VISTA-SL C

ISTRUZIONI D’USO E DI INSTALLAZIONE

INSTALLATION AND USER’S MANUAL

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

INSTALLATIONS-UND GEBRAUCHSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

GEBRUIKS- EN INSTALLATIEAANWIJZINGEN

D812047 00100_01 05-09-13

AUTOMAZIONI PORTE

AUTOMATION DOORS

AUTOMATIONS POUR PORTES

AUTOMATICTUREN

AUTOMATIZACIONES PARA PUERTAS

AUTOMATISERINGSSYSTEMEN DEUREN

Attenzione! Leggere attentamente le “Avvertenze” all’interno! Caution! Read “Warnings” inside carefully! Attention! Veuillez lire attentivement les Avertissements qui se trouvent à l’intérieur!

Achtung! Bitte lesen Sie aufmerksam die „Hinweise“ im Inneren! ¡Atención¡ Leer atentamente las “Advertencias”en el interior! Let op! Lees de “Waarschuwingen” aan de binnenkant zorgvuldig!

ARIAEVO

VISTA-SL C

(ARIA-EVO)

B

Traversa da installare, Crosspiece to be installed, Entretoise à installer,

Zu installierende Querstrebe, Travesaño por instalar, Te Installeren Dwarsdrager.

Traversa già installata, Crosspiece already installed, Entretoise déjà montée, Bereits installierte Querstrebe,

Travesaño instalado, Reeds geïnstalleerde Dwarsdrager.

MONTAGGIO CARTER, ASSEMBLING THE COVER , MONTAGE DU CARTER,

MONTAGE VERKLEI, DUNG, MONTAJE CÁRTER , MONTAGE CARTER.

C

PASSAGGIO CAVI, CABLE ROUTING, PASSAGE DES CÂBLES,

KABELDURCHFÜHRUNG, PASO CABLES, KABELDOORGANG.

CARTER

COVER

CARTER

VERKLEIDUNG

CARCASA

CARTER

TRAVERSA

CROSSPIECE

ENTRETOISE

QUERSTREBE

TRAVESAÑO

DWARSDRAGER

CERNIERA

HINGE

CHARNIÈRE

SCHARNIER

CREM ALLERA

SCHARNIER

*

*

*

*

*

*

1

2 3

5

5 mm

∅ 9

90°

V1

CARTER, COVER, CARTER, VERKLEIDUNG, CARCASA, CARTER

TRAVERSA,CROSSPIECE, ENTRETOISE,

QUERSTREBE, TRAVESAÑO, DWARSDRAGER.

Cavo di terra con occhielli alle estremità,

Earth wire with ring terminal at both ends,

Câble de mise à la terre avec extrémités

munies d’œillet,

Erdungskabel mit Öse an den Enden,

Cable de tierra con ojal en el extremo,

Aardingsleiding met oog aan de

uiteinden.

6

16

V1

V2

10

5

D2

6

6

R1

4

M5

D1

*

8 mm

12 mm

8 mm

12 mm

*

*

*

*

*

B

C

D1

V1

*

*

A

24 V ~

24 V ~

Messa a terra Carter Vista SL C, / Earthing the Vista SL C Cover,

Mise à terre du carter Vista SL C, / Erdung des Vista SL C Kurbelgehäuses,

Puesta a tierra Cárter Vista SL C, / Aarding Carter Vista SL C

230 V ~

1 2

4A

4B

V2

D2

R1

R1

Aiutarsi con alcool. Non usare grassi o altri lubricanti.

Insert with the aid of alcohol. Do not use grease or other lubricants.

Servez-vous d’alcool. N’utilisez ni graisses ni aucun autre lubriant.

Benutzen Sie Alkohol. Verwenden Sie keine Fette oder sonstige Schmiermittel.

Ayudarse con alcohol. No usar grasas u otros lubricantes.

Gebruik maken van alco hol. Geen vetten of andere smeringsmiddelen gebruiken.

EXT

INT

~

INTRO

A

D812047 00100_01

2 - VISTA-SL C (ARIA-EVO)

D

E

HT=75mm

HFP=57,5 mm

=Altezza di ssaggio della traversa

=Crosspiece fastening height

=Hauteur de xation de l’entretoise

=Befestigungshöhe der Querstrebe

=Altura de jación del travesaño

=Bevestigingshoogte van de dwarsdrager.

=Spazio fra pavimento ed anta mobile

=Space between oor and moving door

=Espace libre entre le sol et le vantail mobile

=Raum zwischen Boden und Tür

=Espacio entre el piso y la hoja móvil

=Ruimte tussenvloer en beweegbare vleugel

=Altezza dell'anta nita

=Finished door height

=Hauteur du vantail ni

=Höhe der fertigen Tür

=Altura de la hoja lista

=Hoogte van de voltooide vleugel

=Altezza della traversa VISTA SL C

=VISTA SL C crosspiece height

=Hauteur de l’entretoise VISTA SL C

=Höhe der Querstrebe VISTA SL C

=Altura del travesaño VISTA SL C

=Hoogte van de dwarsdrager VISTA SL C

HFT

HGP

HFP

=Altezza di ssaggio prolo WMP,

=WMP prole fastening height,

=Hauteur de xation WMP,

=Befestigungshöhe Prol WMP,

=Altura de jación perl WMP,

= Bevestigingshoogte proel WMP.

HA

HT

HA= HFT - HGP - HT

HFT= HGP + HA + HFP

DETERMINAZIONE DELL’ALTEZZA DI FISSAGGIO DELLA TRAVERSA,

DETERMINING HEADER FASTENING HEIGHT,

ÉTABLISSEMENT D ELA HAUTEUR DE FIXATION DE L’ENTRETOISE,

BESTIMMUNG DER BEFESTIGUNGSHÖHE DER QUERSTREBE,

DETERMINACIÓN DE LA ALTURA DE FIJACIÓN DEL TRAVESAÑO,

BEPALING VAN DE BEVESTIGINGSHOOGTE VAN DE DWARSDRAGER.

G

F

H

VP

50

PU

CA = PU + S

S

Pf

Am

CA

VISTA SL C

PU = CA - S

1/2 VP

PU

CA

Pf

Am

Am

Pf

CA

1/2 VP

1/2 VISTA 1/2 VISTA

PU = 2 CA

Denizione, Denition, Dénition,

Denition, Denicion, Denitie.

Pf

= Parte fissa

= Fixed part

= Partie fixe

= Feste Seite

= Parte fija

= Vast deel

Am

= Anta mobile

= Mobile leaf

= Vantail mobile

= Beweglicher Flügel

= Hoja móvil

= Beweegbare Vleugel

VP

= Vano Passaggio

= Passage space

= Baie de passage

= Durchgangsbreite

= Vano pasaje

= Doorgangsbreedte

TSPEI

= Vite Testa Piana Svasata Esagono Incassato

= Flat countersunk head screw

= Vis à tête plate évasée

= Senkschrauben benutzen

= Tornillo de cabeza avellanada hexágono

encajonado

= Schroef met Platte Verzonken kop met Binnenze-

skant

TE

= Vite Testa Esagono

= Hexagonal head screw

= Vis à tête hexagonale

= Sechskantige Schraube

= Tornillo de cabeza hexágono

= Schroef met Zeskantkop

VP

50

PU S

Pf

Am

CA

VISTA

PU = CA - S

PU

= Passaggio Utile

= Usable passage space

= Passage utile

= Nutzdurchgang

= Pasaje útil

= Nuttige Doorgang

S

= Sormonto

= Overlap

= Superposition

= Überschneidung

= Sobreposición

= Overlapping

CA

= Corsa utile Anta

= Leaf stroke

= Course utile du vantail

= Nutzbarer Türlauf

= Carrera útil de la hoja

= Nuttige Slag Vleugel

Esterno, Outside, Extérieur, Außen, Exterior, Extern.

