WALK-BEHIND

POWER TROWELS

B430

B436

B436E

B436SD

B440

B446

Doc. # OI-B09001

Orig. Rel. - 05-2010

Curr. Rev. - 00

Rev. Date - 05-2010

Bartell Morrison Inc.

375 Annagem Blvd.,

Mississauga, ON, Canada

L5T 2A7

Toll Free (N.A.): 1 866 501 1683

Local: +1 905 364 4200

Fax: +1 905 364 4201

OWNER’S

MANUAL

BARTELL MORRISON INC.

artell

ORIGINAL

LANGUAGE

B436

B436E

B436SD

B446

Doc. # OI-B09001

Orig. Rel. - 05-2010

Curr. Rev. - 02

Rev. Date - 06-2013

Bartell Morrison Inc. Bartell Morrison (USA) LLC

375 Annagem Blvd. 12 Industrial Drive,

Mississauga, Ontario, Canada Keyport, New Jersey, USA

L5T 3A7 07735

Toll Free (N.A.): (866) 501-1683 Toll Free: 888-999-1570

Phone: (905) 364-4200 Phone: (732) 566-5400

Facsimile: (905) 364-4201 Facsimile: (732) 566-5444

www.bartellmorrison.com www.bmiamerica.com

ORIGINAL LANGUAGE OPERATING INSTRUCTIONS FOR

BARTELL WALK-BEHIND POWER TROWELS

© 2010 Bartell Morrison Inc.

No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying and recording, or by any information storage or

retrieval system without the prior written permission of Bartell

Morrison Inc. unless such copying is permitted by federal

copyright laws.

Address inquiries or reference permissions care of:

Bartell Morrison Inc.,

375 Annagem Blvd.,

Mississauga, Ontario,

Canada, L5T 3A7

Revision

Date Description Approved by.

0 05/2010 Initial release RL

ALInstructions and company information update.08/2012

1

25

2

06/2013 Assembly instructions updated. AL

2013

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an

explosive atmosphere, near

combustible materials or where

ventilation does not clear exhaust

fumes.

WARNING

BURN HAZARD

Never come into contact with the

engine or muffler when engine is

operating or shortly after it is

turned off. Serious burns may

occur.

CAUTION

ROTATING HAZARD

Never place hands or feet inside

safety guard rings. Serious injury

will result from contact with rotating

blades.

CAUTION

MOVING PARTS

Before starting the machine ensure

that all guards and safety devices

are in place and functioning

properly.

ATTENTION

READ OWNERS MANUAL

Read and understand operator's

manual before using this machine.

Failure to follow operating

instructions could result in serious

injury or death.

!

!

!

!

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

TABLE OF CONTENTS

QUALITY ASSURANCE/MACHINE BREAK-IN .......................................................................................................4

WALK-BEHIND POWER TROWEL WARRANTY ....................................................................................................5

MAINTENANCE RECORD ........................................................................................................................................6

ROUTINE SERVICE INTERVALS .............................................................................................................................7

FOREWORD..............................................................................................................................................................9

SAFETY PRECAUTIONS ..........................................................................................................................................9

ASSEMBLY INSTRUCTIONS ...................................................................................................................................9

1. TROWELS .............................................................................................................................................................9

2. STABILIZER RING.................................................................................................................................................9

3. HANDLE ASSEMBLY ............................................................................................................................................9

4. STATIONARY RING ..............................................................................................................................................9

5. ENGINE CONTROLS ............................................................................................................................................9

6. BELT GUARD ........................................................................................................................................................9

DIAGRAM 1 .............................................................................................................................................................10

OPERATION (FLOATING) ......................................................................................................................................11

OPERATION (FINSHING) .......................................................................................................................................11

1. STARTING PROCEDURES - WARM TEMPERATURES ...................................................................................11

2. STARTING PROCEDURES - COLD TEMPERATURES.....................................................................................11

3. STOPPING PROCEDURES ................................................................................................................................11

LUBRICATION ........................................................................................................................................................11

1. ENGINE OIL.........................................................................................................................................................11

2. SPIDER PLATE ...................................................................................................................................................11

3. GEARBOX ...........................................................................................................................................................11

4. GEARBOX OIL CHANGE ....................................................................................................................................11

5. GREASE FITTINGS.............................................................................................................................................11

ENGINE OIL SPECIFICATIONS..............................................................................................................................11

STORAGE................................................................................................................................................................12

MAINTENANCE.......................................................................................................................................................12

1. AIR CLEANER .....................................................................................................................................................12

2. LUBRICATION .....................................................................................................................................................12

3. SPARK PLUG ......................................................................................................................................................12

4. BELT TENSION ...................................................................................................................................................12

ELECTRIC POWER TROWEL OPERATION..........................................................................................................13

SETTING UP THE ELECTRIC POWER TROWEL .................................................................................................14

STARTING THE ELECTRIC POWER TROWEL ....................................................................................................14

