ESAB LHF 400 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

Questo manuale è adatto anche per

Valid for serial no. 906--xxx--xxxx0455 675 027 050816

LHF 250, LHF 400,

LHF 630, LHF 800

104

Instruction manual Èíñòðóêöèÿ ïî ýêñïëóàòàöèè

-- 2 --

Rights reserved to alter specifications without notice.

Îñòàâëÿåì çà ñîáîé ïðàâî èçìåíÿòü ñïåöèôèêàöèþ áåç ïðåäóïðåæäåíèÿ.

Ðóññêèé 3...............................................

ENGLISH 9..............................................

Ðóññêèé

TOCr

-- 3 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ 4........................................

2 ÂÂÅÄÅÍÈÅ 4.......................................................

3 ÒÅÕÍÈ×ÅÑÊÈÅ ÄÀÍÍÛÅ 5.........................................

4ÓÑÒÀÍÎÂÊÀ 6.......................................................

4.1 Ïîäêëþ÷åíèå ê ýëåêòðîñåòè 6..............................................

5 ÝÊÑÏËÓÀÒÀÖÈß 7..................................................

5.1 Óïðàâëåíèÿ è ðàçú¸ìû 7...................................................

6 ÎÁÑËÓÆÈÂÀÍÈÅ 7.................................................

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 8.......................................

ÈÍÑÒÐÓÊÖÈÈ ÏÎ ÑÁÎÐÊÅ 15.........................................

ÑÕÅÌÀ 16..............................................................

ÑÏÈÑÎÊ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ 21........................................

bh10d2r -- 4 --

1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ

ÏÐÎ×ÒÈÒÅ È ÏÎÉÌÈÒÅ ÈÍÑÒÐÓÊÖÈÞ ÏÎ ÝÊÑÏËÓÀÒÀÖÈÈ ÏÅÐÅÄ ÒÅÌ, ÊÀÊ ÏÎ ÄÊËÞ×ÈÒÜ

ÎÁÎÐÓÄÎÂÀÍÈÅ È ÍÀ×ÀÒÜ ÐÀÁÎÒÓ

ÇÀÙÈÒÈÒÅ ÑÅÁß È ÎÊÐÓÆÀÞÙÈÕ !

ÏÐÅÄÓÏÐÅÆÄÅÍÈÅ !

ÄÓà ÎÂÀß ÑÂÀÐÊÀ È ÐÅÇÊÀ ÌÎÃÓÒ ÏÐÈ×ÈÍÈÒÜ ÂÐÅÄ ÂÀÌ È ÎÊÐÓÆÀÞÙÈÌ. ÏÐÈÌÈÒÅ

ÍÅÎÁÕÎÄÈÌÛÅ ÌÅÐÛ ÁÅÇÎÏÀÑÍÎÑÒÈ ÏÐÈ ÏÐÎÂÅÄÅÍÈÈ ÑÂÀÐÎ×ÍÛÕ ÐÀÁÎÒ.

ÎÇÍÀÊÎÌÜÒÅÑÜ Ñ ÒÅÕÍÈÊ ÎÉ ÁÅÇÎÏÀÑÍÎÑÒÈ, ÐÀÇÐÀÁÎ ÒÀÍÍÎÉ ÍÀ ÂÀjÅÌ ÏÐÅÄÏÐÈßÒÈÈ.

ÏÎÐÀÆÅÍÈÅ ÝËÅÊÒÐÈ×ÅÑÊÈÌ ÒÎÊ ÎÌ ÎÏÀÑÍÎ ÄËß ÆÈÇÍÈ !

S Óñòàíîâèòå è çàçåìëèòå ñâàðî÷ íûé àïïàðàò â ñîîòâåòñòâèè ñ ïðèìåíÿåìûìè ñòàíäàðòàìè.

S Íå êàñàéòåñü îã îëåííûõ ýëåêòðè÷åñêèõ ÷àñòåé èëè ýëåêòðîäîâ ãîëûìè ðóêàìè, ìîêðûìè ïåð÷àòêàìè

èëèìîêðîéîäåæäîé.

