Univex RotorBake E11 Manuale del proprietario

- Categoria

- Piani cottura

- Tipo

- Manuale del proprietario

Questo manuale è adatto anche per

Electrical and gas ovens for pastry and bread

RDRE

T11 - E11

Series 14

Instruction Manual

SUMMARY

Summary ................................................................................................................................................................. 1

Declaration Of Conformity ........................................................................................................................................ 3

General Warnings ..................................................................................................................................................... 4

Shipping .................................................................................................................................................................... 5

Unloading And Handling ........................................................................................................................................... 6

Technical Data And Identification ............................................................................................................................. 7

Volumes And Connections Of Electric Version Of Unit ............................................................................................ 8

Volumes And Connections Of Gas Version Of Unit ................................................................................................. 9

Electrical Data For Electric Version ........................................................................................................................ 10

Electrical Data For Gas Version ............................................................................................................................. 10

Water Connection For Both Versions ..................................................................................................................... 10

Room ...................................................................................................................................................................... 11

Positioning Of Electric Version................................................................................................................................ 12

Positioning Of Gas Version ..................................................................................................................................... 12

Electrical Connection .............................................................................................................................................. 13

Burner ..................................................................................................................................................................... 14

Water And Drain Connection .................................................................................................................................. 14

Steam Discharge Connection (1) ............................................................................................................................ 15

Exhaust Discharge Connection For Gas Version (2) .............................................................................................. 15

Air Flow Adjustment In Electrical And Gas Version ................................................................................................ 16

Commissioning ....................................................................................................................................................... 17

Instructions For Use ................................................................................................................................................ 18

Safety Instructions For The User ............................................................................................................................ 18

Control Panel 80P .................................................................................................................................................. 19

Switching On And Off:............................................................................................................................................. 19

Setting The Language: ............................................................................................................................................ 19

Setting The Time: ................................................................................................................................................... 20

Characteristics Of Programmes In Progress - Preheating And Baking Time Extension: ....................................... 20

Manual Baking Mode: ............................................................................................................................................. 20

How To Set A Manual Programme: ........................................................................................................................ 21

Programme Mode (Customizable Programming): .................................................................................................. 22

Executing A Customized Programme: .................................................................................................................... 23

Preset Programmes: ............................................................................................................................................... 23

Vision Control Panel ............................................................................................................................................... 24

Settings Menu ......................................................................................................................................................... 25

Working Modes: ...................................................................................................................................................... 25

Manual Programming: ............................................................................................................................................ 27

Baking Parameters: ................................................................................................................................................ 28

Multi-Timer Mode .................................................................................................................................................... 29

Execution Of A Manual Program ............................................................................................................................ 30

Execution Of A Chef Program ................................................................................................................................ 32

Execution Of A Recipe Program ............................................................................................................................. 32

Procedure To Download The Recipes From Bestfor Website ................................................................................ 34

Enabling Usb Menu ................................................................................................................................................. 36

Alarm Codes: .......................................................................................................................................................... 38

Cleaning And Care .................................................................................................................................................. 38

Causes Of Malfunction ........................................................................................................................................... 39

Technical Service.................................................................................................................................................... 40

Notes: ...................................................................................................................................................................... 40

RDRE - electric version - gas version - Page 2

ELECTRIC VERSION

BAKE OFF ITALIANA SRL VIA CASTELBOLOGNESI,6 - ZONA P.M.I. TELEFONO 0532/732333

CAP. SOC. € 93.600,00 I.V. 44044 CASSANA / FERRARA FAX 0532/730589

DICHIARAZIONE DI CONFORMITÀ AI SENSI DELLE DIRETTIVE:

DECLARATION OF CONFORMITY TO THE DIRECTIVES:

DÉCLARATION DE CONFORMITÉ SUR LA BASE DES DIRECTIVES:

CERTIFICACIÓN DE CONFORMIDAD A LA DIRECTIVA:

BASSA TENSIONE: 2006/95/CE

LOW VOLTAGE:

BASSE TENSION: EN60335-2-42:2003

BAJA TENSIÒN: EN60335-1:2002; A11

EN50336:2003

COMPATIBILITÀ ELETTROMAGNETICA: 2004/108/CE

EMC:

EMC: EN55014-1:2000; A1; A2

COMPATIBILIDAD ELÈCTROMAGNETICA: EN55014-2:1997; A1

EN61000-3-2:2000

EN61000-3-3:1995; A1

TIPO DI PRODOTTO: FORNO ROTATIVO

PRODUCT TYPE: ROTARY OVEN

TYPE DE PRODUIT: FOUR ROTATIF

TIPO DE PRODUCTO: HORNO ROTATIVO

MODELLO: ROTORBAKE E11

MODEL: ROTORBAKE E11

MODÈL: ROTORBAKE E11

MODELO: ROTORBAKE E11

CON LA PRESENTE L’AZIENDA DICHIARA SOTTO LA PROPRIA RESPONSABILITÀ, CHE IL PRODOTTO SOPRACITATO SODDISFA PER

PROGETTAZIONE E COSTRUZIONE I REQUISITI DELLA DIRETTIVA “BASSA TENSIONE” E “COMPATIBILITÀ ELETTROMAGNETICA”. LA

CONFORMITÀ È STATA VERIFICATA CON L’AUSILIO DELLE SEGUENTI ARMONIZZATE:

WE, THE COMPANY, DECLARE HERE WITH ON OUR OWN RESPONSABILITY THAT THE ABOVE-MENTIONED PRODUCT MEETS THE

REQUIREMENTS OF THE LOW VOLTAGE DIRECTIVE FOR WHAT CONCERNS EMGINEERING AND CONSTRUCTION AND EMC CONFORMITY HAS

BEEN CONTROLLED WITH THE AID OF THE FOLLOWING HARMONIZED STANDARDS:

PAR LA PRÉSENTE NOUS DÉCLARONS SOUS MOTRE RESPONSABILITÉ QUE LA PRODUIT SOUS-INDIQUÉ, EN CE QUI CONCERNE SA

PROGETTATION ET FABRICATION EST CONFORME AUX CONDITIONS REQUISES PAR LA DIRECTIVE BASSE TENSION ET COMPATIBILITÉ

ELÉCTROMAGNETIQUE.

LA CONFORMITÉ A ÉTÉ VERIFIÉE A L’AIDE DES NORMES UNIFIÉES SUIVANTES:

CON ESTA LA EMPRESA DECLARA, POR SU MISMA RESPONSABILIDAD, QUE EL PRODUCTO CITADO ANTES ENCUENTRA LOS RECUISITOS DE

PROYETACION Y CONSTRUCCIÓN DE LA DIRECTIVA “BAJA TENSIÓN” Y “COMPATIBILIDAD ELÉCTROMAGNÉTICA”. LA CONFORMIDAD FUE

COMPROVADA CON LAS SIGUIENTES ARMONIZADAS STANDARD:

Ferrara, 20.04.2009 BAKE OFF ITALIANA S.R.L.

GIORGIO BORGHI

RDRE - electric version - gas version - Page 3

GAS VERSION

BAKE OFF ITALIANA SRL VIA CASTELBOLOGNESI,6 - ZONA P.M.I. TELEPHONE 0532/732333

SHARE CAPITAL € 93.600,00 FULLY PAID UP 44044 CASSANA / FERRARA FAX 0532/730589

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

89/392/CEE

WE HEREBY DECLARE ON OUR OWN EXCLUSIVE RESPONSIBILITY THAT THE PRODUCT:

MODEL : ROTOR T11

TO WHICH THIS DECLARATION REFERS IS COMPLIANT WITH THE FOLLOWING STANDARDS:

prEN XXX : 1994 STANDARD OF TYPE C ROTARY OVEN

EN292-1 : 1992 BASIC CONCEPTS, GENERAL PRINCIPLES OF

DESIGN, TERMINOLOGY, BASIC METHODOLOGY

EN292-2 : 1992 BASIC CONCEPTS, GENERAL PRINCIPLES OF

DESIGN, TECHNICAL PRINCIPLES AND SPECIFICATIONS.

