Xgard IR

Installation, operating and maintenance instructions

Instructions d’installation, d’utilisation et d’entretien

Installations-, Betriebs- und Wartungsanleitung

Instrucciones de instalación, funcionamiento y mantenimiento

Istruzioni per l’installazione, l’uso e la manutenzione

Installatie-,bedienings-en onderhoudsinstructies

Instrukcja montażu, obsługi i konserwacji

Instruções de instalação, operação e manutenção

M07692

Issue 6 April 2018

6ème édition Avril 2018

6 Ausgabe April 2018

Edición 6 Abril 2018

Edizione 6 Aprile 2018

Uitgave 6 April 2018

Wydanie 6, kwiecień 2018

Versão: 06 de abril de 2018

Gas Detector

Détecteurs de gaz

Gasdetektoren

Detectores de gas

Rilevatori di gas

Gasdetectors

Detektor gazu

Detectores de gás

Contents

Diagram 1: Xgard IR certification labels ..............................................1

Schéma 1 : étiquettes de certification Xgard IR ..................................1

Abbildung 1: Xgard IR-Zulassungsschilder ..........................................1

Diagrama 1: etiquetas de certificación de Xgard IR ............................1

Diagramma 1: Targhette di certificazione Xgard IR .............................1

Afbeelding 1: Labels met Xgard IR certificaten ....................................1

Rys. 1: Etykiety certyfikacyjne Xgard IR ..............................................1

Diagrama 1: etiquetas de certificação do XGard IR .............................1

Diagram 2: Xgard IR dimensioned view ..............................................2

Schéma 2 : vue dimensionnée du Xgard IR .......................................2

Abbildung 2: Xgard IR – Ansicht mit Maßen ........................................2

Diagrama 2: Vista dimensionada de Xgard IR .....................................2

Diagramma 2: Immagine dimensionata di Xgard IR ............................2

Afbeelding 2: Xgard IR maatschets ....................................................2

Rys. 2: Wymiary Xgard IR ....................................................................2

Diagrama 2: vista dimensionada do XGard IR .....................................2

Diagram 3: Xgard IR exploded view ....................................................4

Schéma 3 : Vue éclatée du Xgard IR ..................................................4

Abbildung 3: Xgard IR – Vergrößerte Ansicht ......................................4

Diagrama 3: vista despiezada de Xgard IR .........................................4

Diagramma 3: Disegno esploso di Xgard IR ........................................4

Afbeelding 3: Xgard IR opengewerkte tekening ..................................4

Rys. 3: Rysunek złożeniowy Xgard IR .................................................4

Diagrama 3: vista explodida do XGard IR ............................................4

Safety Information ........................................................................................7

Overview ......................................................................................................8

1. Introduction .......................................................................................9

2. Installation .......................................................................................10

3. Operation ........................................................................................13

GB

4. Specification ...................................................................................16

5. Spare parts and accessories ..........................................................17

Warranty .....................................................................................................18

Informations de sécurité .............................................................................20

Vue d’ensemble .........................................................................................22

1. Introduction .....................................................................................23

2. Installation .......................................................................................24

3. Utilisation ........................................................................................27

4. Specification ...................................................................................30

5. Pièces détachées et accessoire .....................................................31

Garantie .....................................................................................................32

Sicherheitsinformationen ............................................................................34

Übersicht ....................................................................................................36

1. Einleitung ........................................................................................37

2. Installation .......................................................................................38

3. Betrieb ............................................................................................41

4. Spezifikation ...................................................................................44

5. Ersatzteile und Zubehör .................................................................45

Gewährleistungserklärung .........................................................................46

Información de seguridad ..........................................................................48

Introducción ................................................................................................50

1. Introducción ....................................................................................51

2. Instalación .......................................................................................52

3. Funcionamiento ..............................................................................55

4. Especificaciones .............................................................................58

5. Piezas de repuesto y accesorioss ..................................................59

Garantía .....................................................................................................60

Informazioni per la sicurezza .....................................................................62

Panoramica ................................................................................................64

1. Introduzione ....................................................................................65

2. Installazione ....................................................................................66

F

D

E

I

3. Utilizzo ............................................................................................69

4. Specifiche .......................................................................................72

5. Parti di ricambio e accessori ..........................................................73

Dichiarazione di garanzia ...........................................................................74