S Èçîëèðóéòå ñåáÿ îò çåìëè è çàãîòîâêè.

S Îáåñïå÷üòå áåçîïàñíîñò ü íà ñâîåì ðàáî÷åì ìåñò å.

ÑÂÀÐÎ×ÍÛÅ ÄÛÌÛ È ÀÝÐÎÇÎËÈ - ìîãóò áûòü îïàñíû äëÿ çäîðîâüÿ.

S Ñòàðàéòåñü, ÷òîáû âàøà ãîëîâà íàõîäèëàñü âíå çîíû äûìà..

S Èñïîëüçóéòå âåíòèëÿöèþ è äûìîîòñîñû äëÿ óäàëåíèÿ äûìîâ è àýðîçîëåé èç çîíû äûõàíèÿ è

îêðóæàþùåãî ïðîñòðàíñòâà

ÈÇËÓ×ÅÍÈÅ ÄÓÃÈ - ìîæåò íàíåñòè âðåä ãëàçàì è êîæå.

S Çàùèùàéòå âàøè ãëàçà è êîæó. Èñïîëüçóéòå ìàñêó ñ ïðàâèëüíî ïîäîáðàííûì çàùèòíûìñòåêëîì è

ñïåöîäåæäó

S Çàùèùàéò å îêðóæàþùèõ ïîñðåäñòâîì ñòåíîê è çàíàâåñîê.

ÏÎÆÀÐÎÎÏÀÑÍÎÑÒÜ

S Èñêðû ïðè ñâàðêå ìîãóò ñòàò ü ïðè÷èíîé ïîæàðà. Îáåñïå÷üòå îòñóòñòâèå ïîæàðîîïàñíûõ ìàòåðèàëîâ

â áëèçëåæàùåé çîíå.

ØÓÌ - Ïîâûøåííûé øóì ìîæåò ïîâðåäèòü ñëóõ

S Çàùèòèòå ñâîè óøè ñ ïîìîùüþ íàóøíèêîâ èëè áåðóøåé.

S Ïðåäóïðåäèòå î ðèñêå îêðóæàþùèõ.

ÑÁÎÉ Â ÐÀÁÎÒÅ - Ïðè ñáîÿõ â ðàáîòå îáðàòèòåñü çà ïîìîùüþ ê ñïåöèàëèñòó.

2 ÂÂÅÄÅÍÈÅ

LHF 250/400/630/800 ÿâëÿþòñÿ ñâàðî÷íûìè âûïðÿìèòåëÿìè ñ òèðèñòîðíûì

óïðàâëåíèåì, ïðåäíàçíà÷åííûìè äëÿ ðó÷íîé ñâàðêè ïîêðûòûìè ýëåêòðîäàìè

(ÌÌÀ), ñâàðêè íåïëàâÿùèìñÿ ýëåêòðîäîì â çàùèòíûõ ãàçàõ (ÒIG) è äëÿ

âîçäóøíî-äóãîâîé ñòðîæêè.

Âûïðÿìèòåëè ìîã óò ðàáîòàòü ñî ñëåäóþùèìè ïóëüòàìè äèñòàíöèîííîãî

óïðàâëåíèÿ: PHA 1, PHA 2, PHA 5, PHB 1, PHB 2, è PHC 2.

Äëÿ ñâàðêèìÒÈà íåîáõîäèìî äîïîëíèòåëüíîå óñòðîéñòâî ñ âûñîêî÷àñòîòíûì

ïîäæèãîì äóãè

LHF 400/630 ñ èçìåðèòåëüíûìè ïðèáîðàìè è âåíòèëÿòîðîì ñ òàéìåðîì.

Ýòè ñâàðî÷íûå âûïðÿìèòå ëè èìåþò íà ïåðåäíåé ïàíåëè âîëüòìåòð è

àìïåðìåòð, ïîçâîëÿþùèå çàìåðÿòü âåëè÷èíû íàïðÿæåíèÿ è òîêà.