EN294 : 1993 SAFETY DISTANCES FOR UPPER LIMBS.

PrEN 953 : 1992 DESIGN AND CONSTRUCTION OF PROTECTIONS.

PrEN 954-1 : 1992 PRINCIPLES OF DESIGN FOR TEST SYSTEMS

THAT AFFECT SAFETY

PrEN 563 : 1994 TOUCHABLE HOT SURFACES

EN 60204-1 : 1993 ELECTRICAL EQUIPMENT ON THE MACHINE

EN 60529 : 1991 COVERINGS AND DEGREE OF PROTECTION

ISO 468 : 1991 ROUGHNESS OF SURFACES

C.M. n°68 : 1969 METHANE HEATING SYSTEMS

C.M. n°73 : 1971 FUEL OIL HEATING SYSTEMS

AS SET FORTH BY DIRECTIVES

89/392/CEE

73/23/CEE

90/396/CEE

98/37/CEE

APPROVAL OF GAS-FIRED OVENS

DWGW N°CE 0085AR0301

BAKE OFF ITALIANA s.r.l.

GIORGIO BORGHI

Ferrara, 03.09.2001

RDRE - electric version - gas version - Page 4

GENERAL WARNINGS

This manual must be delivered along with the appliance, and it must stay with it for the entire duration of the

appliance.

These instructions must be kept near the unit in an easily accessible place for easy reference over time.

Installation, commissioning and maintenance of the oven must be performed only by qualified personnel in

compliance with these manufacturer instructions and with the latest current standards.

No devices or safety devices must be moved, removed, disabled or interrupted, as this would void the

manufacturer's guarantee.

The unit must undergo scheduled maintenance by qualified personnel from the manufacturer.

The oven must be used only for its intended purpose, which is the cooking of all bread and pastry up to the

maximum sizes and weights compatible with the sizes of the pans and cooking chamber. Any other use is

to be considered improper.

It is not advisable to place products with a high alcohol content in the oven.

The oven must be used only by persons who have been properly trained in its use.

The cooking chamber and the inside of the unit need to be cleaned every day. This will safeguard

appearance, hygiene and proper operation.

Upon completion of use, all connections are to be cut off (electrical power, gas and water for those models

which include the latter).

Shut down the unit in the event of malfunction or failure.

Non-original spare parts may not ensure perfect operation and safety of the oven. Therefore, only by

contacting the manufacturer or manufacturer-authorized personnel can you be sure that the spare parts

and labour are of the required quality.

RDRE - electric version - gas version - Page 5

SHIPPING

TRANSPORT

The oven is normally shipped in a wood crate, open on the top and resting on a platform that can be set on a

pallet. The single pieces are protected and placed inside the oven.

Packaging of assembled oven with position of warnings

Side

Front

Address

Packaging for oven in two sections for closed container, with position of warnings

Address

Address

RDRE - electric version - gas version - Page 6

UNLOADING AND HANDLING

The oven must be unloaded with a crane and ropes of a suitable capacity for the weight of the oven, or with a

forklift.

Internal movement is to be carried out using a forklift or hand truck when the oven is still on the pallet.

When taking delivery, check whether the packaging is damaged. If it is, accept delivery with reservation, and take

photographs of any clear damage.

In accordance with current standards, all packaging must be turned in to appropriate collection centres based on

the materials they are made of.

CHECKING

Once the oven has been unpacked, check it thoroughly for any damage

If damage is discovered due to transport, comply with the conditions of the supply contract for the procedure for

obtaining economic coverage.

STORAGE

The oven may not be stacked on other goods without suitable support so as to prevent deformations. It

must not in any way be exposed to the elements.

Temperatures in the storage area must be between -10°C and 70°C. Humidity must be such that condensation

does not form.

The oven has a minimum degree of protection of IP44.

SHUTDOWN

For maintenance or during holidays, etc., do the following:

- Disconnect the supply of water and electrical energy.