Esterno, Outside, Extérieur, Außen, Exterior, Extern.

Interno, Inside, Intérieur, Innen, Interior, Intern.

Interno, Inside, Intérieur, Innen, Interior, Intern.

Interno, Inside, Intérieur,

Innen, Interior, Intern.

Vista SL C 107 - 125: Destra, Right, Droitea, Rechts, Derecha, Rechts.

Vista SL C 107 - 125: Sinistra, Left, Gauche, links, Izquierda, Links. Vista SL C 208 - 229

Esterno, Outside, Extérieur,

Außen, Exterior, Extern.

180

80

69

75

31

30.5

7.5

33.5

±5

±4

HA

HT

HFT

HGP

Pf

Am

HT

HFP

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 3

ITALIANO ENGLISH

FRANÇAIS ESPAÑOL

NEDERLANDS

DEUTSCH

I

J

Vista SL C 107 - 125

Vista SL C 208 - 229

Ø 8,5

1 2 3

A

B

Max 7mm

*

*

*

Non in dotazione / Not supplied /

Ne sont pas fournis /

Nicht im

lieferumfang

/

No asignadas en el

equipamiento base

/ Niet meegeleverd

*

G

A

E

C

D

B

F

Max 5mm

Non in dotazione /

Not supplied / Ne sont pas

fournis /

Nicht im

lieferumfang

/

No asignadas en

el equipamiento base

/

Niet meegeleverd

Non in dotazione /

Not supplied / Ne sont

pas fournis /

Nicht im

lieferumfang

/

No asignadas en el

equipamiento base

/

Niet meegeleverd

*

*

*

*

*

OK

3

1

54

5A

max M8

17.551.5

62.5

2

WMP

12,5

45

M8

1÷2 mm

D812047 00100_01

4 - VISTA-SL C (ARIA-EVO)

K

K1

1

2

3

4

L

Installazione Ante, Installing the Doors, Installation des vantaux, Installation Türügel, Instalación Hojas, Installatie Vleugels.

1

1 2 3

2 3

10

10 10

VISTA SL C

208-229

VISTA SL C

107-125

1

2

10

3

-5 mm

+5 mm

-4 mm

+4 mm

5 5

4

3

Regolazione trasversale anta, Adjusting door crosswise, Réglage transversal du vantail, Einstellung Türügel in Querrichtung, Regulación transversal hoja, Afstellingen Vleugels.

Regolazione altezza anta, Adjusting door height, Réglage de la hauteur du vantail, Einstellung Höhe Türügel, Regulación altura hoja, Afstellingen Vleugels.

Smontaggio ante su porte ssate tra due pareti (dentro un vano luce), Dismantling leaves on doors fastened between two walls (inside an opening),

Démontage du vantail sur les portes xées entre deux murs (dans un logement pour l’éclairage), Ausbau von zwischen zwei wänden (in einer önung) befestigten totügeln,

Desmontaje de hojas en puertas jadas entre dos paredes (dentro de un vano de la puerta), Demontage luiken op deuren bevestigd tussen twee wanden (in een lichtkast).

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 5

M

N

Guida anta a Pavimento, Floor-mounted Door Guide, Guide Vantail Au Sol , Flügelführung Am Boden , Guía De La Hoja Fijada En

El Suelo, Deurgeleiding Op De Vloer.

Regolazione Battute di Finecorsa, Adjusting Travel Limit Stops, Reglage Des Butees De Fin De Course, Einstellung Der Anschläge,

Regulacion De Los Topes De Fin De Carrera, Afstelling Aanslagnokken.

1

3

1

3

2

2A

2B

Anta Mobile, Moving Leaf, Vantail mobile,

Beweglicher Flügel, Hoja Móvil, Vast Deel.

27 mm

23.5 mm

PGI

PPR

ON

OFF

ON

Ø 7,5

Ø 3,5

90°

MAX

Ø 3,5

S: Spazio di sormonto fra

Anta Mobile e Parte Fissa,

S: Overlapping space

between Moving Leaf

and Fixed Part,

S: Espace de chevauche-

ment entre le vantail

mobile et la partie xe,

S: Abstand zwischen

beweglichem Türügel

und festem Teil,

S: Espacio de sobreposición

entre Hoja Móvil y Parte

Fija,

S: Overlappingsruimte

tussen Beweegbare

Vleugel en vast deel.

-4 mm

+4 mm

13

13

S S

Parte Fissa,

Fixed Part,

Partie xe,

Fester Teil,

Parte Fija,

Beweegbare

Vleugel.

Parte Fissa,

Fixed Part,

Partie xe,

Fester Teil,

Parte Fija,

Beweegbare

Vleugel.

10 10

3

D812047 00100_01

6 - VISTA-SL C (ARIA-EVO)

O

B2

B1

B

B3

A1

A

D1

D1

V1

V1

V2

V2

R1

R1

V2

R2

D1

R1

R2

D2

V1

M6

16

R2

D2

R1

D1

6

V2

M5

14

M5

14

6

M6

V1

M6

16

M5

M6

5

8

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 7

P

Q

R

1

1

2

2

Fusibile, Fuse, Fusible,

Schmelzsicherung, Fusible, Zekering:

Fusibile, Fuse,

Fusible,

Schmelzsicherung,

Fusible,

Zekering

N

L

N

L

26

0

Trasformatore

Transformer

Transformateur

Transformator

Transformador

Transformator

Filtro / Filter / Filtre

Filter / Filtro / Filter

Encoder

M

JP2

JP4

JP7

JP8

JP12

JP19

230V 120V

T-1,25A T-2,5A

4

5

6A

AUTOSET, AUTOSET, RÉGLAGE AUTOMATIQUE, AUTOSET,

AJUSTE AUTOMATICO,

AUTOSET.

3

2

6B

Marrone / Brown / Marron /

Braun / Maron / Bruin

Marrone / Brown / Marron /

Braun / Maron / Bruin

Blu-Bianco /

Bleu-White /

Bleu-Blanc /

Blau-Weiß /

Azul-Blanco /

Blauw-Wit

Blu-Bianco / Bleu-White / Bleu-Blanc /

Blau-Weiß / Azul-Blanco / Blauw-Wit

OPEN-KEY

NO

RADAR INT.

NO

RADAR EXT.