Veiligheidsinformatie ..................................................................................76

Overzicht ....................................................................................................78

1. Inleiding ..........................................................................................79

2. Installatie .........................................................................................80

3. Bediening ........................................................................................83

4. Specificatie .....................................................................................86

5. Reserveonderdelen en accessoires ...............................................87

Garantieverklaring ......................................................................................88

Wskazówki bezpieczeństwa .......................................................................90

Informacje ogólne .......................................................................................92

1. Wstęp ..............................................................................................93

2. Instalacja .........................................................................................94

3. Obsługa ..........................................................................................97

4. Specyfikacja ..................................................................................100

5. Części zamienne i akcesoria ........................................................101

Gwarancja ................................................................................................102

Informações de Segurança ......................................................................104

Visão geral ..............................................................................................106

1. Introdução .....................................................................................107

2. Instalação .....................................................................................108

3. Operação ..................................................................................... 111

4. Especificação ................................................................................ 114

5. Peças sobressalentes e acessórios .............................................115

Warranty as Garantia ...............................................................................116

NL

PL

P

Xgard IR

1

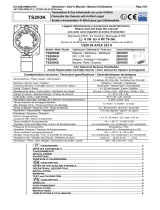

CLASS I, DIVISION 1, GROUPS B, C, & D

AS TO RISK OF FIRE, ELECTRIC SHOCK & EXPLOSIVE HAZARDS ONLY.

WARNING To reduce the risk of ignition of Hazardous Atmosheres

disconnect the equipment from the supply circuit before opening.

Keep assy tightly closed when in operation. Conduit runs must have

CROWCON

sealing fitting connected within 18 inches of enclosure.

XGARD GAS DETECTOR TYPE

<

<

a

<

<

a

2006

C

L

S

A

I

S

66Y6

E

I

F

D

Xgard UL certification label

Label de certification UL du Xgard IR

Xgard UL-Zertifizierungszeichen

Etiqueta de certificación Xgard UL

Etichetta di certificazione UL per Xgard

Xgard UL-certificeringslabel

Etykieta z certyfikatem UL

Etiqueta de certificação UL

ATEX certification label

Label de certification ATEX

ATEX-Zertifizierungszeichen

Etiqueta de certificación ATEX

Etichetta di certificazione ATEX

ATEX-certificeringslabel

Etykieta z certyfikatem ATEX

Etiqueta de certificação ATEX

Diagram 1: Xgard IR certification labels

Schéma 1 : étiquettes de certification Xgard IR

Abbildung 1: Xgard IR-Zulassungsschilder

Diagrama 1: etiquetas de certificación de Xgard IR

Diagramma 1: Targhette di certificazione Xgard IR

Afbeelding 1: Labels met Xgard IR certificaten

Rys. 1: Etykiety certyfikacyjne Xgard IR

Diagrama 1: etiquetas de certificação do XGard IR

-40°C ≤ Tamb ≤ +80°C

-40°C ≤ Tamb ≤ +50°C

Ex d IIC T6 Gb - Ex tb IIIC T80°C Db

Ex d IIC T4 Gb - Ex tb IIIC T110°C Db

ATENÇÃO - RISCO POTENCIAL DE CARGAS

ELETROSTÁTICAS - VER INSTRUÇÕES

Xgard

UL-BR 13.0208X

Etiqueta de certificação do INMETRO

Xgard IR

22

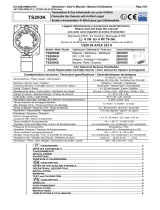

Diagram 2: Xgard IR dimensioned view

Schéma 2 : vue dimensionnée du Xgard IR

Abbildung 2: Xgard IR – Ansicht mit Maßen

Diagrama 2: Vista dimensionada de Xgard IR

Diagramma 2: Immagine dimensionata di Xgard IR

Afbeelding 2: Xgard IR maatschets

Rys. 2: Wymiary Xgard IR

Diagrama 2: vista dimensionada do XGard IR

All dimensions in millimetres

Toutes les dimensions sont données en millimètres

Alle Abmessungen in mm

Todas las dimensiones en milímetros

Tutte le dimensioni sono espresse in millimetri

Alle afmetingen in millimeters

Wszystkie wymiary w mm

Todas as dimensões em milímetros

Xgard IR

3

English

Slots to suit M6 or 1/4” fixings for ceiling

mount

36 Slot CRS

M20, 1/2” or 3/4” NPT cable entry

Slots to suit M6 or 1/4” fixings

155.5 Overall

146 CRS

166.3 Overall

Height 111

Français

Fentes CRS 36 pour les fixations M6 ou

1/4” pour un montage au plafond

Fente CRS 36

Presse-étoupe M20, M25, 1/2” ou

3/4”NPT

Fentes pour fixations M6 ou 1/4”