ELECTRIC POWER TROWEL WIRING DIAGRAM ...............................................................................................16

TROWEL ARM ADJUSTMENT FIXTURE ..............................................................................................................17

1. ADJUSTMENT PROCEDURE.............................................................................................................................17

TROUBLESHOOTING.............................................................................................................................................18

SPECIFICATIONS ...................................................................................................................................................19

COMPANY INFORMATION ....................................................................................................................................20

NOTES.....................................................................................................................................................................22

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

10

13

13

13

13

13

13

13

13

13

13

13

13

14

14

14

14

14

14

15

16

16

18

19

19

20

21

22

23

SETUP PROCEDURE

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

TABLE OF CONTENTS

QUALITY ASSURANCE/MACHINE BREAK-IN .......................................................................................................4

WALK-BEHIND POWER TROWEL WARRANTY ....................................................................................................5

MAINTENANCE RECORD ........................................................................................................................................6

ROUTINE SERVICE INTERVALS .............................................................................................................................7

FOREWORD..............................................................................................................................................................9

SAFETY PRECAUTIONS ..........................................................................................................................................9

ASSEMBLY INSTRUCTIONS ...................................................................................................................................9

1. TROWELS .............................................................................................................................................................9

2. STABILIZER RING.................................................................................................................................................9

3. HANDLE ASSEMBLY ............................................................................................................................................9

4. STATIONARY RING ..............................................................................................................................................9

5. ENGINE CONTROLS ............................................................................................................................................9

6. BELT GUARD ........................................................................................................................................................9

DIAGRAM 1 .............................................................................................................................................................10

OPERATION (FLOATING) ......................................................................................................................................11

OPERATION (FINSHING) .......................................................................................................................................

11

1. STARTING PROCEDURES - WARM TEMPERATURES ...................................................................................

11

2. STARTING PROCEDURES - COLD TEMPERATURES.....................................................................................

11

3. STOPPING PROCEDURES ................................................................................................................................

11

LUBRICATION ........................................................................................................................................................

11

1. ENGINE OIL.........................................................................................................................................................

11

2. SPIDER PLATE ...................................................................................................................................................

11

3. GEARBOX ...........................................................................................................................................................

11

4. GEARBOX OIL CHANGE ....................................................................................................................................

11

5. GREASE FITTINGS.............................................................................................................................................

11

ENGINE OIL SPECIFICATIONS..............................................................................................................................

11

STORAGE................................................................................................................................................................

12

MAINTENANCE.......................................................................................................................................................

12

1. AIR CLEANER .....................................................................................................................................................

12

2. LUBRICATION .....................................................................................................................................................

12

3. SPARK PLUG ......................................................................................................................................................

12

4. BELT TENSION ...................................................................................................................................................

12

ELECTRIC POWER TROWEL OPERATION..........................................................................................................

13

SETTING UP THE ELECTRIC POWER TROWEL .................................................................................................

14

STARTING THE ELECTRIC POWER TROWEL ....................................................................................................

14

ELECTRIC POWER TROWEL WIRING DIAGRAM ...............................................................................................

16

TROWEL ARM ADJUSTMENT FIXTURE ..............................................................................................................

17

1. ADJUSTMENT PROCEDURE.............................................................................................................................

17

TROUBLESHOOTING.............................................................................................................................................

18

SPECIFICATIONS ...................................................................................................................................................

19

COMPANY INFORMATION ....................................................................................................................................

20

NOTES.....................................................................................................................................................................

22

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

CREATED: 07/04

REVISED: 06/13

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

QUALITY ASSURANCE / MACHINE BREAK IN

The Bartell Walk-Behind Power Trowel is the product of extensive engineering

development designed to give long life and unmatched performance. The Walk-Behind

Power Trowels are shipped partially assemble, and only require filling with fuel and a brief

check of lubricant levels in preparation for operation.

You can help ensure that your Power Trowel will perform at top levels by observing a

simple routing on first use. Consider that your new Power Trowel is like a new car. Just

as you would break in a new car to the road or any new machine to the job, you should

start gradually and build up to full use. Learn what your machine can do and how it will

respond. Refer to the engine manufacturer’s manual for run-in times. Full throttle and

control may be used after this time period, as allowed by material. This will serve to

further break in the machine on your specific application, as well as provide you with

additional practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Bartell Walk-

Behind Power Trowel and wish you many years of satisfied use.

artell

4

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

WALK-BEHIND POWER TROWEL WARRANTY

All products sold by Bartell Morrison Inc. and Bartell Morrison (USA) LLC (the “Company”) are warranted

against defects in materials and/or workmanship; excluding normal wear on wearing components and

components covered by a separate original manufacturers warranty, for a period of 24 months from the

date of sale to the original end user purchaser provided that certain conditions have been met.

Conditions:

1. The equipment serial number has been registered with the Company or its approved dealers,

distributors, representatives or agents.

2. The equipment has been operated in an appropriate manner by qualified individuals.

3. The equipment has been properly maintained as per the instructions included in the Owner’s

Manual.