Äëÿ òîãî, ÷òîáû óìåíüøèòü êîëè÷åñòâî çàíîñèìîé â âûïðÿìèòåëü ïûëè,

÷àñòîòà âðàùåíèÿ âåíòèëÿòîðà â ðåæèìå õîëîñòîãî õîäà ñíèæàåòñÿ äî 300

îá/ìèí. Ïðè âîçðàñòàíèè ñâàðî÷íîãî òîêà âûøå 30 À âåíòèëÿòîð íà÷èíàåò

ðàáîòàòü â ðàáî÷åì ðåæèìå - 1350 îá/ìèí. Ðåëå âðåìåíè ïîääåðæèâàåò

RU

bh10d2r -- 5 --

âûñîêóþ ñêîðîñòü âðàùåíèÿ â òå÷åíèå 6,5 ìèí ïîñëå ïðåêðàùåíèÿ ñâàðêè

ä ëÿ ïîëíîãî îõëàæäåíèÿ âûïðÿìèòåëÿ.

3 ÒÅÕÍÈ×ÅÑÊÈÅ ÄÀÍÍÛÅ

LHF 250 LHF 400 LHF 630 LHF 800

Ìàêñ. íàãðóçêà

ïðè ÏÂ 35 % 250 A/30 V 400 A/36 V 630 A/44 V 800 A/44 V

ïðè ÏÂ 60 % 200 A/28 V 315 A /33 V 500 A/40 V 630 A/44 V

ïðè ÏÂ 100 % 160A/26V 250 A/30 V 400 A/36 V 500 A/40 V

Ðåæèìû ðàáîòû 8A/20V-250A/30(

33)V

8A/20V-400A/36

V

8A/20V-630A/44(

49)V

8A/20V-800A/44(

50)V

Íàïðÿæåíèå

õîëîñòîãî õîäà

78-84 V 80-87 V 65-72 V 65-72 V

Ïîòðåáëÿåìàÿìîùí

îñòü ïðè 400 V

300 W 340 W 615 W 640 W

Êîåô. ìîùíîñòè

(ìàêñ. òîê)

0,88 0,90 0,87 0,82

ÊÏÄ (ìàêñ. òîê) 68 % 74 % 77 % 78 %

Ê ëàññ çàùèòû IP 23 IP 23 IP 23 IP 23

Êëàññ ïðèìåíåíèÿ

Ìàññà 160 êã 195 êã 260 êã 295 êã

Ãàáàðèòû:äxøxâ 1310 / 765 / 705 1310 / 765 / 705 1310 / 765 / 705 1310 / 765 / 705

Ðàáî÷èé öèêë

Ðàáî÷èé öèêë ïðåäñòàâëÿåò ñîáîé äîëþ (â %%) äåñÿòèìèíó òíîãî èíòåðâàëà, â òå÷åíèå

êîòîðîé ìîæíî ïðîèçâîäèòü ñâàðêó ïðè îïðåäåëåííîé íàãðóçêå á åç ïåðåãðóçêè.

Êëàññ êîæóõà

Íîðìû IP óêàçûâàþò êëàññ êîæóõà, ò.å., ñòåïåíü çàùèòû îò ïðîíèêíîâåíèÿ ò âåðäûõ

îáúåêòîâ è âîäû. Îáîðóäîâàíèå ñ ìàðêèðîâêîé IP 23 ïðåäíàçíà÷åíî äëÿ íàðóæíîé è

âíóòðåííåé óñòàíîâêè.

Ê ëàññ çîíû óñòàíîâêè

Ýòîò ñèìâîë îçíà÷àåò, ÷òî èñòî÷íèê ïèòàíèÿ ïðåäíàçíà÷åí äëÿ èñïîëüçîâàíèÿ â çîíàõ

ñ ïîâûøåííîé îïàñíîñòüþ ïîðàæåíèÿ ýëåêòðîòîêîì.

