DOC023.97.80570

9525sc DCCP System

10/2020, Edition 6

User Manual

Bedienungsanleitung

Manuale utente

Manuel de l'utilisateur

Manual del usuario

Brugervejledning

Kullanıcı Kılavuzu

Εγχειρίδιο χρήσης

Table of Contents

English..............................................................................................................................3

Deutsch.......................................................................................................................... 30

Italiano............................................................................................................................ 58

Français......................................................................................................................... 86

Español........................................................................................................................ 114

Dansk............................................................................................................................142

Türkçe...........................................................................................................................169

Ελληνικά...................................................................................................................... 196

2

Table of Contents

1 Specifications on page 3

2 General information on page 4

3 Installation on page 10

4 Startup on page 17

5 User interface and navigation on page 18

6 Operation on page 20

7 Advanced operation on page 21

8 Maintenance on page 22

9 Troubleshooting on page 28

10 Replacement parts and accessories

on page 29

Section 1 Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions 91 x 62 x 38 cm (36 x 24.5 x 15 inches)

Weight Degas-only DCCP system : 27.7 kg (61 lb)

DCCP system: 50 kg (110 lb)

Power requirements US: 110 to 120 VAC, 1 phase, 50/60 Hz

EU: 220 to 240 VAC, 1 phase, 50/60 Hz

Main supply voltage fluctuation ±10% of nominal voltage

Power consumption 1.6 kVA

Pollution degree 2

Installation category II

Altitude 2000 m (6562 ft) maximum

Operating temperature Without regenerative cooling option: 2 to 50 °C (36 to 122 °F), 0 to

85% relative humidity, non-condensing

With regenerative cooling option: 2 to 45 °C (36 to 113 °F), 0 to

85% relative humidity, non-condensing

Operating temperature

(recommended)

23 to 27 °C (73 to 81 °F)

Storage temperature 0 to 50 °C (32 to 122 °F)

8315 Conductivity sensor Cell constant, k: 0.01 cm

-1

Measurement range: 0.01 to 200 μS/cm

Sensor accuracy: less than ± 2%

Power to the sensor(s) is supplied by the controller.

Controller power requirements 100 to 240 VAC ±10%, 50/60 Hz

Controller and instrument

rating

IP66/NEMA 4X

Sample water Flow rate: 100 to 150 mL/min; 6 to 9 L/hr (1.5 to 2.4 gal/hr)

Temperature: 25 °C ± 1 °C (77 °F ± 2 °F) recommended; 2 to

54 °C (36 to 129 °F) without regenerative cooling option or 2 to

45 °C (36 to 113 °F) with regenerative cooling option

Pressure: 6.9 bar (100 psig)

English 3

Specification Details

Cooling water

Note: Cooling water is not used if the instrument has the regenerative cooling option.

Flow rate: 0.8 L/min (0.2 gal/min)

Temperature: 22 °C (71.6 °F)

Use clean water with no suspended solids and a low hardness.

Use water that is low in chlorides. Chlorides can cause corrosion

in the stainless steel coil and shell.

Sample water connections ¼-inch tube fittings

Cooling water connections ¼-inch tube fittings

Flow cell ¾-inch FNPT, 316 stainless steel

Certifications CE, UL, CSA

Section 2 General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

2.1 Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this

product including, without limitation, direct, incidental and consequential damages, and disclaims

such damages to the full extent permitted under applicable law. The user is solely responsible to

identify critical application risks and install appropriate mechanisms to protect processes during a

possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

2.1.1 Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or

serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death

or serious injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that

requires special emphasis.

4 English

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European

domestic or public disposal systems. Return old or end-of-life equipment to the

manufacturer for disposal at no charge to the user.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

This symbol indicates the need for protective eye wear.

This symbol indicates that the marked item can be hot and should not be touched without

care.

This symbol, when noted on the product, identifies the location of a fuse or current

limiting device.

2.1.3 Certification

C A U T I O N

This equipment is not intended for use in residential environments and may not provide adequate

protection to radio reception in such environments.