4. All claims for warranty must be filed on proper forms and include the serial number of the

equipment along with proof of purchase.

Any evidence of failure to meet these conditions may result in a denial of the warranty claim.

Consideration of warranty claims will be at the sole discretion of the Company, or its authorized dealers,

distributors, representatives or agents.

The Company may, at its discretion, request that the equipment to be considered for warranty be returned

at the owner’s expense to an authorized repair facility for inspection.

Under this warranty we may, at our discretion

, repair or replace a part or the whole of the defective

component or equipment.

Our Warranty coverage is limited to the cost to repair or replace the defective portion of the equipment and

a reasonable (as determined by the Company) amount of labour to conduct the repair or replacement.

Under no circumstances shall the Company be liable for any additional or exceptional costs beyond the

cost to repair or replace the defective portion of the equipment. The Company shall not be held

accountable for; costs associated with travel to inspect or repair defective equipment, costs for transporting

defective equipment to or from an authorized repair facility, costs incurred to repair or replace the defective

equipment at any facility other than one authorized by the Company or ancillary damage caused by or as a

result of the defective equipment.

Under no circumstances shall equipment be returned to the Company or its authorized dealers, distributors,

representatives or agents without the approval of the Company as evidenced by a Returned Goods

Number. To obtain a Returned Goods Number contact the factory or your authorized dealer, distributor,

representative or agent.

This warranty is for the sole benefit of

the original end user purchaser and is not transferable to any other

company or person.

5

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

36

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

MAINTENANCE RECORD

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

This Walk-Behind Power Trowel has been assembled with care and will provide years of service. Preventative

maintenance and routine service are essential to the long life of your Power Trowel. Your dealer is interested in

your new machine and has the desire to help you get the most value from it. After reading through this manual

thoroughly, you will find that you can do some of the regular maintenance yourself. However, when in need of parts

or major service, be sure to see your Bartell dealer. For your convenience we have provided this space to record

relevant data about your Walk-Behind Power Trowel. When in need of parts or service be prepared to provide your

Trowel serial number. Locate the serial number now and record in the space below.

Date Purchased:

Type of Machine:

Dealer Name:

Model:

Dealer Phone:

Serial Number:

REPLACEMENT PARTS USED MAINTENANCE LOG

PART NO. QUANTITY COST DATE DATE OPERATION

6

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

Routine Service

Intervals

Each

use

After 1.5

months

or

50 hrs

Each 3

months

or

100 hrs

Each 6

months

or

200 hrs

Each 9

months

or

300 hrs

Each 12

months

or

400 hrs

General Inspection:

Guards Check

o o o o o

Warning stickers Check

o o o o o

Test run: Check operation

o o o o o

Controls:

Dead-man switch operation Check

o o o o o o

Check

o o o o o o

Pitch control

Lubricate

o o o o o

Engine:

Check Level

o o o o o o

Engine oil

Change

o o o

Engine oil filter Replace

o o

Oil cooler Clean

o o o o

Cooling Fins Clean

o o o o o

Check - clean

o o o o o o

Air cleaner

Replace

o

Check

o

Air Intake Line

Replace

2 yrs

Check tightness

o o

Drive Belt

Replace

500 hrs

Valve clearance Check-adjust

o o

Check & Clean

o o o o

Fuel filter

Replace

o o

Fuel Tank Clean

500 hrs

Engine wiring Check

o

7

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

Routine Service Intervals

Due to the nature and environment of use, Walk-Behind Power Trowels could be exposed to severe

operating conditions. Some general maintenance guidelines will extend the useful life of your trowel.

The initial service for your power trowel should be performed after 25 hours of use, at which time your

mechanic (or authorized repair shop) should complete all of the recommended checks in the schedule

above. The chart on page 6 (six) is handy for keeping a record of the maintenance performed and the parts

used for servicing your trowel.

Regular service according to the schedule above will prolong the life of the Walk-Behind Power Trowel and

prevent expensive repairs.

Keeping your Walk-Behind Power Trowel clean and free from debris is the single most important regular

maintenance operation, over and above the checks in the service schedule above, that can be performed.

After each use your Walk-Behind Power Trowel should be cleaned to remove any dust and debris from the

undercarriage and surrounding components. Use of a power washer will make clean up quick and easy,

especially if a non-stick coating was applied prior to use.

In the

Service Schedule above, items that should be checked, replaced or adjusted are indicated by “o” in

the appropriate column. Not all Walk-Behind Power Trowel models include the same features and options

and as such not all service operations may have to be performed. For ease of recording place a checkmark

(

√

) through the “o” when the item is complete. If an item is not required or not completed place an “x”

through the “o” in the box.

All Walk-Behind Power Trowels have governed engine speed of 3600 rpm. See engine manufacturer’s

manual for exact specifications. Care should be used when making any adjustments to the Walk-Behind

Power Trowel not to change the governed speed.

