Jotul F 371 Manuale del proprietario

- Categoria

- Camini

- Tipo

- Manuale del proprietario

Jøtul F 370 Series

GB - Installation and Operating Instructions 2

FR - Manuel d’installation et d´utilisation 22

ES - Instrucciones para instalación y mantenimiento 42

IT - Manuale di installazione ed uso 62

NL - Installatie- en montagehandleiding 82

Jøtul F 370 Series

Manual Version P02

The manuals which are enclosed with the product must be kept throughout the product’s entire service life. Les manuels fournis avec le produit doivent être

conservés pendant toute la durée de vie du produit. Los manuales suministrados con este producto deben guardarse durante todo el ciclo de vida del producto.

I manuali inclusi con il prodotto vanno conservati per l’intera durata di vita del prodotto. De bij de haard meegeleverde handleidingen moeten gedurende de

volledige gebruiksduur van de haard bewaard blijven.

Jøtul F 371 Jøtul F 373 Jøtul F 374 Jøtul F 375 Jøtul F 376 Jøtul F 377 Jøtul F 379

2

Table of contents

Installation manual with technical data

1.0 Relationship to the authorities ................... 2

2.0 Technical data .............................................. 2

3.0 Safety ............................................................ 3

4.0 Installation ..................................................8

5.0 Daily use ......................................................18

6.0 Maintenance ...............................................18

7.0 Service ......................................................... 19

8.0 Operational problemes -

troubleshooting .........................................20

9.0 Optional Equipment ..................................20

10.0 Warranty ......................................................21

1.0 Relationship to the

authorities

Installation of a fireplace must be according to local codes and

regulations in each country.

All local regulations, including those which refer to national

and European standards, must be observed when installing the

product.

The installation can only be put into use after it has been checked

by a qualified inspector. Contact your local building authorities

before installing a new fireplace.

A product data plate of heat-resistant material is affixed to the

product. This contains information about identification and

documentation for the product.

2.0 Technical data

Material: Cast iron

Finish: Black or grey varnish

Fuel: Wood

Log length, max.: 30 cm

Flue outlet: Top, rear

Flue pipe dimension: Ø150 mm/min. 177 cm2 cross

section

Approx. weight:

- with cast iron base: Approx. 163 kg

- with cast iron pedestal: Approx. 156 kg

- with cast iron leg: Approx. 154 kg

- with cast iron base

and glass door: Approx. 165 kg

- with glass base: Approx. 158 kg

- Jøtul F 377 with soapstone: Approx. 220 kg

- Jøtul F 377 HT with soapstone: Approx. 270 kg

- Jøtul F 377 with heat storage

system and soapstone: Approx. 330 kg

- with three legs: Approx. 149 kg

Optional extras: Decoration plates, cover for

side windows, rotating set

(Jøtul 373), glass decoration

- top/sides/front, soap stone -

top, wood store, cast iron door

for base (Jøtul F 371), High

Top, Jøtul F 377 soapstone,

Jøtul F 377 HT soapstone,

convection kit, heat storage

system

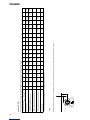

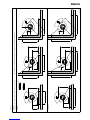

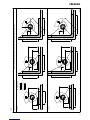

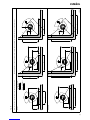

Dimensions, distances: See fig. 1

Technical data according to EN 13240

Nominal heat output: 5,5 kW

Flue gas mass flow: 5,9 g/s

Recommended chimney draught: 12 Pa

Efficiency: 73%@5,8 kW

CO emission (13% O2): 0.12%

Flue gas temperature: 330o C

Operational type: Intermittent

Intermittent combustion in this context means normal use of the

fireplace, i.e. fuel is added as soon as the fuel has burnt down to

a suitable amount of embers.

On all our products there is a label

indicating the serial number and

year. Write this number in the

place indicated in the installation

instructions.

Always quote this serial number when

contacting your retailer or Jøtul.

les combustibles recommandés.

Respectez les consignes d'utilisation. Utilisez uniquement

Verwenden Sie nur empfohlenen Brennstoffen.

Montage- und Bedienungsanleitung beachten.

Follow user`s instructions. Use only recommended fuels.

standard

Certificate/

The appliance can be used in a shared flue.

Minimum distance to adjacent combustible materials:

Emission of CO in combustion products

Serial no: Y-xxxx, Year: 200x

Manufacturer:

N-1602 Fredrikstad

Norway

Jøtul AS

POB 1441

Sweden

EUR Intermittent

Nominal heat output

Norway

Country

Operational type

Fuel type

Operation range

Efficiency

Klasse II

Classification

Standard

Flue gas temperature

Room heater fired by solid fuel

Product:

Jøtul

SP Sveriges Provnings- och

221546

Forskningsinstitut AB

SP Swedish National

Testing and Research

Institute

:

Approved by

:

:

:

:

:

:

:

Minimum distance to adjacent combustible materials:

OGC SP

EN

Serial no.