RU

bh10d2r -- 6 --

4ÓÑÒÀÍÎÂÊÀ

Ââîä â ýêñïëóàòàöèþ äîëæåí ïðîèçâîäèòüñÿ êâàëèôèöèðîâàííûì

ñïåöèàëèñòîì.

ÂÍÈÌÀÍÈÅ!

Íàñòîÿùåå èçäåëèå ïðåäíàçíà÷åíî äëÿ ïðîìûøëåííîãî èñïîëüçîâàíèÿ. Ïðè

èñïîëüçîâàíèè â áûòîâûõ óñëîâèÿõ îíî ìîæåò ñîçäàâàòü ðàäèî÷àñòîòíûå ïîìåõè.

Ïîëüçîâàòåëü îòâå÷àåò çà ïðèíÿòèå ñîîò â åòñòâóþùèõ ìåð ïðåäîñòîðîæíîñòè.

S Óñòàíîâêà äîëæíà ïðîèçâîäèòüñÿ êâàëèôèöèðîâàííûì ýëåêòðèêîì.

S Ïåðåä ïîäêëþ÷åíèåì ê ýëåêòðîñåòè óáåäèòåñü, ÷òî äàííîå îáîðóäîâàíèÿ

ðàññ÷èòàíî íà íàïðÿæåíèå ïèòàþùåé ñåòè.

S Âûáåðèòå ñå÷åíèÿ êàáåëåé è âåëè÷èíû ïðåäîõðàíèòåëåé â ñîîòâåòñòâèå ñ

ðàçäåëîì ”Ïîäêëþ÷åíèå ê ýëåêòðîñåòè”.

S Ïîäñîåäèíèòå êàáåëü ïèòàíèÿ ê âûïðÿìèòåëþ â ñîîòâåòñòâèè ñ ìåñòíûìè

òðåáîâàíèÿ è óñòàíîâèòå â ùèòêå ñîîòâåòñòâóþùèå ïðåäîõðàíèòåëè.

S Óñòàíîâèòå àïïàðàò â ïîä õîäÿùåì ìåñòå è óáåäèòåñü, ÷òî äîñò óï âîçäóõà

ä ëÿ îõëàæäåíèÿ àïïàðàòà íå ïåðåêðûò.

4.1 Ïîäêëþ÷åíèå ê ýëåêòðîñåòè

LHF 250 LHF 400 LHF 630 LHF 800

×àñòîòà 50 Hz 50 Hz 50 Hz 50 Hz

Íàïðÿæåíèå 230/400/

415/ 500 V

230/400/

415/ 500 V

230/400/

415/ 500 V

230/400/

415/ 500V

Òîê ïðè

ÏÂ 100%

20/11/11/9A 34/19/19/16 A 65/38/38/30 A 86/49/49/40 A

ÏÂ 60% 25/14/14/11 A 42/24/24/20 A 81/47/47/38 A 10 7/62/60/50A

ÏÂ 35% 31/ 18/18/14 A 53/31/31/25 A 102/59/59/47A 136/79/79/63A

Ïðåäîõðàíèòåëü 25/16/16/16 A 63/25/25/20 A 80/50/50/35 A 100/63/63/50A

ÑåPåíèå êàáåëÿ

(4õìì2)

4/1,5/1,5/1,5 10/4/4/2,5 25/10/10/6 35/10/10/10

LHF 250 LHF 400 LHF 630 LHF 800

×àñòîòà 60 Hz 60 Hz 60 Hz 60 Hz

Íàïðÿæåíèå 230/440/550V 230/440/550V 230/440/550V 230/440/550V

Òîê ïðè

ÏÂ 100%

20/11/9 A 34/19/16 A 65/38/30 A 86/49/40 A

ÏÂ 60% 25/14/11 A 42/24/20 A 81/47/38 A 107/62/50 A

ÏÂ 35% 31/ 18/14 A 53/31/25 A 102/59/47 A 136/79/63 A

Ïðåäîõðàíèòåëü 25/16/16 A 63/25/20 A 80/50/35 A 100/63/50 A

Ñå÷åíèå êàáåëÿ

(4õìì2)

4/1,5/1,5 10/4/2,5 25/10/6 35/10/10

Ñå÷åíèå êàáåëåé ñîîòâ åòñòâóåò jâåäñêèì íîðìàì.