NO

NC

NC

NC

NC

NC

STOP

SAFE 1

SAFE 2

COM

COM

NO

EMERGENCY

SAFE 4

SAFE 3

V TEST

+

-

+

-

RS 485

31,5V

DC max 500mA

24V

DC max 30mA

A

B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

NC

NC

NO

COM

COM

NO

USCITA STATO PORTA

DOOR STATUS OUTPUT

SORTIE ÉTAT PORTE

AUSGANG STATUS TUR

SALIDA ESTADO PUERTA

UITGANG DEURSTATUS

USCITA ALLARME

ALARM OUTPUT

SORTIE ALARME

ALARMAUSGANG

SALIDA DE ALARMA

UITGANG ALARM

Connettore programmatore palmare JP18

Palmtop programmer connector JP18

Connecteur programmateur de poche JP18

Steckverbinder Palmtop-Programmierer JP18

Conector del programador de bolsillo JP18

Connector Programmeerbare Palmtop JP18

Tasti programmazione

Programming keys

Touches de programmation

Programmierungstasten

Botones de programación

Programmeringstoetsen

FIG. Q1

FIG. Q2

Connessione schermo con cavi

Screen connection with auxiliary cables

Connexion écran avec câbles

Anschluss Abschirmung mit Kabeln

Conexión pantalla con cables

Verbinding scherm met kabels

Trasformatore

Transformer

Transformateur

Transformator

Transformador

Transformator

Filtro

Filter

Filtre

Filter

Filtro

Filter

Fusibile

Fuse

Fusible

Schmelzsicherung

Fusible

Zekering

L N

D812047 00100_01

8 - VISTA-SL C (ARIA-EVO)

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 9

S1

COLLEGAMENTO SENSORI RILEVAMENTO / SICUREZZA CON VERIFICA

CONNECTION OF DETECTION/SAFETY SENSORS AND TEST

CONNEXION 4 CAPTEURS DE DETECTION/SECURITE AVEC VERIFICATION

ANSCHLUSS 4 SENSOREN ERFASSUNG/SICHERHEIT MIT ÜBERPRÜFUNG

CONEXIÓN 4 SENSORES DETECCIÓN/SEGURIDAD CON CONTROL

VERBINDING 4 DETECTIE/VEILIGHEIDSSENSOREN MET CONTROLE

S2

S3

S4

SAFE1= 1, 3, 5

SAFE2= 0, 2, 4

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

SAFE1= 1, 3, 5

SAFE2= 1, 3, 5

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

SAFE1= 1, 3, 5

SAFE2= 1, 3, 5

SAFE3= 1, 3, 5

SAFE4= 0, 2, 4

SAFE1= 1, 3, 5

SAFE2= 1, 3, 5

SAFE3= 1, 3, 5

SAFE4= 1, 3, 5

+ -

+

TEST

-

OPEN SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17

12 13

+ -

+

TEST

-

OPEN SAFETY

+ -

+

TEST

-

OPEN SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 16 17

12 13 12 13

+ -

+

TEST

-

OPEN SAFETY

+ -

+

TEST

-

OPEN SAFETY

+ -

+

TEST

-

SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 16 17 16 17

12 13 12 13 12 13

+ -

+

TEST

-

OPEN SAFETY

+ -

+

TEST

-

OPEN SAFETY

+ -

+

TEST

-

SAFETY

+ -

+

TEST

-

SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 12 13 12 13 12 13 12 1316 17 16 17 16 17

D812047 00100_01

10 - VISTA-SL C (ARIA-EVO)

T1

COLLEGAMENTO 4 SENSORI RILEVAMENTO/SICUREZZA SENZA VERIFICA

CONNECTION OF 4 DETECTION/SAFETY SENSORS WITHOUT TEST

CONNEXION 4 CAPTEURS DE DETECTION/SECURITE SANS VERIFICATION

ANSCHLUSS 4 SENSOREN ERFASSUNG/SICHERHEIT OHNE ÜBERPRÜFUNG

CONEXIÓN 4 SENSORES DETECCIÓN/SEGURIDAD SIN CONTROL

VERBINDING 4 DETECTIE/VEILIGHEIDSSENSOREN ZONDER CONTROLE

T2

T3

T4

SAFE1= 0, 2, 4

SAFE2= 0, 2, 4

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

SAFE1= 0, 2, 4

SAFE2= 0, 2, 4

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

SAFE1= 0, 2, 4

SAFE2= 0, 2, 4

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

SAFE1= 0, 2, 4

SAFE2= 0, 2, 4

SAFE3= 0, 2, 4

SAFE4= 0, 2, 4

+ -

+

-

OPEN SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17

+ -

+

-

OPEN SAFETY

+ -

+

-

OPEN SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 16 17

+ -

+

-

OPEN SAFETY

+ -

+

-

OPEN SAFETY

+ -

+

-

SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 16 17 16 17

+ -

+

-

OPEN SAFETY

+ -

+

-

OPEN SAFETY

+ -

+

-

SAFETY

+ -

+

-

SAFETY

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VISTA SL C

16 17 18 19 20

21 22 23

RADAR

INT.

RADAR

EXT.

STOPSAFE 1 SAFE 2COM SAFE 4SAFE 3 V TEST V TEST

16 17 16 17 16 17 16 17

ON ON

OFF OFF

S1

S2

S3

+

-

OK

ON ON

OFF OFF

S1

S2

S3

+

-

OK

70 71

COM

STOP

S1

S2

S3

+

-

OK

S1

S2

S3

+

-

OK

8888

rst8

8888

. ...

U

1 2 3 4

65

!

<3s

+

AA

ADAB AC

16

VISTA SEL

19

21

21

15

23

19

13

18

23

24

20

Pf

SBV

Am

Installazione inglobata in serramento,

Incorporated in door frame, Intégrée à l’huisserie,

Eingebaut in den Rahmen, Englobado en el

cerramiento, Installatie opgenomen in stelkozijn.

Installazione a sotto, Ceiling mounting,

Fixation au plafond, Befestigung an der Decke,

Fijación en el techo, Plafondmontage.

SBV

22

9

17

11

14

10

10

2

4

3

1

5

6

7

8

9

12

14

15

1

31

15.5

4

46

50

30.5

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 11

AB1

Lungh. max 3600 mm

*

1

*

1

Lungh. max 3600 mm / Max. length 3600 mm / Longueur maxi 3600 mm

Max. Länge 3.600mm / Longitud máx.3600 mm / Max. lengte 3600 mm

Lungh. max 3600 mm

*

1

SLV SBV C1

*

*

*

*

*

*

*

Non in dotazione / Not supplied / Ne sont pas fournis

Nicht im lieferumfang / No asignadas en el equipamiento base/ Niet meegeleverd

SLV SBV C2

SBV C

*

*

SBV C

G1

G1

G1

40

8

1

2

3

9

9

12

5

V1

V1

D812047 00100_01

12 - VISTA-SL C (ARIA-EVO)

AE

Gruppo Batterie

Battery unit

Groupe Batteries

Batteriengruppe

Batteriengruppe

Grupo Baterías

Groep Batterijen

Scheda carica batteria SBS

Battery charger card SBS

Carte du chargeur de batteries SBS

Karte Batterieladung SBS

Karte Batterieladung SBS

Placa carga batería SBS

Kaart acculader SBS

Opzionale

Optional extra

Facultatif/ve

Option

Opcional

Optioneel

N

L

N

L

26

0

Trasformatore

Transformer

Transformateur

Transformator

Transformador

Transformator

Filtro / Filter / Filtre

Filter / Filtro / Filter

Encoder

M

Opzionale

Optional extra

Facultatif/ve

Option

Opcional

Optioneel

JP2

JP4

JP7

JP8

JP12

JP19

Fusibile, Fuse,

Fusible,

Schmelzsicherung,

Fusible, Zekering.