ENGLISH

3

ENGLISH

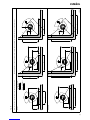

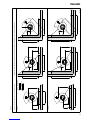

Air supply

The outside air connection may be fitted directly to the Jøtul F 370

Series through:

• The base/pedestal/leg or

• through a flexible supply hose from the outside/chimney

(only if the chimney has its own duct for external air) and to

the product’s outside air connector.

Through an outside wall

Through the floor and ground plate

Through the floor and basement

Indirectly through an outside wall

3.0 Safety

NB! To guarantee optimal performance and safety, Jøtul stoves

must be fitted by a qualified installer.

Any modifications to the product by the distributor, installer

or consumer may result in the product and safety features not

functioning as intended. The same applies to the installation of

accessories or optional extras not supplied by Jøtul. This may

also be the case if parts that are essential to the functioning

and safety of the fireplace have been disassembled or removed.

In all these cases, the manufacturer is not responsible or liable

for the product and the right to make a complaint becomes null

and void.

3.1 Fire Prevention Measures

There is a certain element of danger every time you use your

fireplace. The following instructions must therefore be followed:

• The minimum safety distances when installing and using the

fireplace are given in fig. 1.

• Ensure that furniture and other flammable materials are not

too close to the fireplace. Flammable materials should not be

placed within 1 metre of the fireplace.

• Allow the fire to burn out. Never extinguish the flames with

water.

• The fireplace becomes hot when lit and may cause burns if

touched.

• Only remove ash when the fireplace is cold. Ash can contain

hot embers and should therefore be placed in a non-

flammable container.

• Ash should be placed outdoors or be emptied in a place where

it will not present a potential fire hazard.

In case of chimney fire:

• Close all hatches and vents.

• Keep the firebox door closed.

• Check the loft and cellar for smoke.

• Call the fire service.

• Before use after a fire an expert must check the fireplace

and the chimney in order to ensure that it is fully functional.

3.2 Floor

Foundation

You need to make sure the foundation is suitable for a fireplace.

See “2.0 Technical Data” for specified weight.

We recommend the removal of any flooring that is not attached

to the foundation (“floating floors”) beneath the installation.

Requirements for protection of wooden

flooring beneath the fireplace

Jøtul F 370 Series (except from Jøtul F 374) has a heat shield

underneath which protects the base from radiation. The product

(except Jøtul from F 374 and Jøtul F 379) has an integrated floor

protection and may therefore be placed directly on a wooden

floor.

Any inflammable floor coverings, such as linoleum, carpets, etc.

must be removed from under the product.

4

ENGLISH

abcdefghi

440

340

440

190

1125

982

1125

771

920

777

920

566

650

550

650

400

480

380

480

280

612

612

552

558

407

407

347

353

701

601

701

501

160

160

100

* 160

* If a steal chimney is used the measure will be 100mm

250 915 710 502 400 539 334 647 50

150 742 537 380 400 524 319 641 50

Med halvisolert skorstein /

With half insulated steel chimney

With side cover, plain

With decor glass sides

Basic model

Min. distance to combustible wall by different configurations, fig. 1a

Measure

Configuration

Jøtul F 370

Jøtul F 370 C (product with convection kit with

side glasses and half insulated chimney)

Jøtul F 377 (product with soap stone sides and top)

5

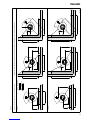

ENGLISH

205

221

452

442

4-4633-P11

1025

740

1150

410

66

181

max 90°

Distance to combustible wall with revolvable pedestal:

See table above.

b

a

c

d

e

f

h

g

i

max 180°

d

a

h

e

494 482

205

247

489

181

205

241

474

88

181

100

Hole in floor for outside air

Ø100mm connection

Jøtul F 371, F 374, F 375, F 376,

F 377, F 379

Min. measure floorplate

X/Y = Acc. to national standards

and regulations.

Combustible wall

X

Y

Fig. 1a

Min. distance to combustible wall:

See table above.