RU

bh10d00

1

bh10d2r -- 7 --

5ÝÊÑÏËÓÀÒÀÖÈß

S Óñòàíîâèòå âûêëþ÷àòåëü (1) â ïîëîæåíèå ”I”. Çàãîðèò ñÿ áåëàÿ èíäèêàòîðíàÿ

ëàìïà (2) è íà÷íåò âðàùàòüñÿ âåíòèëÿòîð îõëàæäåíèÿ.

S Ïåðåêëþ÷àòåëåì (3) óñòàíîâèòå ñïîñîá ñâàðêè.

S Óñòàíîâèòå âåëè÷èíó ñâàðî÷íîãî òîêà ðåãóëÿòîðîì (7) íà ëèöåâîé ïàíåëè è

óñòàíîâèò å ïåðåêëþ÷àòåëü (8) â ïîëîæåíèå ïî íàïðàâëåíèþ ê ðàçúåìó.

.

S Ïîäñîåäèíèòå ñâàðî÷íûé è îáðà ò íûé êàáåëè ê êîíòàêò àì “+” è “ -” íà ïåðåäíåé

ïàíåëè âûïðÿìèòåëÿ. Ïîäñîåäèíèòå îáðàòíûé êàáåëü ê èçäåëèþ

S Âûïðÿìèòåëü ãîòîâ ê ðàáîòå .

5.1 Óïðàâëåíèÿ è ðàçú¸ìû

1. Âêë/Âûêë

2. Áåëàÿ ëàìïà (âûïðÿìèòåëü âêëþ÷åí)

3. Ïåðåêëþ÷åòåëü ñïîñîáà ñâàðêè

4. Âîçäóøíî-äóãîâàÿ ñòðîæêà

5. MMA

6. ÒIG

7. Óñòàíîâêà ñâàðî÷íîãî òîêà

8. Âûêëþ÷àò åëü äèñò. óïðàâëåíèÿ

9. Ðàçúåì äèñòàíöèîííîãî óïðàâëåíèÿ

10. Æ åëòàÿ ëàìïà (îòêëþ÷åíèå ïðè ïåðåãðåâå)

Æ åëòàÿ èíäèêàòîðíàÿ ëàìïà çàãîðàåòñÿ ïðè ñðàáàòûâàíèè òåðìîçàùèòû.

Ïîñëå òîãî, êàê âûïðÿìèòåëü îõëàäèòüñÿ îí àâòîìàòè÷åñêè âêëþ÷èòñÿ

6 ÎÁÑËÓÆÈÂÀÍÈÅ

Çàùèòíûå ùèòû äîëæ åí ñíèìàòü ñ öåëüþ: ïîäêëþ÷åíèÿ, îáñëóæèâàíèÿ è

ðåìîíòà ñâàðî÷íîãî îáîðóäîâàíèÿ òîëüêî ñïåöèàëèñò (èìåþùèé äîïóñê).

Ïðèìå÷àíèå:

à àðàíòìèéíûå îáÿçàòåëüñòâà ïîñòàâùèêà òåðÿþò ñèëó, åñëè ïîêóïàòåëú

ñàìîñòîÿòåëúíî ïûòàåòñÿ ïð îèçâåñòè êàêèå-ëèáî ðàáîòû ïî óñòðàíåíèþ

íåèñïðàâíîñòåé èçäåëèÿ â òå÷åíèå ãàðàíòèéíîãî ñðîêà.

RU

bh10d2r -- 8 --

×èñòêà

Ðåã óëÿðíî ïðîâåðÿéòå, ÷òîáû èñòî÷íèê ïèòàíèÿ íå áûë çàãðÿçíåí.

