EN

ZZV0XXXX rev. 0

RAIZER

817.640

2

original version in Italian dated 09/10/2023

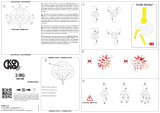

Laden Sie die Übersetzung in Ihrer Sprache herunter

- Download the translation in your language - Bájate

la traducción en tu idioma - Télécharger la traduction

dans vostre langue - Scarica la traduzione nella tua

lingua - 下载您语言版本的手册

817.640 RAIZERwww.kong.it

3

original version in Italian dated 09/10/2023

CONTENTS

1 - SYMBOLOGY AND ASSISTANCE 4

1.1 Symbology 4

1.2 Assistance 4

2 - GENERAL INFORMATION 5

3 - TECHNICAL CHARACTERISTICS 6

3.1 Terminology and materials of parts 6

3.2 Optional components 8

4 - SPECIFIC INFORMATION 9

4.1 Intended use 9

4.2 Positioning 9

4.3 Use of winch 10

5 - MAINTENANCE AND REPAIR 15

5.1 General 15

5.2 Maintenance 15

5.3 Repair 15

6 - STORAGE 16

7 - CHECKS, INSPECTIONS AND SERVICES 17

7.1 Checks 17

7.2 Inspections 17

7.3 Services 17

8 - DURATION AND WARRANTY 18

8.1 Duration 18

8.2 Disposal 18

8.3 Warranty 18

8.4 Legal obligations 18

9 - MARKING 19

9.1 Marking 19

10 - DOCUMENTS 20

10.1 Inspections and services log 20

10.2 Maintenance and repair log 21

4

original version in Italian dated 09/10/2023

CHAPTER

For the sake of comfort and clarity while reading this manual, below are the symbols used

for handling important warnings for a proper and safe use of the device.

1.1

SYMBOLS

REQUIREMENT FOR PROPER USE

It identifies the presence of information for proper use of the device.

INFORMATION REQUIREMENT

It identifies the presence of useful and general information which guides

the reader towards a conscious use of the device and/or performance of

actions.

1

SYMBOLS

AND SUPPORT

For information please contact Kong Customer Support Service by:

- telephone +39 0341 630506

- fax +39 0341 641550

- email: [email protected]

or write to KONG S.p.A. – Via XXV Aprile, 4 – 23804 Monte Marenzo LC - ITALY.

To facilitate support operations, please always communicate or state the serial number (SN)

indicated on the label fixed to the Device.

1.2

SUPPORT

817.640 RAIZERwww.kong.it

5

original version in Italian dated 09/10/2023

Warning: not suitable for

use in an ATEX environment

(Directive 94/9/CE)

The information provided by the

manufacturer (hereinafter information) must

be read and clearly understood by the user

prior to using the device. The information

regards the description of the features,

performance, assembly, disassembly,

maintenance, preservation, disinfection, etc.

of the device. Even though the information

offers tips on use, this information shall

not be considered as a user manual under

actual conditions of use.

WARNINGS AND

LIMITATIONS OF USE:

- this device is to be used only by persons who

are physically fit, trained (instructed and taught)

in its use, or under the direct supervision of

trainers/supervisors who ensure its safety,

- do not use the device until this user manual

has been read and understood in its entirety,

- strictly follow the manufacturer’s information,

improper use of the device is hazardous,

- modifying and/or repairing the device is strictly

forbidden,

- all checks described in chapter 7 must be

carried out prior to and after using the device.

In case of any doubt on the efficiency of the

device, the user must replace it immediately,

- improper use, deformations, falls, wear,

chemical contamination, exposure to

temperatures below -30°C or above +50°C

for textile/plastic components/ devices, and

+100°C for metallic components/devices, are

some examples of causes that can reduce,

limit and end the life of the device,

- the location of the anchor is critical to the

safety of fall arrest: carefully evaluate the

clear height present below the user, the the

height of a potential fall, the elongation of

2

GENERAL INFORMATION

the rope/ rope, the elongation of any energy

absorber/dissipator, the height of the user,

and the “pendulum” effect so as to avoid any

possible obstacles (e.g., the ground, rubbing,

abrasions, etc.),

- the minimum strength of anchor points, made

on both natural and artificial elements, must

be at least 12 kN. The evaluation of those

made on natural elements (rock, plants, etc.)

is only possible empirically, so it must be

carried out by an experienced and competent

person, while for those made on artificial

elements (metals, concrete, etc.) it is possible

scientifically, so it must be carried out by a

qualified person.