Marrone / Brown / Marron /

Braun / Maron / Bruin

Marrone / Brown / Marron /

Braun / Maron / Bruin

Blu-Bianco /

Bleu-White /

Bleu-Blanc /

Blau-Weiß /

Azul-Blanco /

Blauw-Wit

Blu-Bianco / Bleu-White / Bleu-Blanc /

Blau-Weiß / Azul-Blanco / Blauw-Wit

1 2 3 4 5 6 7 8 9 1011 12131415

VISTA - SL C

1617181920

212223

1 2 3 4 5 6 7 8 9 1011 12131415

VISTA - SL C

1617181920

212223

C

A

INT

EXT

B

1

2

2

1

A

+ -

+ -

+ -

= 1

B

C

BUSSOLA

revolving

tambour

betriebsart

schleuse

esclusa

BUSSOLA

revolving

tambour

betriebsart

schleuse

esclusa

= 2

OPEN OPEN

OPEN

MAX

Ø 3,5

S S

V1

30

8

PPA

G

10/12 mm

V1

AG

AF

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 13

A

I

28.5

8

77

L

L/2

L/2

G

H

325

28

296

456

L1 (L.C. LUNGHEZZA CINGHIA)

L1 (L.C. BELT LENGHT)

A

B

C=B+46

186

105

VISTA SL C 116 -125

VISTA SL C 121-125

VISTA SL C 107-125

CODICE MOD. B A C L L1 L.C. G H I

P960558/2 107 750 750 796 1592 900 1976

72

72

72

72

72

72

72

72

72

72

72

72

72

72

72

29058,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

58,5

390

490

590

690

790

890

990

1090

1190

1290

1490

1690

1890

2090

P960559/2 108 850 850 896 1792 1000 2176

P960560/2 109 950 950 996 1992 1100 2376

P960561/2

110 1050 1050 1096 2192 1200 2576

P960562/2 111

1150 1150 1196 2392 1300 2776

P960563/2 112

1250 1250 1296 2592 1400 2976

P960564/2 113 1350 1350 1396 2792 1500 3176

P960565/2 114 1450 1450 1496 2992 1600 3376

P960566/2 115 1550 1550 1596 3192 1700 3576

P960567/2 116 1650 1650 1696 3392 1800 3776

P960568/2 117

1750 1750 1796 3592 1900 3976

P960569/2

119 1950 1950 1996 3992 2100 4376

P960570/2 121

2150 2150 2196 4392 2300 4776

P960571/2 123 2350 2350 2396 4792 2500 5176

P960572/2 125 2550 2550 2596 5192 2700 5576

42

AI

VISTA SL C 107 - 125

1

D812047 00100_01

14 - VISTA-SL C (ARIA-EVO)

AI

VISTA SL C 208 - 229

2

5

130

109

200

H

5

310

23

291

L

L/2

L/2

6

46 46

A A

L1 (L.C. = LUNGHEZZA CINGHIA)

L1 (L.C. = BELT LENGHT)

62

196

B

VISTA SL C

216 - 229

VISTA SL C

221 - 229

VISTA

SL C 208-229

CODICE MOD. B A L L1 L.C. H

P960543/2

208 800 2x525 1952 1145 2466

147

P960544/2

209 900 2x525 2052 1245 2666

147

P960545/2 210 1000 2x550 2192 1345 2866 147

P960546/2 211 1100 2x600 2392 1445 3066 197

P960547/2 212 1200 2x650 2592 1545 3266 247

P960548/2 213 1300 2x700 2792 1645 3466 297

P960542/2 214

1400 2x750 2992 1745 3666 347

P960549/2

215 1500 2x800 3192 1845 3866 397

P960550/2 216 1600 2x850 3392 1945 4066 447

P960551/2 217 1700 2x900 3592 2045 4266 497

P960552/2 219 1900 2x1000 3992 2245 4666 597

P960553/2 221 2100 2x1100 4392 2445 5066 697

P960554/2 223 2300 2x1200 4792 2645 5466 797

P960555/2

225 2500 2x1300 5192 2845 5866 897

P960556/2 227

2700 2x1400 5592 3045 6266 997

P960557/2 229 2900 2x1500 5992 3245 6666 1097

16.5

46

16.5

41 - VISTA SL C 208

46 - VISTA SLC 209/229

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 15

AJ

inv.dir. / richt.umk. / dir.rev.= OFF

inv.dir. / richt.umk. / dir.rev.= ON

D812047 00100_01

16 - VISTA-SL C (ARIA-EVO)

ENGLISH

INSTALLER WARNINGS

Anything that is not explicitly provided for in the installation ma-

nual is not allowed. The operator’s proper operation can only be

guaranteed if the information given is complied with. The Firm shall

not be answerable for damage caused by failure to comply with the

instructions featured herein.

While we will not alter the product’s essential features, the Firm reserves

the right, at any time, to make those changes deemed opportune to

improve the product from a technical, design or commercial point of

view, and will not be required to update this publication accordingly.

WARNING! Important safety instructions. Carefully read and comply with

all the warnings and instructions that come with the product as incorrect

installation can cause injury to people and animals and damage to property.

The warnings and instructions give important information regarding safety,

installation, use and maintenance. Keep hold of instructions so that you can

attach them to the technical le and keep them handy for future reference.

GENERAL SAFETY

This product has been designed and built solely for the purpose indicated herein.

Uses other than those indicated herein might cause damage to the product and

create a hazard.

- The units making up the machine and its installation must meet the requirements

of the following European Directives, where applicable: 2004/108/EC, 2006/95/

EC, 2006/42/EC, 89/106/EC, 99/05/EC and later amendments. For all countries

outside the EEC, it is advisable to comply with the standards mentioned, in ad-

dition to any national standards in force, to achieve a good level of safety.

- The Manufacturer of this product (hereinafter referred to as the “Firm”) disclaims

all responsibility resulting from improper use or any use other than that for

which the product has been designed, as indicated herein, as well as for failure

to apply Good Practice in the construction of entry systems (doors, gates, etc.)

and for deformation that could occur during use.

- Installation must be carried out by qualied personnel (professional installer,

according to EN 12635), in compliance with Good Practice and current code.

- Before installing the product, make all structural changes required to produce

safety gaps and to provide protection from or isolate all crushing, shearing and

dragging hazard areas and danger zones in general in accordance with the

provisions of standards EN 16005 or any local installation standards. Check that

the existing structure meets the necessary strength and stability requirements.

- Before commencing installation, check the product for damage.

- The Firm is not responsible for failure to apply Good Practice in the construction

and maintenance of the doors, gates, etc. to be motorized, or for deformation

that might occur during use.

- Make sure the stated temperature range is compatible with the site in which

the automated system is due to be installed.

- Do not install this product in an explosive atmosphere: the presence of am-

mable fumes or gas constitutes a serious safety hazard.

- Disconnect the electricity supply before performing any work on the system.