Íàñêîëüêî ÷àñòî è êàê äîëæíà îñóùåñòâëÿòüñÿ ÷èñòêà çàâèñèò îò: ïðîöåññà

ñâàðêè, ïðîäîëæèòåëüíîñòè ñâàðî÷íîé äóãè, ðàçìåùåíèÿ è îêðóæàþùåé

ñðåäû. Îáû÷íî äîñòàòî÷íî ïðîäóòü èñòî÷íèê ïèòàíèÿ ñæàòûì âîçäóõîì

(ïîíèæåííîå äàâëåíèå) îäèí ðàç â ãîä.

Ïðè ñèëüíîì çàãðÿçíåíèè ðåêîìåíäóåòñÿ ïðîäóâàíèå è ÷èñòêà ïûëåñîñîì.

S Îòêëþ÷èòå ñâàðî÷íîå îáîðóäîâàíèå îò èñòî÷íèêà ïèòàíèÿ.

S Äîñò àíüòå ê îíòàêòíûé øòåêåð èç ðàçååìà. Çàìêíèòå ðàçååì,, ÷òîáû íå

ïðîèçîøëî íåïðîèçâîëüíîãî âêëþ÷åíèÿ.

Ïðè ñò àöèîíàðíîé óñòàíîâêå, ïåðåâåäèòå ïðåäîõðàíèòåëüíûé

âûê ëþ÷àòåëü â âûêëþ÷åííîå ïîëîæåíèå. Çàìêíèòå âûêëþ÷àòåëü íà

çàìîê.

S Ñíèìèòå çàùèòíûå ùèòû íà èñòî÷íèêå ïèòàíèÿ, ÷òîáû óëó÷øèòü äîñò óï.

Ïîñëå ÷èñòêè óñòàíîâèòå âñå çàùèòíûå ùèòû íà ìåñòî ïåðåä òåì, êàê áóäåò

ïîäê ëþ÷åíî ïèòàíèå.

7 ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ

Çàïàñíûå ÷àñòè ìîæíî çàêàçòú ó áëèæàéøåãî ê Âàì ESAB, (ñì. ïåðå÷åíú íà

ïîñëåäíåé ñòðàíèöå äàííîé áðîøþðû). Ïðè çàêàçå ñëåäóå ò óêàçûâàòú òèï

èçäåäèÿ, çàâîäñêîé íîìåð, íàçâàíèå è íîìåð çàïàñíîé ÷àñòè ñîãëàñíî

çàïàñíûõ ÷àñòåé. Òàêèì îáðàçîì óïðîùàåò ñ ÿ ïðîöåññ îòïðàâêè è

èñêëþ÷àþòñÿ îøèáêè ïðè äîñòàâêå.

RU

ENGLISH

-- 9 --

TOCe

1SAFETY 10...........................................................

2 INTRODUCTION 11...................................................

3 TECHNICAL DATA 11.................................................

4 INSTALLATION 12....................................................

4.1 Connecting to mains 12.......................................................

5 OPERATION 13.......................................................

5.1 Controls and connections 13...................................................

6 MAINTENANCE 14....................................................

7 ORDERING OF SPARE PARTS 14......................................

ASSEMBLY INSTRUCTIONS 15...........................................

DIAGRAM 16............................................................

SPARE PARTS LIST 21...................................................

-- 1 0 --

bh10d13e

1DIRECTIVE

DECLARATION OF CONFORMITY

ESAB Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guarantee that welding

power source LHF 250 / 400 / 630 / 800 from serial number 550 complies with standard IEC/EN

60974--1, in accordance with the requirements of directive (73/23/EEC) and addendum (93/68/EEC)

and with standard EN 50199 in accordance with the requirements of directive (89/336/EEC) and add-

endum (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Anders Birgersson

Managing Director

ESAB Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 411924

Laxå 1995--04--10

2SAFETY

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU -

TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect y our eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with s uitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect y our ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

GB

-- 1 1 --

bh10d13e

3 INTRODUCTION

LHF 250/400/630/800 are thyristor controlled welding rectifiers designed for welding

with coated electrodes, TIG welding and arc air gouging.