Canadian Radio Interference-Causing Equipment Regulation, ICES-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

English

5

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

2.2 Intended use

The 9525sc DCCP System is intended for use by individuals who measure water quality parameters

in a sample stream of high purity water. The 9525sc DCCP System does not treat or alter water.

6 English

2.3 Product overview

The 9525sc degas-only DCCP (degas cation conductivity panel) system removes CO

2

and measures

degassed cation conductivity (DCC). The system measures a sample stream of high purity water.

The system has one sensor and one controller. Refer to Figure 1.

Figure 1 9525sc degas-only DCCP system

1 Heater 7 Power indicator light

1

2 Sample cooler 8 Temperature controller

3 Polymetron 8315 conductivity sensor 9 Sample flow meter

4 SC200 Controller (or Polymetron

9500 controller)

10 Sample flow valve

5 Electrical enclosure 11 Flow cell

6 Power switch

1

The power indicator light starts and stops with the heater.

English 7

The 9525sc DCCP system removes CO

2

and measures specific conductivity (SC), cation

conductivity (CC) and degassed cation conductivity (DCC) and calculates pH. The system measures

a sample stream of high purity water. The system has three conductivity sensors and two controllers.

The top controller is connected to two sensors and shows the SC (channel 1) and CC (channel 2)

measurements. The bottom controller shows the DCC measurement. Refer to Figure 2.

Figure 2 9525sc DCCP system

1 Heater 7 Power switch

2 Sample cooler 8 Power indicator light

2

3 SC200 Controller (or Polymetron

9500 controller)

9 Temperature controller

4 Polymetron 8315 conductivity sensor (3x) 10 Sample flow meter

5 Electrical enclosure 11 Sample flow valve

6 Flow cell (3x) 12 Resin column

2

The power indicator light starts and stops with the heater.

8 English

2.4 Product components

Make sure that all components have been received. Refer to Figure 3. If any items are missing or

damaged, contact the manufacturer or a sales representative immediately.

Figure 3 Product components

1 9525sc DCCP system (or 9525sc degas-only

DCCP system)

4 Tubing clamp for condensate drain

2 Manuals for Polymetron 8315 sensor,

controller and 9525sc DCCP

5 Ferrite for 220–240 V main power

3 Condensate drain tubing,

3

/

8

-inch ID x

2.44 m (8 ft)

English 9

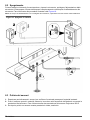

2.5 Customer-supplied parts

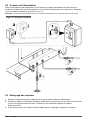

Before installation, collect the components that follow. Refer to Figure 4.

Figure 4 Customer-supplied parts

1 Sample plumbing parts 6 Tubing, ¼-inch OD

3

2 Shutoff valve 7 Electrical parts

3 Tubing, ¼-inch OD 8 110/120 VAC: Wire conductors, 3.31 mm

2

(12 AWG)

4 Cooling water plumbing parts

3

9 220/240 VAC: Wire conductors, 2.08 mm

2

(14 AWG)

5 Shutoff valves (2x)

3

10 Conduit fitting for main power

Section 3 Installation

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this

section of the document.

3.1 Installation guidelines

Install the instrument:

• In a clean, dry, well-ventilated and temperature-controlled location. Refer to the operating

temperature and humidity specifications in Specifications on page 3.

• In a location with no mechanical vibrations and electronic noise.

• As close to the sample source as possible to decrease analysis delay.

• Near an open drain.

• Away from direct sunlight and heat sources.

• So that the power switch is visible and easily accessible.

• In a location where there is sufficient clearance around it to make plumbing and electrical

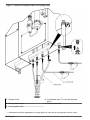

connections. Refer to Figure 5 on page 12.

3

Not applicable to instruments with the regenerative cooling option.

10 English

Most panels are installed on a metal framing system or equivalent mounting structures. The

installation location must have the items that follow:

• Sufficient structural integrity in the floor and wall

• A sufficient anchor location

• A flat, vertical installation surface

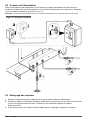

3.2 Mechanical installation

C A U T I O N

Personal injury hazard. Instruments or components are heavy. Use assistance to install

or move.