Failure to have your Walk-Behind Power Trowel regularly serviced and properly maintained in accordance

with the manufacturer’s instructions will lead to premature failure and void the warranty.

8

artell

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK BEHIND POWER

TROWEL INSTRUCTION MANUAL

SAFETY PRECAUTIONS

Always keep unauthorized, inexperienced, untrained

people away from this machine.

Rotating and moving parts will cause injury if

contacted. Make sure guards are in place. Keep

hands and feet away from moving parts.

Fuel the machine only when the engine is stopped,

using all necessary safety precautions.

The engine must always be stopped before

attempting any repair or adjustments. Ignition switch

should be off.

Be careful not to come in contact with the muffler

when the engine is hot, serious burns may result!

ASSEMBLY INSTRUCTIONS

Your new Bartell Walk-Behind Power Trowel has been

shipped to you partially assembled. Filling the fuel tank

and a brief check of lubricant levels in preparation for

operation is required. To complete the assembly the

following instructions will be helpful.

1. TROWELS – Attach trowel blades with screws and

lock washers supplied. See (A) and (B) Fig. 1. Be

careful that adjusting screw (C) does not protrude

below arm when attaching blades. This could cause

the machine to jump and promote excessive wear in

operation.

2. STABILIZER RING – (if supplied) Install using

screws, bushings and lock washers supplied. See

Fig. 1 (D)

3. HANDLE ASSEMBLY – Put cable end Fig. 2 (A)

through hole in yoke

(B) and secure with nut (C),

then install handle bracket on gearbox. To get

proper cable tension, turn control knob Fig. 3,

counter-clockwise to stop position. Guide screw (B)

will now be at the bottom slot. Tighten nut Fig. 4 (A)

until slack is removed from point (B) as indicated. If

more than 2 or 3 threads show through, then nut

should be turned back.

Guide screw, Fig. 3 (B) should be moved to next

lower hole in slide bushing and cable re-adjusted as

above. Turn hand knob completely clockwise and

check for clearance between yoke and gearbox at

point (C) Fig. 4. There should be enough space to

pass a business card through.

4. STATIONARY RING – Install stationary ring as

shown in Fig. 5 with the side bar on engine recoil

side. (May not be exactly as shown). Install rubber

bushings (A) on top and bottom of mounting plate.

Install metal caps (B). Place ring on top and run

screw (C) through caps and rubbers. Tighten lock nut

(D) securely on bottom. It is best to start nuts on all 4

corners before tightening.

5.

ENGINE CONTROLS – Attach throttle control to

handle with screws provided. See DIAGRAM 1 below

for your engine model hook-up. For safety switch

connection, attach wire to terminal provided at

“ON/OFF” location.

The throttle cable must be cut and formed to fit. Feed

the cable through the cable clamp on the engine. Pull

the cable through the clamp until it forms a smooth

arc from the handle to the engine. Mark the cable at

the clamp and pull the cable back from the casing at

the throttle. Without cutting the cable, Cut casing at

the mark and push the cable back through fresh cut

end. Form a small “L” bend in the cable, hook the

inner cable into the throttle block and tighten cable

clamp down onto the casing. With thumb lever and

throttle block in the fully open position, cut

the inner

cable by the thumb lever, leaving enough wire

exposed to secure to the lever. Insert the cable into

the fitting and tighten the screw. Restore throttle to

idle position.

6.

BELT GUARD – Install after machine has been

tested, taking care that it does not touch clutch or

pulley.

9

DANGER:

Never operate the machine in an explosive

atmosphere, near combustible materials or where

ventilation does not clear exhaust fumes. Repair

fuel leaks immediately. Refer to your engine

owner’s manual for more safety instructions.

IMPORTANT:

Before running machine with belt installed, ensure

that engine idles properly and that the safety -switch

shuts off the engine.

ATTENTION:

For any information regarding engine adjustments,

please refer to the engine manual supplied.

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO

, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

STATIONARY RING - Install stationary ring as shown

in Fig. 5 with the side bar on engine recoil side (may

not be exactly as shown). install rubber bushings (A)

on top and bottom of mounting plate. Install metal caps

(B). Placing ring on top and run screw (C) through caps

and rubbers. Tigthen lock nut (D) securely on bottom.

It is best to start nuts on all 4 corners before tigthening.

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

SAFETY PRECAUTIONS

Always keep unauthorized, inexperienced, untrained

people away from this machine.

Rotating and moving parts will cause injury if

contacted. Make sure guards are in place. Keep

hands and feet away from moving parts.

Fuel the machine only when the engine is stopped,

using all necessary safety precautions.

The engine must always be stopped before

attempting any repair or adjustments. Ignition switch

should be off.

Be careful not to come in contact with the muffler

when the engine is hot, serious burns may result!

ASSEMBLY INSTRUCTIONS

Your new Bartell Walk-Behind Power Trowel has been

shipped to you partially assembled. Filling the fuel tank

and a brief check of lubricant levels in preparation for

operation is required. To complete the assembly the

following instructions will be helpful.