- Before any recovery operation ensure that the

weight does not exceed the range defined in

Section 3.3,

- To reduce the risks of exposure/transmission

of infectious diseases carry out cleaning

and disinfection of the device as defined in

Chapter 5,

- Always check the compatibility of the devices

used in combination through the relevant

manufacturer’s information,

- the use of spare parts or accessories other than

those listed in Section 3.4 can be dangerous,

- Avoid exposing the device to heat sources

and contact with chemicals. Reduce direct

exposure to the sun to the extent necessary.

At low temperatures and in humid conditions,

icing can reduce flexibility and increase

the risk of cuts and abrasion on textile and

synthetic devices.

All our devices are tested/ checked piece

by piece in compliance with the procedures

laid down by the Quality System certified

in accordance with the UNI EN ISO 9001

standard. Laboratory tests, testing, information

and standards do not always reproduce the

practical result. Thus, the results obtained

under the actual conditions of use of the device

in the natural environment may differ, even

considerably at times. The

best information lies in the continuous practical

use under the supervision of skilled/

expert/qualified people.

CHAPTER 2

6

original version in Italian dated 09/10/2023

TECHNICAL

SPECIFICATIONS

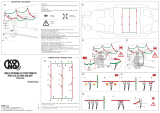

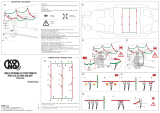

3.1 TERMINOLOGY AND MATERIALS OF PARTS

CHAPTER 3

A) Aluminium alloy rigging plate

B) Connecting eyelets

C) Connecting holes

D) Fixed clamp

E) Tube clamp

F) Tube clamp slots

G) Self-locking nuts

H) Butterfly nuts

I) Winch

I1) Drum

I2) Bushing

I3) Self tailing

J) Protective plate

K) Protective bushing

L) Cranks

3.1.1 Spare parts

E) Tube clamp

G) Self-locking nuts

H) Butterfly nuts

K) Protective bushing

L) Cranks

817.640 RAIZERwww.kong.it

7

original version in Italian dated 09/10/2023

H

x4

x4

I

I2

F

DCBA

K

L

G

E

I3

I1

8

original version in Italian dated 09/10/2023

817630000KK WINCH ADAPTER

Aluminium plate that allows the RAIZER to be assembled on the Ortles Stand and on the

Stelvio fishing pole

817640001KK LARGE TUBE CLAMP

Large tube clamp that allows positioning of the RAIZER on tubes with a diameter of 60 mm.

3.2 OPTIONAL COMPONENTS

x4

x4

817.640 RAIZERwww.kong.it

9

original version in Italian dated 09/10/2023

SPECIFIC

INFORMATION

4.1 INTENDED USE

The 817.640 RAIZER is a device that is:

- suitable for the simultaneous anchoring of 2 persons and for the connection of elements

of personal protection systems against falls from a height (EN 795:2012 and CEN/TS

16415:2013) (plate A),

- a multi-anchor for connections of up to 6 persons (RfU CNB/P/11.114) (plate A),

- used for lifting (max 240 kg) with additional hand-operated lowering function designed for

descents of up to 2 m (EN 1496/B:2017).

This device facilitates the handling of loads (inert or human but not for multi-purpose

use) in work at height and in technical rescue operations.

Do not use the device to lift persons after using it to lift materials.

For descents greater than 2 meters, connect a device to descent points

compliant with the EN 341 standard or, alternatively, to a EN 12841/B device

and an additional safety rope.

CHAPTER 4

4.2 POSITIONING

The 817.640 RAIZER can be positioned, according to the needs of users:

- floating, by means of ropes that connect to anchor points,

- on tubes, through the use of the tube clamp,

- attached to columns or sections, with the help of ratchet belts,

- on the ground, with the use of the Winch Adapter and the Ortles Stand.

The choice of the best positioning must be made by experienced and trained

personnel.

The anchor points must guarantee a minimum strength of 12 kN.

10

original version in Italian dated 09/10/2023

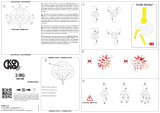

4.2.1 Floating positioning

Position the RAIZER in a “floating” manner using ropes/cables connected to the eyelets (B)

and/or to the connecting holes (C).

The RAIZER must be connected to AT LEAST 3 different anchor points.

MIN 12 kN

MIN 12 kN

MIN 12 kN

817.640 RAIZERwww.kong.it

11

original version in Italian dated 09/10/2023

4.2.2 Positioning on tubes or tubular profiles

The RAIZER can be positioned on tubes with a diameter of 48-50 mm, by means of the tube

clamp (E). For tubes with a diameter of 60 mm, the large tube clamp 817640001KK is available.