Also disconnect buer batteries, if any are connected.

- Before connecting the power supply, make sure the product’s ratings match the

mains ratings and that a suitable residual current circuit breaker and overcurrent

protection device have been installed upline from the electrical system. Have

the automated system’s mains power supply tted with a switch or omnipolar

thermal-magnetic circuit breaker with a contact separation that meets code

requirements.

- Make sure that upline from the mains power supply there is a residual current

circuit breaker that trips at no more than 0.03A as well as any other equipment

required by code.

- Make sure the earth system has been installed correctly: earth all the metal parts

belonging to the entry system (doors, gates, etc.) and all parts of the system

featuring an earth terminal.

- Installation must be carried out using safety devices and controls that meet

standards EN 12978 and EN 16005.

- Impact forces can be reduced by using deformable edges.

- In the event impact forces exceed the values laid down by the relevant standards,

apply electro-sensitive or pressure-sensitive devices.

- Apply all safety devices (photocells, safety edges, etc.) required to keep the

area free of impact, crushing, dragging and shearing hazards. Bear in mind the

standards and directives in force, Good Practice criteria, intended use, the instal-

lation environment, the operating logic of the system and forces generated by

the automated system.

- Apply all signs required by current code to identify hazardous areas (residual

risks). All installations must be visibly identied.

- Once installation is complete, apply a nameplate featuring the door/gate’s data.

- If the automated system is installed at a height of less than 2.5 m or is accessible,

the electrical and mechanical parts must be suitably protected.

- Install any xed controls in a position where they will not cause a hazard, away

from moving parts. More specically, hold-to-run controls must be positioned

within direct sight of the part being controlled and, unless they are key operated,

must be installed at a height of at least 1.5 m and in a place where they cannot

be reached by the public.

- Attach a label near the operating device, in a permanent fashion, with informa-

tion on how to operate the automated system’s manual release.

- Make sure that, during operation, mechanical risks are avoided or relevant

protective measures taken and, more specically, that nothing can be banged,

crushed, caught or cut between the part being operated and surrounding parts.

- Once installation is complete, make sure the motor automation settings are

correct and that the safety and release systems are working properly.

- Only use original spare parts for any maintenance or repair work. The Firm dis-

claims all responsibility for the correct operation and safety of the automated

system if parts from other manufacturers are used.

- Do not make any modications to the automated system’s components unless

explicitly authorized by the Firm.

- Instruct the system’s user on what residual risks may be encountered, on the

control systems that have been applied and on how to open the system manu-

ally in an emergency. give the user guide to the end user.

- Dispose of packaging materials (plastic, cardboard, polystyrene, etc.) in accord-

ance with the provisions of the laws in force. Keep nylon bags and polystyrene

out of reach of children.

WIRING

WARNING! For connection to the mains power supply, use: a multicore cable

with a cross-sectional area of at least 5x1.5mm

2

or 4x1.5mm

2

when dealing

with three-phase power supplies or 3x1.5mm

2

for single-phase supplies (by

way of example, type H05 VV-F cable can be used with a cross-sectional area

of 4x1.5mm

2

). To connect auxiliary equipment, use wires with a cross-sectional

area of at least 0.5 mm

2

.

- Only use pushbuttons with a capacity of 10A-250V or more.

- Wires must be secured with additional fastening near the terminals (for example,

using cable clamps) in order to keep live parts well separated from safety extra

low voltage parts.

- During installation, the power cable must be stripped to allow the earth wire

to be connected to the relevant terminal, while leaving the live wires as short

as possible. The earth wire must be the last to be pulled taut in the event the

cable’s fastening device comes loose.

WARNING! safety extra low voltage wires must be kept physically separate from

low voltage wires.

Only qualied personnel (professional installer) should be allowed to access

live parts.

CHECKING THE AUTOMATED SYSTEM AND MAINTENANCE

Before the automated system is nally put into operation, and during maintenance

work, perform the following checks meticulously:

- Make sure all components are fastened securely.

- Check starting and stopping operations in the case of manual control.

- Check the logic for normal or personalized operation.

- Check that all safety devices are working properly and that the anti-crush safety

device (if tted) is set correctly.

- Impact forces can be reduced by using deformable edges.

- Make sure that the emergency operation works, where this feature is provided.

- Check opening and closing operations with the control devices applied.

- Check that electrical connections and cabling are intact, making extra sure that

insulating sheaths and cable glands are undamaged.

- While performing maintenance, clean the sensors’ optics.

- When the automatic door operator is out of service for any length of time,

activate the emergency release (see “EMERGENCY OPERATION” section) so

that the operated part is made idle, thus allowing the door to be opened and

closed manually.

-

If the power cord is damaged, it must be replaced by the manufacturer or their

technical assistance department or other such qualied person to avoid any risk .

- The maintenance described above must be repeated at least once yearly or at

shorter intervals where site or installation conditions make this necessary.

WARNING!

Remember that the drive is designed to make the gate/door easier to use and

will not solve problems as a result of defective or poorly performed installation

or lack of maintenance

SCRAPPING

Materials must be disposed of in accordance with the regulations in force. There

are no particular hazards or risks involved in scrapping the automated system. For

the purpose of recycling, it is best to separate dismantled parts into like materials

(electrical parts - copper - aluminium - plastic - etc.).

DISMANTLING

If the automated system is being dismantled in order to be reassembled at another

site, you are required to:

- Cut o the power and disconnect the whole electrical system.

- Remove the actuator from the base it is mounted on.

- Remove all the installation’s components.

- See to the replacement of any components that cannot be removed or happen

to be damaged.

THE DECLARATION OF CONFORMITY CAN BE VIEWED ON THIS WEBSITE:

WWW.BFT.IT IN THE PRODUCT SECTION.

AVVERTENZE INSTALLATORE (PORTE) D812061 00200_01

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 25

INSTALLATION MANUAL

1) GENERAL OUTLINE

Motor-driven header for automatic sliding doors with one leaf (mod. VISTA SL

C1) or two (mod. VISTA SL C2).

Complete with control panel. Accessories available for producing a complete

installation.

For VISTA SL C1 models the door will be delivered with the actual door opening

PU on the left (looking at the door from the inside)(Fig. AI).

2) TECHNICAL SPECIFICATIONS

MECHANICAL SPECIFICATIONS

VISTA SL C1 mod. doorway opening min 750mm max 2500mm

VISTA SL C2 mod. doorway opening min 800mm max 2900mm

Single-leaf capacity load mod. VISTA SL C1 100 kg

Double-leaf capacity load mod. VISTA SL C2 80+80 kg

Protection rating IP X0 (Not for installation outdoors)

Crosspiece dimensions See Fig. D

ELECTRICAL SPECIFICATIONS

Power supply

230V- 220V~ ±10%, 50Hz single-phase

120V~ ±15% 50/60Hz

Power input

Rated: 120 W

Maximum: 500 W

Fuses see Fig. Q

Accessories power supply 31,5 VDC max 500mA

Power supply V SAFE 24V max 30mA

Alarm output and door status Contact max 24V 0,5A

Opening/closing speed

Adjustable up to 0,8 m/s (VISTA SL C1)

Adjustable up to 1,6 m/s (VISTA SL C2)

Approach speed

In the range 5 to 10 cm/s in automatic

mode (VISTA SL C1)

In the range 10 to 20cm/s in automatic

mode (VISTA SL C2)

Temperature range

-20°C (no condensation)

+ 50°C (inside cover)

Operating cycle Continuous at 25°C

Emergency batteries (optional extras) 2 x 12V 1.2Ah

Radio-receiver built-in

Rolling-Code

Frequency 433.92 MHz

Max. n° of remotes that

can be memorized

63

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

3) PREPARING THE ELECTRICAL SYSTEM

Prepare the electrical system (g. A), referring to the standards in force. Keep

mains power connections well separated from service connections (photocells,

safety edges, control devices, etc.).