1. TROWELS – Attach trowel blades with screws and

lock washers supplied. See (A) and (B) Fig. 1. Be

careful that adjusting screw (C) does not protrude

below arm when attaching blades. This could cause

the machine to jump and promote excessive wear in

operation.

2. STABILIZER RING – (if supplied) Install using

screws, bushings and lock washers supplied. See

Fig. 1 (D)

3. HANDLE ASSEMBLY –

Put cable end Fig. 2 (A)

through hole in yoke (B) and secure with nut (C),

then install handle bracket on gearbox. To get

proper cable tension, turn control knob Fig. 3,

counter-clockwise to stop position. Guide screw (B)

will now be at the bottom slot. Tighten nut Fig. 4 (A)

until slack is removed from point (B) as indicated. If

more than 2 or 3 threads show through, then nut

should be turned back.

Guide screw, Fig. 3 (B) should be moved to next

lower hole in slide bushing and cable re-adjusted as

above. Turn hand knob completely clockwise and

check for clearance between yoke and gearbox at

point (C) Fig. 4. There should be enough space to

pass a business card through.

4.

STATIONARY RING – Install stationary ring as

shown in Fig. 5 with the side bar on engine recoil

side. (May not be exactly as shown). Install rubber

bushings (A) on top and bottom of mounting plate.

Install metal caps (B). Place ring on top and run

screw (C) through caps and rubbers. Tighten lock nut

(D) securely on bottom. It is best to start nuts on all 4

corners before tightening.

5.

ENGINE CONTROLS – Attach throttle control to

handle with screws provided. See DIAGRAM 1 below

for your

engine model hook-up. For safety switch

connection, attach wire to terminal provided at

“ON/OFF” location.

The throttle cable must be cut and formed to fit. Feed

the cable through the cable clamp on the engine. Pull

the cable through the clamp until it forms a smooth

arc from the handle to the engine. Mark the cable at

the clamp and pull the cable back from the casing at

the throttle. Without cutting the cable, Cut casing at

the mark and push the cable back through fresh cut

end. Form a small “L” bend in the cable, hook the

inner cable into the throttle block and tighten cable

clamp down onto the casing. With thumb lever and

throttle block in the fully open position, cut the inner

cable by the thumb lever, leaving enough wire

exposed to secure to the lever. Insert the cable into

the fitting and tighten the screw. Restore throttle to

idle position.

6.

BELT GUARD – Install after machine has been

tested, taking care that it does not touch clutch or

pulley.

9

DANGER:

Never operate the machine in an explosive

atmosphere, near combustib

le materials or where

ventilation does not clear exhaust fumes. Repair

fuel leaks immediately. Refer to your engine

owner’s manual for more safety instructions.

IMPORTANT:

Before running machine with belt installed, ensure

that engine idles properly and that the safety -switch

shuts off the engine.

ATTENTION:

For any information regarding engine adjustments,

please refer to the engine manual supplied.

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

9

WALK-BEHIND TROWEL INSTRUCTION MANUAL

CREATED: 07/04

REVISED: 06/13

CREATED: 07/04

REVISED: 06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK-BEHIND TROWEL INSTRUCTION MANUAL

SETUP PROCEDURE

Step 1: Trowel shown with handle separate. (Fig. 1) Step 2: Lay handle on ring to prepare for assembly.

(Fig. 2 and 3)

Step 3: Install pitch control cable to yoke and install locknut loosely

(Fig. 4). If needed, turn pitch control knob counter-clockwise until the

stop screw is at the lowest position (Fig. 5).

Step 4: Lift and install handle to position using the supplied four sets of lockwashers and nuts.

Do not torque greater than 18ft-lb. At the yoke; tighten the locknut for pitch control cable (Fig. 6).

If the cable is too loose or tight, the pitch control range position can be moved by changing the

position of the stop screw (Fig. 5). The factory default is the middle position. Turn the pitch control

knob completely clockwise and check for maximum pitch possible. This is possible when the clear-

ance between the yoke and underside of the gearbox is enough to pass a business card through.

Fig. 1 Fig. 2

Fig. 3

Fig. 4

Fig. 5 Fig. 6

10

CREATED: 07/04

REVISED: 06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK-BEHIND TROWEL INSTRUCTION MANUAL

Step 5: Unwrap throttle control and engine safety shut-off wires to

prepare for their assembly. (Fig. 7 and 8)

Step 6: Remove air lter cover and air lter. (Fig. 9) Step 7: Check for free moving engine throttle control

lever and loosen pivot nut if necessary (Fig. 10)

Step 8: Push handle throttle lever all the way

forward for idle position (Fig. 11). If necessary, the

tension screw can be adjusted for smooth operation

while holding throttle position.

