Politec Parvis Solar SMA Technical Manual

- Tipo

- Technical Manual

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

2

INDEX

1

MAIN COMPONENTS

Pag. 3

2

ASSEMBLING THE CABLE PIT

Pag. 4

POSITIONING THE CABLE PIT

Pag. 6

3

INSTALLING THE BASE

Pag. 8

4

PHOTOVOLTAIC PANEL ORIENTATION

Pag. 9

5

INSTALLATION SAMPLES

Pag. 10

6

OPTICAL CONFIGURATION

Pag. 11

OPTICAL TRANSMITTER

Pag. 11

OPTICAL RECEIVER

Pag. 12

7

SANDOR WS TX BOARD

Pag. 13

8

SANDOR WS RX BOARD

Pag. 14

9

SETTING AND FUNCTION

Pag. 15

DIP SWITCH DESCRIPTION

Pag. 15

10

COLUMN ALIGNMENT

Pag. 17

11

CALIBRATION WITH SMA SYSTEM

Pag. 18

12

PARALLEL BEAMS CALIBRATION

Pag. 22

13

ALARM SENSITIVITY ADJUSTMENT

Pag. 23

14

CABLES

Pag. 24

15

TECHNICAL CHARACTERISTICS

Pag. 25

Installation recommendation

Verify that the beam tower is fully watertight once the cover and end caps have been correctly filled at the

end of the installation.

Use the cable glands supplied on the tower for all cabling must pass through the lower end cap using the

cable glands supplied. The missed used of proper accessories decrease the IP grade protection of the

tower.

Avoid any type of obstruction between the transmitter and receiver.

Avoid installing the receivers beams in a position where direct sunlight, at the same angle as the receivers

beams, can enter directly into optics especially at sunset and sunrise

Do not install multiple beams where the transmitter beam can interfere with other receiver beams. It is

always better place either transmitter or receivers back to back.

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

3

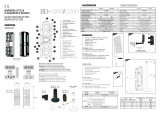

1 MAIN COMPONENTS

N°

Parte

Descrizione

1

Aluminum bar

2

IR pipe

3

Blind cap

4

Lamp Adapter

5

Base

6

Cable Pit

7

Mother board TX

8

Opitical RX/TX

9

Mother board RX

10

Base cover (with cable glands)

11

Rechargeable battery 3.6V

12

Power Board 3.6 V

13

Photovoltaic Panel

13

2

1

3

4

5

11

9

7

8

10

6

12

11

12

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

5

4. Insert and fix the screws in the other sides.

2.1 POSITIONING THE CABLE PIT

The placement of the cable pit for the columns PARVIS is made by concrete all around and not at the bottom,

keeping the top edge same level of ground

For columns PARVIS is possible to keep the top edge ten centimeters below the level of the ground so that it is

visible only the IR tube.

This type of placement is possible only when the cable pit is fixed directly into the ground and not in concrete

or pavement.

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

6

POSSIBLE CORRECTION OF THE INCORRECT

POSITIONING

Placement should be perpendicular to the ground. If the base is not in perfectly level, you can make small

adjustments through the regulation of the inserts in the cablepit.

Loosening the insert on the side to correct inclination you get the increase to the correct position

Wrong positioning.

Example of

setting.

Correct positioning by

adjusting inserts.

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

7

3 INSTALLING THE BASE

Ensure that all the cabling to and from the Parvis beam passes through the supplied cable glands that should be

fitted to the base of the tower. Use the central cable gland for the pre-wired light cabling.

The base cover fitted with the cable glands

Once the cabling is completed the base cover has to be fixed to the base.

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

8

4 PHOTOVOLTAIC PANEL ORIENTATION

Using screws of the cap you can rotate the plastic profile of 120 ° at a time to expose the solar panel as much as

possible in the midday sun.

You can make other minor corrections using the slots

FIXING SCREW

CAP

FIXING SCREW

BASE

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

13

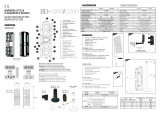

8 SANDOR WS MOTHER BOARD RX

N.B.: When the motherboard is supplied the LED ON will flash.

LED TEST

BATTERY

CONNECTION

3,6 V – 19 Ah

3,6 V

3,0 V

TAMPER

ALARM

TAMPER

SUPPLY

INTERVENTION

DELAY

ADJUSTING

BATTERY LOW (BL)

SIGNAL LOW (SL)

AND FOR REMOTE

(AND)

DIP SWITCH

ANTIMASK P OUTPUT

(AMK)

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

14

9 SETTING AND FUNCTION

DIP SWITCH

The board has Dip Switches to set different functions:

BANCO A 4 DIP SWITCH SCHEDA TX

1

TEST

In ON position goes in test. The TEST LED start blinking.

2

/

Not utilized

3

BEAM ON

It puts in test all TX during alignment (DIP 1 ON). Test LED fixed ON.

4

BEAM OFF

It puts OFF all TX during alignment (DIP 1 ON). Test LED fixed ON.