- Ventilate the oven by leaving the door open. Cover the opening with a net with a mesh of not more than 5 mm

to keep harmful animals out of the oven.

RDRE - electric version - gas version - Page 7

TECHNICAL DATA AND IDENTIFICATION

The essential technical data of the oven are shown on the data plate. All connections are marked on the oven.

When communicating with the manufacturer or the service centre, always provide the model, code and serial

number.

Gas version

Description

U.M.

Value

Notes

Weight

Kg

1600

Largest volume

Mm

155

0x2240

Cart max. diagonal

Mm

1150

Cart max. width

Mm

860

Pan

Cm

80x80 – 80x100

Cart max. load

Kg

200 / 200 / 400

Hook / platform / Reinf. Platf.

Cooking surface

M

2

11,5

18 pans 80x80 - 80x100

Hourly production (approximate)

Kg

195

Max. operating temperature

°C

300

Temperature increase gradient

°C/Min

12

Empty

Temperature increase gradient

°C/Min

6

With full load

Interval of humidification

Min

10

Oven temperature 200°

team discharge fan

Dm

3

/S

250

Fire box volume

Dm

3

/S

72

Installed electrical power

Kw

1.5

Thermal power

Kcal/H

65000

Pressure in fire box

Mbar

-1 -4

With burner on

Fuel oil

Kcal/Kg

10200

Methane gas fuel

Kcal/M

3

8500

LPG fuel

Kcal/Kg

11000

C.M.G. Fuel: heating oil

Kg/H

4

Approximate

C.M.G. Fuel: methane gas

M

3

/H

5

Approximate

Burner:

Type: Single stage blown air

Max length of nosepiece

Nozzle

Power supply voltage

Mm

Gph

V

120

1,75 A 60°

230

With pump calibrated at 12

bar

RDRE - electric version - gas version - Page 8

VOLUMES AND CONNECTIONS OF ELECTRIC VERSION OF UNIT

A - Power supply inlet (Pg 36)

B - Chamber vapour discharge Ø 140

C - Water discharge (1”)

D - Water inlet (¾”)

E – Extractor hood discharge

RDRE - electric version - gas version - Page 9

VOLUMES AND CONNECTIONS OF GAS VERSION OF UNIT

A - Power supply inlet (Pg 36)

B - Smoke discharge

C - Water discharge (1”)

D - Water inlet (¾”)

E - Chamber vapour discharge Ø 140

F - Extractor hood discharge

G -Burner

RDRE - electric version - gas version - Page 10

ELECTRICAL DATA FOR ELECTRIC VERSION

Model

Nominal voltage

AC V

Connection cable

min. type

H07 RN-F

minimum cross-section

Nominal

absorption

kW

RotorBake E11

208 3F VAC 60 HZ

4x35 mm²

50

400 3N VAC 50 HZ

5x10 mm²

50

ELECTRICAL DATA FOR GAS VERSION

Model

Nominal voltage

AC V

Connection cable

min. type

H07 RN-F

minimum cross-section

Nominal

absorption

kW

RotorBake T11

208 3F VAC 60 HZ

4x6 mm²

1.5

400V 3F+N VAC 50 HZ

5x4 mm²

1.5

WATER CONNECTION FOR BOTH VERSIONS

It is advisable to use softened water with hardness of 5°f. If the mains water pressure is not within the range

shown below, a pressure reducer must be installed upstream.

Model

Water

discharge fitting

Water

inlet fitting

Mains pressure

RotorBake E11-T11

1

/

2

“

¾ “

50 - 300 kPa

RDRE - electric version - gas version - Page 11

ROOM

The unit must be placed in a well-ventilated location, if possible under an exhaust hood to ensure rapid removal

of cooking vapours. Comply with requirements on free cross-section for drawing combustion air and for the

removal of any gas leaks.

The temperature in the place of installation must not exceed values of less than + 5° C or more than + 40° C. The

air humidity must be within the range of 40% to 75%. Conditions other than these may have a negative effect on

the unit's operation.

The oven must be levelled.