The welding rectifiers can be used with the following r emote control devices:

PHA 1, PHA 2, PHA 5, PHB 1, PHB 2, och PHC 2.

An auxiliary control unit is required for T IG welding with high frequency ar c ignition.

LHF 400/630, versions with meters and timed co o lin g fan.

These welding rectifiers are equipped with a volmeter, ammeter and a circuit that

reduces the idle speed of the cooling fan.

The meters allow current and voltage settings to be read from the front of the

rectifier.

To minimise the amount of dust and dirt that is drawn into the rectifier the fan runs at

a reduced idle speed of 300 rpm. When welding with currents greater than 30 A the

fan speed increases to its working speed of around 1350 rpm. A timer relay

maintains the higher speed setting for 6 1/2 minutes after welding has stopped to

ensure adequate cooling of the rectifier.

4 TECHNICAL DATA

LHF 250 LHF 400 LHF 630 LHF 800

Maximum load

35 % duty cycle 250 A/30 V 400 A/36 V 630 A/44 V 800 A/44 V

60 % duty cycle 200 A/28 V 315 A/33 V 500 A/40 V 630 A/44 V

100 % duty cycle 160 A/26 V 250 A/30 V 400 A/36 V 500 A/40 V

Setting range 8A/20V--250A/30

(33)V

8A/20V--400A/36

V

8A/20V--630A/44

(49)V

8A/20V--800A/44

(50)V

Open circuit volt. 78--84 V 80--87 V 65--72 V 65--72 V

Open circuit output

at 400 V

300 W 340 W 615 W 640 W

Power factor

(max current)

0,88 0,90 0,87 0,82

Efficiency

(max current)

68 % 74 % 77 % 78 %

Enclosure class IP 23 IP 23 IP 23 IP 23

Application class

Weight 160 kg 195 kg 260 kg 295 kg

Dimens. lxwxh 1310/765/705 1310/765/705 1310/765/705 1310/765/705

Duty cycle

The duty cycle refers to the time as a percentage of a ten--minute period that you can weld at a cer-

tain load without overloading.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP23 is designed for indoor and outdoor use.

Application class

The symbol indicates that the power source is designed for use in areas with increased

electrical hazard.

GB

-- 1 2 --

bh10d13e

5 I NSTALLATION

The installatio n must be executed by a professional.

WARNING!

This product is intended for industrial use. In a domestic environment this product may cause radio

interference. It is the user’s responsibility to take adequate precautions.

S Installation must be carried out by a qualified electrician.

S Check that the welding rectifier is configured for the available mains supply

before connecting it to the mains.

S See Connecting to mains for cable rating and fuse rating.

S Connect the mains cable to the rectifier according to the relevant regulations and

install a suitable fuse in the main fuse box.

S Make sure the welding rectifier is not covered or positioned so that cooling is

obstructed.

5.1 Connecting to mains

LHF 250 LHF 400 LHF 630 LHF 800

Frequency 50 Hz 50 Hz 50 Hz 50 Hz

Voltage 400/415/500 V 400/415/500 V 400/415/500 V 400/415/500 V

Current at

100% duty cycle

11/11/9A 19/19/16 A 38/38/30 A 49/49/40 A

60% duty cycle 14/14/11 A 24/24/20 A 47/47/38 A 62/60/50A

35% duty cycle 18/18/14 A 31/31/25 A 59/59/47A 79/79/63A

Fuse,slow 16/16/16 A 25/25/20 A 50/50/35 A 63/63/50A

Cable area (4xmm2) 1,5/1,5/1,5 4/4/2,5 10/10/6 10/10/10

LHF 250 LHF 400 LHF 630 LHF 800

Frequency 60 Hz 60 Hz 60 Hz 60 Hz

Voltage 440/550V 440/550V 440/550V 440/550V

Current at

100% duty cycle

11/9 A 19/16 A 38/30 A 49/40 A

60% duty cycle 14/11 A 24/20 A 47/38 A 62/50 A

35% duty cycle 18/14 A 31/25 A 59/47 A 79/63 A

Fuse,slow 16/16 A 25/20 A 50/35 A 63/50 A

Cable area (4xmm2) 1,5/1,5 4/2,5 10/6 10/10

Cable areas comply with Swedish regulations.