Product:

Jøtul F 371 / F 373 / F 374 / F 375 / F 376 / F 377 / F 379 / F 370 C

Hole in floor for outside air

Ø100mm connection

Jøtul F 373

Jøtul F 377:Jøtul F 370 C:

Base model:

6

ENGLISH

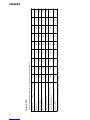

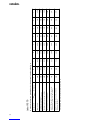

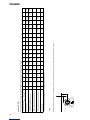

abcdefghi

100

100

643

643

438

438

310

310

200

200

492

492

287

287

421

421

40

40

jkl

mnopqr

550

550

480

380

440

340

735

735

799

669

773

659

934

934

999

884

962

841

st

756

556

1156

930

100 643 438 310 200 552 347 421 100 550 - - 795 - - 994 - - - -

* If a steal chimney is used the measure will be 100 mm

100 671 466 330 200 524 319 441 50 550 400 200 888 - 807 956 - 897 --

100 703 498 354 200 539 334 447 50 550 400 250 892 - 885 961 - 960 - -

Min. distance to combustible wall protected by firewall in different configurations, fig. 1b

Measure

Configuration

Jøtul F 370

Jøtul F 372, F 375, F 376, F 379 with ext. air

through wall

With side cover plain

Basic model

Jøtul F 370 C (product with convection

kit andhalf insulated chimney)

Jøtul F 377 (product with soap stone

sides and top)

Fig. 1 c

Minimum distance to wall for Jøtul F 375, F 376 and F 379 with external air supply through wall

min 100

min 347

8

Requirements for protection of inflammable

floors in front of the fireplace

The front plate must comply with national laws and regulations.

Contact your local building authorities regarding restrictions and

installation requirements.

3.3 Walls

Distance from the wall of flammable material

The fireplace is authorised for use with an uninsulated flue with

the distances to the wall of flammable material as shown in fig 1.

3.4 Ceiling

There must be a minimum distance of 1000 mm to a combustible

ceiling above the fireplace.

4.0 Installation

N.B. Check that the fireplace is free of any damage prior to

commencing installation.

The product is heavy! Make sure you have assistance when

erecting and installing the fireplace.

4.1 Prior to installation

1. Standard product supplied in two packages. One with the

fireplace itself and one with optional base in cast-iron/

concrete/glass or pedestal in cast-iron.

2. When the product is unpacked, the burn plates, baffle plate,

exhaust deflector, base plate, ash pan and riddling grate are

removed. Also remove the small side burn plates and gasket

for flue pipe which are in the ash pan.

Fig. 3

3. Lift off the top plate with the top grid (fig. 3 A) and bowl (fig. 3 B).

4. Check that the operating handles work.

5. If the rear flue pipe outlet is used, first drill holes (fig. 5 A) in

the cut-out covers for the flue pipe before they are knocked

out with the aid of e.g a ball-pane hammer.

6. Place the wooden block (fig. 5 B) that holds the exhaust

deflectors in position so that the side plates are supported

when the cut-out covers are removed.

7. Spread out the cardboard packaging on the floor. Lay the

stove carefully on its side.

ENGLISH

9

ENGLISH

Fig. 4

8. If the glass décor set (optional extras) is to be used, the 4

recessed head screws on the bottom are removed (fig. 4B)

with the aid of the key included with the glass décor set.

4.2 Assembly

Jøtul F 371 - cast-iron base

N.B. If the flexible hose is to be connected through a hole in the

floor, the knock out covers are not knocked out/removed.

Fig. 5

1. If flexible hose, 100 mm diameter, for external air supply is

to be connected to the outlet under the burn chamber (fig. 4 C),

drill one hole (fig. 5 C) in each cut-out cover at the lower part

of the base and knock them out. N.B. Make sure the rear plate

(fig. 6 A) in the base is positioned, when the cut-out cover is

being knocked out.

10

Fig. 6

2. Remove rack and rear plate in the base. Check that the handle

in the external air vent (fig. 4D) is in the foremost position.

3. Assemble the base with the burn chamber with the aid of

the 4 screws (M8x30 mm) from the screws bag (fig. 4 A).

4. Get assistance and carefully lift the product up.

Fig. 7

5. Adjust the product with the help of the 4 adjusting screws

(fig. 7 C).

6. Draw the flexible hose through the hole and fasten it to the

outlet with the aid of a hose clip. N.B. Make sure that the

hose is long enough to avoid any joints.

7. The base area must be protected from heat radiation from

the product with the aid of the accompanying heat shield

(fig. 7 A). Fasten this with the 2 screws as shown in fig. 7 B.

8. Reassemble the the rack and the rear plate in the base.

ENGLISH

11

ENGLISH

Jøtul F 373 - pedestal

Important! If the rotating set is to be assembled, this must be done

now before the pedestal is fastened to the hearth. See assembly

instructions which accompany the rotating set.

Fig. 11

1. Adjust the product with the help of the 3 adjusting screws

(fig. 11 A).

2. Assemble the pedestal to the hearth’s bottom plate with the

aid of the 4 screws from the bag of screws ( (fig. 4 A).