155,5 hors tout

CRS 146

166,3 hors tout

Hauteur 111

Deutsch

Schlitze für 1/4”- oder M6-Schrauben für

Deckenmontage

36 Schlitz-CRS

M20-, M25-, 1/2”- oder

3/4”-NPT- Kabeleingang

Slots to suit M6 or 1/4” fixings

155,5 Gesamt

146 CRS

166,3 Gesamt

Höhe 111

Español

Ranuras de los acoples M6 ó 1/4” para el

montaje en el techo

CRS de ranuras de 36

Entrada de cable M20, M25, 1/2” ó 3/4” NPT

Ranuras para los acoples M6 ó 1/4”

155,5 Overall

146 CRS

166,3 Total

Altura 111

Italiano

Slot per viti M6 o 1/4” per il soffitto

Slot CRS 36

Entrata cavi M20, M25, 1/2” o 3/4” NPT

Slot per viti M6 o 1/4”

155,5 Totale

CRS 146

166,3 Totale

Altezza 111

Nederlands

Sleuven voor M6 of 1/4” bevestigings-

bouten voor montage aan het plafond

36 Sleuf CRS

M20, M25, 1/2” of 3/4” NPT kabelingang

Sleuven voor M6 of 1/4”

bevestigingsbouten

155,5 Totaal

146 CRS

166,3 Totaal

Hoogte 111

Polski

Otwory na śruby M6 lub ¾” do mocow-

ania na suficie

Rozstaw 36 w osi (CRS)

Otwór na dławik kablowy M20, ½” lub

¾” NPT

Otwory na śruby mocujące M6 lub ¼”

155,5

146 CRS

166,3 Overall

Wysokość 111

Português do Brasil

Slots para fixações M6 ou 1/4" para mon-

tagem no teto

Slot 36 de CRS

Entrada de cabo M20 ,NPT 1/2 " ou 3/4"

Slots para fixações M6 ou 1/4"

155,5 Geral

146 CRS

166,3 Geral

Altura 111

Xgard IR

4

Certification label

Grub screw

PCB cover

(M04770)

Enclosure

base

Sensor seal

Sensor retainer

Oring (M04828)

Sensor retainer

Sensor module

Grub screw

Amplifier PCB

Lid Oring

(M04829)

Diagram 3: Xgard IR exploded view

Schéma 3 : Vue éclatée du Xgard IR

Abbildung 3: Xgard IR – Vergrößerte Ansicht

Diagrama 3: vista despiezada de Xgard IR

Diagramma 3: Disegno esploso di Xgard IR

Afbeelding 3: Xgard IR opengewerkte tekening

Rys. 3: Rysunek złożeniowy Xgard IR

Diagrama 3: vista explodida do XGard IR

Xgard IR

5

Français

(Où applicable, les nombres de partie sont

montrés entre parenthèses).

Etiquette Xgard IR

Vis sans tête

Couvercle de carte électronique

d’amplification (M04770)

Socle de boîtier

Cachet de carte électronique de capteur

Joint torique de fixation du capteur

(M01828)

Fixation du capteur

Carte électronique de capteur

Carte électonique d’amplification

Joint torique de couvercle (M04829)

Deutsch

(Wo zutreffend, teÏlnummern sind in

Klammern gezeigt).

Label Xgard IR

Stifttap

Printplaatdeksel (M04770)

Basis behuizing

Sensor zegel

O-ring sensorbehuizing (M01828)

Sensorbehuizing

Sensor module

Versterker van der printplaat

O-ring afdichting voor deksel (M04829)

Español

(Donde aplicable, los números de la parte

se muestran en paréntesis).

Etiqueta Xgard IR

Tornillo de sujeción

Cubierta de la PCB (M04770)

Enclosure base

Sensor seal

Senser retainer O-ring (M04828)

Sensor retainer

PCB de sensor

PCB amplificador

Junta tórica de la cubierta (M04829)

Italiano

(Dove applicable, i numeri di parte sono

mostrati nella parentesi.)