Step 9: Install the throttle control wire into the

throttle control lever. (Fig. 12)

Fig. 7

Fig. 8

Fig. 9 Fig. 10

Fig. 11 Fig. 12

11

CREATED: 07/04

REVISED: 06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

WALK-BEHIND TROWEL INSTRUCTION MANUAL

Step 10: Secure the wire to the cable clamp while

pushing with slight pressure forward. (Fig. 13)

Step 11: Check operation of throttle control lever.

(Fig. 11 and 14)

Step 12: Reinstall air lter and cover (Fig. 15) Step 13: Route engine safety shut-off wire around

engine and install. There are two types that may be

available with the machines. (Fig. 16 and 17)

Step 14: Wrap and secure engine safety shut-off

wire. (Fig. 18)

Step 15: Refer to Owner’s Manual before operating

the trowel.

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

12

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

OPERATION (Floating)

When the slab has set sufficiently firm that the

operator’s footprint leaves a very slight depression on

the surface of the slab, it is ready for the floating

operation.

Under normal operating conditions the machine should

cover as much as 1000 sq. ft. in about 15 minutes. It is

recommended that a slight tension on the trowel control

cable, (but not a definite tilt), during the floating

operation will cause the machine to operate much

smoother. After the floated slab has set sufficiently, it is

ready for the finishing operation.

OPERATION (Finishing)

When starting the finishing operation, never set the

trowels up over 1/4” pitch. This is important. Guiding the

machine on the slab is very simple, a slight upward lift of

the handle causes the machine to travel to the left.

Holding the handle in the neutral position, will slowly

cause the machine to spin in one spot. Slight downward

pressure on the handle causes the machine to travel to

the right. Best results are obtained by covering

approximately 4” on each turn. In other words, let the

machine move right or left, backwards or forwards,

approximately 4” with each revolution of the trowels. To

fill a hole or cut down a

hump, move the unit back and

forth over the problem area.

After the first pass over the slab, the waiting time

between operations is determined in the same manner

as if you were hand troweling. To repeat; the entire

application and action of the troweling machine in regard

to getting on the slab, and the correct pitch of the

trowels, is determined in the same manner as would be

used by a cement finisher when troweling by hand.

STARTING PROCEDURE:

*WARM CLIMATE

Open fuel valve on gas tank. Set throttle lever to “Fast”

idle position, set choke to closed position, start engine.

Open choke slightly to prevent flooding. Move to “Open”

or “Run” position when engine is warm, increase throttle

to maximum operation position (3600 rpm).

STARTING PROCEDURE: *COLD CLIMATE

Follow same procedure as above but allow longer

warm-up period – 3 to 5 minutes. In cold weather, oil is

much heavier to move and requires more time to work

its way into the moving parts. If maximum power is not

attained, allow further warm-up time. Fill fuel tank with

clean gasoline, use safety approved gas containers.

DO NOT MIX OIL WITH GASOLINE – USE UNLEADED

GAS ONLY.

STOPPING PROCEDURE

1. Throttle engine down.

2. Turn off stop switch.

LUBRICATION

1. ENGINE OIL

The long life and successful operation of any piece of

machinery is dependent on frequent and thorough

lubrication.

Before using the trowel, always check your engine for

oil. Use proper engine oil as recommended in the

engine manufacturer’s manual. Fill crankcase to

levels as recommended.

ENGINE OIL SPECIFICATIONS

2. SPIDER PLATE

There are 4 (four) grease fittings on the spider plate,

each must be greased daily. THE SPIDER PLATE

MUST BE GREASED EVERY TIME MACHINE IS

USED.

3. GEARBOX

Check the oil level sight plugs on both gearboxes

daily to ensure the oil is half way on the site glass.

Top up with Agma 8 compounded gear oil only.

Gearbox capacity 16 oz. to 19 oz. (473ml. To 562ml.)

Example: Esso/Exxon Cylesstic TK680.

4. TO CHANGE GEARBOX OIL

Place a pan beneath the drain plug to catch the oil.

Remove the drain plug and the filler plug from the

gearbox. After the oil has drained completely, replace

the drain plug and tighten. Fill the gearbox through

the filler plug with 16 oz. to 19 oz. (473ml. To 562ml.)

of Agma 8 compounded gear oil. Replace the filler

plug and tighten.

11

CAUTION:

Do not let the machine stand in one spot on the

soft cement. Lift from the slab when the floating

operation is complete.

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

All Season SAE 10W-30

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

13

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

STORAGE

The following steps should be taken to prepare your

Walk-Behind Power Trowel for extended storage.

1. Close fuel shut off valve.

2. Siphon excess gasoline from tank.

3. Start engine until it stops from lack of fuel. This will

use up all the fuel in the carburetor and prevent

formation of deposits due to evaporation of fuel.

4. Remove spark plug and pour 2 oz. of SAE-30 or

SAE-40 motor oil into the cylinder. Slowly crank the

engine 2 or 3 times to distribute the oil throughout

the cylinder. This will help prevent rust during

storage. Replace spark plug.

5. Store the unit in an upright position in a cool, dry,

well ventilated area.