3. If the external air supply via the external air vent is to be used,

the flexible hose, 100 mm diameter, is connected to the vent

on the product (fig. 4 C) now.

4. Push the handle in the external air vent to the foremost

position (fig. 4 D).

5. Fasten the hose to the external air vent with the aid of a

hose clip. N.B. Make sure that the hose is long enough to

avoid any joints.

6. If the external air is to be supplied through the floor, place the

flexible gasket (fig. 11 B) around the hose, 100 mm diameter,

that is drawn through the hole in the floor. Note! The hole is

in the center of the pedestal/flue pipe.

7. Push the handle in the external air vent to the rear position

(fig. 4 E).

8. Get assistance and carefully lift the product up and place it

directly above the external air supply.

Important! Check that the handle in the external air vent is in

the foremost position if the external air is not to go through

the pedestal.

Jøtul F 374 - Cast iron leg

If external air supplied via the external air vent is to be used,

connect a flexible hose, Ø 100 mm, to the external air vent

(fig. 4 C) on the product.

Installation with external air

1. Push the lever on the external air vent to its forward position

(fig. 4 D).

2. Attach the hose to the external air vent using a hose clip.

NB! Make sure the hose is long enough to avoid any joints

being necessary.

Fig. 12

3. Move the cast iron leg towards the burn chamber as the

external air hose is passed through the leg and, if appropriate,

through the opening in its back (fig. 12).

Fig. 13

4. Attach the base to the burn chamber using the 4 screws (M8

x 30 mm) from the bag of screws (fig. 13 A).

5. With the help of another person, carefully raise the product

and position it correctly over the external air supply.

12

Fig. 14

6. Adjust the height of the product if necessary, using the

adjustment screws beneath the leg (fig. 14 A).

Fig. 15

7. Replace the cover for the external air supply (fig. 15 A).

Installation without external air

1. Attach the base to the burn chamber using the 4 screws (M8

x 30 mm) from the bag of screws (fig. 13A).

2. With the help of another person, carefully raise the product

and position it correctly over the external air supply.

3. Adjust the height of the product if necessary, using the

adjustment screws beneath the leg (fig. 14A).

4. Replace the cover (fig. 15 A).

Jøtul F 375 - Cast iron base with glass door

1. Assemble the cast iron base as described under point

“Jøtul F 371 - cast iron base”.

Fig. 16

2. Attach the hinge for the glass door to the base using the

M6 x 20 mm screws, which are in the bag of screws for the

glass door (fig. 16 A).

3. Insert the spring between the threaded holes and the hinge

before tightening the screws (fig. 16B).

Fig. 17

4. Screw the other end of the spring firmly in position (fig. 17 A).

5. Attach the door damper to the inside of the glass door in the

bottom right-hand corner (fig. 17 B).

NB! There must be an even gap between the door and the base

to allow the door to hang straight. Adjust the door if necessary,

by tightening or loosening the two screws (fig. 17 C).

ENGLISH

13

Jøtul F 376 – Glass base

NB! If connecting the flex hose through a hole in the floor, do not

knock out the removable cover plates (Fig. 18 A).

Fig. 18

1. Loosen the screws holding the upper glass clips on either

side (Figs. 18 B and C). Check that the lever on the external

air vent is in the forward position (Fig. 4D).

2. If connecting a flex hose (Ø 100 mm) for external air supply

to the external air vent/outlet (Fig. 4 C) beneath the burn

chamber, first drill a hole (Fig. 18 A) in the removable cover

plates before they are knocked out. NB! Leave the rear plate

in the base (Fig. 18 D) in place when the cover plates are

knocked out.

3. Remove the rear plate (Fig. 18 D) in the base.

Fig. 19

4. Place the base in the correct position on the floor plate (if

any). Level the product using the 4 adjustment screws (Fig. 19 A).

5. Attach the base to the burn chamber using the 4 screws

(M8 x 30 mm) from the bag of screws (Fig. 19 B).

6. Carefully raise the product with the help of another person.

7. Adjust the glass door, if necessary, with the screws as shown

in Fig. 17 C. There must be an even gap between the door and

the base to allow the door to hang straight.

Fig. 20

8. Install the side glass panels by positioning them in the lower

glass clips (Fig. 20 A). Lift up the upper clips and press them

down onto the side glass. Make sure there is an even gap

between the side glass and the side plate at both the front

and back. Tighten the front screw for the side glass (Fig. 18 B).

The back screw (Fig. 18 C) should be loosened just sufficiently

to allow the glass clip to be raised without removing the

screw (this makes it easier if replacing the glass later on).

9. Pull the flex hose (if any) through a hole in the floor or rear

of the base (Fig. 18 A) and attach it to the outlet using a hose

clip. NB! Make sure the hose is long enough to make it

unnecessary to have any joints.