Keep mains power connections well separated from safety extra low voltage

connections. Secure the power cable by means of the cable clamp located in

the transformer’s cover. Connect the power cable so that the earth wire (yellow/

green) is longer than the other wires.

4) IDENTIFICATION OF COMPONENTS (Fig. AA)

In the standard composition, the automated VISTA SL C system is made up of:

1 Load-bearing header in oxidized aluminium

2 Power supply unit complete with bipolar switch, mains fuse and noise lter

3 Microprocessor-based control unit ARIA - EVO

4 DC gearbox

5 Optical encoder for detecting travel and checking for obstacles

6 Driven pulley

7 Drive belt

8 2 Door runners with 2 wheels on bearings, anti-derailment wheel, height and

depth adjustable

9 Prole for fastening door leaves

10 Rubber travel limit stops

11 Rubber hinge

12 Cable raceway

13 WMP Wall Mounting Prole

The following accessories are available to complete installation:

14 BBV Battery-powered panic device

15 ERV Electromagnetic bolt and manual release

16 VISTA SEL Digital function pushbutton unit (optional extra)

17 SBV Supporting beam in oxidized aluminium

18 PGI Bottom door guide prole for framed doors

19 PPR Slide for bottom door guide

20 RIP

Automatic sliding door safety and opening sensor

21 FPA1 Photocells (1 amplier, 1 transmitter, 1 receiver)

FPA2 Photocells (1 amplier, 2 transmitters, 2 receivers)

22 CRTV Cover

23 SASAM1-2 Breakout door device.

PPA Clamp for glass doors (Fig. AE).

5) FASTENING METHOD

- Assembling the Cover (Fig. B).

- Cable routing (Fig. C).

WARNING- When fastening the header, only use at countersunk screws

as shown in Fig. I Rif. 1 or screws with heads no more than 5 mm high. If

this condition is not met, collisions may occur with the runners.

6) DETERMINING HEADER FASTENING HEIGHT (Fig. E)

The fastening height HFT of the VISTA SL C header must be measured where the

oor is at its highest (Fig. E). This is to prevent the possibility of the moving door

leaf getting stuck once installation is nished. Once installed, the height of the

doors can still be adjusted by means of the special adjusters on the runners (Fig. L).

WARNING: The VISTA SL C header must be fastened so that it is perfectly

horizontal. This condition must be met to ensure that the automated system

operates properly.

6.1) Fastening to wall (above an opening) (Fig. F - G)

6.2) Mounting between two walls (inside door opening space) (Fig. H)

To position the header symmetrically with respect to the doorway opening, no

matter what kind of installation you are dealing with (above an opening, inside

an opening, etc.), you need to mark both the centre line of the structural opening

and centre line of the VISTA SL C header. Fasten the VISTA SL C header, lining up

the two marks (Fig. H).

7) POSSIBLE INSTALLATIONS

A number of installation methods for the automated system are listed below:

- Wall mounted.

- Ceiling mounted (with supporting beam SBV).

- Incorporated in door frame (with or without supporting beam SBV).

7.1) Wall mounting (Fig. I)

There is a wall mounting prole (WMP) to help with wall mounting (Fig. I). It is

best to attach shims in line with the fastening holes already made in the header.

That way, the fastening points will sit on a solid base and you will avoid the track

bending while screws are being fastened. In the event fastening holes have to

be drilled in addition to those already made, drill them approx. every 600-800

mm: this will also depend on what kind of surface you are dealing with (concrete,

brick, wood, iron, etc.).

7.2) Ceiling mounting (with supporting beam SBV Fig. AB - AC)

This type of installation is particularly suitable if the door leaf and xed panel are

made from frameless glass, and hence are not load-bearing.

7.3) Incorporated in door frame (with or without supporting beam Fig. AD)

The supporting beam is incorporated in a load-bearing door frame or a at prole

is built into the frame that must be thick enough to fasten the VISTA SL C header

securely. If the supporting beam SBV is used, it will be easier to fasten the VISTA

SL C header with the screws and plates provided.

8) DOOR ASSEMBLY AND ADJUSTMENT

8.1) Framed doors

Before removing the door leaf mounting prole in order to fasten it to the actual

leaf, it is advisable to mark the position where the runners are fastened to the

door leaf mounting prole (Fig. AI - AJ). This will make nal adjustment of the

door leaves’ travel limit brackets and centring of the ERV easier. If the top rail of

the framed door leaf is less than 6-7mm thick and the leaf is heavy (>120Kg), it

must be reinforced inside with an iron prole or plate into which the door leaf

mounting prole can be screwed at various points.

8.2) Glass doors (Fig. AE)

The clamping system PPA can be used only for 10 or 12mm-thick tempered

glass doors or laminated safety glass doors.

It must not be used with double glazing. For the sake of simplicity, reference is

made to glass doors from hereon in.

- No holes must be made in the sheet of glass

- Clamp PPA must be fastened to the door mounting prole as illustrated in Fig.

AE.

- Seals G, of a suitable thickness, must be placed on both sides of the sheet of glass,

between the clamp and glass. Use only seals provided for this purpose.

9) DOOR INSTALLATION AND ADJUSTMENT

- Installing the Doors (Fig. K).

- Adjusting the Doors (Fig. L).

10) FLOOR-MOUNTED DOOR GUIDE (Fig. M)

- Framed doors (Fig. M Rif. 3)

- Glass doors (Fig. AE)

- Breakout doors

See the relevant instruction manual for their assembly.

11) ADJUSTING TRAVEL LIMIT STOPS (Fig. N)

D812047 00100_01

26 - VISTA-SL C (ARIA-EVO)

ENGLISH

INSTALLATION MANUAL

If the positions of the RH and LH travel limit stops (parts. 10 Fig. AA) need to be ne-

tuned, carefully check the travel and alignment of the runners carrying the doors.

It is important to remember that the position of the travel limit stops also deter-

mine the control board’s self-learning.

----------------------------------------------------------

12) ARIA-EVO CONTROL BOARD

12.1) TERMINAL BOARD WIRING (Fig. P)

WARNINGS - When performing wiring and installation, refer to the

standards in force and, whatever the case, apply good practice prin-

ciples.

The wires carrying a very low safe voltage (24V) must be kept physically separate

from low-voltage wires, or they must be suitably insulated with at least 1mm of

additional insulation. Wires must be secured with additional fastening near the

terminals, using devices such as cable clamps.