This configuration also allows the device to be used on tripods and monopods.

In order for the device to meet the requirements imposed by the applied

standards, a tightening torque of 40 Nm must be used during the fixed

installation. Frequent removal and reinstallation is not recommended as this

may damage the device. In the event that the user needs to frequently move

the device, it is advisable to reduce the tightening torque applied (however,

never less than 25 Nm) and to use a suitable retention system to avoid any

slippage.

MIN 12 kN

12

original version in Italian dated 09/10/2023

4.2.3 Positioning on columns/sections

It is also possible to position RAIZER on vertical supports such as columns or sections:

inserting the protective bushing (K) instead of the crank (L) in the protective plate (J). In this

way, the device can be placed on the vertical support, locking it with the help of ratchet belts.

4.2.4 Positioning on the ground

It is possible to place RAIZER on the ground by installing it through the Winch Adapter

(817630000KK) on the Ortles Stand bases (817200000KK).

817.640 RAIZERwww.kong.it

13

original version in Italian dated 09/10/2023

4.3 USING THE WINCH

A semi-static rope (EN 1891) with a diameter of between 10 and 12 mm can be manoeuvred

by the winch (I) to lift/lower loads.

Crank rotation

direction (L)

Weight lifted

for each kg applied

Rope recovered

with each crank turn

Clockwise 12,8 kg 12,5 cm

Anti-clockwise 40 kg 4 cm

- Wind the rope on the drum (I1) clockwise for filling;

- pass the rope over the self-tailing tooth (I3);

- lock the rope in the self-tailing groove (I3 for approximately 1 turn.

4.3.1 Lifting

DIFFERENT SPEED

14

original version in Italian dated 09/10/2023

-Remove the rope from the self-tailing (I3), holding it manually;

- slowly slide the rope on the drum (I1) for the length of the descent.

4.3.2 Descent

During the descent, secure the load with an additional safety rope.

817.640 RAIZERwww.kong.it

15

original version in Italian dated 09/10/2023

Maintenance tasks that must be performed by the user are:

a) cleaning: after every use, wash with warm (max. 40 C) potable water, possibly adding a

neutral detergent (e.g. Marseille soap). Rinse and leave to dry in a shaded place, away

from direct sources of heat,

b) lubrication of moving parts with silicone-based oil, to be carried out after cleaning/

disinfection and drying of the device, avoiding contact with any textile components,

c) If necessary, disinfection: soak the product for at least 30 minutes in hot water at the

temperature of 58-60 °C, then let it air-dry, avoiding direct exposure to the sun and heat

sources.

Repair shall be strictly carried out by the manufacturer.

The user is allowed to replace the parts mentioned in paragraph 3.1.1 only,

with new and genuine parts.

817.640 RAIZER is made of highly wear and weather resistant materials. Despite this,

conditions of use make maintenance and, in special cases, repair work necessary.

MAINTENANCE

AND REPAIR

5.1 GENERAL

5.2 MAINTENANCE

5.3 REPAIR

CHAPTER 5

Maintenance and repair operations must be recorded in a special register,

an example of which is indicated in chapter 10.

16

original version in Italian dated 09/10/2023

After cleaning, any disinfection and drying operations, keep the product and its accessories

in a place that is dry (relative humidity 40-90%), cool (temperature 5-40° C) and safe (avoid

UV radiation), chemically neutral (absolutely avoid salty and/or acid environments), away

from sharp edges, sources of heat, humidity, corrosive substances or other possible

jeopardising conditions.

Do not store this device wet!

6 STORAGE

CHAPTER 6

STORAGE

817.640 RAIZERwww.kong.it

17

original version in Italian dated 09/10/2023

Before and after each use, it is necessary to check the device to ensure that it is in an effi-

cient condition and is working correctly, and in particular that:

- it has not undergone mechanical deformation,

- there are no cracks, wear or signs of corrosion,

- the winch drum (I), the anchor points (B and C) and the rope passage points are clean,

- turning the crank both clockwise and anti-clockwise the winch drum (I) turns without

friction.

Perform all pre- and post-use checks defined on the specific information of the devices

used in combination.

Before use, in a safe position, make sure the device is working properly.

The device must be inspected at least once a year, starting from the date of first use, by

expert personnel trained and approved by KONG S.p.A. The date of the first use and the

outcome of the inspection must be recorded in the Inspections and Servicing Register,

regarding which an example is indicated in chapter 10.