10. Replace the rear plate (Fig. 18 D).

11. The base area must be protected from heat radiation from

the product with the aid of the accompanying heat shield

(fig. 7 A). Fasten this with the 2 screws as shown in fig. 7 B.

Jøtul F 377 - with soapstone

Se separate installation manual (cat. no. 10043560).

ENGLISH

14

Jøtul F 379 - with three legs

NB! If connecting the flex hose through a hole in the floor, do not

knock out the removable cover plates (fig. 21 A).

Fig. 21

1. If connecting a flex hose (Ø 100 mm) for external air supply

to the external air vent (fig. 4 C) beneath the burn chamber,

first drill a hole (fig. 21 A) in the removable cover plates before

they are knocked out. NB! Place the parts on a suitable surface

before the cover plates are knocked out.

Fig. 22

2. The accompanying heat shield (fig. 22 A) should be used to

protect the base from the heat radiating from the product.

Secure this first with a screw (fig. 22 B).

3. Secure the brace (fig. 22 C) loosely into place with a screw

(fig. 22 D).

4. Attach the base to the burn chamber using the 4 screws

(M8 x 30 mm) from the bag of screws (fig. 4 A).

5. Screw the legs together at the back edge using 2 screws that

are in the screw holes (fig. 22 E).

6. Secure the brace (fig. 22 C) into place with a screw (fig. 22 F)

and nut at both ends.

7. With the help of another person, carefully raise the product.

8. Level the product using the 4 adjustment screws (fig. 22 G).

9. If the legs are not properly aligned, loosen the screws (fig. 22 F)

on each side. Adjust the legs and tighten the screws again.

10. Tighten the screw (fig. 22 D).

11. Pull the flex hose through the hole and attach it to the outlet

using a hose clip. NB! Make sure the hose is long enough so

that joints are not necessary.

Fig. 23

12. Place the cover (fig. 23 A) into place. Make sure that the pin

(protrusion) B is facing down.

4.3 Chimneys and flue pipes

• The fireplace can be connected to a chimney and flue

pipe approved for solid fuel fired appliances with flue gas

temperatures specified in «2.0 Technical data”.

• The chimney’s cross-section must be at least as big as the

flue pipe’s cross-section. See «2.0 Technical data» when

calculating the correct chimney cross-section.

• Several solid fuel fired appliances can be connected to the

same chimney if the chimney’s cross-section is sufficient.

• Connection to the chimney must be carried out in accordance with

the installation instructions from the supplier of the chimney.

• Before making a hole in the chimney the fireplace should be

test-mounted in order to correctly mark the position of the

fireplace and the hole in the chimney. See fig. 1 for minimum

dimensions.

• Ensure that the flue pipe is inclined all the way up to the chimney.

• Use a flue pipe bend with a sweeping hatch that allows it to

be swept.

Be aware of the fact that it is particularly important that

connections have a certain flexibility in order to prevent

movement in the installation leading to cracks.

Chimney draught; See «2.0 Technical data». If the draught is

too strong you can install and operate a flue damper to control

the draught.

Assembly of flue pipe with top outlet

The product is supplied from the factory with the smoke outlet

mounted for top outlet.

1. Put the top plate (fig. 3 C) on the product.

2. Obtain assistance in lifting the top grate (fig. 3 A) and holding

it up while the flue is fastened.

3. Thread the flue pipe through the grate of the top plate and

place it on the smoke outlet of the top outlet.

4. Tighten well with gasket.

ENGLISH

15

Assembly of flue pipe with rear outlet

The product is supplied from the factory with the smoke outlet

mounted for top outlet. If you want a rear outlet, do the following:

1. Place the product in correct position (fig. 1).

Fig. 24

2. When changing to rear outlet, the smoke outlet (fig. 24 B) is

unscrewed from the top outlet.

3. Unscrew the cover for the rear outlet from the inside of the

burn chamber (fig. 24 A).

Fig. 25

4. Place the gasket on the end of the flue pipe (fig. 25 A).

5. Mount the smoke outlet (fig. 25 B) on the end of the flue pipe

that is fitted with the gasket.

6. Mount the flue pipe and smoke outlet from the inside of the burn

chamber and attach the smoke outlet using M8x30 mm screws.

N.B. If the flue pipe is longer than 350 mm it has to be assembled

into the smoke outlet from the outside of the product.

7. Fasten the cover to the top outlet (fig. 24) with the screws

that fastened the smoke outlet.

N.B. It is important that the joints/flue pipes are completely

sealed. Air leaks can prevent the flue pipe from functioning

properly.

4.4 Mounting of the product

Fig. 26

1. Place the baffle plate with the bar in the groove on the ribs

(fig. 26 A).