13.1) FACTORY CONNECTIONS (Fig. Q Rif. 1)

TERMINAL DESCRIPTION

JP2-JP4

Power supply unit wiring

JP2= brown

JP4= white/blue

JP7-JP8

Gearbox wiring

JP7=brown

JP8=white/blue

JP12 Encoder wiring

JP19 Solenoid lock wiring

13.2) USER CONNECTIONS (Fig. P - Q)

IMPORTANT NOTE: USE ONLY SHIELDED CABLES WITH EARTHED BRAI

DING

TERMINAL DESCRIPTION

L PHASE

N NEUTRAL

EARTH

JP18 Universal palmtop programmer connector

JP10 Connector for additional optional boards

1 Controllers common

2 OPENING SAFE 1 (NC)

3 CLOSING SAFE 2 (NC)

4 STOP (NC) input

5 EXT. RADAR control (NO) input

6 INT. RADAR control (NO) input

7 OPEN KEY (NO) input

8 EMERGENCY input

9 Control common

10 OPENING SAFE 3 (NC)

11 CLOSING SAFE 4 (NC)

12-13 Test output for tested safety devices

14-15

Serial RS485.

14 = A

15 = B

Connection to external programming devices.

Controllers common

Connection of remote door in cage mode

16-17 Accessories power supply

18-19-20

“Alarm” output

18 = NO (voltage-free contact)

19 = COM (voltage-free contact)

20 = NC (voltage-free contact)

21-22-23

“Door status” output

21 = NO (voltage-free contact)

22 = COM (voltage-free contact)

23 = NC (voltage-free contact)

14) CENTRAL PROGRAMMING (Fig.C1)

14.1) PARAMETER MENU

(PARA )

(TABLE “A” PARAMETERS)

14.2) LOGIC MENU logic

(TABLE “B” LOGIC)

14.3 RADIO MENU RADIO

Logic Description

add open

Add Start Open

associates the desired key with the Open command

add

ey

Add Open Key

associates the desired key with the Open Key command

erase 64

Erase List

WARNING! Erases all memorized remote controls from

the receiver’s memory.

cod RX

Read receiver code

Displays receiver code required for cloning remote controls.

u

ON = Enables remote programming of cards via a previously me-

morized W LINK transmitter. It remains enabled for 3 minutes

from the time the W LINK remote control is last pressed.

OFF= W LINK programming disabled.

- IMPORTANT NOTE: THE FIRST TRANSMITTER MEMORIZED MUST BE

IDENTIFIED BY ATTACHING THE KEY LABEL (MASTER).

In the event of manual programming, the rst transmitter assigns the RECEIVER’S

KEY CODE: this code is required to subsequently clone the radio transmitters.

The Clonix built-in on-board receiver also has a number of important advanced

features:

• Cloningofmastertransmitter(rollingcodeorxedcode)

• Cloningtoreplacetransmittersalreadyenteredinreceiver

• Transmitterdatabasemanagement

• Receivercommunitymanagement

To use these advanced features, refer to the universal handheld programmer’s

instructions and to the general receiver programming guide.

14.4 DEFAULT MENU default

Restores the controller’s default factory settings.

14.5 LANGUAGE MENU language

Used to set the programmer’s language on the display.

14.6) AUTOSET MENU Autoset Fig. R

When this function is activated, the parameters relating to door movement and

obstacle detection are automatically set to their optimum values:

- Running speed during opening

- Running speed during closing

- Opening slow-down distance

- Closing slow-down distance

- Opening deceleration distance

- Closing deceleration distance

- Acceleration

- Deceleration

- Opening force

- Closing force

3 complete cycles are performed as the autoset function is run.

While autoset is running, the anti-crush function is not active.

The door must not be stopped or slowed down at any point during its

travel while autoset is running.

14.7 STATISTICS MENU

Used to view the version of the board, the total number of operations (in

hundreds), the number of transmitters memorized and the last 30 errors (the

rst 2 digits indicate the position, the last 2 give the error code). Error 01 is the

most recent.

14.8) PASSWORD MENU

Used to set a password for the board’s wireless programming.

15) CENTRAL OPERATION:

15.1) DOOR OPERATION MODE

Mode 0) Standard operation door (Fig. S)

Reaction to commands:

- Open key:

Opens at high speed, closes at low speed. Opens and activates an Open-key

operation, if activated while the door is open, it sets clear time to zero; reopens

if activated during closing. With the door open, the clear-time countdown is

active. During closing, photocells stop movement instead of reversing. Once

they are cleared, closing is resumed following the TCA countdown. During the

Open-key operation, the radars are not active.

- External radar:

Performs a high-speed cycle. Opens, with the door open, it triggers the auto-

matic closing time; if activated while the door is open, it sets automatic closing

time to zero. Following the automatic closing time, the door closes. During

closing, it causes the door to open again.

During closing, it carries out a reopening manoeuvre.

- Internal radar:

Performs a high-speed cycle. Opens, with the door open, it triggers the automatic

closing time; if activated while the door is open, it sets automatic closing time

to zero. Following the automatic closing time, the door closes. During closing,

it causes the door to open again.

-

Safety device during opening:

During opening, it stops movement until the photocell is cleared. With the

D812047 00100_01

VISTA-SL C (ARIA-EVO) - 27

INSTALLATION MANUAL

door open, it sets the TCA or clear time to zero. If triggered, it prevents the

door from starting to open and close.

- “Presence sensor” safety device:

During opening, movement takes place at slow speed; during other stages,

it has no eect.

- Safety device during closing:

During closing, it reverses movement. With the door open, it sets the TCA or

clear time to zero. If triggered, it prevents the door from starting to open and

close.

- Stop:

Stops movement and cancels all commands.

Mode 1) Door closed at night

This diers from standard mode as follows:

- panic function not active.

- only Open-key input is active (opens quickly, stays open for clear time, closes

slowly).

- during closing, the photocells stop movement for as long as they remain

triggered, without reopening the door.

In cage mode, the internal and external doors are set as “closed by night”.

Mode 2) Door closed by day

This diers from standard mode as follows:

- the door closes slowly and stays closed

- panic function active

- only Open-key input is active (opens quickly, stays open for clear time, closes

slowly)

- during closing, the photocells stop movement for as long as they remain

triggered, without reopening the door.

In cage mode, this type of operation is not permitted.

Mode 3) Totally opened door

This diers from standard mode as follows:

- the door opens totally at slow speed and stays open

Mode 4) Partially opened door

This diers from standard mode as follows:

- the door opens partially (distance according to “partial opening” setting) at

slow speed and stays open.

In cage mode, this type of operation is not permitted.

Mode 5) Partial opening

This diers from standard mode as follows:

- like standard mode, except opening stops at the partial distance entered as

the “partial opening” setting.

In cage mode, the internal and external doors are set as “partial open”.

Mode 6) Chemist’s opening

This diers from standard mode as follows:

- the door opens and closes at slow speed and stops at the value entered for

“chemist’s opening”.

- only the Open-key command is enabled

- automatic closing is not enabled.

- during closing, the photocells stop movement for as long as they remain

triggered, without reopening the door.

In cage mode, this type of operation is not permitted.

Mode 7) cage open to inside (Enabled in cage mode only)

The external door is set as “closed by day”.

The internal door is set as “total open”.