C A U T I O N

Personal injury hazard. Lift the instrument by the stainless steel backplate. Do not lift the

instrument by the mounted components. The mounted components can break and

cause damage to the instrument and personal injury.

C A U T I O N

Personal injury hazard. Sharp edges can cause cut wounds. Wear personal protective

equipment to prevent injury.

Install the instrument on a wall. Refer to Figure 5. To install on drywall, attach the instrument to the

wood studs with

3

/

8

-inch (M10) hardware.

Use sufficient supports to keep vibrations, gravity and thermal loads on the connections to a

minimum.

English

11

Figure 5 Mounting dimensions

3.3 Electrical installation

3.3.1 Connect the controller to power

Connect the controller to line power by hard-wiring in conduit. Refer to the controller documentation

for instructions.

3.3.2 Connect external devices to the controller

Connect the controller relays, analog outputs and digital inputs to external devices as necessary.

Refer to the controller documentation for instructions.

3.3.3 Wiring the instrument for power

D A N G E R

Electrocution hazard. Protective Earth Ground (PE) connection is required.

D A N G E R

Electrical shock and fire hazards. Make sure to identify the local disconnect clearly for

the conduit installation.

12 English

W A R N I N G

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially wet

locations, a Ground Fault Interrupt device must be used for connecting the equipment to

its mains power source.

W A R N I N G

Electrical shock and fire hazards. Make sure that the user-supplied power cord and non‐

locking plug meet the applicable country code requirements.

Connect power to the controller(s) with electrical conductors and conduit. Do not use a power cord.

Make sure that a circuit breaker with sufficient current capacity is installed in the power line. The

circuit breaker size is based on the wire gauge used for installation. Install the device in a location

and position that gives easy access to the disconnect device and its operation.

For installation with conduit:

• Install a local disconnect for the instrument within 3 m (10 ft) of the instrument. Put a label on the

disconnect that identifies it as the main disconnect device for the instrument.

• Make sure that the electrical conductors for the power and safety ground service drops for the

instrument are a minimum of 3.31 mm

2

(12 AWG) (for 110 V) and a minimum of 2.08 mm

2

(14 AWG) (for 220 V) and the wire insulation is rated for 300 VAC or higher and 60 °C (140 °F)

minimum.

• Connect equipment in accordance with local, state or national electrical codes.

• Connect the conduit through a conduit hub that holds the conduit securely and seals the enclosure

when tightened to keep the NEMA 4x rating of the instrument.

• If metal conduit is used, make sure that the conduit hub is tightened so that the conduit hub

connects the metal conduit to safely ground.

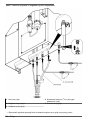

3.3.4 Connect the instrument to power

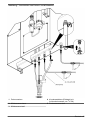

Connect power to the electrical enclosure. Refer to Table 1 and the illustrated steps in Figure 6.

After the wires are connected, tighten the conduit fitting, close the electrical enclosure and tighten the

screws.

Notes:

• At illustrated step 3, cut an opening in the top or bottom of the electrical enclosure for the conduit.

• At illustrated step 4, install a conduit fitting in the opening to keep the enclosure rating of the

instrument (NEMA 4x).

• At illustrated step 6, make sure that the free length of wire conductors for the electrical enclosure

is a minimum of 150 mm (6 in.).

For electrical safety, the protective earth ground wire (G) must be at least 0.5 inches longer than the

Line (L) and Neutral (N) wires. Make sure that each wire goes through the applicable cable clamp as

shown in Figure 6.

English

13

Figure 6 Connect power

14 English

Table 1 Wiring information—AC power

Terminal Description Color—North America Color—EU

L Hot or phase (L) Black Brown

N Neutral (N) White Blue

G Protective earth ground (G) Green Yellow with green stripe

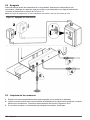

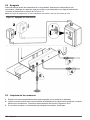

3.4 Plumbing

3.4.1 Connect the sample water and cooling water

Note: Do not install metric equivalent tubing, pipes or fittings on the instrument. Leaks can occur.