2. Move the base plate through the opening and place it on

the bottom.

ENGLISH

16

Fig. 27

3. Place the riddling grate in position on the base plate. Check

that the riddling grate’s slot on the right side is entered into

the riddling bar (fig. 27 A).

4. Place the ash pan at the bottom of the product.

5. Place the rear burn plate in the base plate’s rear groove.

6. Place the side burn plates on each side in the base plate’s side

grooves. Move the baffle plate in and place it so that it rests

on the side and rear burn plates.

7. Hold the baffle plate while the other side burn plate is

mounted.

Fig 28

8. Let the baffle plate rest on the burn plates.

9. Place the small side burn plates (fig. 28 A) in the base plate’s

groove under the side glasses.

10. Replace the top plate with the top grid and bowl.

11. Place the product data plate which is in the ash pan,

underneath the burn chamber.

ENGLISH

17

4.5 Control of functions

When the product is set up, always check the control functions.

These shall move easily and function satisfactorily.

Jøtul F 370 is equipped with the following controls:

Fig. 29

Air vent fig. 29 A

Pushed in: Closed

Pulled out: Open

Ignition vent, fig. 29 B

Pushed in: Closed

Pulled out: Open

Riddling grate (same handle as for the ignition vent) (Fig. 29 B)

Right handle is pushed in and out.

Handle for door fig. 29 C:

Is opened by pulling handle out.

4.6 Use

• Open the air vent and the ignition vent by pulling it out all

the way (fig. 29 A & B). If necessary, keep the door slightly

open. (Use a glove, for example, as the handle can become hot.)

• Place two medium sized logs in/out on each side of the base.

N.B. In order to avoid sooting on the glass, it is important that

the log is not placed adjacent to the glass on the product.

• Crumple some newspaper (or birch bark) between these and

add some kindling wood in a criss-cross pattern on top and

light the newspaper. (Fig. 30)

• Gradually increase the size of the fire, but the wood should

not be stacked higher than the horizontal holes on the back

burn plate. See fig. 29 H.

• Finally, place a medium-sized log on the top of the pile.

• Place 2 or 3 briquettes or kindling sticks under the top layer

of kindling and light the fire.

• NB: The maximum height of the pile of the wood should

be just below the horizontal holes. The holes must not be

covered.

• Close the ignition vent (fig. 29 B) when the firewood has

ignited and the fire is burning well.

• Check that the afterburning (secondary combustion) starts. This

is best indicated by yellow, flickering flames under the baffle.

• Then regulate the rate of combustion to the desired level of

heating by adjusting the air vent (fig. 29 A).

Fig. 30

Adding firewood

Stoke the stove frequently but only add small amounts of fuel at

a time. If the stove is filled too full, the heat created may cause

extreme stress in the chimney. Add fuel to the fire in moderation.

Avoid smouldering fires as this produces the most pollution.

The fire is best when it is burning well and the smoke from the

chimney is almost invisible.

4.7 Danger of overheating

The fireplace must never be used in a manner that

causes overheating

Overheating occurs when there is too much fuel and/or too much

air so that too much heat develops. A sure sign of overheating is

when parts of the fireplace glow red. If this happens, reduce the

air vent opening immediately.

Seek professional advice if you suspect that the chimney is not

drawing properly (too much/too little draught). For further

information, see «4.0 Installation» (Chimney and flue pipe).

ENGLISH

18

4.8 Ash removal

Jøtul F 370 has an ash pan which makes it easy to remove the ashes.

1. Only remove ashes when the fireplace is cold.

2. Push/pull the handle for the ash grate/ignition vent out and

in several times so that the ashes fall down into the ash pan.

Use something like a glove to grab the handle on the ash pan.

3. Make sure that the ash pan doesn’t fill up so high that it keeps

ash from coming through the grate into the pan.

5.0 Daily use

Odours when using the fireplace for the first time

When the fireplace is used for the first time, it may emit an

irritating gas which may smell slightly. This happens because

the paint dries.The gas is not toxic but the room should be

thoroughly ventilated. Let the fire burn with a high draught until

all traces of the gas have disappeared and no smoke or odours

can be detected.

Heating advice

NB: Logs that have been stored outdoors or in a cold room should

be brought indoors 24 hours before use to bring them up to room

temperature.

There are various ways of heating the stove but it is always

important to be careful about what you put in the stove. See the

section on “Wood quality”.

Wood quality

By quality wood we mean most well-known types of wood such

as birch, spruce and pine.

The logs should be dried so that the moisture content is no more

than 20%.

To achieve this, the logs should be cut during the late winter. They

should be split and stacked in a way that ensures good ventilation.

