Before commissioning the machine, read operating

instructions and observe warnings and safety instructions!

Operating Instructions No. 998715-A 03.16

3901

&

Verticutter

8200-V6R

8200 971

with wheel drive

Operating Instructions

Translation of the original operating instructions

50 cm

2 agria Verticutter 8200-V6R

Symbols, Name Plate

Please complete:

Machine Type No. ......................

Identification No.

...................................................

Engine Type: ..............................

Engine No. .................................

Date of Purchase: ......................

For name plate, refer to p3/fig. A/12.

For Engine type and number, refer

to p3/fig. B/8.

Please state these data when

ordering spare parts to avoid wrong

deliveries.

Only use original agria spare

parts!

Specifications, figures and

dimensions stated in these

instructions are not binding. No

claims can be derived from them. We

reserve the right for improvements

without changing these instructions.

This delivery comprises:

l

Operating instructions

l

Verticutter – basic machine

l

Steering handle with fixings

Symbols

W

Warning – Danger

Important information

Choke

Fuel

Öl

Engine Start

Engine Stop

Engine oil level

Air filter

Air cooling

Visual check

Fast

Slow

Knife shaft drive

Wheel drive

Open (unlocked)

Closed (locked)

Clockwise

Anti clockwise

è - Serviceç

= contact Your agria workshop

agria Verticutter 8200-V6R 3

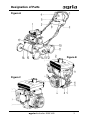

Designation of Parts

Figure A

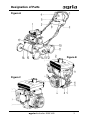

Figure B

Figure C

4 agria Verticutter 8200-V6R

Figure A

1 Engine

2 Top part of steering handle

3 Speed control lever

4 Handle for wheel drive engagement

5 Handle for engagement of knife shaft drive

6 Engine-off switch

7 Grip handle for fast lift-out

8 Bowden cable set screw of wheel drive

9 Bowden cable set screw of knife shaft drive

10 Wheel scraper

11 Rear wheel (drive wheel)

12 Name plate/ID no.

13 Knife shaft bearing

14 Front wheel

15 Knob for slitting depth adjustment

16 Knife shaft housing

17 Belt guard

Figure B

1 Fuel tank

4 Starter handle

5 Recoil starter

6 Radiator grille

8 Engine type no.

9 Engine oil drain plug

10 Engine oil filler plug

11 Fuel tap

13 Spark plug/spark plug connector

Figure C

2 Carburetor

3 Air filter

4 Governor linkage

5 Exhaust with guard

Designation of Parts

agria Verticutter 8200-V6R 5

Index

Amount of Delivery .................. 2

Recommendations

Lubricants, Anti-Corrosive Agents.... 6

Fuel ................................................... 6

Maintenance and Repair .................. 6

Designation of Parts ................ 3

Unpacking, Assembly .............. 7

1. Safety Instructions......... 8–12

2. Specifications

Dimensions ..................................... 12

Verticutter........................................ 13

Engine............................................. 13

Noise Level ..................................... 13

Vibration Acceleration Value........... 13

Operation on Slopes....................... 13

3. Devices and Operating

Elements

Engine............................................. 14

Knife Shaft Drive ............................. 15

Wheel Drive .................................... 15

Slitting Depth Adjustment ............... 16

Fast lift-out Mechanism .................. 16

4. Commissioning and

Operation

Commissioning the Machine .......... 17

Starting the Engine ......................... 18

Shutting off the Engine ................... 19

Verticutter Operation....................... 20

General Comments on

Verticutter Turf Care........................ 21

5. Maintenance

Machine .................................... 22–25

Wheel drive ............................... 26–27

Wheels ............................................ 27

Wheel Scraper ................................ 27

Knife Shaft Drive ............................. 28

Knives ............................................. 29

General ........................................... 30

Cleaning.......................................... 30

Storage ........................................... 31

Wiring Diagram....................... 31

6. Troubleshooting............ 32–33

Varnishes, Wear Parts............ 33

Inspection and Maintenance

Chart........................................ 34

Declaration Conformity ......... 35

Note fold-out page!

Figs. A, B, C .............................. 3

3

5

6

2

1

4

6 agria Verticutter 8200-V6R

Recommendations

Lubricants and

Anti-Corrosive Agents

Use the specified lubricants for en-

gine and gearbox (see “Specificati-

ons”).

