW CONNECTOR 3 - 55 07530-02302 AIR TAIL JAW SPOOL 1 -

23 07536-02216 LOCKNUT 1 - 56 07530-02311 TRIGGER HOUSING 1 -

24 07005-10074 2MM CONNECTOR 1 - 57 07536-02601 HANDLE MOULDING AS-

SEMBLY RIGHT HAND 1 -

25 07007-00017 DUST CAP 1 - 58 07536-02602 HANDLE MOULDING AS-

SEMBLY LEFT HAND 1 -

26 07007-00300 TRIGGER BUTTON 1 - 59 07530-02603 END CAP 1 -

27 73200-02022 SAFETY LABEL 1 - 60 07536-02800 TAIL JAW PISTON ASSEM-

BLY 1 -

28 07007-01504 CE MARK LABEL 1 - 61 07536-02215 FITTING ADAPTER 1 -

29 07008-00438 FLEXIBLE HOSE ASSEM-

BLY 1 - 62 07003-00142 BONDED SEAL (NOT

SHOWN) 1 1

30 07005-01323 M3 BARB ELBOW 1 - 63 07003-00194 BONDED SEAL (NOT

SHOWN) 1 1

31 07125-00215 SPRING 1 - 64 07001-00442 SCREW (NOT SHOWN) 1 1

32 07151-00403 TAIL JAWS 1

pair 2 65 07530-00501 PLUG (NOT SHOWN) 1 -

33 07003-00016 'O' RING 1

19

ORIGINAL INSTRUCTION ENGLISH

6.4 DISMANTLING INSTRUCTIONS

• When dismantling the intensier assembly, rst disconnect the air supply hose to intensier inlet Connector 22.

• Using an Allen Key* undo four Screws 27 and remove Protection Plate 24.

• Disconnect the trigger hose 47 from the intensier Valve 43 or 48 by depressing the outlet collet and withdrawing the hose.

• Remove Cover Plate 4 and Gasket 35 by removing Screws 37 and Washers 36 using Allen Key*.

• Ensure that gasket is not damaged to ensure a proper seal on assembly.

• Invert intensier assembly and drain oil from reservoir into a suitable container.

• Remove Quick Release Connector 32 together with Connector 31 and Seals 33 with suitable spanner*.

• Remove intensier Valve 43 or 48 by removing the xing screws with a suitable spanner taking care to retain ‘O’ Ring 21

located in the Intensier Body Casting.

• Remove Screw 19 using a suitable Allen Key* and remove Silencer Cover 16, Foam Silencer 15, Spacer 18 and Retaining

Plate 20.

• Pull o the 6mm Plastic Tube 41 from Vacuum Connectors 42.

• From the base of the intensier insert a 3mm Allen Key * through the two holes and unscrew the Vacuum Connectors

42. Note:

• Care must be taken as the vacuum connectors are locked and sealed in place using Loctite® 574.

• If dicult to remove, the vacuum connectors can be drilled out using a /” or 4.7mm diameter drill.

• To reassemble the Vacuum Connectors 42, the following procedure must be followed: -

• Soak the vacuum connectors in a suitable primer, i.e. Perma Bond A905

• Place a drop of Loctite® 574 in the intensier threaded hole.

• From the base of the intensier insert the Allen Key * through the hole. Ensure that the Allen Key * is free from

Loctite® 574 before inserting into the vacuum connector.

• Rotate the Allen Key while applying Loctite® 574 to the base of the vacuum connector.

• Screw the Vacuum connector into the intensier, ensuring that there is sucient Loctite® 574 at the base of the

tting such the thread is not visible.

• Using a screwdriver, carefully remove internal Retaining Ring 14. Clean and inspect groove for sign of damage.

• Using Extractor*, insert male threaded end into End Cover 12 and withdraw it along with intensier Sleeve 28 and ‘O’

Rings 10 and 13.

• Insert Rod* through the connector orice at the front of the intensier body and tap out Piston Rod 9 and Piston

Assembly.

• Using a suitable Allen Key*, unscrew two Screws 25 and remove End Cover 12 from intensier Sleeve 28.

• Remove Seal Plug 7 with spanner*.

• Insert rod* through connector orice at the front of the intensier body and push out Seal Housing 5 and associated ‘O’

rings and lip seals.

• Remove Valve Housing Assembly 34 from the main body with a suitable spanner*. Clean by blowing through with a

low-pressure air jet.

• Remove Piston Rod 9 from intensier Air Piston 11 by gripping the rst 20 mm (3/4”) of the rod in a vice tted with soft

jaws, taking care not to damage or mark the working surface.

• Unscrew locking Nut 17 with a suitable spanner*.

• Assemble in the reverse order of dismantling, observing the following:

• Clean all parts and renew all ‘O’ rings.

• Lubricate all seals using Moly Lithium grease.

• Valve Housing Assembly 34 must be retted using a thread sealing adhesive.

* Refers to items included in the 0753 MkII Service Kit. For complete list see page 14.

Item numbers in bold refer to the illustration and parts list opposite.

20

ENGLISH ORIGINAL INSTRUCTION

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

in altre lingue

- français: Stanley 07536 Manuel utilisateur

- español: Stanley 07536 Manual de usuario

- Deutsch: Stanley 07536 Benutzerhandbuch

- Nederlands: Stanley 07536 Handleiding

- português: Stanley 07536 Manual do usuário

- dansk: Stanley 07536 Brugermanual

- svenska: Stanley 07536 Användarmanual

Documenti correlati

Altri documenti

-

Avdel 0753 MKII 07530 MKII Manuale del proprietario

-

Avdel 07537 Manuale del proprietario

-

Facom Y.135F Manuale del proprietario

-

Avdel GENESIS NG4 Manuale del proprietario

-

GYS HYDROPNEUMATIC RIVETING MACHINE RIV508 Manuale del proprietario

-

Avdel GENESIS NG3 Manuale del proprietario

-

Makita DRV150 Manuale utente