ON

1

2

3

4

5

6

7

8

9

10

i.e.: Function AND 1-2 with 3 beams

8 DIP SWITCHES

1

AND

At least 2 optical must be interrupted to give alarm

2

AND 1-2

AND function only for 1st and 2nd beam, usefull in case of growing grass

3

BEAM 3

First 3 RX are active

4

BEAM 4

/

5

BEAM 5

/

6

BEAM 6

/

7

S. LOW

FOG disqualification active

8

A. CRAWL

ON - Anti crawling active. In this condition if the first beam (lower) is interrupted for

more than 2 seconds, it will generate an alarm, independently of its configuration

(i.e. AND)

9

AMK

/

10

TEST

Active or disable the TEST

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

15

CONNECTOR 8

1

HTR

Non utilizzato

2

3

ALLARME

NC Alarm relay

4

5

TAMPER

NC Tamper relay

6

7

SUPPLY

Possibility to supply the radio trasmitter with 3,0 or 3,6 V

8

CONNECTOR 4

BL

BATTERY LOW

Low battery indication (negative open collector)

SL

SIGNAL LOW

Fog disqualification (negative open collector)

AND

REMOTE

CONTROL

Giving a positive (3,6 V) the AND function is activated

AMK

ANTIMASK

Segnalazione di mascheramento data dalla chiusura al negativo di un open

collector.

10 COLOUMN ALIGNMENT

For proper alignment once installed barriers orient optical groups of the transmitters and receivers each optical

groups in the direction of others. Adjusting horizontally through the manual movement, and vertically through

the front screws placed above the lenses.

Vertical adjustment

Horizontal adjustment

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

16

11 CALIBRATION WITH SMA SYSTEM

You can improve the calibration through the use of the supplied filter

1. Fold the device by following the folds preset

2. Place the filter in front of the optics TX positioning the two hooks on the pins of the fork optics to

effectively search the signal alignment with critical conditions.

Simply applying the filter only on the TX, no need to repeat the operation RX.

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

17

3. Connect the battery cable.

4. Put in ON DIP 10 on the motherboard receiver until the entrance to the programming mode indicated by

the flashing LED test.

5. Start the alignment of the barrier is on activating the transmitter optics TX TEST, pressing the dedicated

button for about 3 seconds until the TEST LED turns orange.

DIP 10

ORANGE

LED

TEST

BUTTON

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

18

6. Turn the TEST on the corresponding optics receiver by pressing the dedicated button for about 3

seconds until the TEST LED turns orange , the Buzzer and LED alignment go ON.

7. Through the TRANSMITTER lens shifts , find the maximum optical alignment based on the BUZZER

and LED (high-brightness) of alignment, the 'increase in the frequency of blinking of the LEDs and the

whistle of the corresponding BUZZER indicate better ALIGNMENT.

8. By a FULL rotation on the horizontal axis of the RECEIVER optics , you make the SCANNING of the

optical signal.

BUTTON

TEST

ORANGE

LED

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

19

9. Rotating the optical RX find the maximum value of which corresponds to the ALIGNMENT LED

(high-brightness) FIXED and whistle CONTINUOUS of the BUZZER.

10. Exit the function by repressing the ALIGNMENT TEST button for about 3 seconds on both optics

(TX-RX) ensuring that the orange LED TEST is shown in original condition.

11. When finished, remove the shade that acts as a attenuator, with the certainty of having found the

optimum value.

12. Once the alignment of all the beams is finished, re-press the test button on the motherboard for 5

seconds until the LED turns off.

For the next 30 seconds the barrier will sound continuously in case of alignment not effective or

interruption of a beam; correct the orientation of the columns so that the buzzer emits no longer any

sound.

.

TEST

BUTTON

ORANGE

LED

POLITEC s.r.l. | Parvis Solar Sma – Ver. 1.1

20

12 PARALLEL BEAMS CALIBRATION

Put TEST optics TX1 and RX1 and proceed with the calibration as previously explained.

Put TEST optics TX2 and RX2 and proceed with the calibration as previously explained.

N.B.: During the alignment phase of a transmitter the other TX are switched off automatically.

RX2

TX2

RX1

TX1

RX2

TX2

RX1

TX1

RX2

TX2

RX1

TX1

RX2

TX2

RX1

TX1

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Politec Parvis Solar SMA Technical Manual

- Tipo

- Technical Manual

in altre lingue

- English: Politec Parvis Solar SMA

Altri documenti

-

INIM BD-Q200 Manuale utente

INIM BD-Q200 Manuale utente

-

INIM TRIPLICATE PHOTOELECTRIC BEAM Guida d'installazione

-

CAME BQ810AS-BQ815AS-BE820AS-BE825AS Guida d'installazione

-

PRASTEL FOTO9S2A Manuale del proprietario

-

WisyCom MCR41S-42S Manuale utente

-

SEA USER 1 Manuale del proprietario

-

BFT Ares Manuale del proprietario

-

CAME SIPARIO Guida d'installazione

-

BFT Giotto BT A U Manuale utente

-

SEA USER 2 24V Manuale del proprietario