GB

-- 1 3 --

bh10d13e

6OPERATION

S Set switch (1) to position ”I”. The white lamp (2) will light and the fan will start.

S Select the welding method using the toggle switch (3).

S Adjust the welding current using the knob (7) on the front, and set the toggle

switch (8) to the position nearest the socket.

S Select suitable earth and return cables and connect them to the terminals

marked + and -- on the front of the rectifier. Connect the return cable to the work

piece.

S The rectifier is now ready for welding.

6.1 Controls and connections

1. On/Off

2. White lamp (power on)

3. Method selector switch

4. Arc air gouging

5. MMA

6. TIG

7. Current setting

8. Remote switch

9. Remote socket

10. Yellow lamp (thermal cut--out)

The yellow lamp comes on when the thermal cut--out trips.

When the r ectifier has cooled down the thermal cut -- out is automatically reset.

GB

bh10d001

-- 1 4 --

bh10d13e

7 MAINTENANCE

Note!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any

faults.

Only those persons who have appropriate electrical knowledge (authorised

personnel) may remove the safety plates to connect or carry out service,

maintenance or repair work on welding equipment.

Cleaning

Check regularly that the power source is free from dirt.

How often, and to what extent, cleaning should be carried out depends on the

welding process, arc time, disposition and the surrounding envir onment. It will

normally suffice to blow the power source clean using compressed air (reduced

pressure) once a year.

If the power source is very dirty, brushing and vacuuming are recommended.

S Disconnect the welding power source from the mains current supply.

S Remove the adapter from the socket. Lock the socket to prevent unauthorised

connection.

At fixed installations, the safety switch should be set to the off position. Lock

the switch.

S Remove the power source’s safety plates for best access.

After cleaning, all safety plates must be mounted before you connect the power

source to the mains supply.

8 ORDERING OF SPARE PARTS

LHF 250, LHF 400, LHF 630, LHF 800 is designed and tested in accordance with the in-

ternational an European standards IEC/EN 60 974--1 and EN 60 974--1.

It is the obligation of the service unit which has carried out the service or repair work

to make sure that the product still conforms to the said standard.

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as desig-

nation and spare part number as shown in the spare parts list on page 21.

This will simplify shipme nt and ensure you get the right part.

GB

Assembly instructions Èíñòðóêöèè ïî ñáîðêå

-- 1 5 --

bh10a12a

bh10d002

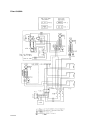

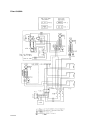

Diagram Ñõåìà

-- 1 6 --

bh10e12a

Prim. 250/400

-- 1 7 --

bh10e12a

Sek. 250/400

-- 1 8 --

bh10e12a

Prim. 630/800

-- 1 9 --

bh10e12a

Sek. 630/800

-- 2 0 --

sida

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

ESAB LHF 400 Manuale utente

- Categoria

- Sistema di saldatura

- Tipo

- Manuale utente

- Questo manuale è adatto anche per

Documenti correlati

-

ESAB LHF 250 Manuale utente

-

ESAB LHL 315 Manuale utente

-

ESAB LHF 800 Manuale utente

-

ESAB LHF 250 Manuale utente

-

ESAB LHF 405 Pipeweld, LHF 615 Pipeweld Manuale utente

-

ESAB LAW 420, LAW 520 Manuale utente

-

ESAB LHF 800 Manuale utente

-

ESAB LHF 410 PC Manuale utente

-

ESAB M1 10Prog CAN Manuale utente

-

ESAB LUA 400 Manuale utente