We recommend using Bio-lubrica-

ting oil or Bio-lubricating grease

for “open” lubricating points or nipp-

les (as specified in the operating in-

structions).

We recommend using Bio-slushing

oil for preservation of machines and

implements (do not apply on painted

external covers). Oil can be brushed

or sprayed on.

Anti-corrosive agents are environ-

mentally friendly and degrade fast.

Using ecologically safe Bio-lubri-

cants and Bio-anti-corrosives, you

contribute to environmental protec-

tion and to the wellbeing of humans,

animals and plants.

Fuel

This engine runs smoothly on

commercial unleaded regular and

supergrade petrol as well as on

leaded supergrade petrol.

Do not add oil to petrol.

If, for environmental reasons, you use

unleaded petrol, make sure the fuel is

drained completely when shutting down

the engine for more than 30 days. This

is to prevent resin residue from

depositing in the caburetor, fuel filter,

and tank. Or add a fuel stabilizer to the

fuel.

For further instructions refer to “Engine

Preservation”.

Maintenance and Repair

The trained mechanics of your agria

workshop carry out expert maintenance

and repair.

You should only carry out major

maintenance work and repairs on your

own, if you have the proper tools and

knowledge of machines and internal

combustion engines.

Do not hammer against the flywheel

with a hard object or metal tools as it

might crack and shatter in operation

causing injuries and damage. Only use

suitable tools for pulling the flywheel.

agria Verticutter 8200-V6R 7

Unpacking and Assembly

l

Open the top of the

cardboard box.

l

Cut the box open on all

four corners and fold

down the sides.

l

Swivel the top part of

steering handle (1) to the

rear and mount the moun-

ting parts (2-4)

l

Tighten all screwed

connections and attach

the caps (5) to the nuts.

l

Mount the steering

bracket (7) with the spring

washers (8) and screws

(9) at the steering hand-

le.

l

Attach the Bowden and

electric cables to the

steering handle’s bottom

part, using the cable ties

(6). Ensure that all cables

are routed properly.

Ensure they are not bent

or squeezed.

Starting-up

See instructions on page

17.

1 Top part of steering handle

2 Truss head screw M8

3 Oval washer

4 Locking nut M8

5 Nut cap

6 Cable tie

7 Steering bracket

8 Spring washer

9 Screw M6

8 agria Verticutter 8200-V6R

1. Safety Instructions

Before starting the engine, read the

operating instructions and note:

Warning

This symbol marks all paragraphs

which affect your safety. Pass all safety

instructions on to other users and

operators.

Due Use

With its rotating knives, the verticutter

is constructed for use on grassed

surfaces for in-depth cleaning and the

removal of thatch, moss and flat-

growing weeds from the grass (due

use).

Any other type of use is considered

undue. The manufacturer is not liable

for any damages resulting from undue

use, for which the risk lies with the user

alone.

For reasons of safety do not use the

verticutter to drive other tools or

attachments. The verticutter (equipped

with wheel drive) is not suited for pulling

lawn sweepers and spreaders. The

same applies for attaching trailers to

ride on or transport clippings. The only

attachment allowed on the verticutter

is the grass collecting box provided by

the manufacturer.

Due use includes compliance with

manufacturer’s instructions on

operation, service and maintenance.

Any unauthorized modifications to the

verticutter render manufacturer liability

null and void.

General Instructions on Safety

and Accident Prevention

Basic Rule:

The standard accident prevention

regulations must be adhered to, as well

as all other generally accepted rules

governing operational safety,

occupational health and road traffic

regulations.

Check the verticutter for operational

safety each time you take up operation.

Only persons familiar with the

verticutter and instructed on the

hazards of operation are allowed to

use, service and maintain the machine.

Teenagers younger than 16 years are

not allowed to operate the verticutter!

Only work in good light and visibility.

Operator’s clothes should fit tight. Avoid

wearing loose fitting clothes. Wear so-

lid shoes.

Note the warning and instruction signs

on the verticutter for safe operation.

Comply for your own safety.

When transporting the verticutter on

vehicles or trailers outside the area to

be cultivated, ensure that the engine is

turned off.

Careful with rotating tools – keep at a

safe distance!

The knives may coast due to flywheel

mass on the engine. Keep at a safe

distance while the shaft is coasting.

Before you service or maintain the

verticutter, wait until the shaft has come

to a complete stop and remove the

spark plug.