Items to collect:

• Shutoff valve (3x)

• ¼-inch tubing OD

•

3

/

8

-inch tubing ID

• Tubing clamp

1. Use ¼-inch tubing and three shutoff valves to connect the sample water and cooling water. Refer

to Figure 7.

2. Use the supplied

3

/

8

-inch ID tubing and tubing clamp to connect the condensate drain to an open

drain. Refer to Figure 7.

Notes:

• Do not connect cooling water to instruments with the regenerative cooling option. Instruments

with the regenerative cooling option do not have a cooling water inlet or outlet.

• Refer to Specifications on page 3 for the cooling water and sample water specifications.

• Make sure to use a back pressure regulator or a head cup to control the sample water

pressure and keep a constant sample flow rate.

• Keep the operating temperature of the sample flow as constant as possible for best

performance.

• For the best results, use a temperature-controlled cooling water source that keeps the cooling

water at 25 °C (77 °F).

• Make the drain lines as short as possible.

• Make sure that the drain lines have a constant slope down.

• Make sure that the drain lines do not have sharp bends and are not pinched.

• Make sure that the drain lines are open to air and are at zero back pressure.

English

15

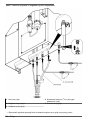

Figure 7 Connect the sample water and cooling water

1 Sample outlet 4 Condensate drain (

3

/

8

-inch OD stainless

steel)

2 Cooling water outlet

4

5 Sample water inlet

3 Cooling water inlet

4

4

Instruments with the regenerative cooling option do not have a cooling water inlet or outlet.

16 English

Section 4 Startup

W A R N I N G

Burn hazard. The heater surface and surrounding area gets hot. Do not touch.

W A R N I N G

Burn hazard. Obey safe handling protocols during contact with hot liquids.

1. Examine the resin beads in the resin column. Refer to Figure 1 on page 7.

2. Replace the resin beads when the resin beads nearest to the color indicator label on the resin

column are brown/orange. Refer to Replace the resin beads on page 24.

Note: The color change of the resin beads starts at the top and continues to the bottom of the resin column.

New resin beads are dark purple.

3. Set the flow rate of the cooling water flow as follows, if applicable:

a. Use the shutoff valve at the cooling water outlet to adjust the flow rate of the cooling water to

approximately 0.8 L/min (0.2 gal/min).

b. Make sure that there are no leaks at the cooling water fittings.

4. Set the flow rate of the sample water as follows:

a. Open the shutoff valve for the sample water inlet.

b. Turn the sample flow valve to set the flow rate of the sample water to between 100 to

150 mL/min. Refer to Figure 1 on page 7.

c. Make sure that there are no leaks at the sample water fittings.

5. Set the instrument to on. Refer to the illustrated steps in Figure 8.

• The power indicator light comes on.

Note: The power indicator light starts and stops with the heater.

• The heater increases the sample temperature to the boiling point of water.

6. Wait for the temperature that shows on the left display of the temperature controller to increase to

approximately 106 °C (223 °F). Refer to Figure 9 on page 19.

Note: The temperature controller may not get to 106 °C (223 °F), based on local air pressure and temperature.

7. Examine the condensate water that comes out the condensate drain. When the temperature and

sample flow rate are set correctly, a small flow of condensed water continually comes out from

the condensate drain.

• If no condensate water comes out the condensate drain, decrease the sample flow rate (range:

100 to 150 mL/min) or increase the temperature setpoint (range: 106 to 108 °C, 223 to 226 °F).

• If drops of hot boiling water come out the condensate drain, increase the sample flow rate

(range: 100 to 150 mL/min) or decrease the temperature setpoint (range: 106 to 108 °C, 223 to

226 °F).

Refer to Set the temperature on page 20 to change the temperature setting.

8. Let the instrument operate until the reading(s) is stable (approximately 10 to 15 minutes).

English

17

Figure 8 Set the instrument to on

Section 5 User interface and navigation

5.1 SC Controller or Polymetron controller

Refer to the controller documentation for keypad description and navigation information.