The wood stacks should be covered to protect the logs from rain.

The logs should be brought indoors during early autumn and

stacked/stored for use in the coming winter.

Be especially careful never to use the following materials as fuel

in your fireplace:

• Household rubbish, plastic bags, etc.

• Painted or impregnated timber (which is extremely toxic).

• Laminated wooden planks.

• Driftwood

These may harm the product and are also pollutants.

NB: Never use petrol, paraffin, methylated spirit or similar liquids

to light the fire. You may cause serious injury to yourself and

damage to the product.

Wood consumption

Jøtul F 370 has a nominal heat output of 5,5 kW. Use of

wood, with nominal heat emission: Approx. 1,9 kg/h. Another

important factor for proper fuel consumption is that the

logs are the correct size. The size of the logs should be:

Kindling:

Length: 30 cm

Diameter: 2-5 cm

Amount per fire: 6-8 pieces

Firewood (split logs):

Length: Ca 20 - 30 cm

Diameter: Approx. 8 cm

Intervals for adding wood: Approximately every 45 minutes

Size of the fire: 1.4 kg

Amount per load: 2 pieces

Nominal heat emission is achieved when the air vent (fig. 29 A)

is open approximately 100% and the handle for the ignition vent

pulled out approximately 1-2 cm (fig. 29 B).

6.0 Maintenance

6.1 Cleaning the glass

The product is equipped with an air wash for the glass. Air is

sucked in through the air vent on the top of the product and

down along the inside of the glass.

However, some soot will always stick to the glass, but the quantity

will depend on the local draught conditions and adjustment of

the air vent. Most of the soot layer will normally be burned off

when the air vent is opened all the way and a fire is burning

briskly in the fireplace.

Good advice! For normal cleaning, moisten a paper towel with

warm water and add some ash from the burn chamber. Rub it over

the glass and then clean the glass with clean water. Dry well. If it

is necessary to clean the glass more thoroughly we recommend

using a glass cleaner (follow the instructions on the bottle).

6.2 Cleaning and soot removal

Soot deposits may build up on the internal surfaces of the

fireplace during use. Soot is a good insulator and will therefore

reduce the fireplace’s heat output. If soot deposits accumulate

when using the product, they can be easily removed by using a

soot remover.

In order to prevent a water and tar layer from forming in the

fireplace you should regularly allow the fire to burn hot in order

to remove the layer. An annual internal cleaning is necessary to

get the best heating effect from the product. It is a good idea

to do this in connection with the sweeping of the chimney and

flue pipes.

6.3 Sweeping of flue pipes to the chimney

On certain free-standing fireplaces the top plate can be lifted off

and the pipe swept through the top.

Otherwise, flue pipes must be swept through the flue pipe

sweeping hatch or through the product’s door opening. Then,

the baffle must be removed.

ENGLISH

19

6.4 Inspection of the fireplace

Jøtul recommends that you personally inspect your fireplace

carefully after sweeping/cleaning. Check all visible surfaces for

cracks. Also check that all joints are sealed and that the gaskets

are in the correct position. Any gaskets showing signs of wear or

deformation must be replaced.

Thoroughly clean the gasket grooves, apply ceramic glue

(available from your local Jøtul dealer), and press the gasket well

into place. The joint will dry quickly.

6.5 Exterior maintenance

Painted products may change colour after several years usage. The

surface should be cleaned and brushed free of any loose particles

before new paint is applied.

7.0 Service

Warning! Any unauthorised change to the product is illegal.

Only use original spare parts.

7.1 Replacing the baffle/exhaust

deflector

(N.B. If you use tools, be aware that the vermiculite plates may

be damaged by rough treatment).

1. Lift up the front edge of the baffle plate and tilt it out

(fig. 29 G). Remove the side burn plates (fig. 29 F) and the

rear burn plate (fig. 29 E).

2. The exhaust deflector, in cast-iron - that is located above the

baffle plate, rests with the bar on the ribs at the rear flue

outlet (fig. 26 A). Lift the exhaust deflector slightly up, pull it

forward and tilt it out.

3. For reassembly follow the same procedure for installation,

but in reverse.

7.2 Replacement of burn plates/base

plate

(N.B. If you use tools, be aware that the vermiculite plates may

be damaged by rough treatment).

1. Lift up the front edge of the baffle plate and tilt it out. Remove

the side burn plates (fig. 29 F) and the rear burn plate (fig. 29 E).

2. Then lift up the grate and the base plate and take it out (fig.

29 D).

3. Follow the same procedure for installation, but in the opposite

sequence.

4. When reassembling the grate and the base plate, make sure

that the riddling bar (fig. 27 A) that moves the riddling grate

is threaded into the slot on the right edge of the grate.