1

agria Verticutter 8200-V6R 9

1. Safety Instructions

Beware of coasting tools. Before you

start working on them wait until they

have come to a complete stop.

Do not change engine governor

settings. High engine speed increases

risk of accidents.

Working Area and Hazardous

Area

The user is liable to third parties

working within the machine’s working

range.

Staying in hazardous area is not

permitted.

Check the immediate surroundings of

the machine before you start it. Watch

out for children and animals.

Before you start work, clear the area

from any foreign object. During

operation, always watch out for further

objects and remove them in time.

For operation in enclosed areas, ensure

that a safe distance is kept to

enclosures to prevent damage to tools.

Watch out during slitting operation to

prevent the knives from hitting

obstacles such as border stones,

kerbstones, roots, etc.

Shut off the engine before you transport

the verticutter outside the area of

operation.

Operation and Guards

Before you start the engine

Become familiar with all guards and

controls and their functions. Above all,

learn how to turn the engine off quickly

and safely in an emergency.

Ensure that all guards are fitted and

positioned to provide protection.

Starting the engine

Do not start engine in closed rooms.

The carbon monoxide contained in the

exhaust fume is extremely toxic when

inhaled.

Careful when starting the verticutter

and during operation. Keep your

hands and feet off the rotating

knives!

Do not upend or tilt the verticutter when

you start the engine.

Do not step in front of the verticutter to

start the engine.

When starting the engine, ensure the

wheel drive (if equipped) is not

engaged

Do not use assist-starting liquids when

using electrical assist-starting devices

(jumper cable). Danger of explosion.

1

10 agria Verticutter 8200-V6R

1. Safety Instructions

Operation

Never leave the operator’s position at

the steering handle while the machine

is at work.

Never adjust the handles during work

– danger!

The operator always has to keep at a

safe distance from the rotor housing as

set by the steering handle. This applies

in particular for turning the verticutter.

Do not pull but push the verticutter

when making a turn.

If blockages occur, turn off the engine

and clean the machine with an

appropriate tool.

In case of damage to the verticutter,

immediately turn off the engine and

have it repaired.

If steering causes problems,

immediately bring the verticutter to a

halt and turn it off. Have the malfunction

removed without delay.

To prevent the machine from slipping

in hillside operation, make sure it is

secured by another person who uses

a bar or a rope to hold the machine.

This person has to walk further up the

slope and at a safe distance from the

knife shaft housing.

If possible, always work across the

slope.

End of Operation

Never leave the verticutter unattended

with the engine running.

Before you leave the verticutter, turn off

the engine.

Secure the verticutter against

unauthorized use. If the machine is

equipped with an ignition key, remove

the key. For all other versions, remove

the spark plug connector to secure the

machine.

Grass Collecting Box

If the grass box is not removed/attached

properly, stray stones or wood may be

thrown out by the rotating knives and

injure the operator.

Before you remove the grass box or

adjust the slitting depth, shut off the

engine and wait until the knife shaft has

come to a stop.

Maintenance

Never carry out any maintenance or

cleaning with the engine running.

In addition, always remove spark plug

connector before you work on the

engine.

Regularly check all guards and tools

exposed to wear and tear and replace

them, if necessary.

Replace damaged knives.

Always wear safety gloves and use pro-

per tools when exchanging knives.

Do not carry out repairs like welding,

grinding, drilling, etc. on structural and

safety-relevant parts!

Keep the verticutter clean to avoid risk

of fire.

Check nuts and bolts regularly for tight

fit and re-tighten them, if necessary.

1

agria Verticutter 8200-V6R 11

1. Safety Instructions

Ensure that you re-install all guards and

adjust them properly after maintenance

and cleaning.

Only use original agria spare parts. All

other conventional spare parts must

correspond to quality and technical

requirements specified by agria.

Storage

It is not allowed to store the verticutter

in rooms with open heating.

Never park the verticutter in closed

rooms with fuel left in tank. Fuel

vapours are hazardous.

Engine, Fuel, and Oil

Never let the engine run in closed

rooms. Extreme danger of intoxication!

Careful when dealing with fuel. Great

danger of fire!

Never refill fuel close to open fire,

inflammable sparks or hot engine parts.

Do not refill fuel in closed rooms. Do

not smoke when refilling!

Refill only with the engine switched off

and cooled down.

Do not spill any fuel, use a proper filling

device.