This can be checked wither with a spirit level or by setting a pan on top that has a small amount of water in it.

The backs and sides must be 10 cm from other appliances and flammable walls. If the distance is less or the

position is next to other units that give off heat (e.g. fryers), appropriate measures must be taken such as placing

protection against radiance

The manufacturer suggests a distance of 50 cm to allow for cleaning and service.

Make sure the openings of the unit are not obstructed or covered!

Strict compliance with fire prevention measures must be ensured

RDRE - electric version - gas version - Page 12

POSITIONING OF ELECTRIC VERSION

!

Attention!

During positioning and installation, ensure compliance with the following prescriptions, technical rules

and directives:

- current legal requirements

- local building and fire codes

- accident prevention requirements

- directives and regulations of the provider of electrical energy

- current CEI regulations

- building directives for fire prevention techniques for ventilation systems

- any special local requirements

- workplace requirements

- rules for kitchen safety

- Interior Ministry Circular no. 68 dated 25.11.1959 and subsequent variations, "Standards of safety for

mains-connected heating systems"

- Current standards for chimneys and connections

- directives on ventilation systems for kitchens

POSITIONING OF GAS VERSION

!

Attention!

During positioning and installation, ensure compliance with the following prescriptions, technical rules

and directives:

- current legal requirements

- local building and fire codes

- Law no. 1083 dated 06.12.71 “Standards of safety for the use of combustible gas"

- Circular letter no. 412/4183 dated 06.05.75 “Standards of safety for kitchen systems fuelled by LPG"

- Standards UNI - CIG 7129/72 “Standards gas systems supplied by the LPG distribution system"

- accident prevention requirements

- directives and regulations of the provider of gas

- directives and regulations of the provider of electrical energy

- current CEI regulations

- building directives for fire prevention techniques for ventilation systems

- any special local requirements

- workplace requirements

- rules for kitchen safety

- Law no. 1083 dated 06.12.71 “Standards of safety for the use of combustible gas"

- Interior Ministry Circular no. 68 dated 25.11.1959 and subsequent variations, "Standards of safety for

mains-connected heating systems"

- Current standards for chimneys and connections

- directives on ventilation systems for kitchens

Remove protective film from the outer panels of the oven by detaching it slowly. Make sure to remove any

residues of adhesives. Residual adhesive can be removed using suitable products such as stain remover

RDRE - electric version - gas version - Page 13

ELECTRICAL CONNECTION

!

Attention!

The electrical connection must be made only by qualified personnel. It must be in compliance with CEI

requirements and specifications.

Check the setup of the oven. Compare the data for the available mains voltage and current with the information

on the data plate. The electrical diagram is included with this manual.

The unit must be connected to the mains only if between it and the mains there is an omnipolar switch with at

least 3 mm of opening between contacts for each pole. This must be in an easily accessible position near the

oven.

The connection cable must be at least type H07 RN-F. The minimum cross-section and the number of wires are

shown in the table "Electrical Data". Fixed connections require the use of conduits which must comply with

standards.

Remove the cover of the electrical panel, insert the cable in the cable clamp and connect the single wires to the

corresponding terminal. The plate near the terminal block shows the correct positions of the phases.

After connecting the cable to the terminal block, tighten the cable clamp and close again.

Electrical safety is ensured only when the unit is properly earthed as required by current standards.

The oven is also to be included in an efficient equipotential system. This connection is made with the terminal

marked with the symbol located on the back of the unit.

!

Attention!

Connection to the gas mains must be carried out only by specialized personnel with a valid license to do

so. The manufacturer shall not be held liable if this requirement is not complied with.

The oven belongs to category II

2H3+

. This means it is suitable for operation with the following gases and at the

following pressures:

Methane H 20 mbar

LPG 28-30/37 mbar

Connection may be made only after receiving approval from the energy provider.

Connection to gas pipes may be permanent, or it may be possible to disconnect it by installing upstream a cock

with certified closing. The cock must be in an easily accessible position near the oven.

If hoses are used, they must be made of stainless steel, and they must comply with applicable standards. It is

severely prohibited to reduce the diameter of the gas inlet.