Mode 8) cage open to outside (Enabled in cage mode only)

The external door is set as “total open”. The internal door is set as “closed by day”.

15.2) RADAR OPERATION MODE

Mode 0) Radar in standard mode:

- internal radar control enabled

- external radar control enabled

Mode 1) Internal radar:

- internal radar only enabled

(in cage mode, only the radar inside the building is enabled)

Mode 2) External radar:

- external radar only enabled

(in cage mode, only the radar outside the building is enabled)

15.3) BUZZER OPERATION MODE

Mode 0:

he buzzer does not sound during opening/closing. It is only triggered in an

emergency to report.

Mode 1:

The buzzer sounds at the beginning of each opening operation or when move-

ment is reversed.

Mode 2:

The buzzer sounds at the beginning of each opening and closing operation or

when movement is reversed.

Mode 3:

The buzzer sounds for the full duration of operation.

Mode 4:

The buzzer sounds during opening if the opening photocell is occupied.

15.4) LOCKING DEVICE OPERATION MODE

Mode 0:

Motor always free (lock always powered).

Mode 1:

Motor locked on closing position.

Mode 2:

Motor locked every time it is stopped.

Mode 3:

Motor locked every time it is stopped for more than 20 sec.

Mode 4:

Motor reacts with 10N to forced opening.

Mode 5:

Motor reacts with maximum force to forced opening.

Mode 6:

“Elastic”. Only use in installations tted with the “VISTA ELA” kit.

Mode 7:

Use only with installations tted with “ELA SL 24.B KIT”. For details regarding the

operation refer to the relative manual.

Mode 8:

Use only with installations tted with “ELA SL 24.B KIT”. For details regarding the

operation refer to the relative manual.

15.5) EMERGENCY INPUT OPERATION MODE

Mode 0:

NO input, opens and stays open for as long as the input is active.

Mode 1:

NO input, closes and stays closed for as long as the input is active.

Mode 2:

NC input, opens and stays open for as long as the input is active.

Mode 3:

NC input, closes and stays closed for as long as the input is active.

15.6) ALARM OUTPUT OPERATION MODE

The alarm output is activated in the following cases:

- the door stays open as a result of the photocell being triggered for longer

than the time entered for the “alarm_time” parameter;

- there is an obstacle alarm;

- opening is being forced while the door is applying an opposite force (lock

mode = 4 or 5);

The alarm output is deactivated in the following cases:

- when the closing travel limit is reached

- when the stop key is pressed

15.7) DOOR STATUS OUTPUT OPERATION MODE

Mode 0:

Output active if the door is not fully closed

Mode 1:

Output active if the door is not fully open

15.8) ANTI-PANIC FUNCTION

“ON” When there is no mains power and the battery is connected, the door

performs a complete opening cycle and then stops in the open position.

“OFF” When there is no mains power, the door opens and stays open if battery

voltage drops below 20V.

15.9) ANTI-CRUSH FEATURE

If an obstacle interferes with the door’s movement, slowing it down, the door’s

movement is reversed during closing, or it is stopped during opening. The

sensitivity can be adjusted via the display by modifying the opening force and

closing force parameters.

15.10) CONNECTING A NUMBER OF DOORS WITH CENTRAL CONTROL PA-

NELS (Fig. AH)

Refer to the U-link module’s instructions.

Serial line connections to produce a hardwired centralized control system must

be made using only 2-wire cabling of the kind used for telephone systems.

The length of the cable between one unit and the next must not be greater

than 250 m.

The master panel is the one that sends commands to all the other panels belonging

to the same zone. Only one master can be specied per zone. A zone comprises

one or more doors connected to each other. Dierent zones are identied se-

parately with a dierent number, which can be set via the DISPLAY or using a

universal handheld programmer.

Possible commands through a central controller are:

a) Open-key via button. All doors belonging to the same zone open and, once

the set clear time is up, close again, returning to the mode set with the master

unit’s mode selector. This command is useful for entering in the morning and

leaving once the closed by night function has been set.

b)

Closed by night. All doors belonging to the zone enter closed-by-night mode.

c) Closed by day. All doors belonging to the zone enter closed-by-day mode.

d) Total/partial opening. All doors belonging to the zone enter total/partial-open

mode.

e) Internal/external radar or with external radar only. All doors belonging to the

zone open with internal radar only.

15.11) CONNECTING 2 DOORS IN cage MODE (Fig. AG)

Connections and settings:

cage mode comprises 2 automatic doors, connected via 485 serial line:

- (1) EXTERNAL

- (2) INTERNAL

3 radars are connected:

- (A) EXTERNAL RADAR (connected to the EXTERNAL card’s external radar)

- (B) CENTRAL RADAR (connected to the EXTERNAL card’s internal radar)

- (C) INTERNAL RADAR (connected to the INTERNAL card’s internal radar)

All the other activation and safety inputs are managed autonomously by the

INTERNAL and EXTERNAL door. To set cage mode, you must:

- set CAGE=2 on the EXTERNAL door

- Set CAGE=1 on the INTERNAL door

Denition of individual radar modes

• RadarAexternaldoor(1)

With doors closed, it activates opening of the external door and allows entry

inside the cage door. If the internal door is open, this door is closed before

the external door is opened. In the event of simultaneous operations, the

external door is given priority. Once the external door is closed, it activates

opening of the internal door and allows entry inside the building.

• RadarB

positioned in the middle of the cage door In normal mode, it detects the

presence of a person inside the cage door and, during exit, allows the external

D812047 00100_01

28 - VISTA-SL C (ARIA-EVO)

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

in altre lingue

- English: BFT Vista SLC User manual

- français: BFT Vista SLC Manuel utilisateur

Documenti correlati

-

BFT Vista TL Manuale utente

-

BFT Deimos BT A Manuale utente

-

BFT ICARO N F Manuale del proprietario

-

BFT Icaro Manuale utente

-

BFT MOOVI 30 Manuale del proprietario

-

BFT Thalia P Manuale utente

-

BFT RIGEL 5 Installation and User Manual

-

BFT Sub BT Manuale del proprietario

-

BFT Rigel 6 Manuale del proprietario

-

BFT Rigel 6 Manuale utente

Altri documenti

-

Leaf Aptus-II Guida d'installazione

Leaf Aptus-II Guida d'installazione

-

Key Automation 580ISWIND Manuale utente

Key Automation 580ISWIND Manuale utente

-

CAME MA7471 Manuale del proprietario

-

CAME M7571 Manuale del proprietario

-

CAME MI6030, MI6040, MI6130, MI6140 Guida d'installazione

-

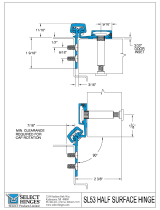

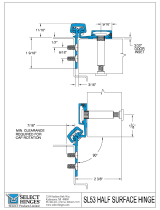

SELECT HINGES SL53 HD Heavy Duty Half Surface Geared Continous Hinges Manuale utente

SELECT HINGES SL53 HD Heavy Duty Half Surface Geared Continous Hinges Manuale utente

-

CAME FLUO-SL Guida d'installazione

-

CAME MI6010, MI6020, MI6110, MI6120 Guida d'installazione

-

Key Gates Wind Guida utente

-

Miller NA214046U Manuale del proprietario