Coperchio O-ring

PCB amplificatore

Coperchio circuito stampato (M04770)

Base di chiusura

Sigillo di sensore

Supporto sensore O-ring (M01828)

Supporto sensore

Modulo di sensore

PCB amplificatore

Coperchio O-ring (M04829)

Nederlands

(Waar toepasbaar, de onderdeelnummers

zijn in haakjes gescrokken).

Label Xgard IR

Stifttap

Printplaatdeksel (M04770)

Basis behuizing

Sensor zegel

O-ring sensorbehuizing (M01828)

Sensorbehuizing

Sensor module

Versterker van der printplaat

O-ring afdichting voor deksel (M04829)

Polski

(Numery części w nawiasach, gdy są sto-

sowane. Części pokazane – patrz rozdział

„Części i akcesoria”).

Etykieta z certyfikatem

Śruba dociskowa

Osłona PCB (M04770)

Podstawa obudowy

Uszczelka czujnika

O-ring uchwytu czujnika (M04828)

Uchwyt czujnika

Moduł czujnika

PCB wzmacniacza

O-ring pokrywy (M04829)

Xgard IR

6

Português do Brasil

(Se for caso disso, os números de peça

são indicado entre parênteses).

Etiqueta de certificação

Parafuso sem cabeça

Proteção da pIaca (M04770)

Base do invólucro

Selo do sensor

O-ring de vedação do sensor (M04828)

Retentor do sensor

Módulo do sensor

PCI do amplificador

O-ring da tampa (M04829)

English

7

English

Safety information

• Xgard IR gas detectors must be installed, operated and maintained in strict accordance with

these instructions, warnings, label information, and within the limitations stated.

• The lid on Xgard IR must be kept tightly closed until power to the detector is isolated oth-

erwise ignition of a flammable atmosphere can occur. Before removing the cover for main-

tenance or calibration purposes, ensure the surrounding atmosphere is free of flammable

gases or vapours.

• Maintenance and calibration operations must only be performed by qualified service

personnel.

• Only genuine Crowcon replacement parts must be used, substitute components may invali-

date the certification and warranty of the detector.

• Xgard IR detectors must be protected from extreme vibration, and direct sunlight in hot

environments as this may cause the temperature of the detector to rise above its specified

limits and cause premature failure. A sunshade is available for Xgard IR.

• This equipment must not be used in a Carbon Disulphide atmosphere.

• Xgard IR will not detect hydrogen.

• Xgard IR detectors are certified for use in atmospheres that may contain flammable dusts.

They will not however detect the presence of flammable dust, and the response of the gas

sensor may be compromised by becoming blocked in a dusty environment. Xgard IR detec-

tors should be inspected regularly if used in a dusty environment.

• For Exd certified Xgard IR cable glands with a sealing compound must be used where

Group IIC gases are likely to be present (ref: EN60079-14:2008 section 10.4.2).

Hazardous area classifications:

Zone 0: An area classified as Zone 0 will have ignitable concentrations of flammable gases,

vapours or liquids either continuously present or present for long periods of time under

normal operating conditions. Intrinsically Safe (Exia) detectors are suitable for use in

Zone 0, provided they are connected via a suitable zener barrier or galvanic isolator.

Zone 1: An area classified as Zone 1 is likely to have ignitable concentrations of flammable gases,

vapours or liquids present under normal operating conditions. Flameproof (Exd) detectors

are suitable for use in Zone 1. Intrinsically Safe (Exia) detectors are suitable for use in

Zone 1, provided they are connected via a suitable zener barrier or galvanic isolator.

Zone 2: An area classified as Zone 2 is not likely to have ignitable concentrations of flammable

gases, vapours or liquids present under normal operating conditions. Flameproof (Exd)

detectors are suitable for use in Zone 2. Intrinsically Safe (Exia) detectors are suitable

for use in Zone 2, provided they are connected via a suitable zener barrier or galvanic

isolator.

Areas that may contain flammable dusts are categorized as Zone, 20, Zone 21 and Zone 22.