The device must be serviced by KONG S.p.A., or by expert personnel trained and approved

by KONG S.p.A. if:

- any malfunctions are detected,

- the result of the pre and post use check or of the inspections is negative.

The outcome of the servicing must be recorded in the Inspections and Servicing Register,

regarding which an example is indicated in chapter 10.

The revised device is guaranteed for one year from the revision date.

CHECKS,

INSPECTIONS

AND SERVICES

7.1 CHECKS

7.2 INSPECTIONS

7.3 SERVICES

CHAPTER 7

18

original version in Italian dated 09/10/2023

DURATION

AND WARRANTY

Read carefully the section “Warnings and limitations of use” in Chapter 2. The service life of

this device is determined by the outcome of the at least annual inspections (Section 7.2) and

any revisions.

8.1 DURATION

Follow the rules in force in the country of use and the waste disposal procedures of the

reference hospital facility for proper disposal.

8.2 DISPOSAL

The manufacturer guarantees the compliance of the device with the regulations in force

at the time of production. Warranty covering defects is limited to defects regarding raw

materials and manufacturing defects. The warranty does not cover normal wear, oxidation,

damage caused by non-compliant use and/or in competition, improper maintenance,

transportation, preservation or storage. Warranty will be immediately deemed null and void

should the device be modified or tampered with. Validity corresponds to the legal validity

of the country where the device was sold, as from the date of sale, by the manufacturer.

No claims shall be raised against the manufacturer once the aforementioned period has

expired. Any repair or replacement request under warranty must be accompanied by a

proof of purchase. Should the defect be recognised, the manufacturer undertakes to repair

or, replace or refund the device at his discretion. The manufacturer shall not be held liable

beyond the invoice price of the device in any case whatsoever.

8.3 WARRANTY

CHAPTER 8

Professional and free time activities are often regulated by special national laws which can

impose limits and/or obligations concerning the use of these devices. The user has the

obligation to know and apply such laws which could provide for limits different from those

indicated in this information.

8.4 LAW OBLIGATIONS

817.640 RAIZERwww.kong.it

19

original version in Italian dated 09/10/2023

MARKING

9.1 MARKING

CHAPTER 9

Compliance with the European Regulation 2016/425

0068

Production surveillance notified body

MTIC InterCert S.r.l. Via G. Leopardi, 14 - 20123 Milan (MI) Italy

EN 795:12/A EN Compliance with the standard EN 795:2012 Type A

1496:17/B CEN/ Compliance with the standard EN 1496:17 type B

TS 16415:13 Compliance with technical specification CEN/TS 16415:13

Leggere sempre e seguire le informazioni fornite dal fabbricante

LLLLLL XXXX Batch number

MM/YYYY Month and year of manufacture

REQUIRED MBS 12 kN Minimum strength required for anchoring

MAX 6 Maximum number of simultaneous users (CEN/TS 16415:13)

MAX 36kN Maximum applicable load (CEN/TS 16415:13)

WLL 240 kg Working limit load (EN 1496:17) calculated by applying the safety co-

efficient 1:2

9.1.1 Plate use marking

9.1.2 Winch use marking

20

original version in Italian dated 09/10/2023

DOCUMENTS

817.640 RAIZER

Batch number: First use date:

CHAPTER

10

10.1 INSPECTIONS AND SERVICING REGISTER

INSPECTION AND SERVICING

DATE I/R Description Outcome Manager

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

La pagina si sta caricando...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

in altre lingue

- English: Kong RAIZER User manual

Documenti correlati

-

Kong ORTLES Manuale utente

Kong ORTLES Manuale utente

-

Kong 3RIG Manuale utente

Kong 3RIG Manuale utente

-

Kong 911 Hive Manuale utente

Kong 911 Hive Manuale utente

-

Kong 911 CANYON Manuale utente

Kong 911 CANYON Manuale utente

-

Kong X-TRIM 4 Manuale utente

Kong X-TRIM 4 Manuale utente

-

Kong Lecco 2.0 Tactical Manuale utente

Kong Lecco 2.0 Tactical Manuale utente

-

Kong 911 Armor Manuale utente

Kong 911 Armor Manuale utente

-

Kong Kit Everest Carbon Tactical Manuale utente

Kong Kit Everest Carbon Tactical Manuale utente

-

Kong Half Rolly Manuale utente

Kong Half Rolly Manuale utente

-

Kong X-TWO (AW169) Manuale utente

Kong X-TWO (AW169) Manuale utente