In case of fuel-spillage, push the

verticutter away from the spillage

before you start the engine.

Ensure the fuel is of required quality.

Store fuel in approved cans only.

Store anti-corrosive agents and

stabilizing liquids out of reach of

children. If sickness and vomiting occur,

see a doctor. If fuel has contacted eyes,

rinse them thoroughly, avoid inhaling of

vapours.

Read and observe enclosed

instructions.

Before you dispose of opened and

seemingly empty pressurised tins (e.g.

of assist-starting liquids) make sure

they are completely empty. Empty them

in ventilated places safe from spark

formation or flames. If necessary,

dispose of tins in hazardous waste

deposits.

Be careful when draining hot oil –

danger of burns.

Ensure the oil is of required quality.

Storage is in approved cans only.

Dispose of oil, greases, and filters

separately and properly.

Electrical System

Persons having a pacemaker must not

touch live parts of the ignition system

when the engine is running.

1

12 agria Verticutter 8200-V6R

1. Safety Instructions

b = 430 mm

h = 660 mm

l = 740 mm

S = 685 mm

H = 1020 mm

L = 1450 mm

Dimensions

Explanation of Signs

Wear individual protective ear

plugs.

Wear protective gloves.

Wear solid shoes.

1

Explanation of Warning Symbols

Before doing any cle-

aning, maintenance

and repair work, shut

off the engine and

remove spark plug

connector.

Keep off the knives

while the engine is

running!

Do not touch rotating

machine parts. Wait

until they have come

to a complete stop.

Do not operate the

machine without

guards! Move guards

in place before you

take up operation.

agria Verticutter 8200-V6R 13

2. Specifications

Engine manufacturer: .............Robin

Type:....................................... EH17D

Version:.... Fan-air-cooled 1-cylinder-

4-stroke engine (petrol),

overhead valves

Bore:........................................ 67 mm

Stroke:..................................... 49 mm

Cubic capacity: ................... 172 ccm

Output: ...............4.0kW at 3,600 rpm

Torque: ..... max. 11 Nm at 2,600 rpm

Spark plug:....... Champion WR 7 AC

NGK BR 6 HS

Electrode gap: ..........0.6 mm–0.7 mm

Ignition system:

Contactless electronic solenoid

ignition, ignition point is pre-set, radio

remote screened according to VDE

0879

Valve lash (engine cold):

Intake: .................. 0.08 mm–0.11 mm

Outlet: .................. 0.08 mm–0.11 mm

Starter: ......................... Recoil starter

Cold start system: ..................Choke

Fuel tank capacity:.................... 3.6 l

Fuel: ....................Conventional petrol

octane number min. 85 RON

(refer to fuel recommendations)

Air filter:................. Dry filter element

with foamed pre-filter

Carburetor: .......... horizontal, floating

Mix control screw:

in base setting . approx. 3/8 turn open

Rated speed: .................... 3,600 rpm

Top no-load speed: ......... 3,800 rpm

Idling speed: .................... 1,200 rpm

Engine oil:

Filling quantity .............. approx. 0.65 l

Multi-grade oil SAE 10W-40 API-SC

Working width:........................ 50 cm

No. of knives: ................................ 19

Slitting circumference ........ 220mm Ø

Shaft speed: ..................... 2,500 rpm

Rotational direction of knife shaft:

.. reverse, opposed to travel direction

Slip clutch: ...............between knives

Height adjustment:......Centrally and

steplessly via crank bolt;

fast lift-out mechanism

Discharge: ........................To the rear

Wheels:

Front wheels ...........................23cm Ø

Rear wheels .......................... 23cm Ø

with special ball bearings

Wheel drive: ........... approx. 2.5km/hr

Rear-wheel drive via worm gear with

integrated conus clutch and internally

toothed gearwheel with overrunning

clutch. Engagement is via handle on

steering handle. Oil quantity in

worm gear: approx. 0.2l

SHELL Agroma Multipurpose 15W40 CD

or Harvella TX 10W40

Steering handle: .................. foldable

Noise level............................. L

wa

100

in accordance with EC directive

84/538/EEC

Vibration acceleration value: on

steering handle grip ....a

hwy

= 9.3 m/s

2

in accordance with ISO 5349 at 85% of

rated engine speed with tools at work

Operability on Slopes:

Engine performance (oil level is at top

”max.” mark) on slopes is satisfactory

as long as the operator is still able to

walk on the slope and operate the

verticutter without extraordinary effort.