Notes:

In North America ‘Divisions’ are used to categorise risk where:

Division 1 is equivalent to Zone 0 or 1

Division 2 is equivalent to Zone 2

Under European ATEX rules hazardous area equipment has been re-defined under ‘equip-

ment categories’ where:

Equipment Category 1 is suitable for Zone 0

Equipment Category 2 is suitable for Zone 1

Equipment Category 3 is suitable for Zone 2

Overview

8

English

Product overview

Xgard IR is an infrared gas detector, which is available in two versions for the detec-

tion of :

• Common hydrocarbon gases in the range 0-100%LEL.

• Carbon dioxide in the range 0-2% volume or 0-5% volume.

Xgard IR is a certified Flameproof (Exd) detector suitable for use in ATEX Zone 1, Zone

2, Zone 21 or Zone 22 hazardous areas.

UL certified versions are suitable for use in Division 1 or Division 2 areas.

Please refer to the certification label on the detector junction box to identify the type of

certification that relates to the product supplied. Hazardous area definitions are shown

in the Hazardous area classifications section on page 1.

Note: if no certification label is fitted to the junction box, the detector is not certi-

fied for use in hazardous areas.

Each version of Xgard IR is identified by a label fitted on the junction box body. Please

quote the ‘model number’, ‘gas range’ and ‘sensor type’ when contacting Crowcon for

advice or spares.

Product description

Xgard IR comprises of a universal assembly to accommodate either HC or CO

2

IR gas

sensors. The assembly comprises five main parts; the junction box, junction box lid,

amplifier/terminal PCB, sensor PCB and sensor retainer. These are shown in exploded

form in Diagram 3 (see page 4).

A cover is fitted over the amplifier PCB to provide protection when the junction box is

opened. This cover is designed to allow access to all cable terminals, test points and

potentiometers without the need for removal.

The junction box is manufactured from corrosion resistant aluminium with a durable

polyester coating (stainless steel option is available). The junction box is supplied with

1 x M20, ½" or ¾" NPT cable gland entry, on the right hand side for customer use. The

junction box is suitable for fixing on the wall or ceiling using M6 or ¼" fixings. Cable

gland adaptors are available if required (see Spare parts and accessories section).

1. Introduction

9

English

1.1 Flameproof flammable gas detector

Xgard IR is a flameproof gas detector, designed to detect hydrocarbon gases or CO

2

.

Xgard IR is powered by 24 V dc (nominally) and provides a 4-20 mA signal (sink or

source) proportional to the gas concentration. The detector is certified II 2 GD Ex db

IIC T6 Gb, and is suitable for use in Zone 1, Zone 2, Zone 21 and Zone 22 hazardous

areas.

Electrical connections to the detector are made via the terminal block on the PCB

shown below.

Diagram 4: Xgard IR PCB layout

(Shown with PCB cover removed).

Internal grounding

terminal (earth)

Sink

Supplemental

external

grounding

terminal (earth)

Source

TP1

TP2

Test

points

TP3

VR3

TP4

2.Installation

10

English

2.1 Location

The detector should be mounted where the gas to be detected is most likely to be pre-

sent. The following points should be noted when locating gas detectors:

• To detect gases which are lighter than air, such as methane, detectors should be

mounted at high level and Crowcon recommend the use of a collector cone (Part

No. C01051).

• To detect heavier than air gases, such as flammable vapours or CO

2

, detectors

should be mounted at low level.

• When locating detectors consider the possible damage caused by natural events

e.g. rain or flooding. For detectors mounted outdoors Crowcon recommend the

use of a Spray Deflector (Part No. C01052).

• Consider ease of access for functional testing and servicing.

• Consider how the escaping gas may behave due to natural or forced air currents.

Mount detectors in ventilation ducts if appropriate.

• Consider the process conditions. For example, butane is normally heavier than air,

but if released from a process which is at an elevated temperature and/or pres-

sure, the gas may rise rather than fall.

The placement of sensors should be determined following advice of experts having

specialist knowledge of gas dispersion, the plant processing equipment as well as

safety and engineering issues. The agreement reached on the locations of sensors

should be recorded.

WARNING

This detector is designed for use in Zone 1, Zone 2, Zone 21 and Zone 22

hazardous areas, and is certified II 2 GD Ex db IIC T6 Gb. Installation must

be in accordance with the recognised standards of the appropriate authority

in the country concerned.

For further information please contact Crowcon. Prior to carrying out any

installation work ensure local regulations and site procedures are followed.