7.3 Replacing the inner/outer side

glass

1. Lift up the front edge of the baffle plate and tilt it out Remove

the side burn plates (fig. 29 F) and the rear burn plate (fig. 29 E).

2. The exhaust deflector, in cast-iron - that is located above the

baffle plate, rests with the bar on the ribs at the rear flue

outlet (fig. 26 A). Lift the exhaust deflector slightly up, pull it

forward and tilt it out.

3. Remove riddling grate, base plate and ash pan (fig. 29 D).

Fig. 31

Fig. 32

4. Unscrew the upper and lower screws (fig. 31 A and 32 A), and

tilt the glass holder with the glass carefully out through the

door. N.B. The glass holder also keeps the outer glass in place

5. Remove the glass and possibly replace gaskets. If needed

replace the external glass.

6. For reassembly follow the same procedure for installation,

but in reverse.

ENGLISH

20

8.0 Operational problems -

troubleshooting

Poor draught

1. Check the length of the chimney and that it complies with

national laws and regulations. (See also «2.0 Technical

data» and «4.0 Installation» (Chimney and flue pipe) in the

installation manual for information.)

2. Make sure that the minimum cross section on the chimney is

according to «2.0 Technical data» in the installation manual.

3. Make sure that there is not anything preventing the smoke

gasses from escaping: branches, trees, etc.

4. Upon suspicion of excessive/poor draught in the chimney,

seek professional help for measurement and adjustment.

The fire extinguishes after a while

1. Make sure that the firewood is sufficiently dry.

2. Find out whether there is negative pressure in the house, close

mechanical fans and open a window close to the fireplace.

3. Check that the air vent is open.

4. Check that the flue outlet is not clogged by soot.

Unusual amount of soot accumulates on the

glass

Some soot will always stick to the glass, but the quantity depends

on:

1. Moisture in the fuel.

2. The local draught conditions.

3. Air vent opening.

Most of the soot will normally burn off when the air vent is

opened all the way and a fire is burning briskly in the fireplace.

(See «6.1 Cleaning the glass».)

9.0 Optional equipment

9.1 Decoration plates

Decoration plates, cover for side windows (2 units), black paint -

cat. no. 50037271 (350990).

Decoration plates, cover for side windows (2 units), grey paint -

cat. no. 50037272 (350991).

Soapstone, top 25 mm one-piece - cat. no. 50012988 (350992).

Soapstone, top 25 mm three-piece - cat. no. 50013013 (361011)

(substitute for 50012988 (350992) installed with steel chimney).

9.2 Glass decoration, top, sides and front

(see separate installation manual)

Glass set for rear smoke outlet, black paint,

- cat. no. 51012250 (350993)

Glass set for rear smoke outlet, grey paint,

- cat. no. 51012251 (350994)

Glass set for top smoke outlet, black paint,

- cat. no. 51012252 (350995)

Glass set for top smoke outlet, grey paint,

- cat. no. 51012253 (350996)

9.3 Rotating kit

(See separate installation manual)

Rotating set for Jøtul F 373, - cat. no. 51012254 (350997)

9.4 Wood store

Black paint - cat. no. 50012995 (351160)

Grey paint - cat. no. 50013037 (351161)

9.5 Cast iron door for base (Jøtul F 371)

Black paint - cat. no. 51036917 (351115)

Grey paint - cat. no. 51036918 (351116)

9.6 High Top

Cat. no. 51012304

9.7 Heat storage system

Cat. no. 10026701

9.8 Soapstone

Jøtul F 377 soapstone kit, cat. no. 21043545

Jøtul F 377 HT soapstone kit, cat. no. 21043546

9.9 Convection kit

Jøtul F 370 C convection, sides, BP, cat. no. 50043647

Jøtul F 370 C, convection, top, BP, cat. no. 50043642

ENGLISH

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

Jotul F 371 Manuale del proprietario

- Categoria

- Camini

- Tipo

- Manuale del proprietario

in altre lingue

- English: Jotul F 371 Owner's manual

- français: Jotul F 371 Le manuel du propriétaire

- español: Jotul F 371 El manual del propietario

- Nederlands: Jotul F 371 de handleiding

Documenti correlati

Altri documenti

-

Jøtul F 475 Installation And Operating Istructions

-

Jøtul F 271 Installation Instructions Manual

-

Jøtul F 162 Installation And Operaing Instructions

-

Jøtul F 400 Installation And Operating Instructions Manual

-

Jøtul Oslo F 500 Installation And Operating Instructions Manual

-

Jøtul F 600 Installation Instructions With Technical Data

-

SEVERIN ZB 8182 SEVO Istruzioni per l'uso

-

STUV 16-H Guida d'installazione