Weight: ......................... approx. 69 kg

Dimensions: .................. see page 12

2

14 agria Verticutter 8200-V6R

3. Devices and Operating Elements

The verticutter agria type 8200-V6R is

suited for usual operation in horticulture

and turf care.

Engine

The four-stroke petrol engine runs on

commercial petrol (refer to fuel

recommendations).

During the first 20 operating hours

(break-in period) do not operate the

engine at maximum speed.

Even after the break-in period never

operate the engine at higher speed than

is necessary for the work in hand.

I

High engine speed is harm-

ful to any engine and consid-

erably affects its longevity. This

applies especially for no load

operation. Any overspeed (have the

engine roar) can result in immediate

damage.

Cooling System

The engine is fan-cooled. Therefore

keep the grille on the recoil starter and

the cooling fins on the cylinder clean

and free from sucked-in plant trash.

Idling-Speed

Always ensure that idling-speed is

adjusted correctly. At low speeds and

with the speed control lever set to idle,

the engine is supposed to run smoothly

and without run-out.

Air Filter

The air filter purifies the air intake. A

clogged filter reduces engine output.

Ignition System

The engine is equipped with a

maintenance-free, contactless

electronic ignition system. We

recommend to have necessary check-

ups done by an expert only.

Speed Control Lever

The speed control lever (A/3) on the

steering handle steplessy controls

engine speed from min = idling speed

to max = maximum speed.

Engine-shut-off switch

The verticutter is equipped with a shut-

off switch (A/6). This switches the

ignition off (engine off).

Position ”I” = Operation

Position ”0”= Engine off

3

agria Verticutter 8200-V6R 15

3. Devices and Operating Elements

Knife Shaft Drive

The machine is equipped with a V-belt

clutch with pulley fitted between engine

and knife. Actuation is via the handle

(A/5).

0 = Handle is moved to the rear

I = Handle is moved forward and

knife shaft starts rotating

I

Do not actuate the handle at

high engine speed because this

will quickly ruin the V-belt. Ensure the

V-belt is adjusted properly. See

instructions!

W

Do not tie down this handle.

Knife Shaft

19 knives are arranged around the

shaft. They are bolted to the shaft at a

pretension of 15 Nm (1.5mkg).

l

This pretension generates axial

friction force which drives the knives.

Pretension must not exceed 15 Nm to

ensure the slip clutch engages when

the machine hits a stone or another

obstacle.

Wheel drive

Wheel drive is via a worm gear with

integrated conus clutch and internally

toothed gearwheel with overrunning

clutch on the rear wheels.

Engagement/disengagement is via

handle (A/4).

Wheel drive engagement

Move the handle to the steering hand-

le to position ”I”

– The verticutter moves forward

Wheel drive disengagement

Release the handle which will go to

position ”0”

– You can now push or pull the

verticutter.

W

Do not tie down this handle.

3

16 agria Verticutter 8200-V6R

3. Devices and Operating Elements

Setting the Slitting Depth

W

Ensure the engine is shut off

and the shaft has stopped.

l

Park the verticutter on level ground

and turn the knob (A/15 on the knife

shaft housing) to set the slitting depth

in such a way that the knives barely

touch the ground.

l

Tur n the knob (A/15) to set the desi-

red slitting depth – one turn corre-

sponds to about 1mm depth adjustment

l

The proper slitting depth is 2 mm –

3 mm

Fast Lift-Out

W

Ensure the engine is shut off

and the shaft has stopped.

Use the fast lift-out mechanism to bring

the verticutter in transport position to

prevent the knives from being damaged

when transporting the verticutter on

paved paths or concrete tiles.

Transport Position:

l

Pull the grip-handle of the fast lift-

out mechanism (A/7) all the way out

l

Press on the steering handle

l

Release the grip-handle and press

on the steering handle until the height

adjustment mechanism locks into

transport position

Working Position:

l

Pull the grip-handle of the fast lift-

out mechanism (A/7) all the way out

l

Push up the steering handle

l

Release the grip-handle and

continue pushing up the steering hand-

le until fast lift-out mechanism locks into

working position.

3

agria Verticutter 8200-V6R 17

4. Commissioning and Operation

I

Caution: For reasons of

transport, the machine is

not filled with engine oil!