Xgard IR 2.Installation

11

English

2.2 Mounting

Xgard IR should be installed at the designated location with the sensor pointing down.

This ensures that dust or water will not collect on the sensor and stop gas entering the

cell. The mounting detail is shown in Diagram 2. Care should be taken when installing

the detector to avoid damaging the painted surface and screw threads of the junction

box and sensor retainer.

2.3 Cabling requirement

Cabling to Xgard IR must be in accordance with the recognised standards of the

appropriate authority in the country concerned and meet the electrical requirements

of the detector.

Crowcon recommend the use of steel wire armoured (SWA) cable and suitable explo-

sion proof glands must be used. Alternative cabling techniques, such as steel conduit,

may be acceptable provided appropriate standards are met.

Xgard IR requires a dc supply of 10-30 V, at up to 100 mA. Ensure there is a minimum

of 10 V at the detector, taking into account the voltage drop due to cable resistance. For

example, a nominal dc supply at the control panel of 24 V has a guaranteed minimum

supply of 18 V. The maximum voltage drop is therefore 8 V. Xgard IR can demand up

to 100 mA and so the maximum loop resistance allowed is 80 Ohms.

A 1.5 mm

2

cable will typically allow cable runs up to 3.3 km. Table 1 below shows the

maximum cable distances given typical cable parameters.

C.S.A. Resistance (Ohms per km) Max. Distance

mm

2

Awg Cable Loop (km)

1.0 17 18.1 36.2 2.2

1.5 15 12.1 24.2 3.3

2.5 13 7.4 14.8 5.4

Table 1: maximum cable distances for typical cables

The acceptable cross sectional area of cable used is 0.5 to 2.5 mm

2

(20 to 13awg). The

table is provided for guidance only, actual cable parameters for each application

should be used to calculate maximum cable distances.

2.Installation Xgard IR

12

English

2.4 Electrical connections

All connections are made via the screw terminal block mounted on the PCB in the

junction box. The terminals are marked ‘+’, ‘sig’ and ‘-’ and correct polarity should be

observed when connecting the detector to control equipment. Xgard IR is factory set

as a ‘current sink’ device unless otherwise specified when ordering. To reset to ‘current

source’, open the junction box and move the two links on the amplifier PCB from the

‘sink position to the ‘srce’ position, as shown in Diagram 4.

Note: The internal grounding terminal (see diagram 4) shall be used as the grounding

means of the Xgard IR gas detector. The external grounding terminal is only to be used

where local authorities permit or require such a connection. Where possible, to limit

radio frequency interference, the junction box and cable armour should be grounded at

the control panel (safe area) only to avoid earth loops.

Diagram 5: Xgard IR electrical connections

-VE

+VE

1 2 3 4 5 76 8 119 10 12

SIG

-VE

+VE

SIG

Xgard IR PCB Control panel

10-30 V cc

4-20 mA

(Sink or Source)

Earth

3. Operation

13

English

3.1 Commissioning procedure

1. Open the junction box of the detector by unscrewing the lid in an anti-clockwise

direction (having loosened the retaining grub-screw first).

2. Check that all electrical connections have been made and are correct, as shown in

Diagram 5.

3. Measure the voltage across the ‘+’ and ‘-’ terminals and check a minimum supply of

10 V d.c. is present.

4. Leave the detector to stabilise for at least 45 minutes.

5. Remove the PCB cover and check the amplifier balance by connecting a Digital Volt

Meter (DVM) set to the dc mV range to test points TP3 and TP4 (see Diagram 4).

Adjust potentiometer VR3 so that the DVM reads ‘0.00 mV’. The PCB cover can now

be re-fitted.

6. To zero the detector, connect the DVM to the test points marked ‘TP1’ and ‘TP2’ on

the amplifier PCB, as shown in Diagram 4.

Note: At the test points, Zero will read 40 mV = 4 mA.

Full scale deflection will read 200 mV = 20 mA. There is a current clamp of 25 mA

on the 4-20 mA output.

Zeroing the detector

7. Hydrocarbon detectors: ensure the detector is in clean air. Adjust the ‘ZERO’

potentiometer (accessible via a hole in the PCB cover) until the DVM reads 40 mV.

Check that the control panel display reads 0%LEL.