MAINTENANCE

Maintaining your Walk-Behind Power Trowel will insure

long life to the machine and its components.

AIR CLEANER - Keep air filter clean at all times. Wash

away dust and debris using a non-oil based cleaning

solvent. Let the filter dry before re-installing.

LUBRICATION – Check engine oil regularly. Use

proper engine oil as recommended. See previous

chart. Fill crankcase to levels as recommended in

manufacture’s engine manual.

SPARK PLUG

– Check and clean spark plugs

regularly. A fouled, dirty or

carboned spark plug causes

hard starting and poor engine performance. Set spark

plug gap to recommended clearance. Refer to engine

manual.

BELT TENSION – IMPORTANT!

If there is excessive belt play, there will be a decrease

in the power transmission capability which could lead to

premature wear and failure of the belt. The normal belt

play should be 1/2” to 5/8” which is attained by

depressing one side of the belt at the mid-point of the

span between pulleys. Tighten all engine mount

fasteners.

CHART FOR MINIMUM WIRE SIZE OF EXTENSION CORD

Nameplate AMPS CORD LENGTH

25’ 50’ 100’ 150’

0-6 18 AWG 16 AWG 16 AWG 14 AWG

6-10 18 AWG 16 AWG 14 AWG 12 AWG

10-12 16 AWG 16 AWG 14 AWG 12 AWG

12-16 14 AWG 12 AWG (NOT RECOMMENDED)

12

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

14

The electric models of Bartell Power Trowels require appropriate power sources, connections,

extension cords, and surge protection. Bartell Morrison Inc. is not responsible for damage to person

or property due to improper use or setup of an Electric Power Trowel. Select your power supply and

other provisions based on the specific type of trowel being operated.

While the Electric Power Trowel has internal surge protection to protect the motor, electronics, and

operator from internal power surges, the power supply should be equipped with an appropriate

breaker to protect the equipment and personnel on the job site from potential harm from a damaged

power supply cord.

The following safety precautions should always be observed when operating Bartell Electric Power

Trowels, in addition to the stated precautions for regular power trowels:

The operator is responsible for the protection of the electrical power supply cord. Do not let the

cord come into contact with the trowel blades under any circumstances. If the cord does touch the

blades, immediately power down the trowel, unplug the electrical supply, and inspect the cord for

damage. Cords with damaged insulation should be replaced immediately.

If the trowel blades stick or jam a surge will be created, tripping the external breaker. Avoid starting

the trowel after sitting on green concrete for extended periods without first breaking the bond or

applying some water to the surface for lubrication. Avoid hitting obstacles with the blades as this

can cause physical damage to the blades, transmission, or trip the breaker.

13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

ELECTRIC POWER TROWEL OPERATION

WALK-BEHIND TROWEL INSTRUCTION MANUAL

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

15

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

While the trowel should be cleaned daily, and the electronic components are splash-resistant,

avoid spraying water or other liquids directly on the motor, starter box, or handle controls, as this

can damage the electronics. Never immerse the trowel in water. If water intrusion into the

electronics is suspected, have the trowel inspected by an authorized BMi representative before

operating.

Do not attempt to disable the electric safety switch on the right handle of the trowel.

Do not pull the trowel by the safety switch housing.

Always unplug the trowel for storage or transportation.

SETTING UP THE ELECTRIC POWER TROWEL

STARTING THE ELECTRIC POWER TROWEL

The Bartell Electric Power Trowel

ships without the handle attached.

When installing the handle, ensure

that the control plug at the lower end

of the handle is plugged into the

receptacle at the lower left of the

motor starter box and retained with

the clip.

The box is protected with two (2)

timed fuses. If your trowel will not

start, and the breakers at the line

and starter box are ok, then you

may need to replace the fuses.

14

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

16

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

1. Plug the trowel into the electrical supply. If the line power is on, the green power indicator

lamp on the top of the trowel will glow.

2. Turn the master starter switch clockwise to the ON (vertical) position. If it will not stay in the

ON position, then turn it fully counterclockwise to the OFF position and try again. The internal

breaker of the starter box will not let the master switch be turned on until it has been reset by

turning it off.

3. With the master switch ON, stand at the operator position behind the handle. The motor will

not start until the safety handle is fully depressed, and it will immediately stop if the safety

handle is released. Squeeze the safety handle with your right hand until it is fully depressed,

and hold this for the duration of operation.

4. Brace your hip against the shield pad on the handle for better control. Bartell Electric Power

Trowels operate at a constant speed which is achieved immediately after startup, so there will

be some kick. With your left hand, press the green start button. The trowel will immediately

begin to turn.

NOTE: If the trowel appears to hesitate or the motor strains for more than 3 seconds, release the

safety handle and inspect the blades for any obstructions or bonding to the concrete. Clear the

obstacle and try again.

5. To stop the trowel, simply release

the safety handle or press the red stop button. Do not

release the handles until the blades have stopped rotating. If leaving the trowel for any

extended period, turn the master switch to the OFF position.