5.2 Temperature controller

Figure 9 shows the display and keys on the temperature controller. The temperature controller shows

the actual temperature on the left display and the maximum temperature on the right display.

Refer to Table 2 for descriptions of the keys and the display.

For more information on the temperature controller, refer to the Watlow EZ-ZONE PM Express User's

Guide (available online).

18

English

Figure 9 Temperature controller

1 Left display 5 Up arrow key

2 Output activity 6 Infinity key

3 Right display 7 Advance key

4 Down arrow key

Table 2 Temperature controller—Display and keys

Display/Key Name Description

Left display Shows the actual temperature.

In the Operations or Setup

menu, shows the process value

or setpoint data.

1 2

Output 1, Output 2 and right

display

Output 1 and 2 shows which

output is set to on.

The right display shows the

maximum temperature. In the

Operations or Setup menu,

shows the menu display.

Up/Down arrow keys Selects new data when

Advance key is pushed.

Moves forward or backward

through software menus and

parameters.

Starts and stops the timer.

English 19

Table 2 Temperature controller—Display and keys (continued)

Display/Key Name Description

Infinity key Stops alarms.

Push to go back one level.

Push and hold for two seconds

to go back to the Operations

menu.

Advance key Moves forward through

parameter prompts.

Section 6 Operation

6.1 Configure and calibrate the sensor(s)

1. Configure the sensor(s). Refer to the Polymetron 8315 sensor documentation.

2. Calibrate the sensor(s). Refer to the Polymetron 8315 sensor documentation.

6.2 Set the temperature units

Set the temperature units that show on the temperature controller to °F or °C.

1. At the temperature controller, push and hold and until "SEt" (setup parameters menu)

shows on the right display.

2. Push or until "gLbL" shows on the left display.

3. Push to select "gLbL".

"C_F" (temperature unit of measure parameters) shows on the right display.

4. Push or to select the temperature unit (C or F) on the left display.

5. Push and hold for two seconds to go back to the default display.

6.3 Set the temperature

Set the temperature to between 106 and 108 °C (223 and 226 °F). The default temperature is 108 °C

(226 °F).

To identify the correct temperature setting, refer to the last steps in Startup on page 17.

1. At the temperature controller, push and hold and until "oPEr" (operations menu) shows

on the right display.

2. Push or until "LooP" shows on the left display.

3. Push until "C.SP" shows on the right display.

4. Push or to select the temperature.

5. Push and hold for two seconds to go back to the default display.

6.4 Set the temperature alarm setpoint

The recommended temperature alarm setpoint is 110 °C (230 °F). When a temperature alarm

occurs, the instrument removes power to the heater until the heater temperature decreases to below

the alarm setpoint.

1. At the temperature controller, push and hold and until "oPEr" (operations menu) shows

on the right display.

2. Push or until "ALM" shows on the left display.

20

English

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

in altre lingue

- English: Hach 9525sc User manual

- français: Hach 9525sc Manuel utilisateur

- español: Hach 9525sc Manual de usuario

- Deutsch: Hach 9525sc Benutzerhandbuch

- dansk: Hach 9525sc Brugermanual

- Türkçe: Hach 9525sc Kullanım kılavuzu

Documenti correlati

-

Hach 9525sc Manuale utente

Hach 9525sc Manuale utente

-

Hach Polymetron 9526 Basic User Manual

Hach Polymetron 9526 Basic User Manual

-

Hach Polymetron 9523sc pH Basic User Manual

Hach Polymetron 9523sc pH Basic User Manual

-

Hach POLYMETRON 8394 Manuale utente

-

Hach A1000XP Basic User Manual

Hach A1000XP Basic User Manual

-

Hach SIGMA 900 Manuale utente

Hach SIGMA 900 Manuale utente

-

Hach Lange astroTOC Basic User Manual

Hach Lange astroTOC Basic User Manual

-

Hach CL17sc Manuale utente

-

Hach 8398 Series Manuale utente

Hach 8398 Series Manuale utente