Before you operate the engine the

first time, fill in engine oil!

Commissioning the

Machine

Please note that engine longevity and

operational reliability depend to a large

extent on its breaking-in. Always allow

a cold engine to warm up for some

minutes and never operate it at full

throttle at the beginning. Make sure the

air filter is serviced regularly and to use

clean fuel.

Please note: for the first 20 hours of

operation (break-in period) do not use

the engine at full power.

For this purpose, park the verticutter

in such a way that the engine is level.

For the proper oil filling quantity and

quality see ”Specifications”.

Check the oil level after filling.

Check oil level

l

Remove the oil plug and clean the

dipstick with a clean cloth. Push the

dipstick back into the oil reservoir (do

not screw it down). Remove the oil

dipstick and read the oil level.

l

If the oil level is below the bottom

notch on the stick, top up engine oil

(see specifications), filling it to the rim

of the oil filler neck.

l

Screw down the plug and tighten it.

Ensure that the plug sits tight in the oil

filler neck when the engine is running.

Before each start:

l

Check the engine oil-level (see

illustration) and top up oil, if necessary

– do not add too much oil!

l

Check whether the fuel tank

contains enough fuel.

Do not fill the fuel tank until the fuel

overflows. Leave enough approx. 5 mm

for the fuel to expand.

W

Be careful when dealing with

fuel. Great danger of fire!

Never refill fuel close to open fire,

inflammable sparks or hot engine

parts. Do not refill fuel in closed

rooms. Refill only with the engine

shut off and cooled down.

Do not smoke

when refilling!

Do not spill any

fuel, use a proper

filling device.

W

Do not start the engine in

closed rooms. Exhaust fu-

mes contain carbon monoxide which

acts toxic when inhaled.

Keep your feet clear off the knife

shaft housing.

3

18 agria Verticutter 8200-V6R

4. Commissioning and Operation

Starting the Engine

l

Open the fuel tap (B/9)

l

Engine cold: Pull the CHOKE lever

(C/4)

l

Engine warm: Leave the CHOKE

lever in normal operating position or

move it to ”middle position”

l

Switch the engine-off switch (A/6) to

”I”, operating position

l

Move the speed control lever (A/3)

to approx. 1/3 speed position

l

Pull the starter cord handle (B/4)

until you feel the starter clutch engage.

Then pull hard and fast to start the

engine. After the start, guide the cord

back. Do not let it snap back.

l

Once the engine is started and let it

warm up for a short time. Slowly move

the choke lever to operating position (if

actuated).

1/3

4

agria Verticutter 8200-V6R 19

4. Commissioning and Operation

Shutting off the Petrol

Engine

l

Move speed control lever to idling

speed and let the engine run idling for

a about 30 seconds.

l

Switch the engine-off-switch to

position ”0”

l

Close the fuel tap

I

Note: The engine-off switch

(A/6) also serves as emergency

off-switch. In an emergency release

the handle for instant engine shut-off.

I

If the verticutter is downed for a

long period, do not turn the en-

gine off by pressing the engine-off-

switch. Instead, close the fuel tap and

let the engine run until it comes to a

stop due to lack of fuel. This is to ensure

the carburetor is empty to avoid resin

deposits.

W

Secure the verticutter against

unauthorized use. Remove the

spark-plug connector.

4

66

66

630 sec

20 agria Verticutter 8200-V6R

4. Commissioning and Operation

Verticutter Operation

l

Before slitting can be carried out,

ensure the turf is cut as short as

possible and is swept.

l

Do not operate the verticutter on wet

lawns and in rainy weather.

Before you start operation remove any

obstacles from the area to be slitted.

Watch out for obstacles during work.

l

Set the slitting depth

l

Start the engine (as described in

”Starting Engine”)

W

Check function of engange-

ment of knife shaft drive and

wheel drive engagement - only

operate the machine if these circuits

are working!

l

Wear individual protective ear plugs

and solid shoes

l

Engage the knife shaft drive by

pressing shortly on the steering hand-

le to tilt the machine for the knives to

rotate freely. This is to allow the knife

shaft to pick up full speed (V-belt slip)

l

Engage wheel drive

Before moving off check the immediate

surroundings for children and animals.

Work Speed

For slitting thatched and mossy lawns

it may be desirable to switch the wheel

drive off and push the verticutter by

hand (slowlier than with wheel drive

engaged).

4

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36