15

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

17

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

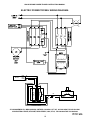

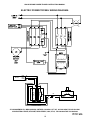

ELECTRIC POWER TROWEL WIRING DIAGRAM:

16

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

CONTROL BOX

PIN2

PIN1

PIN3

CONTROL

PLUG

SAFETY SWITCH

STOP

START

1 3

2 4

COM

NO

DEADMANOFF

G

W

BL

K

W

BL

K

BR

BL

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

18

WALK BEHIND POWER TROWEL INSTRUCTION MANUAL

The trowel arm adjustment fixture (20801) is reversible.

By rotating the arm clamping fixture and the ring bolt,

both left hand and right hand trowel arms may be

adjusted. Before attempting adjustment, determine

whether the trowel arm is right handed or left handed.

When adjusting left hand trowel arms use the side of the

fixture marked “L”. When adjusting right hand trowels

arms use the opposite side. The adjustment bar will be

set on “36” for the Walk-behind trowel arm.

ADJUSTMENT PROCEDURE

1. Remove all trowel arm assemblies (1 & 2 arm and

attached lift lever) from suspected maladjusted spider

plate.

2. Remove lift lever (2) from trowel arm (1) by first

loosening jam nut (3) then square head screw (4). If

upon inspection (method left to discretion of

serviceman) any trowel arm (1) is found to be in a

bent condition, it must either be brought back to its

original straight condition (method left to the

serviceman’s discretion) or replaced with new part.

3. Replace lift levers (2) on new or straightened arms

(1) by reversing procedure as described above.

4. Place trowel arm assembly (1 and 2) in fixture (5)

with lift lever (2) butting up against fixture. Clamp in

place with bolts

(6).

5. Loosen locknut (7) and screw carriage bolt (8) down

to full depth allowable. This will provide for ample

clearance to swing precision ground adjustment bar

(9) over head of carriage bolt.

Adjustment bar (9) is stamped for appropriate size of

machine. Swing appropriate side directly over carriage

bolt (8) and secure in place with bolt (10).

6. Adjust carriage bolt (8) upwards until contact is made

with adjustment bar (9); holding carriage bolt in

position with one wrench, tighten locknut (7) to secure

in position with second wrench.

7. This same procedure is to be followed with ALL arms

from spider plate assembly, and will ensure correct

and exact adjustment.

TROWEL ARM ADJUSTMENT SCREW

The trowel arm adjustment screw is to be used for field

adjustment of blade level, in the event of a damaged

trowel arm, to enable completion of the job. At the end of

the job repairs should be made to eliminate the damage.

When assembling trowel blades to trowel arms, the

adjustment screw should NEVER protrude below the

under-side surface of a trowel arm.

If the adjustment screw is not flush with the underside of

the trowel arm, then this will cause the power trowel to

bounce and vibrate especially at high speed. This will

also cause the trowel blades to leave an uneven finish to

the concrete due to

the blades not being level to one

another.

Make certain that the adjusting screw is held firmly in

place while tightening the bolt which secures the blade to

the trowel arm.

17

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA L5T 3A7, 905-364-4200 FAX 905-364-4201

CREATED: 07/04

REVISED: 05/10

TROWEL ARM ADJUSTMENT FIXTURE

PART #20801

Ex: Unit 36” (B436)

1)10810A – Trowel arm

2)10817A – Lift lever

3)10808 – Jam nut

4)10809 – Set screw

5)10824 – Block top

6)10507 – Bolt

7)10808 – Jam nut

8)10807 – Carriage bolt

9)10832 – Adjustment bar

10) 10507 – Bolt

Figure

5a.

NOTE: IT IS IMPORTANT THAT WHEN TIGHT -

ENING SQUARE HEAD NUT (4), IT SEATS ITSELF

SECURELY INTO DIMPLE MACHINED IN ARM.

NOTE: IT IS VITALLY IMPO RTANT TO ENSURE

THAT ONCE THE CARRIAGE BOLT IS ADJUSTED

TO THE CORRECT HEIGHT, IT DOES NOT MOVE

BEFORE, OR DURING THE TIGHTENING OF

LOCKNUT.

06/13

375 ANNAGEM BLVD., MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-6400 FAX 732-566-5444

19

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

Bartell B446 Manuale del proprietario

- Tipo

- Manuale del proprietario

in altre lingue

- English: Bartell B446 Owner's manual

Altri documenti

-

Nexus NXT-90 Manuale utente

-

Weider PRO 9625 SYSTEM 15936 Manuale utente

-

Vemer AGMA22 neoprene 3m Manuale utente

-

Husqvarna FS309 Manuale utente

-

Ingersoll-Rand RX-264H Operation & Maintenance Manual

-

Peerless ACC-DHP6 Manuale utente

-

OKI LD620D Manuale del proprietario

-

Klipsch KG 3 Manuale del proprietario

-

OKI LD640D Manuale utente

-

OKI LD640Ds Guida utente