Carbon Dioxide detectors: as air contains 300/400ppm of CO

2

normally, the sen-

sor must be zeroed using 100% nitrogen test gas. Apply 100% N

2

gas at a flow-rate

of 0.5 litres per minute via a flow adaptor (part number C03005). Adjust the ‘ZERO’

potentiometer (accessible via a hole in the PCB cover) until the DVM reads 40 mV.

Check that the control panel display reads 0%. Remove the zero gas.

Calibrating the detector

8. Apply calibration gas (concentration should ideally be at least 50% of full scale

concentration) to the detector at a flow rate of 0.5–1 litre/minute via a flow adaptor

(Part No. C03005). Contact Crowcon for the supply of calibration gas.

WARNING

Prior to carrying out any work ensure local regulations and site procedures are

followed. Never attempt to open the detector or junction box when flammable

gas is present. Ensure that the associated control panel is inhibited so as to

prevent false alarms.

3. Operation Xgard IR

14

English

9. Allow the gas reading to stabilise (usually 30 to 60 seconds) and adjust the ‘CAL’

pot until the DVM reads the appropriate reading (eg for a hydrocarbon gas detector

120 mV = 12 mA = 50% LEL). If the concentration of the calibration gas used is not

50% of scale, the following formula can be used to calculate the reading:

160

40

Range

Gas mV setting×

+=

Example: calibrating a 0-5% CO

2

detector using 3% CO

2

test gas

160

5

40×

+=3 136 mV

10. If the control equipment display requires adjustment consult the operating manual for

the equipment.

11. Remove the gas and allow the sensor to completely settle before re-checking the

zero setting.

12. Close the junction box of the detector ensuring that the lid is securely tightened, and

the grub-screw is secured.

13. The detector is now operational.

Note: ATEX certified Xgard flammable gas detectors will be supplied calibrated for com-

pliance with EN60079-20-1 (where for example 100% LEL methane = 4.4% volume).

UL certified detectors will be supplied calibrated for compliance with North American

standards (where 100% LEL methane = 5% volume).

3.2 Routine maintenance

Site practices will dictate the frequency with which detectors are tested. Crowcon would

recommend that detectors be gas tested at least every 6 months and re-calibrated as

necessary. To re-calibrate a detector follow the steps given in 3.1.

The sinter should be inspected regularly, and replaced if it has become contaminated. A

blocked sinter may prevent gas from reaching the sensor.

When performing maintenance on Xgard IR, ensure that the sensor retainer and junc-

tion box lid O-rings are present and in good condition to maintain the ingress protection

of the product. See the ‘Spare parts and accessories’ section for the part numbers of

replacement O-rings.

The sensor used in Xgard IR should provide in excess of 5 years trouble-free operation.

In the event of a sensor failure, the sensor module should be replaced.

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

Crowcon M07692 Manuale utente

- Tipo

- Manuale utente

in altre lingue

- English: Crowcon M07692 User manual

- français: Crowcon M07692 Manuel utilisateur

- español: Crowcon M07692 Manual de usuario

- Deutsch: Crowcon M07692 Benutzerhandbuch

- Nederlands: Crowcon M07692 Handleiding

- português: Crowcon M07692 Manual do usuário

- polski: Crowcon M07692 Instrukcja obsługi

Documenti correlati

-

Crowcon Xgard Bright Manuale utente

-

Crowcon Xgard Bright User's And Operator's Manual

-

Crowcon Xgard Manuale utente

-

Crowcon Gasmaster Manuale utente

-

Crowcon VORTEX Manuale utente

-

Crowcon IRmax Manuale utente

-

Crowcon TXgard Plus Manuale utente

-

Crowcon IRmax Installation, Operating And Maintenance Instruction

-

Crowcon Gas-Pro IR Manuale utente

-

Crowcon Gas-Pro Istruzioni per l'uso

Altri documenti

-

NAD m25 Manuale utente

-

Beghelli Pluraluce Extreme Manuale utente

-

PNI GD-01 Gas Detector Manuale utente

-

Vetus PD1000 Manuale utente

-

olympia electronics TS293KI Manuale utente

olympia electronics TS293KI Manuale utente

-

Smartwares FGA-13410 Manuale del proprietario

-

Smartwares FGA-13410 Manuale del proprietario

-

Wohler GS 300 Manuale utente

-

SCANGRIP NOVA-EX Manuale del proprietario

-

Exor eX7xx Touch Panel 7 Inch PCAP Multitouch Guida d'installazione