Once connection is complete, check the seals with a leak detection spray that does not cause corrosion.

It is absolutely prohibited to use open flames!

RDRE - electric version - gas version - Page 14

BURNER

!

See the specific requirements provided by the manufacturer.

Installation, calibration, testing and guarantee documentation are all provided by the nearest service centre

designated by the manufacturer of the burner.

Before making connections, check that the burner is compatible with the provided fuel.

Attach the burner to the flange above the oven after inserting the gasket of insulating material that is included in

the packaging.

To prevent possible gas leaks, it is advisable to use a gas detector connected to a cut-off valve which, if required,

interrupts the flow.

WATER AND DRAIN CONNECTION

There must be a tap to close the water supply between the units and the water mains. The fitting upstream for

the water connection must be compliant with current requirements. The water connection fitting is located on the

back of the unit and is duly marked.

Information on acceptable water pressure is shown in the paragraph "Water Connection".

It is advisable to connect to a source with softened water, with a degree of hardness between 2 and 5° fH.

It is advisable to use a hose that is capable of absorbing small changes in pressure.

Before making the connection, let water run out of the pipes.

The drain should be made using rigid, heat-resistant pipe (maximum length 2 m). Drain water is to be carried to

the drain system in a constant flow with a funnel or siphon. It is prohibited to reduce the diameter of the pipe.

!

Attention!

A drain which is not properly constructed may release unpleasant odours into the cooking chamber!

RDRE - electric version - gas version - Page 15

STEAM DISCHARGE CONNECTION (1)

The steam released from the cooking chamber is placed in the atmosphere through special steam ducts. The

steam ducts (exhaust hood and chimney) can be installed separate from one another, or they can be combined

in a single duct. The connection between the two ducts must necessarily be as shown in figure. Other types of

joints may compromise proper release of vapours.

At the base of every upwards section of the steam release duct, there must be a collection chamber and a drain

pipe for condensation. There must also be a suitable opening for cleaning and inspection.

EXHAUST DISCHARGE CONNECTION FOR GAS VERSION (2)

The length and shape of the discharge pipe affects the negative pressure in the combustion chamber. It

is advisable to run the pipes upwards for at least 2 metres. Nonetheless, check the negative pressure in

the combustion chamber, which should be between -1 and -4.

RDRE - electric version - gas version - Page 16

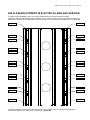

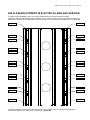

AIR FLOW ADJUSTMENT IN ELECTRICAL AND GAS VERSION

To obtain precise distribution and even cooking, adjust the air flow outlet shutters as follows:

Loosen the M8 nuts that hold the shutters inside the oven. Adjust the opening of the shutters as shown in the

table below. Tighten the nuts. Make sure that while doing so, the opening as in the table below is maintained.

10mm

10mm

11mm

11mm

11mm

11mm

13mm

13mm

13mm

13mm

15mm

15mm

15mm

15mm

17mm

17mm

17mm

17mm

18mm

18mm

18mm

18mm

21mm

21mm

The above adjustments are those which are best for even cooking. If they are changed by unskilled or

unauthorized persons, this work is not covered by the guarantee.

RDRE - electric version - gas version - Page 17

COMMISSIONING

PRELIMINARY OPERATIONS FOR ELECTRIC VERSION

!

Attention!

check that:

- all connections have been made correctly

- the film has been completely removed

- the main electrical switch upstream is activated

- the water tap is open

INSTRUCTIONS FOR THE USER

The oven may be delivered to the user only after all of the work and checks described in this manual have been

performed.

The use of the oven must be fully explained to the user, especially as concerns safety. This must be done with

the aid of these instructions.

It should be pointed out to the user that modifications to the room where the unit is installed may affect the flow of

combustion air. Therefore, this would require the unit's operation to be checked again by a specialized technician.

The client should be advised to take out a service contract, since this type of unit requires at least one check per

year.

PRELIMINARY OPERATIONS FOR GAS VERSION

INSTRUCTIONS FOR THE USER

Refer to the supplementary tag on the back of the oven to check admissible mains pressure for proper operation,

which are as follows:

For LPG:

Operation is permitted for a range of mains pressure between 20/25 and 35/45 mbar,

Operation is not permitted with mains pressure less than 20/25 and greater than 35/45 mbar.

If the mains pressure in the place of installation is different from what is indicated above, or is not within the range

of pressure, advise the system installer and do not commission the system until the cause has been discovered

and eliminated.

For METHANE H:

Operation is permitted for a range of mains pressure between 17 and 25 mbar,

Operation is not permitted with mains pressure less than 17 and greater than 25 mbar.

If the mains pressure in the place of installation is different from what is indicated above, or is not within the range

of pressure, advise the provider and do not commission the system until the cause has been discovered and

eliminated.

CHECK OF THERMAL YIELD

Checking the thermal yield consists of the following points:

First of all, compare the data on the data plate and supplementary plate concerning the category of the unit and

the gas adjustment with the gas provided at the location (type of gas and connection pressure). If this information

does not match, check correspondence of burner/type of gas.

The unit is to be commissioned with the given nominal yield, the required nozzle and the primary air adjustment

device.

An additional check of the nominal capacity can be provided by the volumetric method.

RDRE - electric version - gas version - Page 18

Cart

Insertion

- Set the time for the humidification cycle.

- Completely open the door.

- Check that the steam extractor starts working.

- Push the cart into the oven until the upper bearing of the cart enters the housing of the hook.

- Close again, and turn the door handle clockwise until it is locked horizontally.

Extraction

- An acoustic signal will advise you that the set cooking time has expired.

- Begin taking the products out of the oven as follows:

- Release the door, and leave it ajar for a few moments. This will allow any residual steam to be extracted.

- Now open the door completely. Using heat resistant gloves, extract the cart.

- Close again, and turn the door handle clockwise until it is locked horizontally.

INSTRUCTIONS FOR USE

SAFETY INSTRUCTIONS FOR THE USER

!

Attention!

Only after completing all connections, the unit is ready for commissioning.

The unit can be safely operated only if the following instructions are adhered to.

The user may use this appliance only after he has been properly instructed on its use and operation.

Coverings or parts of the unit which can only be removed with the aid of a tool must absolutely not be

removed.

The unit must be monitored while in use.

During operation, the door becomes hot. Be very careful with it.

Be very careful when opening the door during operation or when the unit is hot, as hot vapours may be

released by it!

Protect the unit from freezing temperatures.

All work concerning installation or repair of the unit are to be performed by qualified personnel in

compliance with current standards.

At least once a year, have the unit checked by qualified personnel from the manufacturer. For this

purpose we suggest stipulating a service contract.

The unit must be cleaned on a daily basis.

The unit is not protected against splashes of water. Therefore, do not use direct or pressurized jets of

water

Note: The noise level at in the workplace is less than 70 dB (A). This information is required for certain

national safety standards.

Delayed start: allows the operator to perform start-up and hence the pre-heating phase at a certain time by

setting the day and time using the programming knob. Enter the menu to set in order the day of the week, start-

up time and enabling.

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

La pagina sta caricando ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

Univex RotorBake E11 Manuale del proprietario

- Categoria

- Piani cottura

- Tipo

- Manuale del proprietario

- Questo manuale è adatto anche per

in altre lingue

- English: Univex RotorBake E11 Owner's manual

Altri documenti

-

Unox BakerTop Manuale utente

-

Foster S4000 Manuale utente

-

Foster Oven Manuale utente

-

Sanyo MPR-1411 Manuale utente

-

Sanyo MDF-U74VC Manuale utente

-

Hobart HFEI D Series Installation, Use And Maintenance Instructions

-

Alfa Network Zeno Manuale utente

-

Whirlpool ADN 510 Guida d'installazione

-

Whirlpool ADN 500 Guida d'installazione

-

Firex betterpan DBRG...-C series Owner's Instruction Manual